Method for preparing multistage metal micro-nanostructures inside micro fluidic chip

A technology of microfluidic chips and micro-nano structures, which is applied in the fields of microelectronics and life sciences, and can solve problems such as difficult integration of multi-level metal micro-nano structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Example 1: Preparation of two-dimensional silver micro-nano structures by laser processing on various substrates

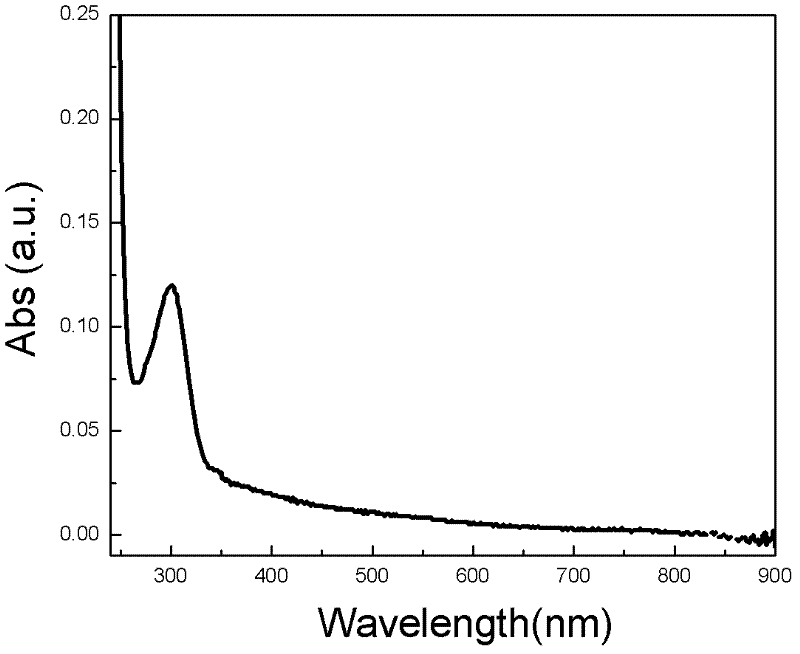

[0062] (1) Configure silver plating solution for laser processing

[0063] a. Main salt: Silver nitrate (Silver nitrate, AgNO 3 ; FW 169.88; boiling point 440 ° C; melting point 212 ° C;), the concentration is 0.083mol / L.

[0064] b. Complexing agent: ammonia aqueous (ammonia aqueous), add an appropriate amount to make the silver nitrate solution just clear and slowly add dropwise to adjust the pH value to 10.8.

[0065] c. Reducing agent: sodium gluconate (sodium gluconate, molecular formula: C 6 h 11 NaO 7 , molecular weight 218, content not less than 99.0%, analytically pure, Tianjin Guangfu Institute of Fine Chemicals), concentration 0.078mol / L.

[0066] Configuration process: at room temperature, first weigh 0.034g of silver nitrate and 0.034g of sodium gluconate and mix them directly in a small vial, add 2mL of deionized water, and then dropwise ...

Embodiment 2

[0083] Example 2: Preparation of 3-level silver micro-nano structure by laser processing

[0084] (1) Preparation of silver plating solution for laser processing

[0085] The step of preparing the silver plating solution for laser processing is the same as in Example 1.

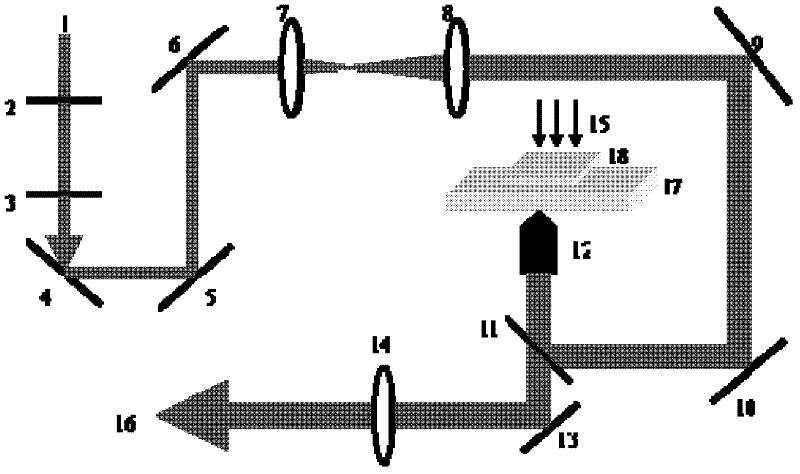

[0086] (2) Build micro-nano processing system and design processing program

[0087] With embodiment 1.

[0088] (3) Prepare the substrate for processing

[0089] With embodiment 1.

[0090] (4) Preparation of multi-level silver nanosheet micro-nano structure

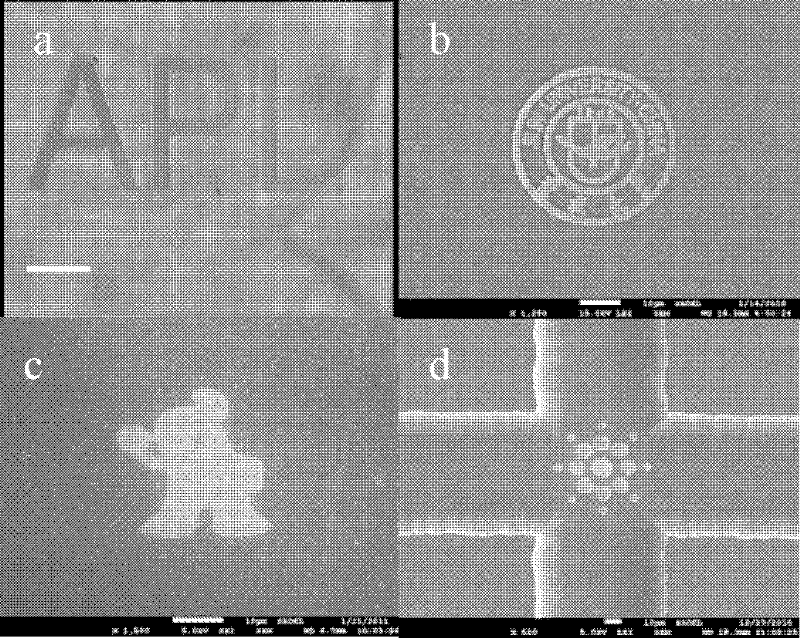

[0091] [1] using figure 1 The processing system shown is to prepare multi-level silver micro-nano structures in the chip channel. The processing program is designed based on the rectangular block structure, and the scanning path is scanned point by point from outside to inside clockwise or counterclockwise or horizontally from left to right. Nanosheet silver microstructures were prepared by controlling the scanning step length, the number of sca...

Embodiment 3

[0105] Example 3: Local and selective integration of SERS detection substrates in microfluidic chips

[0106] (1) Preparation of silver plating solution for laser processing

[0107] The step of preparing the silver plating solution for laser processing is the same as in Example 1.

[0108] (2) Build micro-nano processing system and design processing program

[0109] With embodiment 1.

[0110] (3) Prepare the chip

[0111] The microfluidic chip to be used is subjected to routine cleaning treatment, ultrasonic cleaning with acetone, ethanol, and deionized water.

[0112] (4) Preparation of multi-level silver micro-nano structures at the bottom of the chip channel

[0113] Pack the plating solution in the channel of the microfluidic chip with an air pump, place the chip in the laser processing system, and use the three-dimensional mobile platform and monitoring system to find the specific position in the channel where the silver micro-nano structure is to be integrated, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Spot diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com