Polyvinylidene fluoride super-hydrophobic self-cleaning coating and preparation method thereof

A polyvinylidene fluoride, self-cleaning coating technology, applied in the coating and other directions, can solve the problems of high preparation cost, expensive equipment, complicated process, etc., and achieve the effect of simple preparation method and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

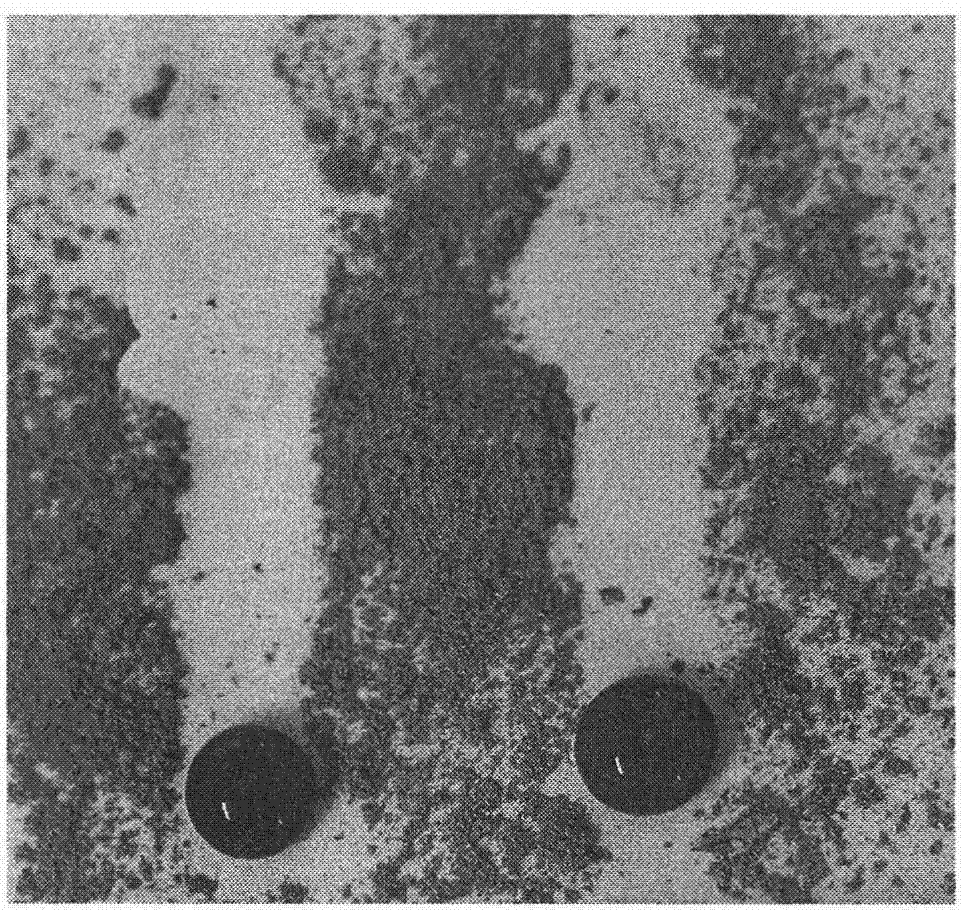

Image

Examples

Embodiment 1

[0038] (1) Preparation of the solution: add 5% polyvinylidene fluoride by mass to a mixed solvent of 75% dimethylacetamide solvent and 20% cyclohexanone diluent, at 50°C Heating and stirring for 1 h to obtain a homogeneous solution, the homogeneous solution was allowed to stand for 48 h in an electric heating blast drying oven at 50°C to fully deaerate and wait for use;

[0039] (2) Preparation of coating: Coat the defoamed polyvinylidene fluoride solution on a non-woven fabric at 50°C, seal it in a metal box, immerse the metal box in a constant temperature water bath at 10°C, and keep the 0.5h to cure the coating gel;

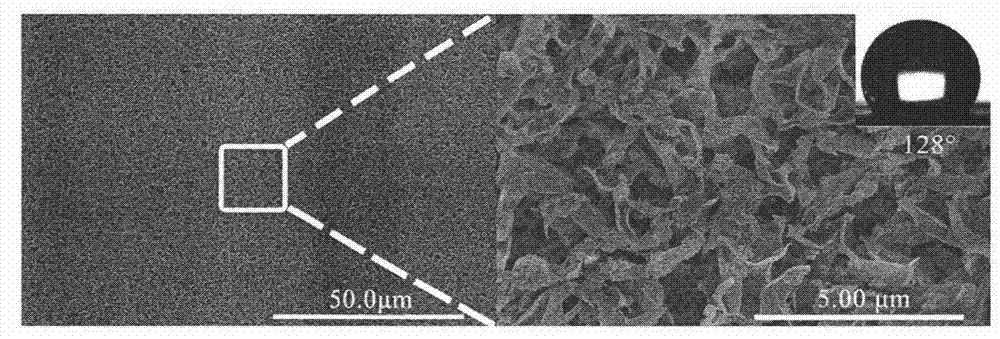

[0040] (3) Post-treatment: the cured coating is washed three times in methanol, and the washed coating is naturally dried to obtain a polyvinylidene fluoride superhydrophobic self-cleaning coating with a micro-nano bi-level structure on the surface;

[0041] The polyvinylidene fluoride superhydrophobic self-cleaning coating prepared in this example has a cont...

Embodiment 2

[0043] (1) Preparation of solution: add 40% polyvinylidene fluoride by mass to a mixed solvent of 40% dimethylformamide solvent and 20% ethylene glycol ester diluent. Heating and stirring at 140 °C for 4 hours to obtain a homogeneous solution, the homogeneous solution was left for 48 hours in an electric heating blast drying oven at 140 °C to fully deaerate and wait for use;

[0044] (2) Preparation of coating: Coat the defoamed polyvinylidene fluoride solution on a non-woven fabric at a temperature of 140 °C, seal it in a metal box, and immerse the metal box in a constant temperature water bath at 80 °C. Keep for 48h to cure the coating gel;

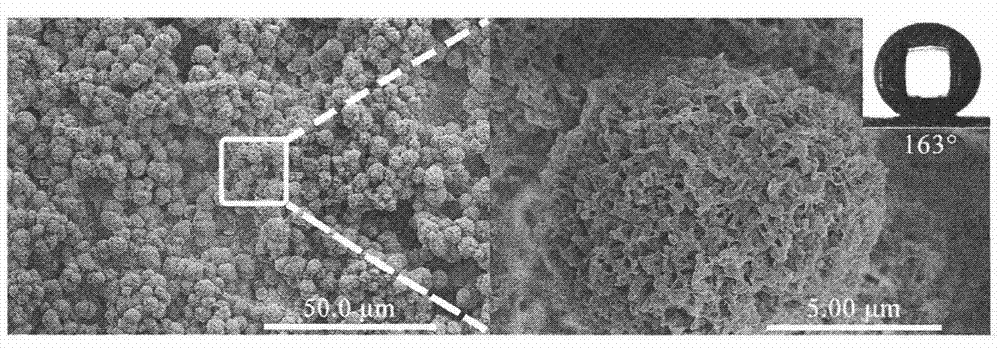

[0045] (3) Post-treatment: the cured coating is washed three times in methanol, and the washed coating is naturally dried to obtain a polyvinylidene fluoride superhydrophobic self-cleaning coating with a micro-nano bi-level structure on the surface;

[0046] The polyvinylidene fluoride superhydrophobic self-cleaning coating prepared in...

Embodiment 3

[0048] (1) Preparation of solution: 15% polyvinylidene fluoride was added to a mixed solvent of 40% dimethyl sulfoxide solvent and 45% triethyl phosphate diluent, Heating and stirring for 3 hours in the environment of 100 °C to obtain a homogeneous solution, the homogeneous solution was left for 48 hours in an electric heating blast drying oven at 100 °C to fully deaerate and wait for use;

[0049] (2) Preparation of coating: Coat the defoamed polyvinylidene fluoride solution on a non-woven fabric at 100°C, seal it in a metal box, immerse the metal box in a constant temperature water bath at 50°C, and keep the 24h, the coating gel is cured;

[0050] (3) Post-treatment: the cured coating is washed three times in distilled water, and the washed coating is naturally dried to obtain a polyvinylidene fluoride super-hydrophobic self-cleaning coating with a micro-nano bi-level structure on the surface;

[0051] The polyvinylidene fluoride superhydrophobic self-cleaning coating prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com