Large-size whole wafer nano-impressing device and impressing method thereof

A nano-imprint, large-scale technology, applied in the direction of photolithography, optics, optomechanical equipment, etc. on the pattern surface, to achieve the effect of low defect, simple structure, simple structure and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

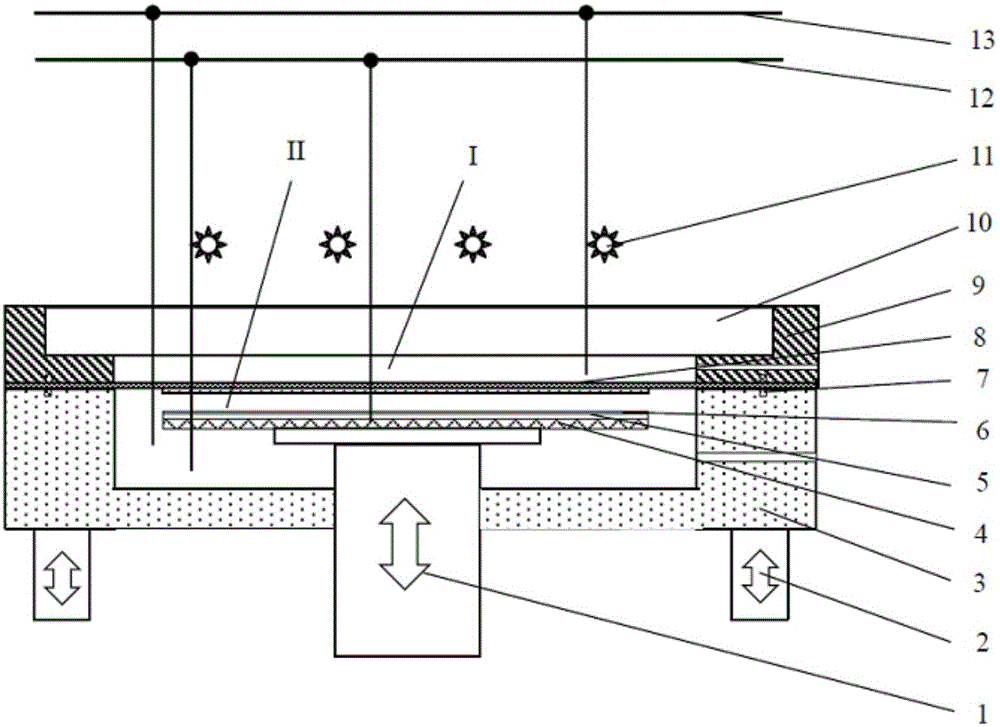

[0062] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

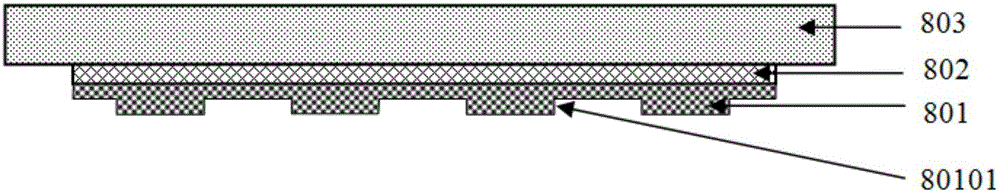

[0063] figure 1 It is a structural schematic diagram of the nano-imprinting device for a large-sized wafer of the present invention, which includes: a second lifting mechanism 1, a first lifting mechanism 2, a lower cavity 3, a wafer carrier 4, a wafer 5, an imprinting material 6, Sealing ring 7, mold 8, upper cavity 9, transparent glass (quartz glass) 10, exposure light source 11, vacuum pipeline 12, pressure pipeline 13; wherein, the workbench is placed at the bottom of the center of the device, and the workbench wears Through the lower cavity 3, the inside of the workbench is provided with a second lifting mechanism, and the carrier table 4 is horizontally placed inside the lower cavity 3; The bottom is connected; the wafer holder 4 is placed on the workbench; the wafer 5 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com