Sample enrichment chip, manufacturing method and enrichment method and on micronano structure

A micro-nano structure and enrichment technology, applied in the field of analytical chemistry, to achieve the effects of portability, small size and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

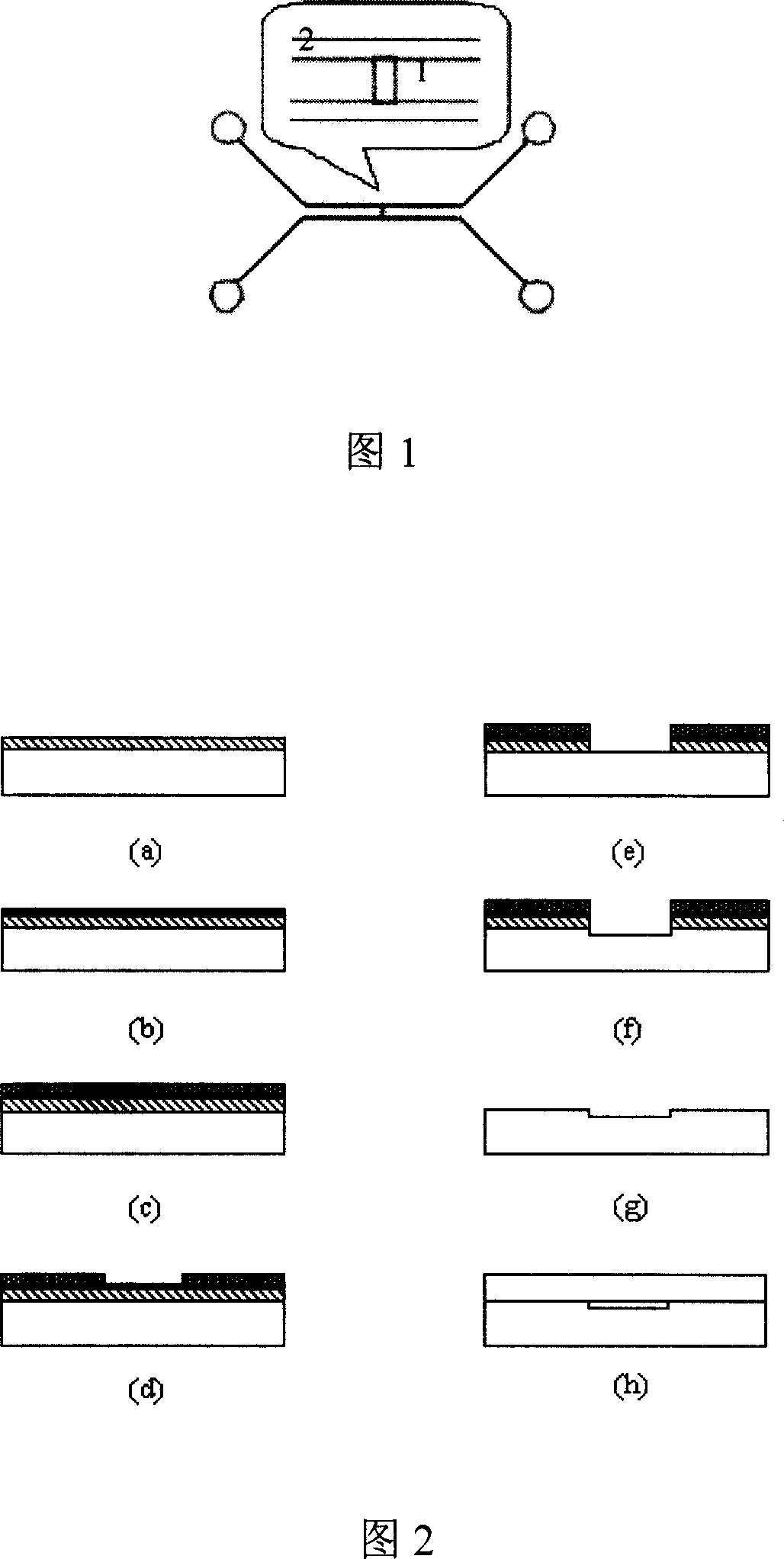

[0023] Example 1 Manufacturing process of sample enrichment chip based on micro-nano structure

[0024] 1. First, nano-channels and nano-scale transmission pipes are processed on the surface of quartz glass by MEMS technology

[0025] A. Fabrication of micron-scale transmission pipes

[0026] 1) First photolithography

[0027] ①Cleaning: ultrasonically clean the quartz glass substrate with acetone, ethanol, and deionized water for 5 minutes; blow dry with nitrogen; dry,

[0028] ② Evaporate hexamethyldisiloxane, apply photoresist 6809 and spin the glue, the speed is 4000rpm, the glue throwing time is 30s,

[0029] ③Pre-baking: 100℃, 6min

[0030] ④ Photolithography: at 12mW / cm 2 Intensity Lithography, Machine Lithography, 12s,

[0031] ⑤ Development: 18s,

[0032] ⑥Priming film for 10s,

[0033] ⑦ Harden the film in an oven at 120°C for 30 minutes;

[0034] 2) Micron-scale pipeline corrosion

[0035] ① Chromium removal: Use chromium corrosion solution prepared by ceri...

Embodiment 2

[0060] The enrichment method of embodiment 2 enrichment chip

[0061] On the basis of the chip after low-temperature bonding in Example 1, the following two process steps are used to achieve enrichment

[0062] 1. Chip surface treatment: use 1mol / L NaOH solution to fill the newly bonded chip, rinse 3 times, let stand for 30min, and rinse with deionized water.

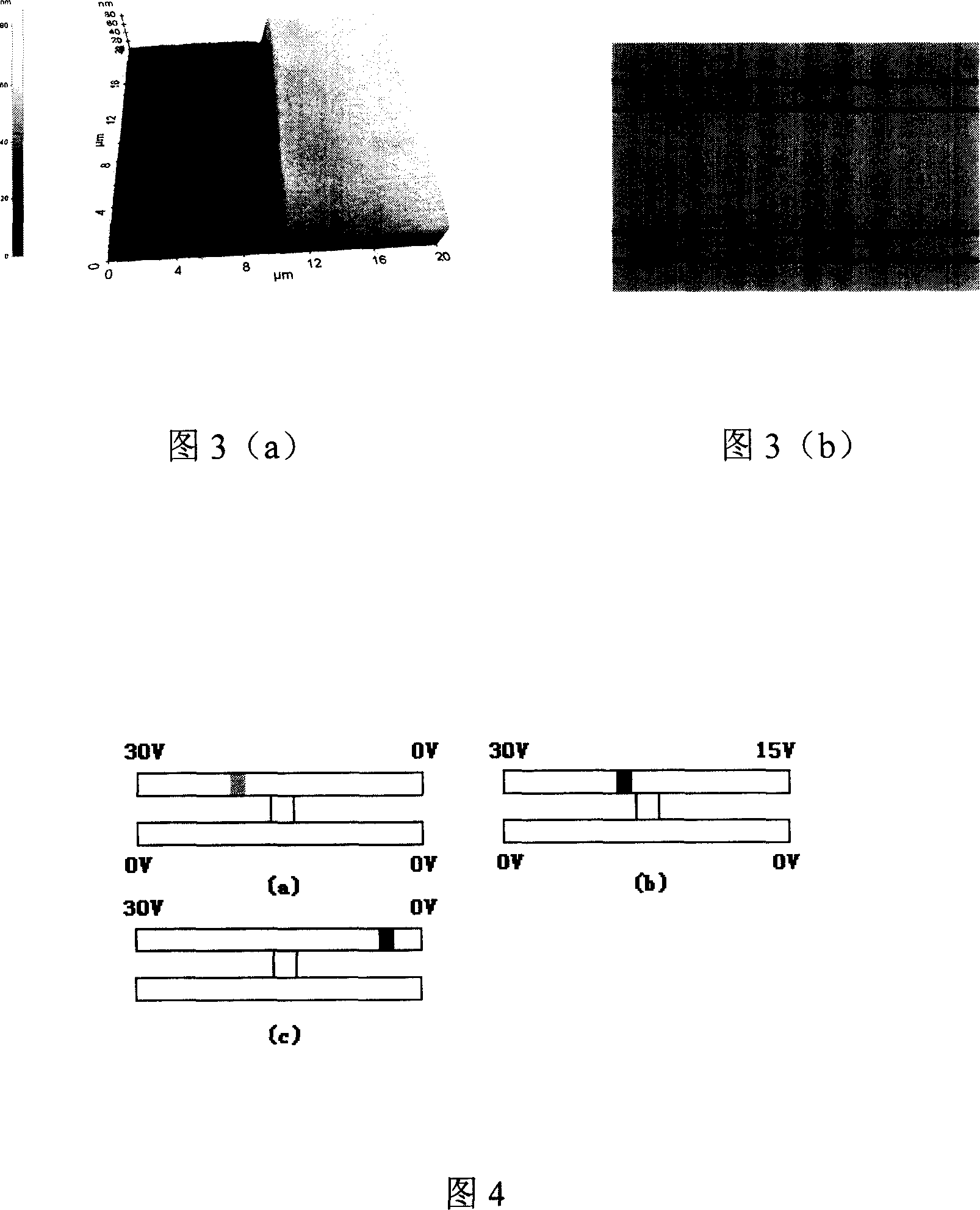

[0063] 2. The protein labeled with FITC fluorescent dye is used as the sample, and 0.75mmol / L boric acid is used as the buffer solution; the sample is transferred to the nano-ion trap area with a 30V DC voltage, as shown in Figure 4 (a); the sample band is due to The ions caused by the nanometer region are trapped, piled up and enriched continuously, as shown in Figure 4(b); the compressed sample is tuned by using voltage, and introduced into the detection area for sample detection, as shown in Figure 4(c).

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com