Organic pigment nano particle dispersion and preparation method, photo-sensitive resin combination, trans-printing material, filter, liquid display device and ccd device

A technology of liquid crystal display device and photosensitive resin, which is applied in the field of photosensitive resin composition and organic pigment nanoparticles, which can solve the problems of no acquisition, uneven display, display adaptability (decreased display durability, etc.), and achieve time-dependent changes Effects of small size, improved contrast, and excellent display characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0086] The organic pigments used in the preparation of the organic pigment nanoparticles of the present invention are not particularly limited as long as they can form particles by the reprecipitation method, and may be used alone, or in combination.

[0087] The organic pigment is not limited by the hue, and examples thereof include perylene, perylene, quinacridone, quinacridonequinone, anthraquinone, tribenzopyrenedione, benzimidazolone, disazo condensate, disazo, azo Nitrogen, indanthrene, phthalocyanine, triaryl cation, dioxazine, aminoanthraquinone, diketopyrrolopyrrole, thioindigo, isoindoline, isoindolinone, pyranthrone, or isothrone Violet compound pigments, or mixtures thereof.

[0088] More specifically, perylene compound pigments such as C.I. Pigment Red 190 (C.I. No. 71140), C.I. Pigment Red 224 (C.I. No. 71127), C.I. Pigment Violet 29 (C.I. No. 71129), C.I. Pigment Orange 43 (C.I. No. 71105) ), or C.I. Pigment Red 194 (C.I. No. 71100), C.I. Pigment Violet 19 (C.I...

Embodiment 1

[0605] [Preparation of concentrated pigment solution]

[0606] To 2000 ml of dimethyl sulfoxide, 60.0 ml of sodium methoxide 28% methanol solution, 100 g of pigment C.I. Vinylpyrrolidone, to prepare Pigment Solution A. At the same time, 1800 ml of water containing 20 ml of 1 mol / l hydrochloric acid was separately prepared as a poor solvent.

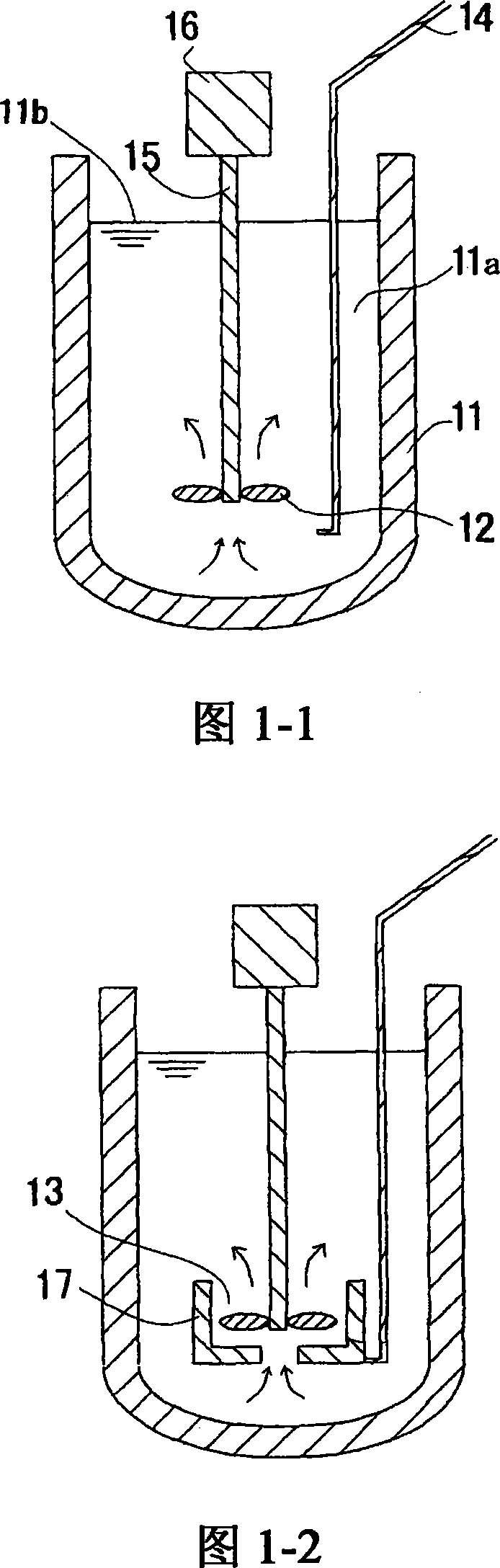

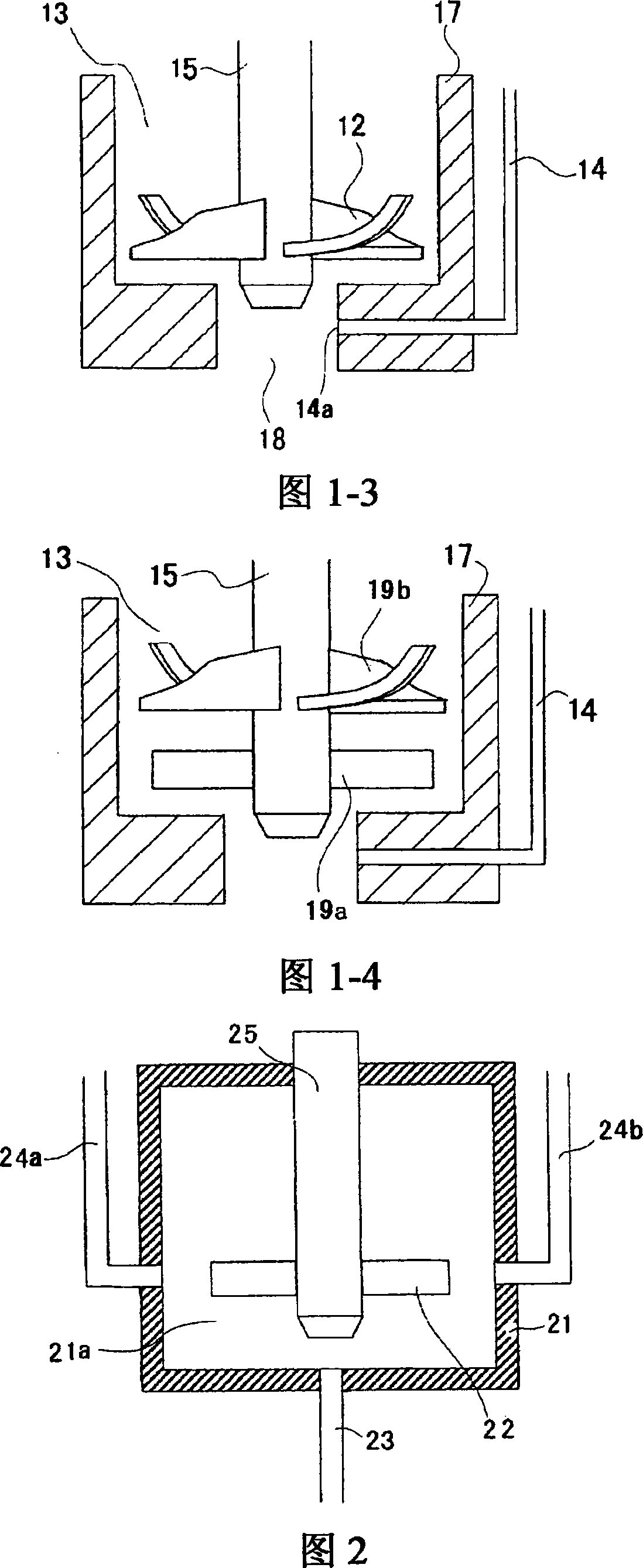

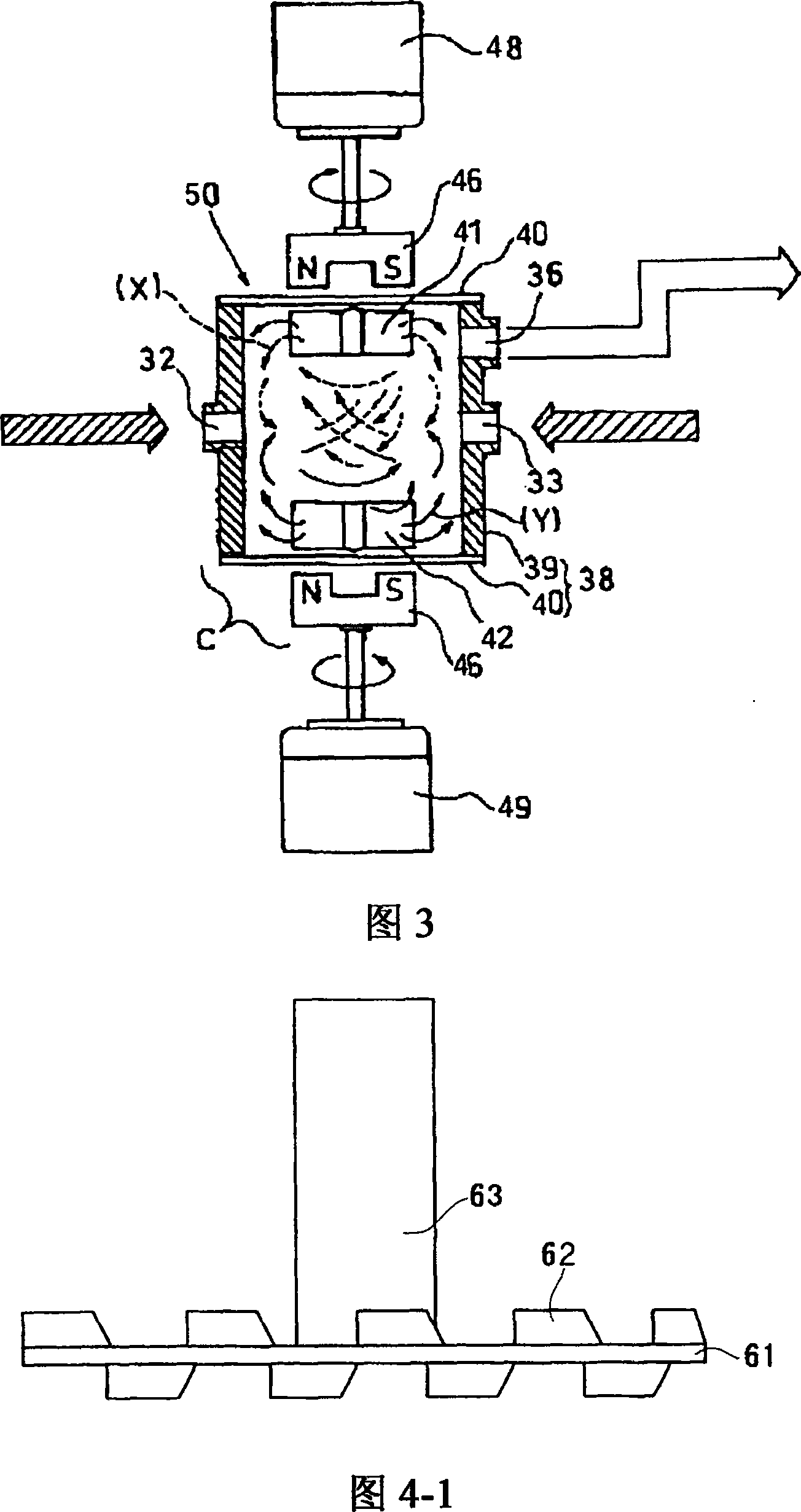

[0607] At this time, the temperature was controlled at 18° C., and the GK-0222-10 type Ramondostar-Ra manufactured by Fujisawa Pharmaceutical Co., Ltd. was used to stir 1800 ml of poor solvent at a speed of 500 rpm. NP-KX-500 large-capacity non-pulsation pump injects 500ml of pigment solution A at a flow rate of 80ml / min to form organic pigment particles and make a pigment dispersion. The particle diameter and monodispersity of the pigment dispersion liquid were measured using Natrac UPA-EX150 manufactured by Nikkiso Co., Ltd., and the measured number average particle diameter was 48 nm, and Mv / Mn was 1.44.

[0608] For the pigment dis...

Embodiment 2

[0705] In addition to adding 10g of pigment dispersant A (exemplary compound (7) among the compounds represented by the general formula (D1)) to the pigment solution A of Example 1, other paste concentrated pigments were prepared in the same manner as in Example 1. Liquid B (nanopigment concentration: 35% by mass). The number average particle diameter of the pigment fine particles measured in the same manner as in Example 1 was 38 nm, and the Mv / Mn thereof was 1.38. The sum of the residual alkali metal and alkaline earth metal concentrations of this concentrated pigment solution B was 110 ppm.

[0706] Pigment dispersion composition B was prepared in the same manner as in Example 1 except that concentrated pigment solution B was used instead of concentrated pigment solution A in the preparation of pigment dispersion composition A in Example 1. Next, a liquid crystal display device was fabricated in the same manner as in Example 1 except that the concentrated pigment solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com