Solid electrolytic capacitor and manufacturing method thereof

A technology of solid electrolysis and solid electrolyte layer, which is applied in the direction of solid electrolytic capacitors, capacitor electrodes, capacitor parts, etc., can solve the problems of variable size, increase of intrinsic resistance, increase of interface resistance, etc., and achieve the effect of small change over time

Active Publication Date: 2008-10-15

PANASONIC CORP

View PDF1 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, the resistance of the interface between the solid electrolyte layer 3 and the carbon layer 4A increases.

In addition, external oxygen or moisture intruding from the gap between the carbon layer 4A and the solid electrolyte layer 3 causes an increase in the intrinsic resistance of the solid electrolyte layer 3 itself.

As a result, the ESR of a solid electrolytic capacitor changes with time and tends to increase

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach 1

Embodiment approach 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Login to View More

Abstract

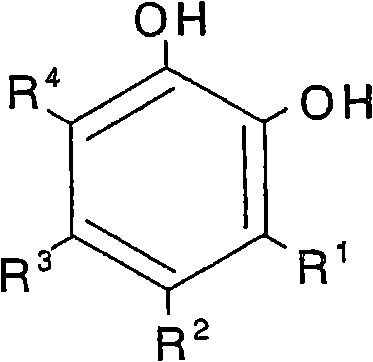

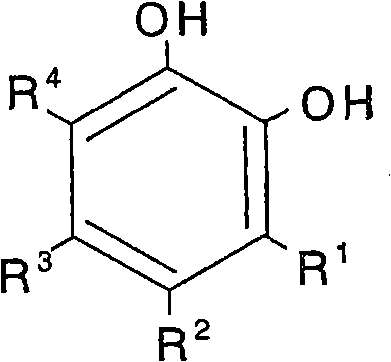

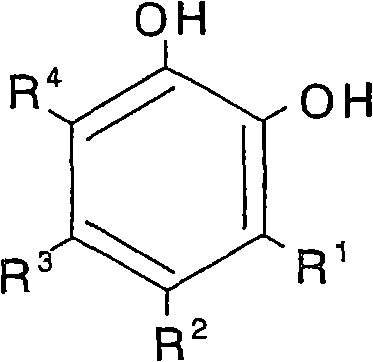

A carbon layer is formed on a solid electrolyte layer of the solid electrolytic capacitor, and a conductor layer connected to a cathode terminal is further disposed thereon. The carbon layer contains carbon particles, and a first additive or a second additive. The first additive is formed from at least one of those selected from the group consisting of hydrated silica and silicate. The second additive is formed from at least one of those selected from the group consisting of a condensation product of an aromatic sulfonic acid with formaldehyde, a condensation product of an aromatic sulfonate with formaldehyde, polystyrene sulfonic acid, and polystyrene sulfonate.

Description

Solid electrolytic capacitor and method of making the same technical field The present invention relates to a solid electrolytic capacitor used in various electronic instruments and a manufacturing method thereof. Background technique In recent years, with the development of digital instruments, there has been a strong demand for capacitors with low equivalent series resistance (hereinafter referred to as ESR) and excellent in high frequency characteristics. In response to such demands, capacitors using solid electrolyte layers such as manganese dioxide, polypyrrole, and polythiophene as electrolytes are being developed and commercialized. FIG. 2 is a cross-sectional view of a conventional solid electrolytic capacitor. This solid electrolytic capacitor has a capacitive element 5 , an anode terminal 6 , a cathode terminal 8 , and an exterior resin 9 . Capacitive element 5 is composed of anode body 1 , dielectric oxide film layer 2 , solid electrolyte layer 3 , and cathod...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01G9/15H01G9/04

Inventor 盛博美松浦裕之齐藤佳津代小泽正人

Owner PANASONIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com