Dispersion stabilizer and application thereof

A dispersion stabilizer, unsaturated technology, applied in the direction of coating, pigment slurry, etc., can solve the problems of short efficacy, stickiness, and water-based calcium carbonate pigments cannot be used normally, and achieve the effect of stable and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

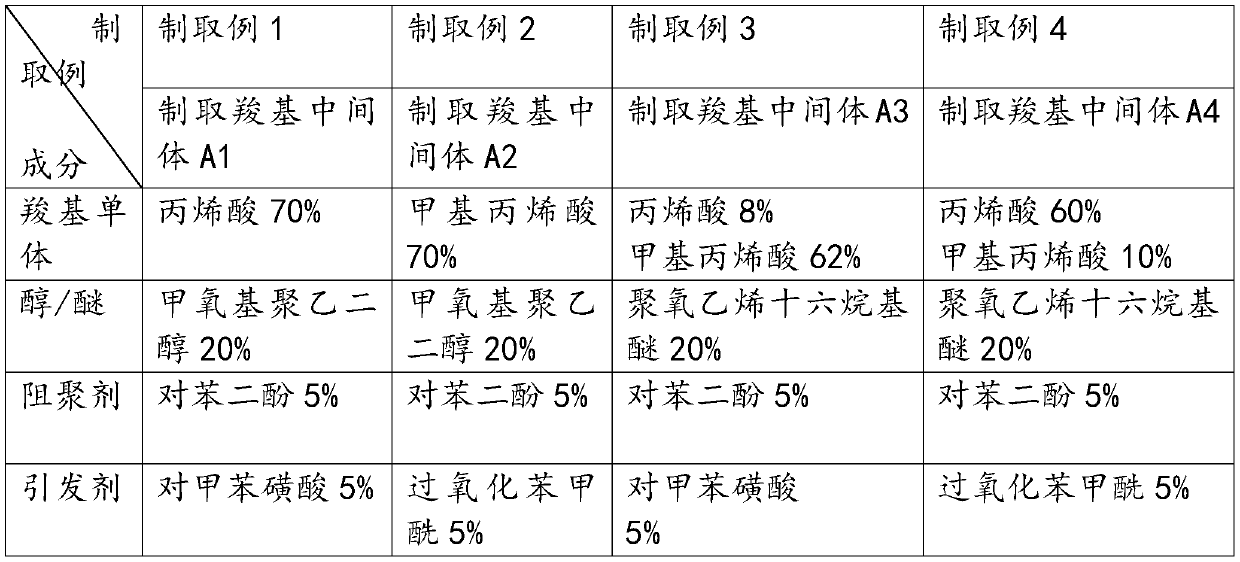

[0027] 1. Preparation of carboxyl intermediates, as described in the table below

[0028] Table 1

[0029]

[0030] Concrete preparation process is as follows:

[0031] Preparation Example 1: Preparation of Carboxyl Intermediate A1

[0032] 1) Add 20 parts of EO-PO ethylene glycol methoxypolyethylene glycol and 5 parts of hydroquinone as a polymerization inhibitor to the reaction kettle, heat to 80-85°C, and continue the reaction until it is completely molten. Then add 35 parts of carboxyl monomer acrylic acid, and heat up to 100-105°C. After the temperature stabilizes, add 5 parts of initiator p-toluenesulfonic acid, and keep the temperature for 5 hours.

[0033] 2) Cool the temperature to 90°C, add 35 parts of carboxyl monomer acrylic acid after the temperature stabilizes, keep it warm for 30 minutes, and finally lower it to 40°C, which is the carboxyl intermediate A1 of the present invention.

[0034] Preparation Example 2: Preparation of Carboxyl Intermediate A2

[...

Synthetic example 1

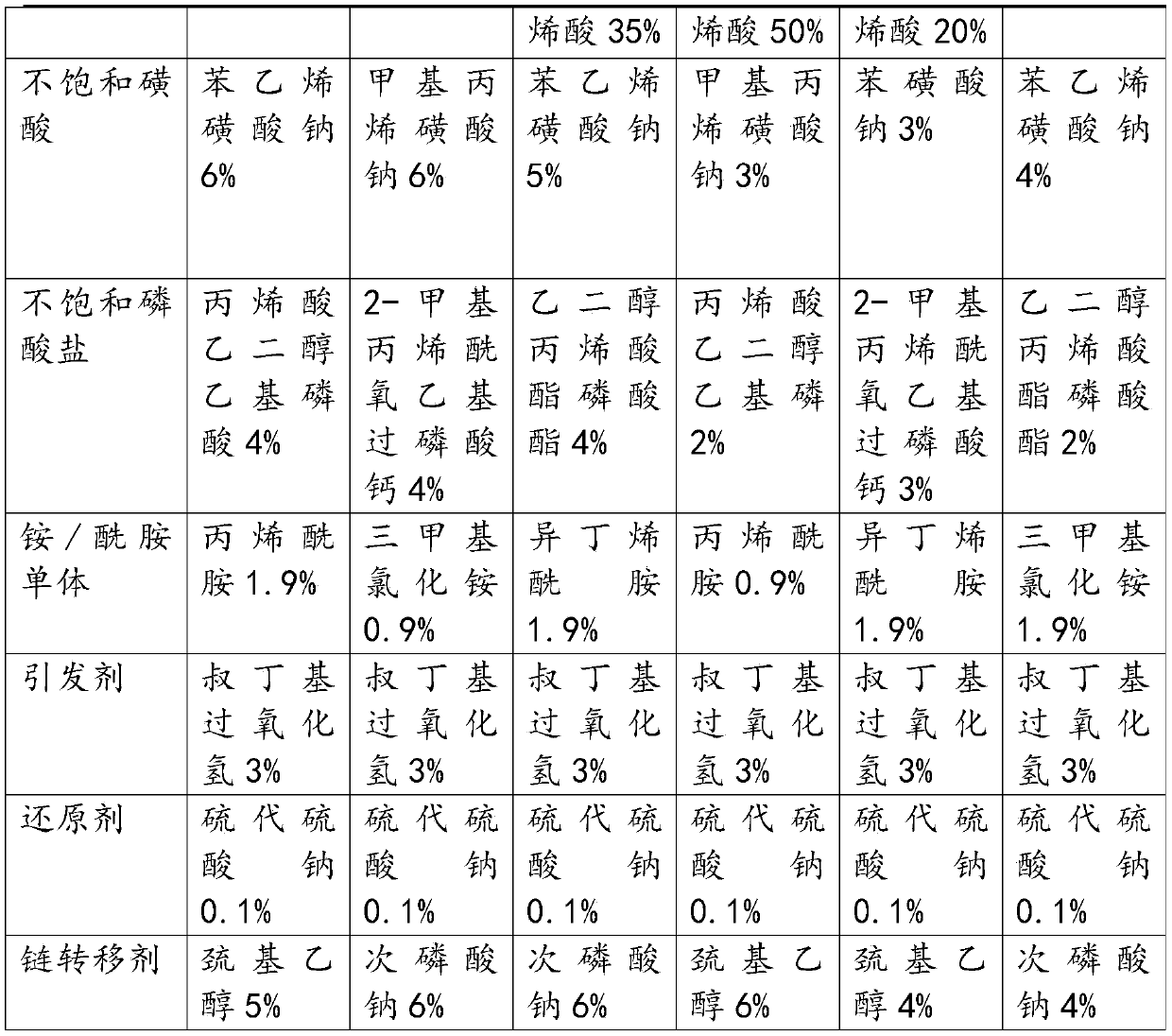

[0044] Synthesis Example 1: Synthesis of High Molecular Block Polymer B1

[0045] 1) Add deionized water, 2.5 parts of chain transfer agent mercaptoethanol (accounting for 50% of the total amount of chain transfer agent) and 0.1 part of reducing agent sodium metabisulfite in the reactor, and start heating while stirring. When the temperature reaches 80°C, add 3 parts of initiator tert-butyl hydroperoxide, 10 parts of carboxylic acid intermediate, 6 parts of sulfonic acid monomer sodium styrene sulfonate, 4 parts of phosphate monomer Acrylic acid ethylene glycol ethyl phosphoric acid, 1.9 parts of ammonium / amide monomer acrylamide and the remaining 2.5 parts of chain transfer agent mercaptoethanol (accounting for 50% of the total amount of chain transfer agent) were added dropwise and reacted for 200 minutes.

[0046] 2) After the raw materials are added dropwise, steam is introduced, the temperature is increased to 100° C. and stabilized, then aged for 60 minutes, and finally ...

Synthetic example 2

[0047] Synthesis Example 2: Synthesis of Polymer B2

[0048] The specific operation steps are the same as those in Synthesis Example 1, and the substances and specific contents added sequentially to the synthetic polymer B2 are as described in Table 2 Synthesis Example 2, wherein the aging treatment temperature is 105° C., and the time is 50 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com