Bell-shaped Fe3O4@void@SiO2 nano-chain and preparation method

A nano-chain, core-shell technology, used in the preparation of microspheres, microcapsule preparations, coatings, etc., to achieve excellent microwave absorption performance, enhance multiple absorption, and facilitate dissipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

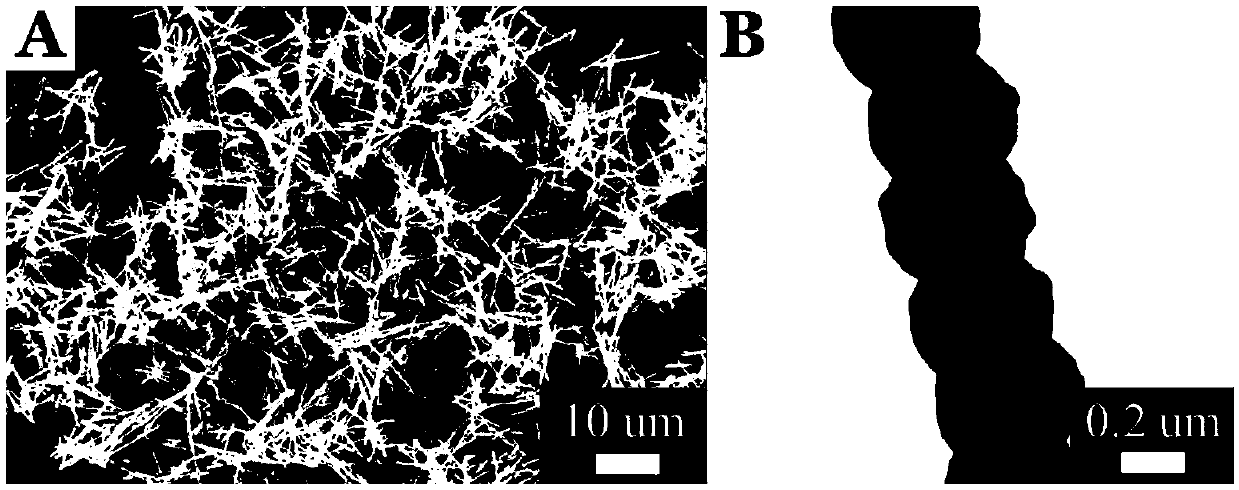

[0030] Step 1. Core-shell Fe 3 o 4 Preparation of @P(DVB-MAA) nanochains: 0.028g of Fe 3 o 4Particles, 0.26g of monomer methacrylic acid MAA, 0.08g of crosslinking agent divinylbenzene DVB were added to 80mL of acetonitrile, dispersed uniformly by ultrasound, and then added 1.6wt% of the total amount of monomer and crosslinking agent The initiator azobisisobutyronitrile (AIBN) was subjected to distillation and precipitation polymerization induced by an external magnetic field at a water bath temperature of 80 ° C. After 1 hour of reaction, the core-shell Fe 3 o 4 @P(DVB-MAA) nano chain;

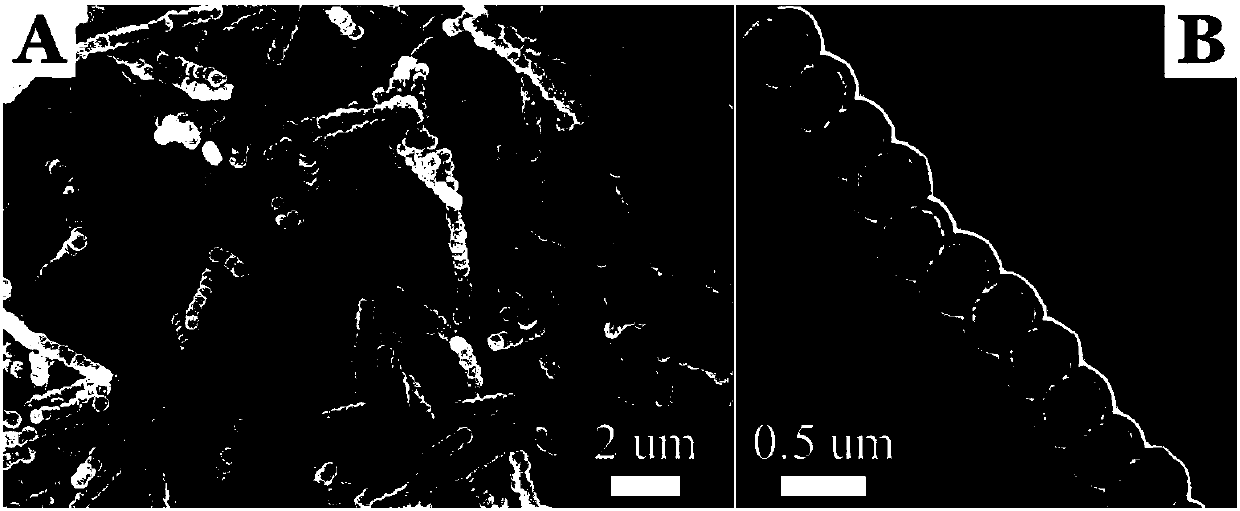

[0031] Step 2, double shell Fe 3 o 4 @P(DVB-MAA)@SiO 2 Preparation of nanochains: the core-shell Fe 3 o 4 @P(DVB-MAA) nanochains were dispersed in a mixed solvent of 73mL ethanol and 7mL water; then 1.8mL of 25% ammonia water was added, and mechanically stirred for 1 hour to make the solution evenly mixed; slowly dropwise added 0.09g of orthosilicic acid Ethyl ester, react at room t...

Embodiment 2

[0038] Step 1. Core-shell Fe 3 o 4 Preparation of @P(DVB-MAA) nanochains: 0.3g of Fe 3 o 4 Particles, 0.3g of monomeric methacrylic acid MAA, 0.09g of crosslinking agent divinylbenzene DVB were added to 100mL of acetonitrile, dispersed uniformly by ultrasound, and then 1.9wt% of the total amount of monomer and crosslinking agent was added The initiator azobisisobutyronitrile (AIBN) was subjected to distillation and precipitation polymerization induced by an external magnetic field at a water bath temperature of 85 °C, and the core-shell Fe was obtained after 1.5 hours of reaction. 3 o 4 @P(DVB-MAA) nano chain;

[0039] Step 2, double shell Fe 3 o 4 @P(DVB-MAA)@SiO 2 Preparation of nanochains: the core-shell Fe 3 o 4 @P(DVB-MAA) nanochains were dispersed in a mixed solvent of 72mL ethanol and 8mL water; then 1.6mL of 28% ammonia water was added, and mechanically stirred for 1.5 hours to make the solution evenly mixed; slowly dropwise added 0.1g of methyl orthosilicate ...

Embodiment 3

[0042] Step 1. Core-shell Fe 3 o 4 Preparation of @P(DVB-MAA) nanochains: 0.026g of Fe 3 o 4 Particles, 0.3g of monomer methacrylic acid MAA, 0.08g of crosslinking agent divinylbenzene DVB were added to 90mL of acetonitrile, dispersed uniformly by ultrasound, and then added 1.6wt% of the total amount of monomer and crosslinking agent The initiator benzoyl peroxide (BPO) was subjected to distillation and precipitation polymerization induced by an external magnetic field at a water bath temperature of 80°C, and the core-shell Fe was obtained after 1 hour of reaction. 3 o 4 @P(DVB-MAA) nano chain;

[0043] Step 2, double shell Fe 3 o 4 @P(DVB-MAA)@SiO 2 Preparation of nanochains: the core-shell Fe 3 o 4 @P(DVB-MAA) nanochains were dispersed in a mixed solvent of 72mL ethanol and 8mL water; then 2.0mL of 28% ammonia water was added, and mechanically stirred for 1.5 hours to make the solution evenly mixed; Ester, react at room temperature for 6 hours; freeze-dry after mag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shell thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com