Transparent mortar mixture simulating rheological property of cement mortar and preparation method of transparent mortar mixture

A rheological property, cement mortar technology, applied in the field of materials, can solve the problems of difficult to intuitively obtain the motion parameters of media components, difficult to test physical models of rheological concrete, and difficult to obtain the motion laws of internal components, etc. Small time change, obvious pseudoplastic characteristics, good transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The simulated water-cement ratio is 0.5, the sand-cement ratio is 1:1, and the cement is a carbomer gel medium with rheological properties of P.O42.5 cement mortar. It is composed of the following components in weight percentage: deionized water 94.5%, Carbomer resin powder 0.3%, neutral regulator triethanolamine 0.2%, transparent glass beads 5%.

[0016] Add carbomer resin powder to deionized water, add triethanolamine dropwise after it is completely dissolved, stir evenly and let it stand for 5-10 minutes to obtain transparent carbomer gel, then add transparent glass beads and stir evenly. .

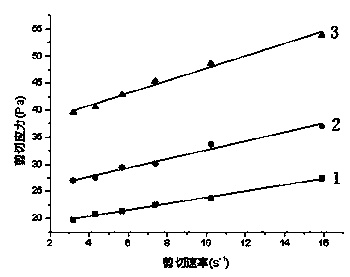

[0017] 1. Fit test

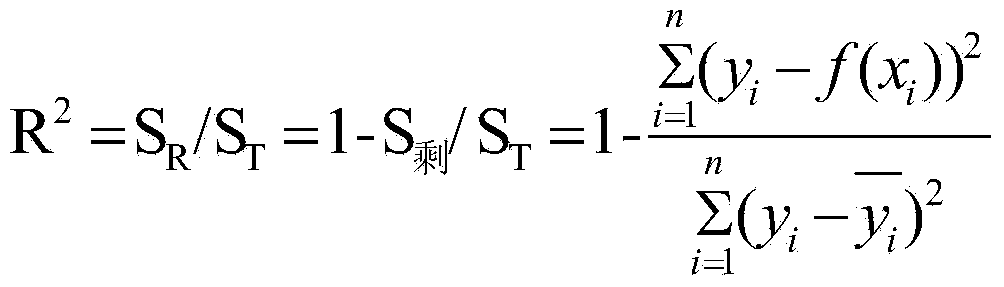

[0018] Select the residual sum of squares test method, which can highlight the differences between parameter values when the curve trends are similar, so as to improve the accuracy and find the curve with the highest degree of fitting. According to the principle of regression analysis, the correlation index R is used for the effect of curve regression 2...

Embodiment 2

[0043] The simulated water-cement ratio is 0.48, the sand-cement ratio is 1:1, and the cement is a transparent mortar mixture with rheological properties of P.O42.5 cement mortar. It is composed of the following components in weight percentage: deionized water 93.46%, Carbomer resin powder 0.32%, neutral regulator triethanolamine 0.22%, transparent glass beads 6%.

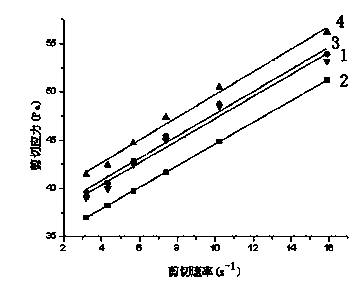

[0044] Comparing the yield stress τ of the two rheological parameters 0 and plastic viscosity μ, the regression curve equation of the transparent mortar mixture obtained by mixing the concentration of 0.32% carbomer gel and 6% transparent glass microspheres and the water-cement ratio is 0.48, the sand-cement ratio is 1:1, and the cement is P .O42.5 Fitting degree of cement mortar R 2 is 0.98.

[0045] Under the condition of significance level α=0.05, the yield stress τ of the transparent mortar mixture as the simulated medium of cement mortar with a water-cement ratio of 0.48 0 and plastic viscosity μ have obtai...

Embodiment 3

[0047] The simulated water-cement ratio is 0.45, the sand-cement ratio is 1:1, and the cement is a transparent mortar mixture with rheological properties of P.O42.5 cement mortar. It is composed of the following components in weight percentage: deionized water 92.41%, Carbomer resin powder 0.35%, neutral regulator triethanolamine 0.24%, transparent glass beads 7%.

[0048] Comparing the yield stress τ of the two rheological parameters 0 and plastic viscosity μ, the regression curve equation of the transparent mortar mixture obtained by mixing the concentration of 0.35% carbomer gel and 7% transparent glass microspheres and the water-cement ratio is 0.45, the sand-cement ratio is 1:1, and the cement is P .O42.5 Fitting degree of cement mortar R 2 is 0.99.

[0049] Under the condition of significance level α=0.05, the yield stress τ of the transparent mortar mixture as the simulated medium of cement mortar with a water-cement ratio of 0.45 0 and plastic viscosity μ have obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com