Large area micro nano structure soft impression method

A technology of micro-nano structure and soft embossing, which is applied in the direction of photolithography, optics, and opto-mechanical equipment on the patterned surface. Quickly and batch copy imprinting and other issues to achieve the effect of ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1, the line structure of the line feature size of 100 nanometers and 20 microns copied by the method of the present invention, as shown in Figures 1, 2, 3, 4, and 5, the production process is as follows:

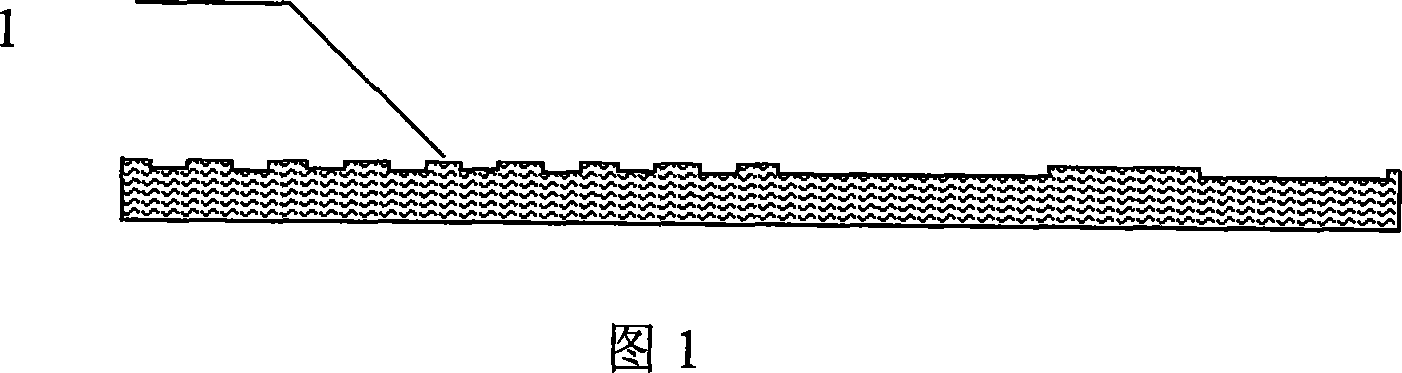

[0038] (1) First use the existing electron beam direct writing to make a hard template with a micro-nano structure. The line feature sizes are 100nm and 20 microns respectively. Figure 1 is a cross-sectional view of the hard template structure, and 1 represents the material silicon of the hard template;

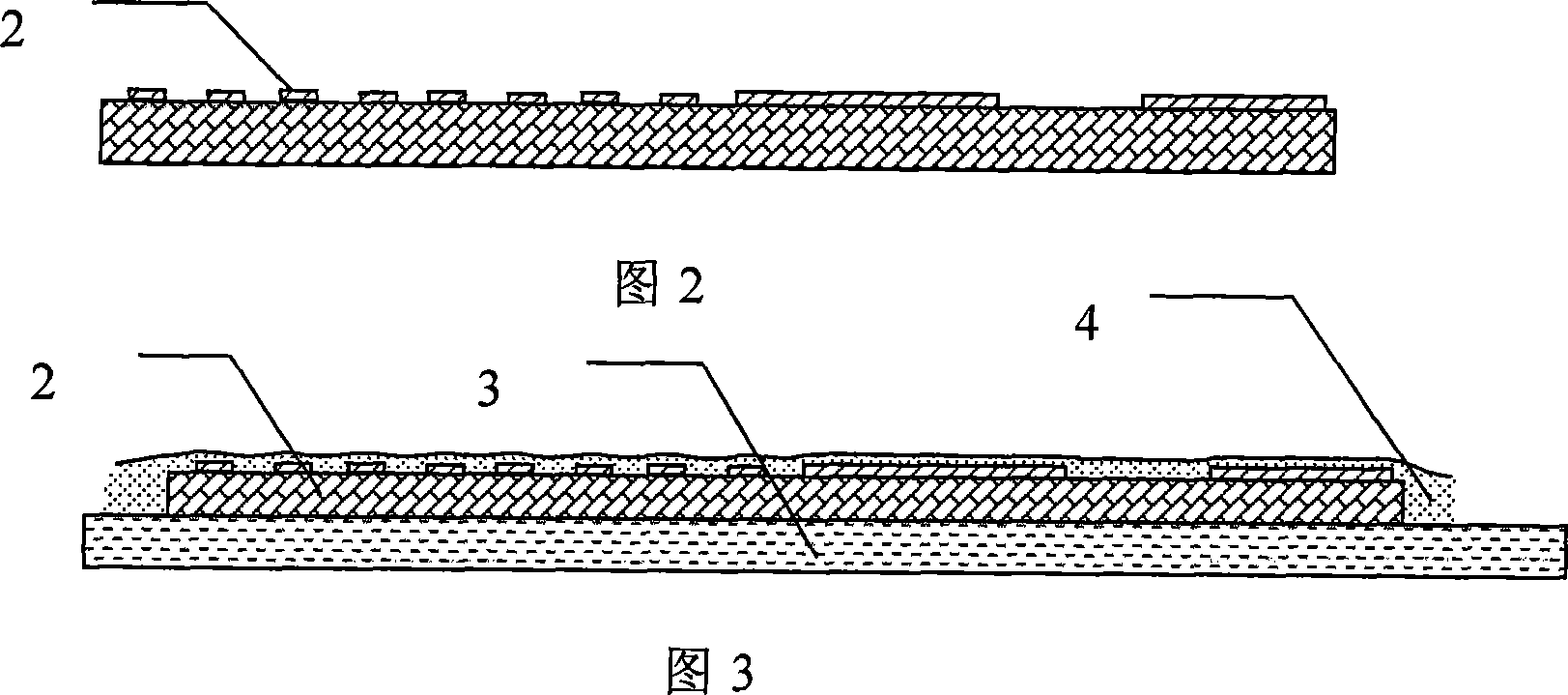

[0039] (2) Casting the pre-polymerized PDMS material on the surface of the hard template to form a soft PDMS template, the section is as shown in Figure 2, and 2 represents the material PDMS of the soft template;

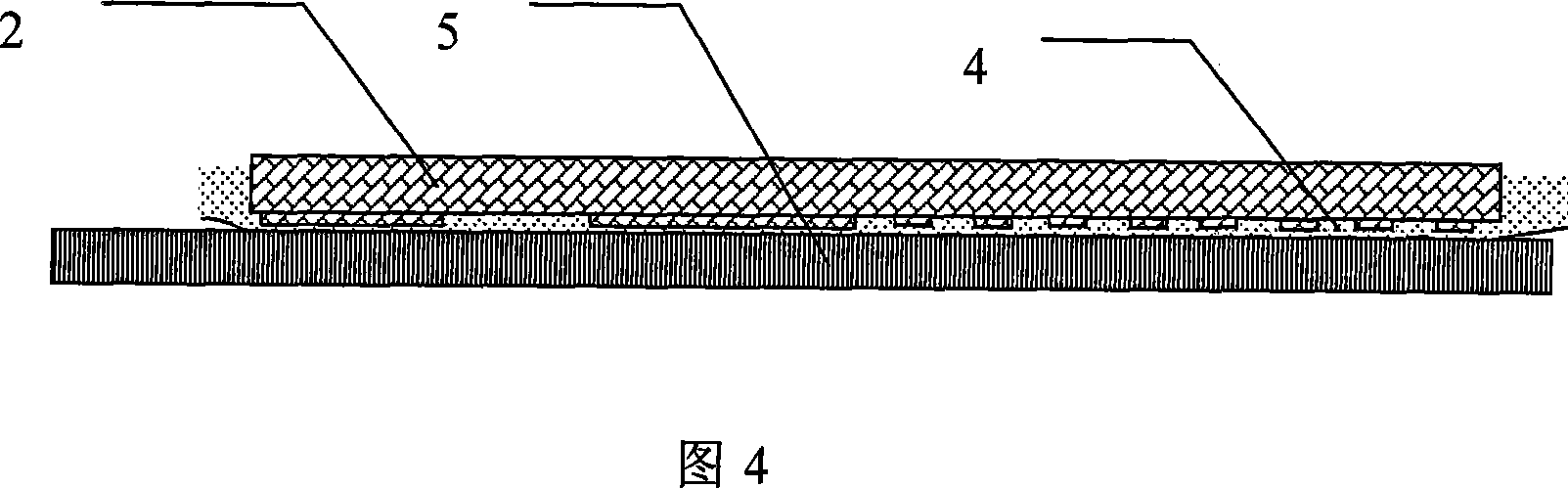

[0040] (3) Adhering the non-graphic surface of the soft template to the substrate surface 3 through double-sided polishing;

[0041](4) Place the substrate 3 adhered with the soft template on the suction cup of the glue spinner, drop the photore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com