Patents

Literature

80results about How to "Reduce thixotropy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

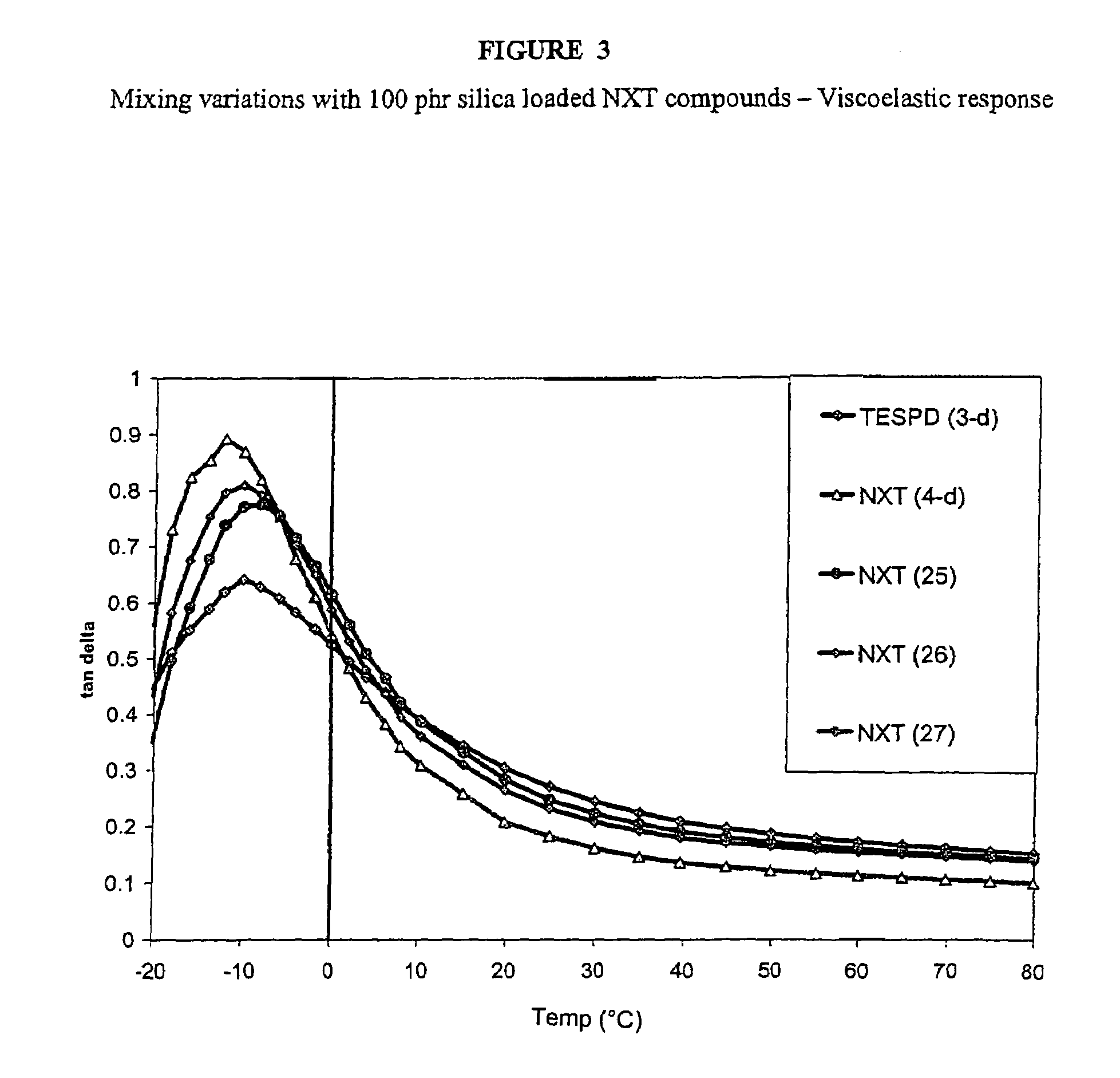

Silica-rubber mixtures having improved hardness

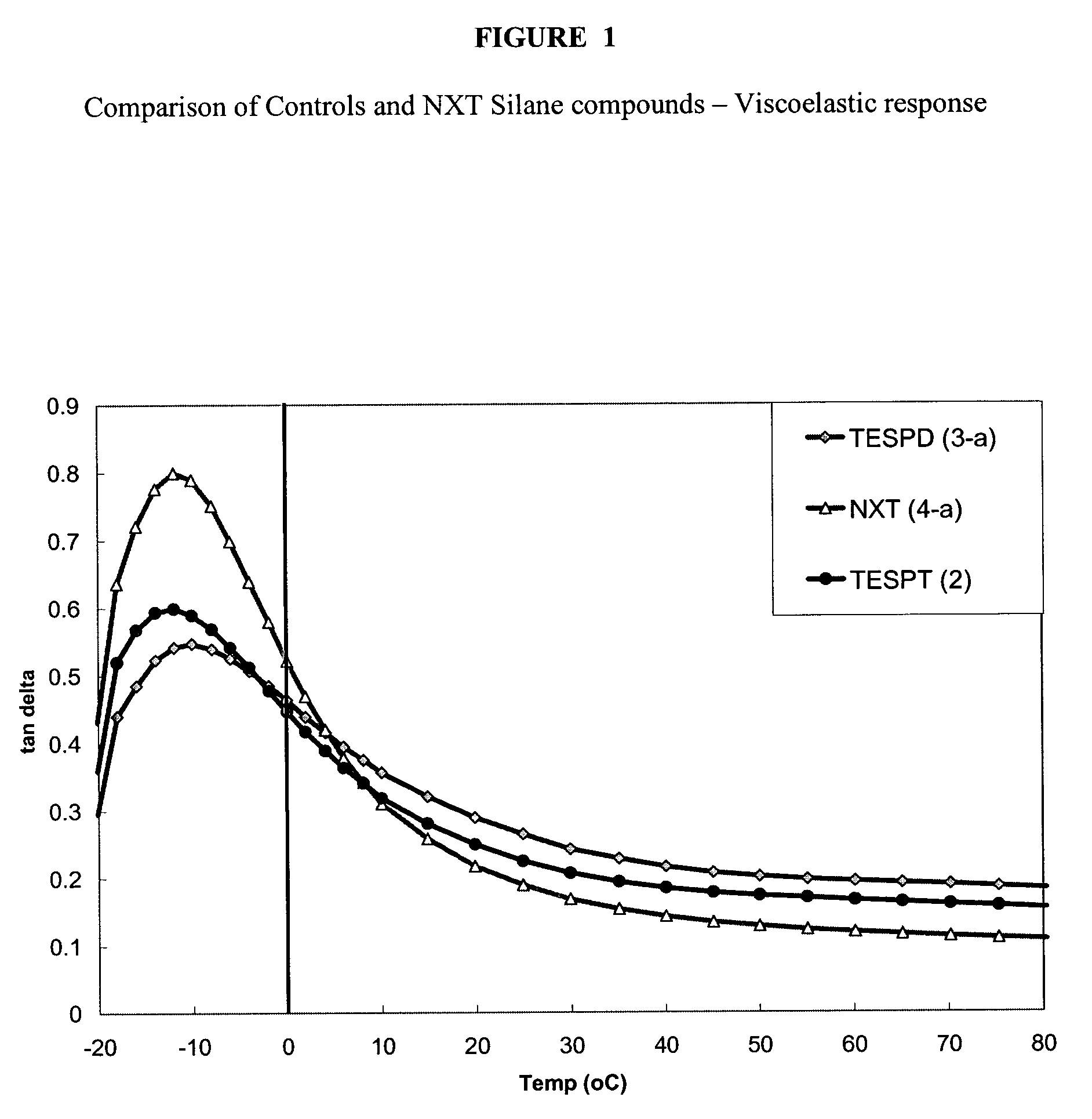

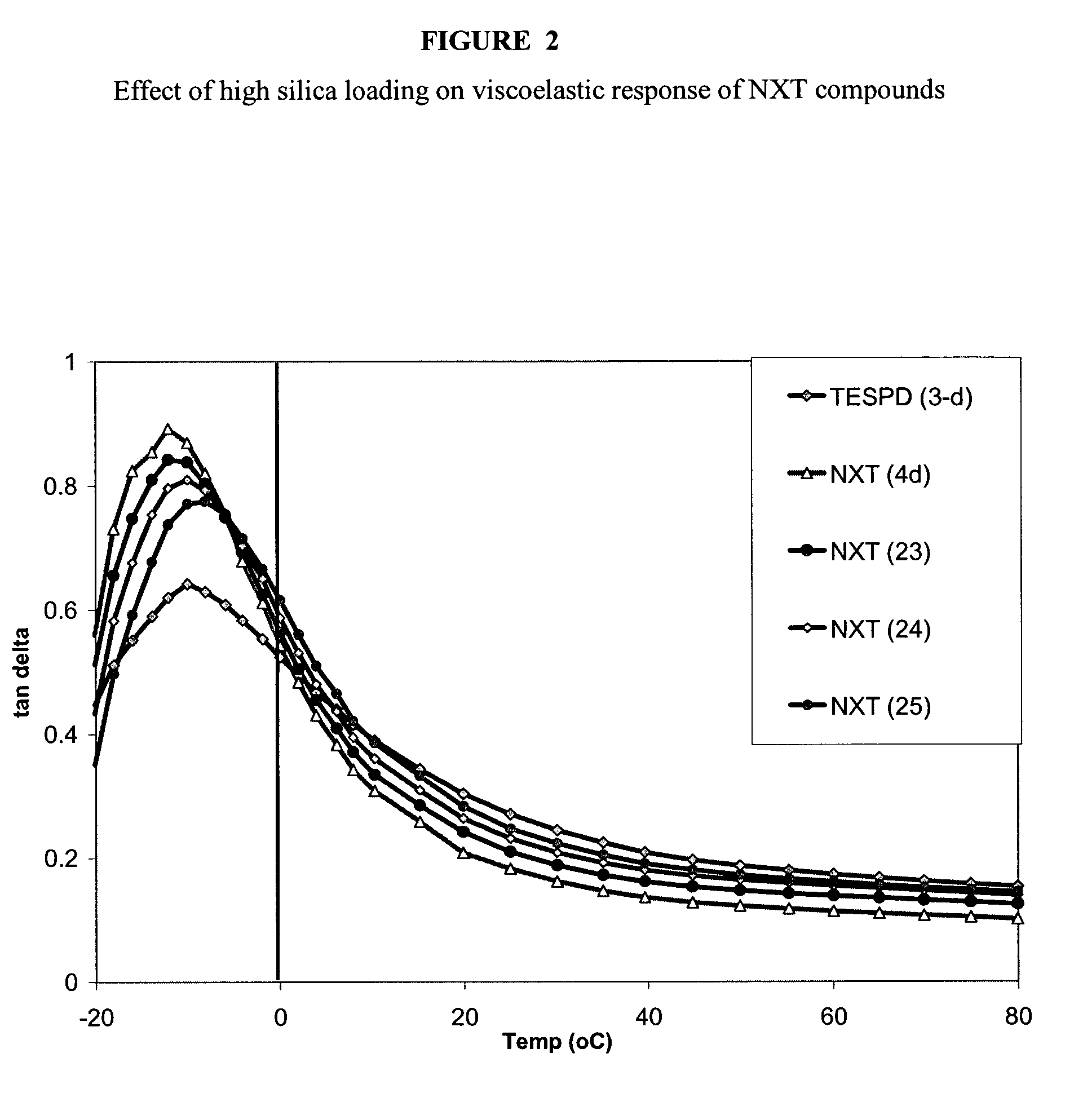

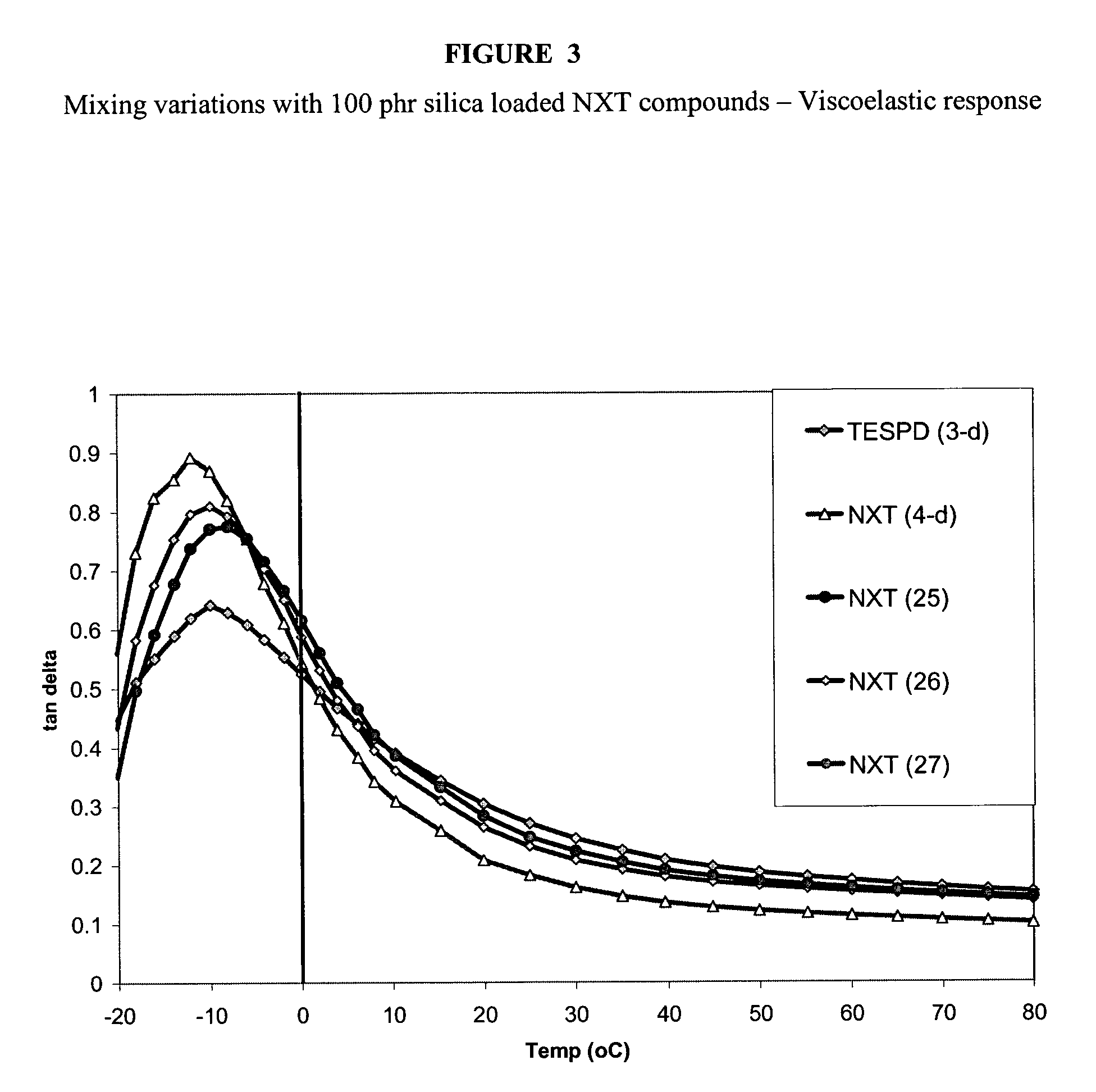

InactiveUS20050277717A1Eliminates and reduces filler network effectReduce hardnessSpecial tyresSilanesOrganic group

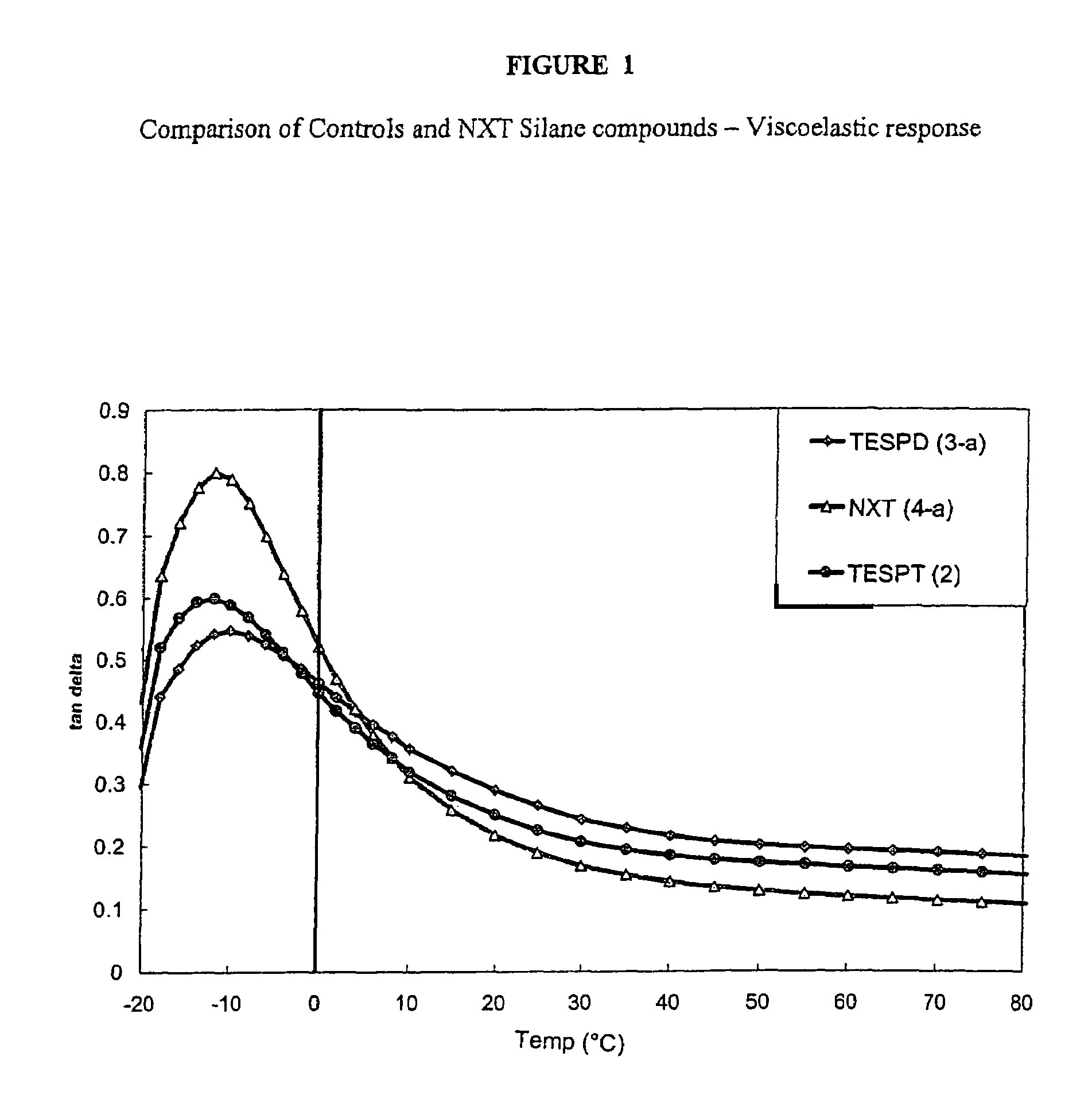

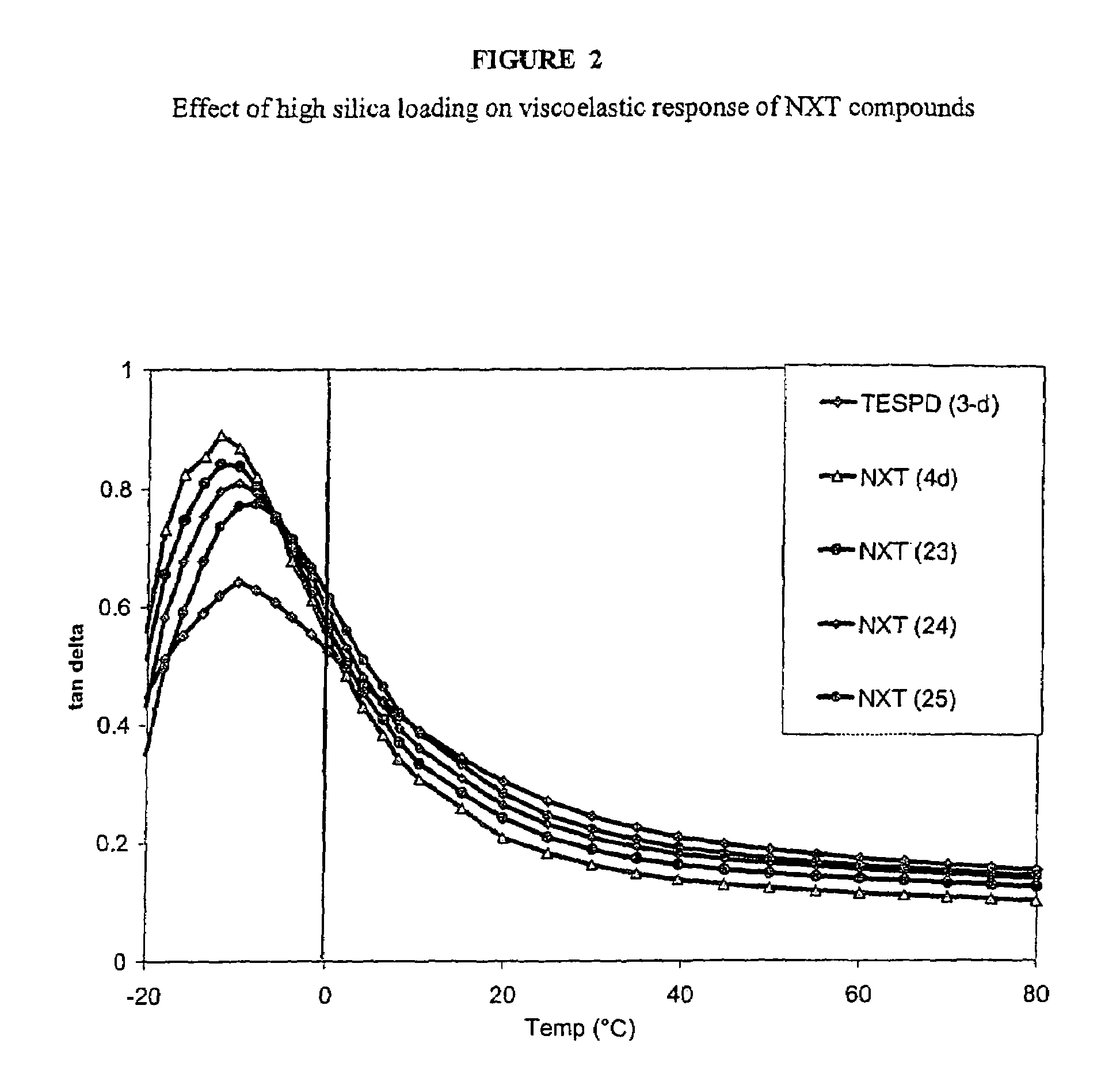

A method for increasing the hardness of silica / rubber mixtures is disclosed wherein the method comprises blending with said mixture at least one silane and a hardness-increasing amount of at least one member selected from the group consisting of thixotropic fumed silica; precipitated silica; an MQ resin wherein Q is SiO4 / 2, M is R1R2R3SiO1 / 2, and R1, R2, and R3 are the same or different functional or non-functional organic groups; carbon black; a thermoplastic resin; and a thermosetting resin.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

Heat-conductive silicone grease composition being high in heat conductivity and low in viscosity, and preparation method of the silicone grease composition

ActiveCN107603224ALiquidity is not affectedLiquidity impactHeat-exchange elementsNetwork structureSilicone grease

The invention discloses a heat-conductive silicone grease composition being high in heat conductivity and low in viscosity and freeness degree, and a preparation method of the silicone grease composition. The heat-conductive silicone grease composition includes organo-polysiloxane, heat conductive filler and other additives. By selecting the heat conductive fillers in multiple dimensions (one-dimension, two-dimension and three-dimension) and multiple scales (micron, submicron and nanometer) and in special ranges, synergistic effect among the multi-dimension and multi-scale fillers is achieved,thus achieving compact stack of the fillers in a local network structure. The heat-conductive silicone grease not only is improved in heat-conductivity but also has good flowability, low viscosity and low freeness degree.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

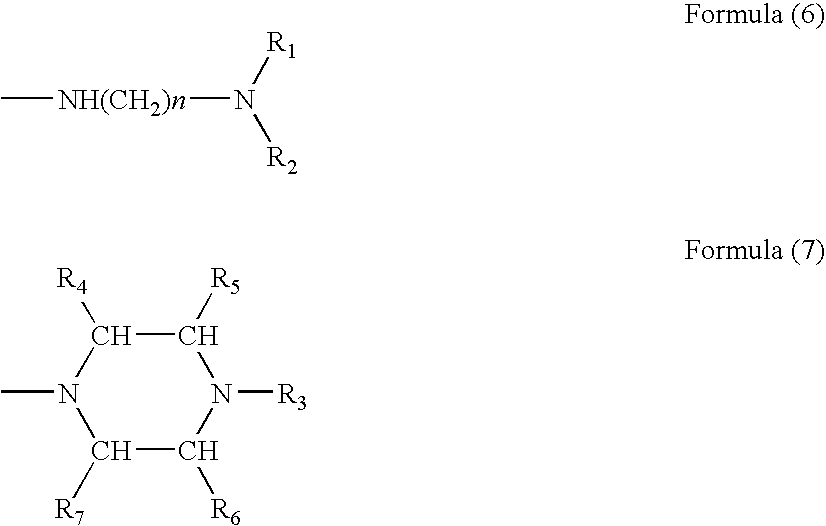

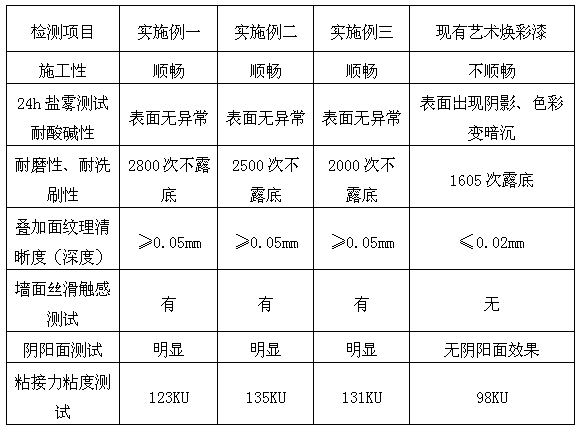

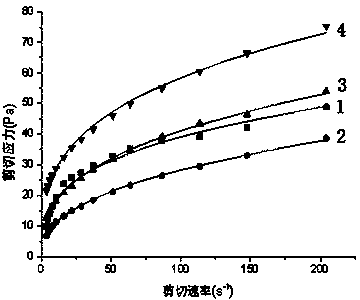

Preparation method of polyacrylamide nano composite fracturing fluid

ActiveCN104109525AHigh temperature resistantSalt resistantDrilling compositionIn situ polymerizationFracturing fluid

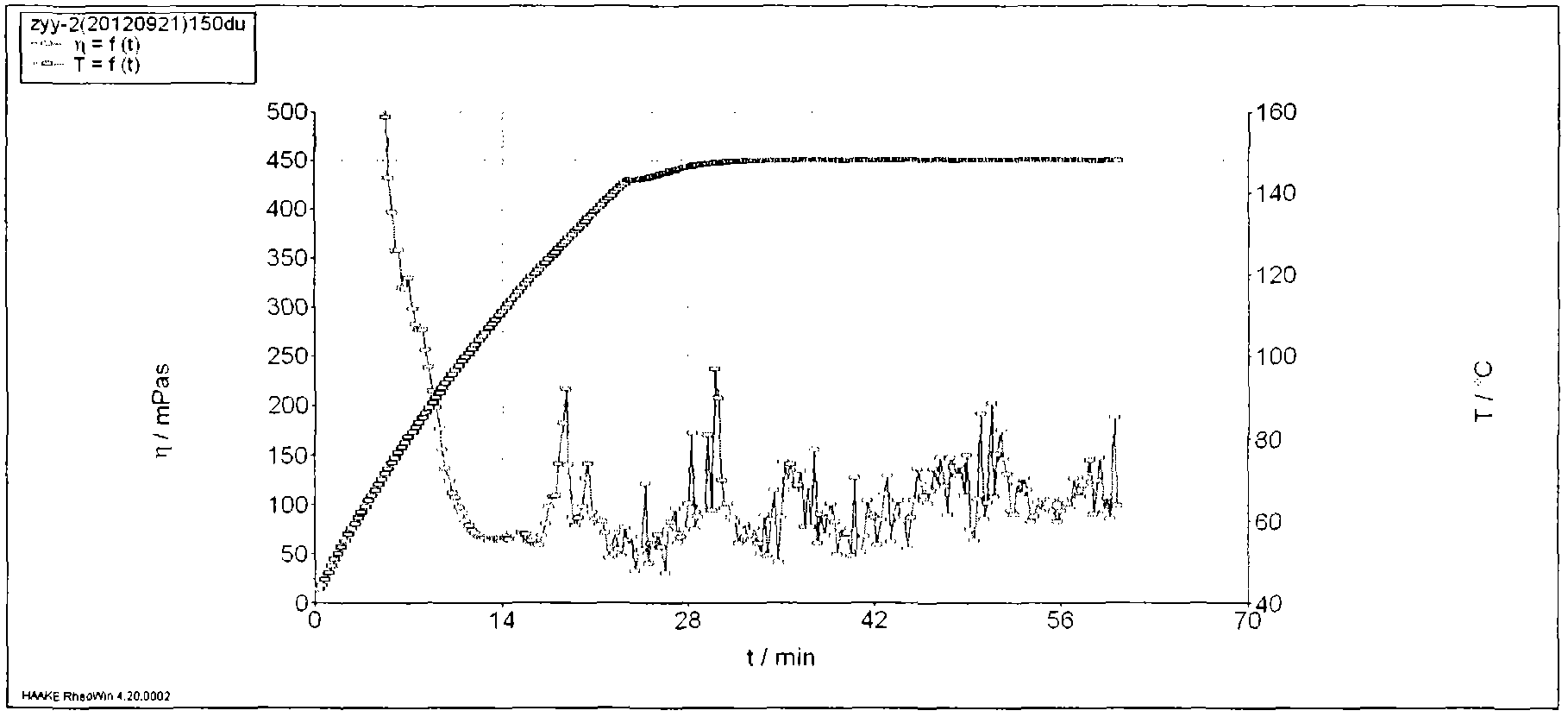

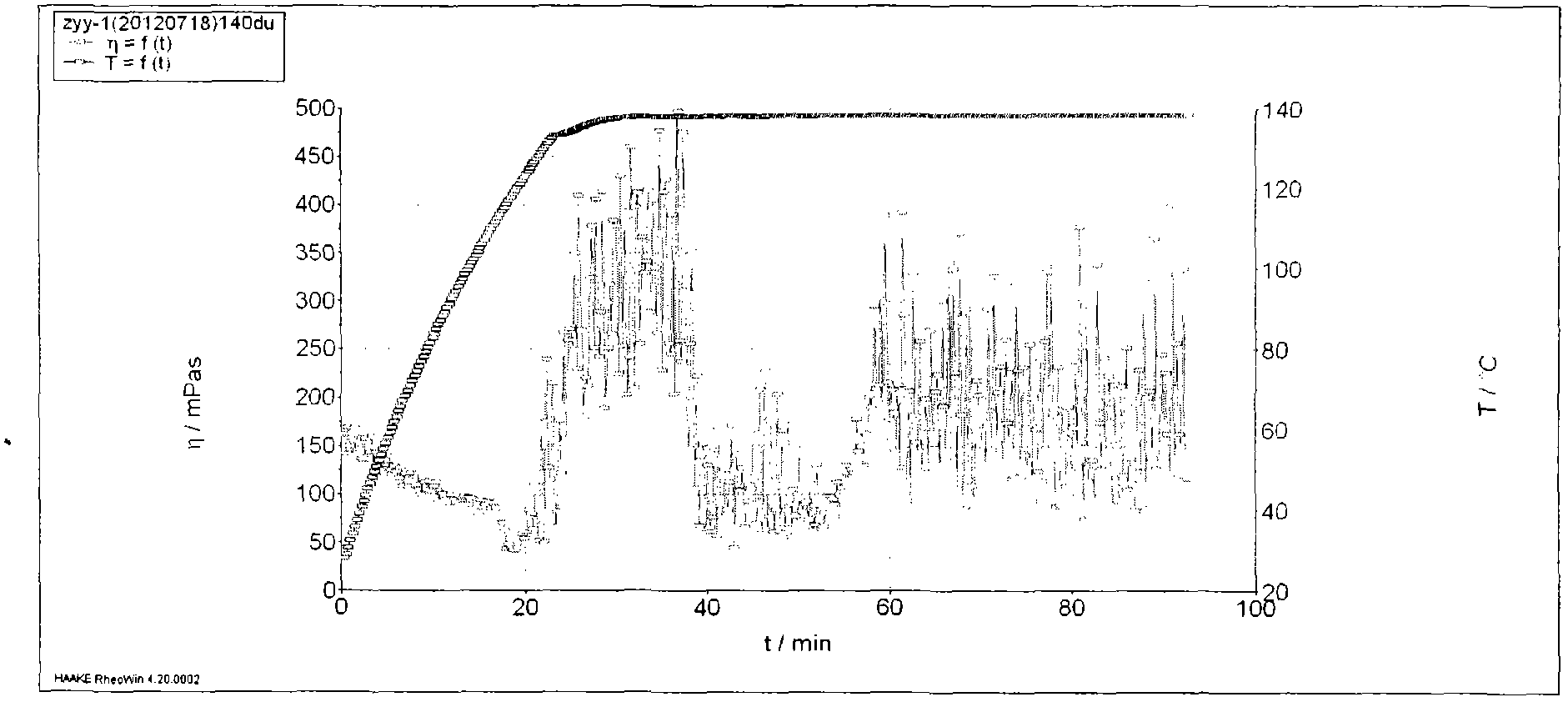

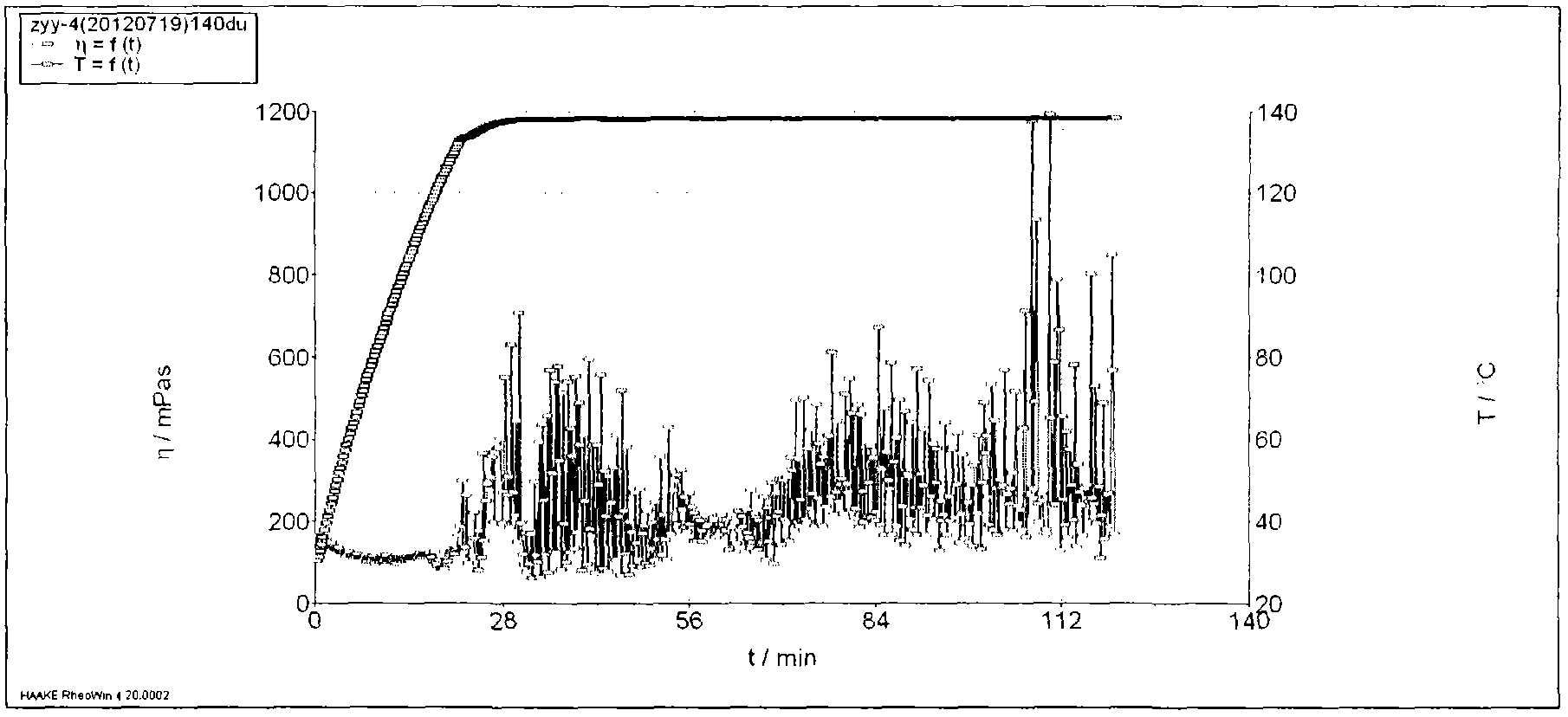

The invention adopts polyacrylamide and a nano inorganic phase to prepare a polyacrylamide nano composite material through an in-situ polymerization method and then forms a fracturing fluid thickening agent. The nano inorganic phase is prepared by mixing the products of intercalation reactions between an organic long-chain intercalator and layered silicate with magnesium nitrate and aluminum nitrate. The nano inorganic phase, acrylamide monomer, a coupling agent, a complexing agent, an initiator, an oxidant, a reductant, a cosolvent, an auxiliary agent, and deionized water form a suspension fluid reaction system, and the polyacrylamide nano composite material is formed after the polymerization-intercalation composite reactions. The polyacrylamide nano composite material with a mass percentage of 0.25% is taken as the thickening agent, and then is mixed with a crosslinking agent with a mass percentage of 0.20%, a gel breaker with a mass percentage of 0.20%, and other auxiliary agents to form a fracturing fluid system. The system is sheared for 70 minutes under a shearing speed of 170 s<-1> at a temperature of 150 DEG C so as to form a fracturing fluid with a viscosity larger than 50 mPa.s, and the fracturing fluid has the characteristics of high temperature resistance, shearing resistance, low frictional resistance, complete glue breaking effect, and good compatibility with the formation fluid.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Silica-rubber mixtures having improved hardness

A method for increasing the hardness of silica / rubber mixtures includes blending with the mixture at least one silane and a hardness-increasing amount of at least one member selected from the group consisting of thixotropic fumed silica, precipitated silica and an MQ resin, wherein Q is SiO4 / 2, M is R1R2R3SiO1 / 2, and R1,R2,and R3 are the same or different functional or non-functional organic groups, carbon black, a thermoplastic resin or a thermosetting resin.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

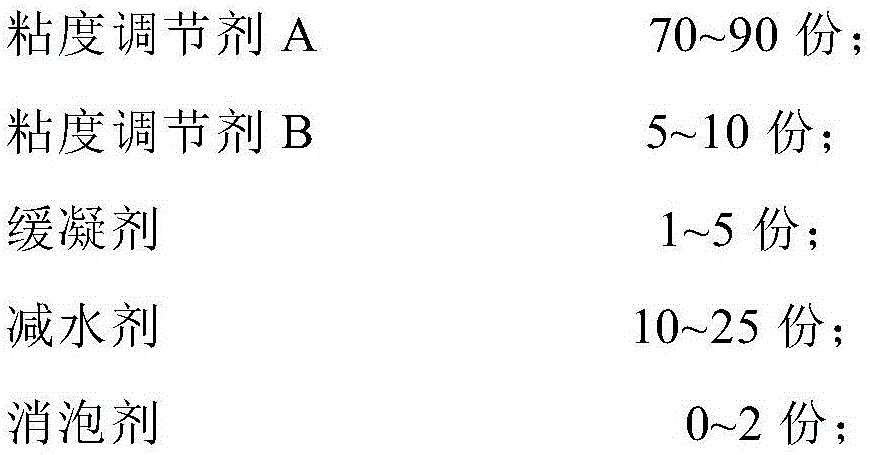

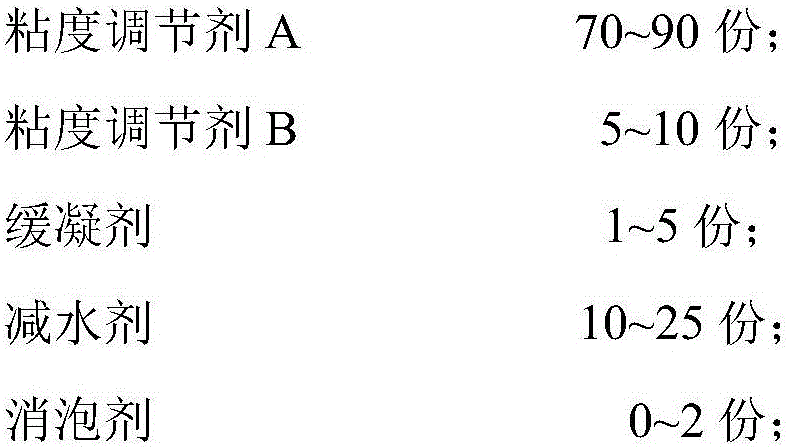

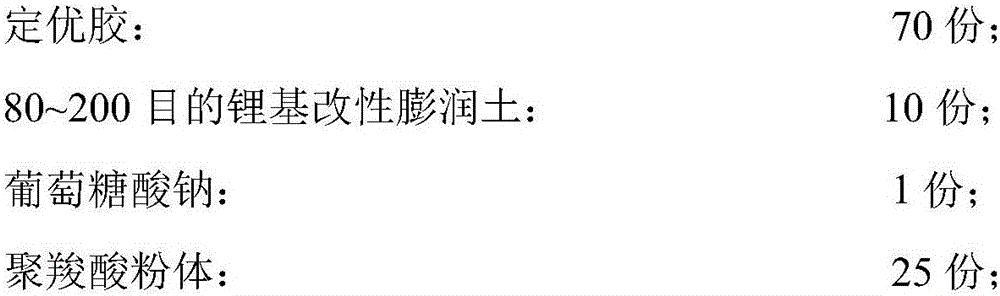

Cement base rheological stabilizing agent and preparation method and application thereof

The invention provides a cement base rheological stabilizing agent and a preparation method and application thereof.The stabilizing agent is prepared from the following components, by weight, of 70-90 parts of viscosity regulating agent A, 5-10 parts of viscosity regulating agent B, 1-5 parts of retarder, 10-25 parts of water reducing agent and 0-2 parts of anti-foaming agent.The stabilizing agent can be applied to dry-mixed mortar or concrete.The stabilizing agent can adjust the viscosity of a cement base system, has anti-sedimentation and bleeding-proof functions and can keep excellent compatibility with a polycarboxylate water reducing agent and improve the mixability of the cement base system at the plastic stage, the application property of the cement base rheological stabilizing agent is further improved, and the cement base rheological stabilizing agent can be widely applied to cement-based materials such as duct grouting materials (agents), grouting materials, cement mortar and concrete and is widely applied to the fields of highway bridges, railways, buildings and the like.

Owner:上海英杉新材料科技有限公司

Amorphophallus glucomannan drying agent and preparation method thereof

InactiveCN101670276AReasonable formulaLow costOther chemical processesChemical industryPotassium persulfate

The invention relates to an amorphophallus glucomannan drying agent which consists of amorphophallus glucomannan, propenoic acid, sodium hydroxide, ethanol, hydrochloric acid, potassium persulfate, N,N-methylene-bisacrylamide, calcium chloride and water. The preparation method of the drying agent comprises the steps of: preparing deacetylation amorphophallus glucomannan and deacetylation amorphophallus glucomannan-propenoic acid copolymer; mixing the deacetylation amorphophallus glucomannan and the deacetylation amorphophallus glucomannan-propenoic acid copolymer according to a proportion; andcrushing and pelleting after expansion. The drying agent has the advantages of reasonable formula, low cost, strong water absorption, safety, no toxicity, no harm to skin and eyes, biodegradability and the like, and can be widely applied to the fields such as food, medicine, chemical industry and the like.

Owner:FUJIAN AGRI & FORESTRY UNIV

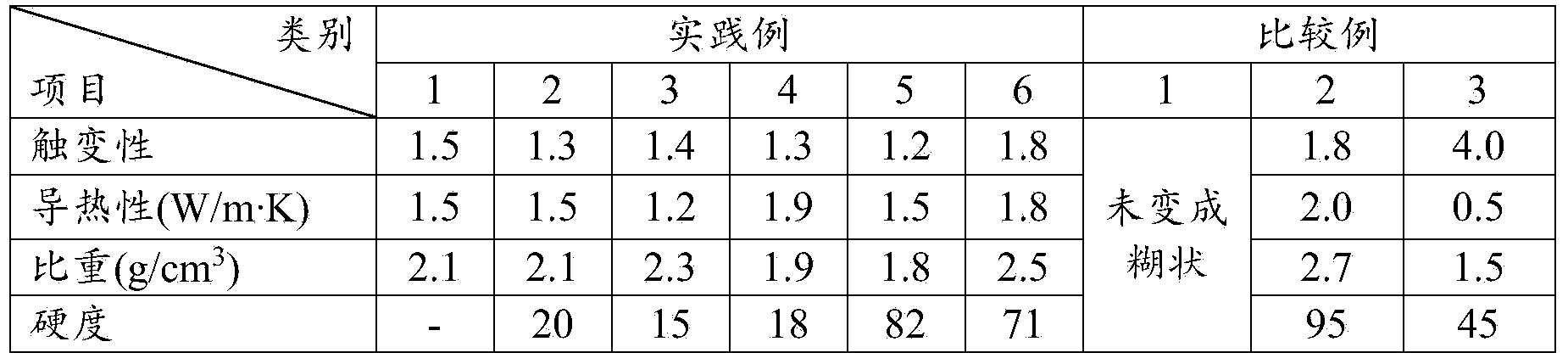

Thermally conductive silicone composition

A thermally conductive silicone composition comprising: (A) an organopolysiloxane that is liquid at 25°C and preferably has a viscosity of from 100 to 1,000,000 mPa.s; (B) an aluminum oxide powder having an average particle size of not more than 10 mum and preferably from 1 to 8 µm; and (C) an aluminum hydroxide powder having an average particle size of greater than 10 µm and preferably not greater than 50 µm, has low thixotropy, low specific gravity, and high thermal conductivity.

Owner:DOW TORAY CO LTD

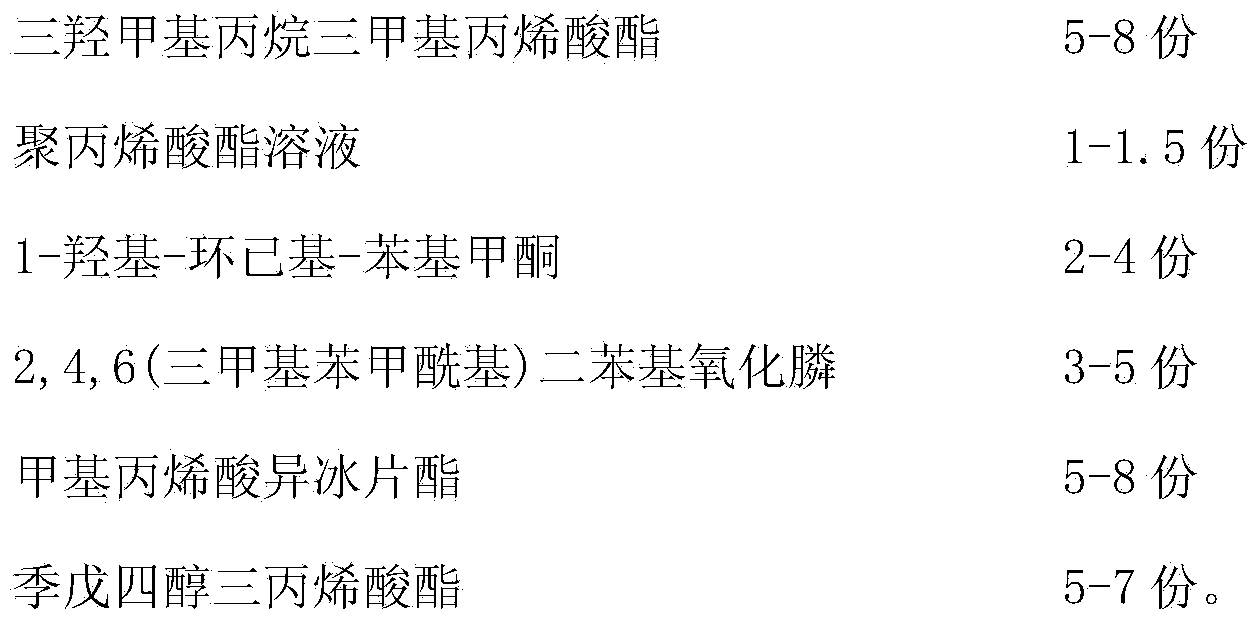

Anti-permeable UV silk printing paper gloss oil and preparation method thereof

ActiveCN104179065AHigh gloss retentionHigh fullnessDefoamers additionPaper coatingPolymer scienceAcrylic resin

The invention relates to the technical field of gloss oil, and in particular relates to anti-permeable UV silk printing paper gloss oil and a preparation method of the anti-permeable UV silk printing paper gloss oil. The anti-permeable UV silk printing paper gloss oil is prepared from the following components in parts by weight: 40-60 parts of acrylic resin, 15-25 parts of acrylic monomer, 8-12 parts of a photoinitiator, 2-4 parts of an organic polymeric delustering agent, and 0.5-4 parts of an assistant; the preparation method comprises the following steps: a. pre-dispersing the acrylic monomer and the organic polymeric delustering agent in a mixing pot in parts by weight, and uniformly mixing; b. continuously adding the acrylic resin, the photoinitiator and the assistant in the mixing pot in parts by weight and mixing uniformly to prepare oil; and c. filtering the oil. The anti-permeable UV silk printing paper gloss oil can achieve good anti-permeable effect, low thixotropic behavior, low influence on glossiness, excellent adhesive force, high fullness and the like, and has wide applicability.

Owner:东莞宏石功能材料科技有限公司

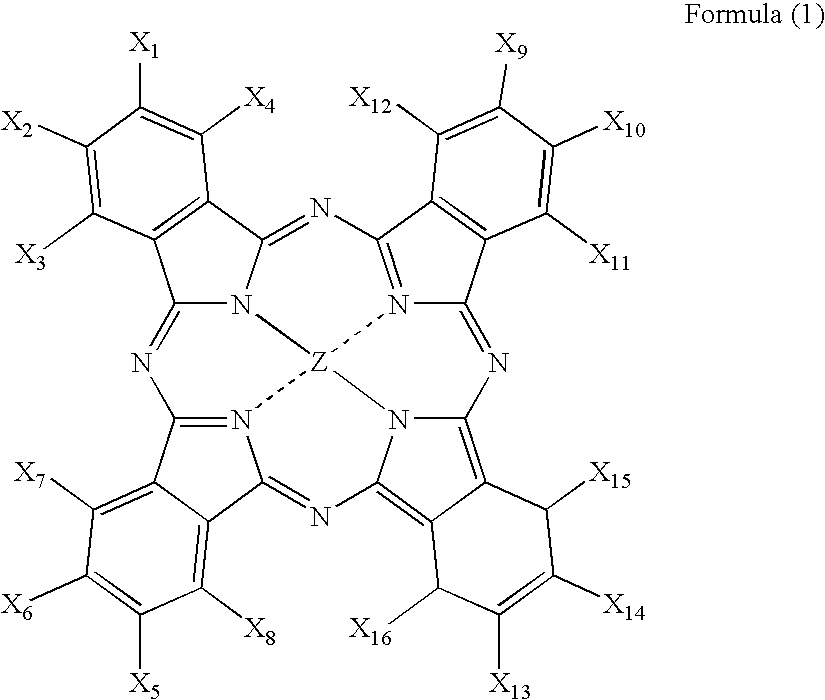

Colored composition

InactiveUS7156912B2Favorable dielectric loss tangent variationImprove dispersionPorphines/azaporphinesPrinted circuit manufacturePhthalocyaninePigment

A colored composition is disclosed that includes a pigment carrier, formed from a transparent resin, its precursor or a mixture thereof, and a halogenated phthalocyanine pigment that has been treated with a higher fatty acid. If required, this colored composition may also include a dye derivative with a basic group, and / or a dye derivative with an acidic group or a salt thereof.

Owner:TOYO INK SC HOLD CO LTD

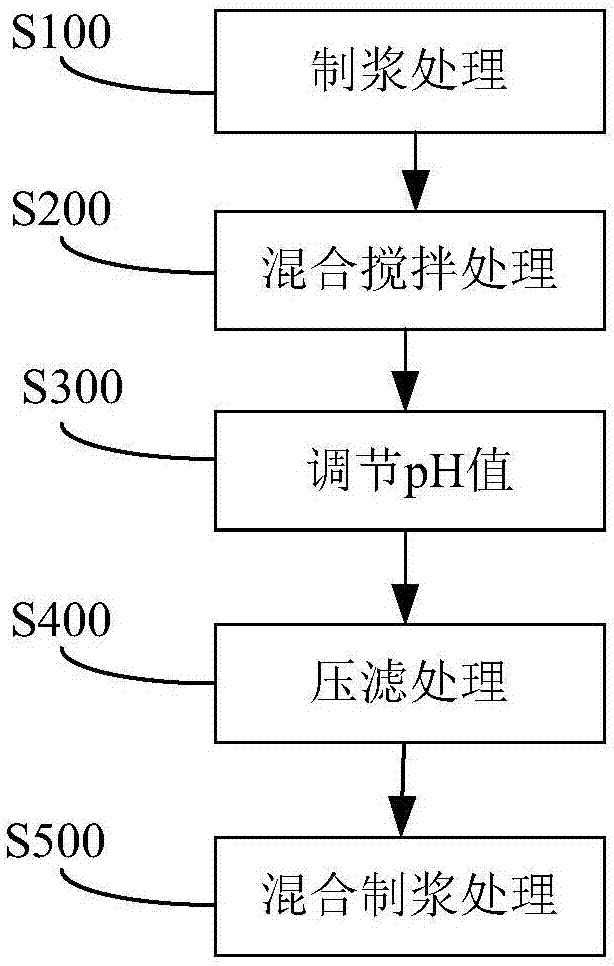

Method for preparing titanium dioxide slurry

InactiveCN106947295AReduce viscosityReduce or shield hydrogen bondsInorganic pigment treatmentHydrogenPulp treatment

The invention discloses a method for preparing a titanium dioxide slurry. The method comprises the following steps: pulping a titanium dioxide base material to obtain a titanium dioxide protoplasm; mixing and stirring the titanium dioxide protoplasm and an aluminum-containing compound to make the surfaces of titanium dioxide base material particles of the titanium dioxide protoplasm coated with an aluminum film in order to obtain aluminum coated titanium dioxide particles; adjusting the pH value of the slurry for coating the aluminum film to be less than 7 in order to obtain a pH value adjusted slurry; carrying out press filtration treatment on the pH value adjusted slurry to obtain a filter cake; and carrying out mixing and pulping treatment on the filter cake and a dispersant to obtain the titanium dioxide slurry. The method reduces or shields hydrogen bonds on the surfaces of the titanium dioxide base material particles through coating the surfaces of the titanium dioxide base material particles, so the titanium dioxide base material particles easily undergo solid-liquid separation to form the filter cake, sodium chloride is effectively removed, and the viscosity of the titanium dioxide slurry is reduced.

Owner:YUNNAN METALLURGICAL XINLI TITANIUM IND CO LTD

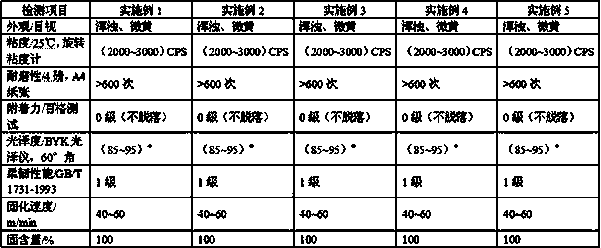

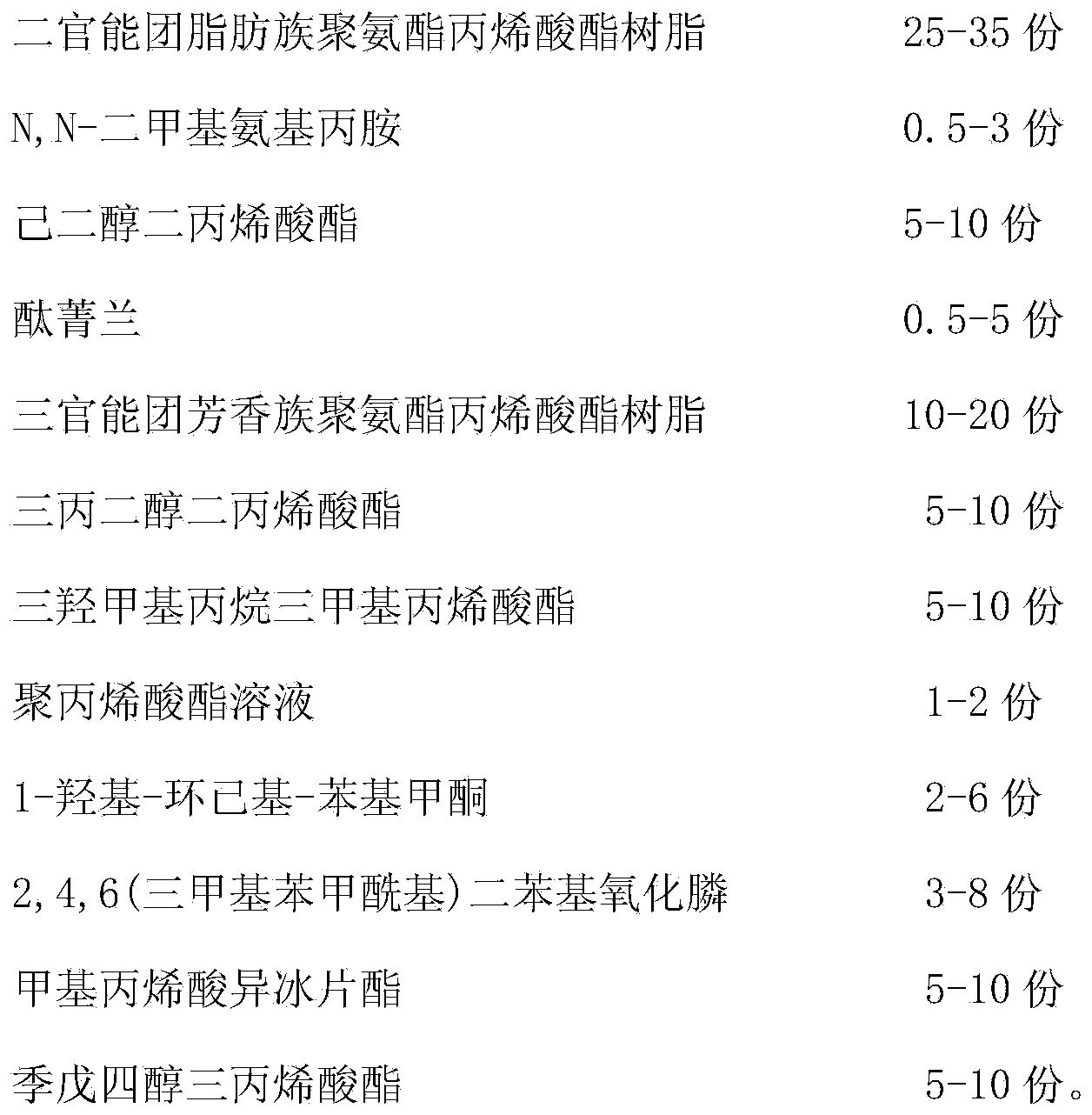

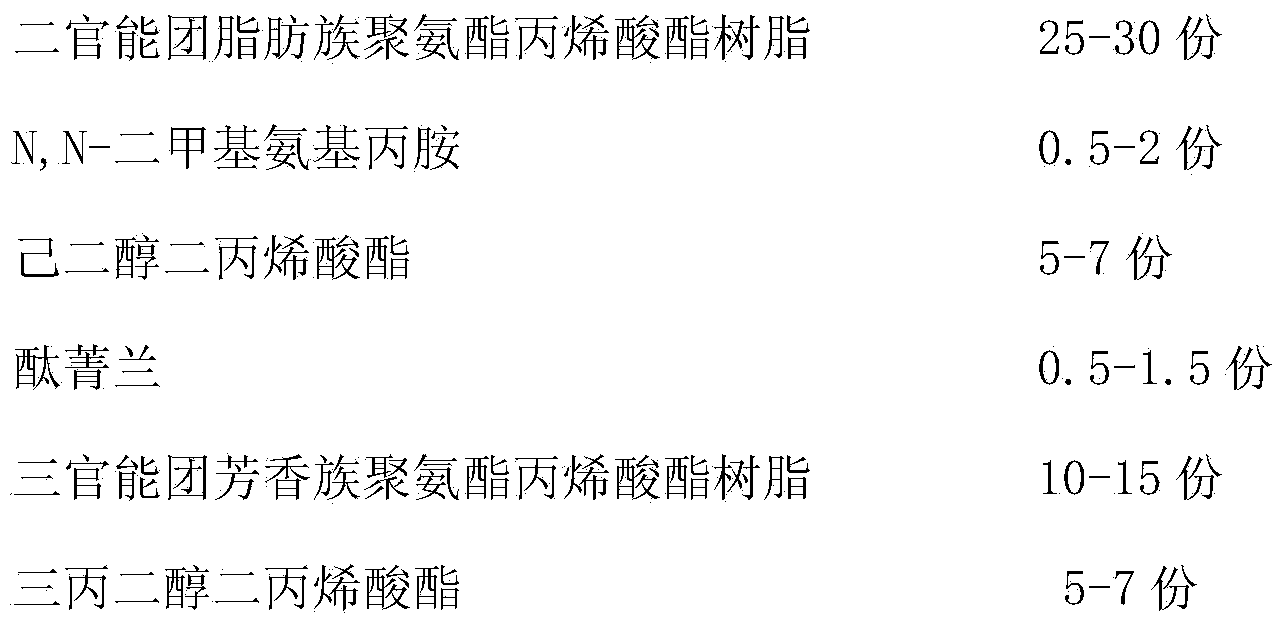

UV-curable strippable ink as well as production method and construction method of UV-curable strippable ink

ActiveCN104327593ALow viscosityReduce thixotropyInksPrinting after-treatmentScreen printingHazardous substance

The invention relates to the technical field of chemical engineering and particularly relates to an UV-curable strippable ink as well as a production and construction methods of the UV-curable strippable ink. The UV-curable strippable ink disclosed by the invention has the advantages of low viscosity, good thixotropy, short curing time and no need of high temperature baking during the curing process, can improve the curing efficiency and is suitable for continuous operation; since the UV-curable strippable ink contains no volatile substances, such substances harmful to human bodies and the device as HCl and oil fume cannot be produced and the UV-curable strippable ink is in full compliance with requirement for environment protection; the production method of the UV-curable strippable ink is simple in process and low in cost; according to the construction method of the UV-curable strippable ink, the UV-curable strippable ink is not adhered to a board during the screen printing process and is easy to strip in the later manufacturing procedure, does not pollute a substrate and has good toughness and acid-alkali resistance, and the yield rate in the manufacturing procedure can be preferably improved.

Owner:GUANGZHOU SHUANGKE NEW MATERIAL

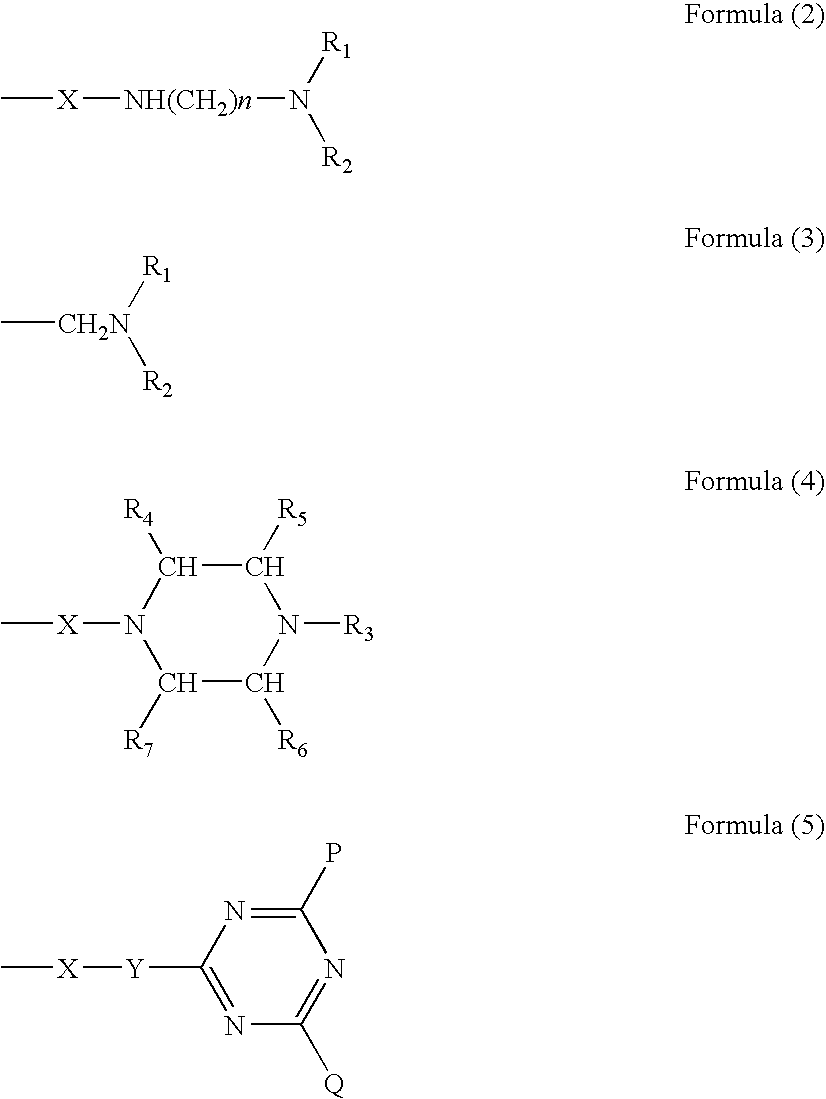

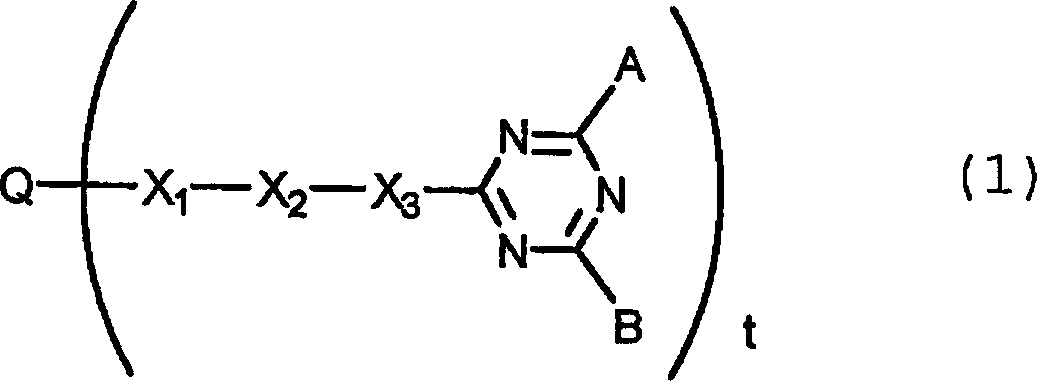

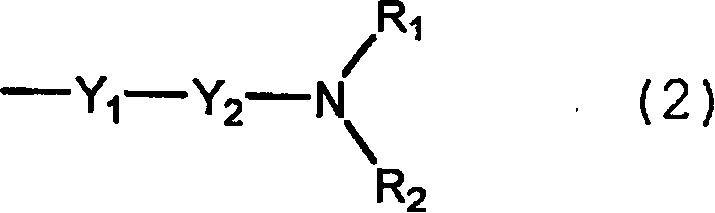

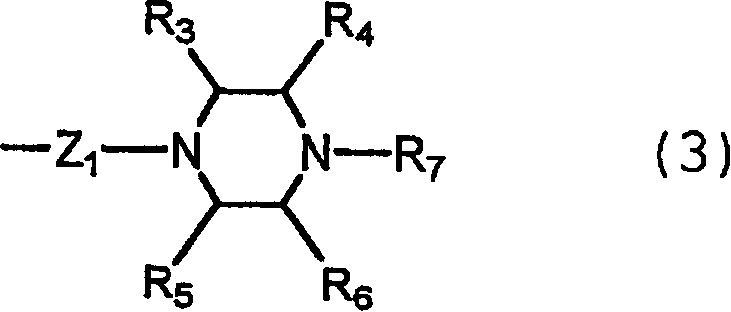

Pigment dispersing agent, pigment composition and pigment dispersion

InactiveCN1834165AHigh transparencyHigh tinting strengthFruit and vegetables preservationTransportation and packagingQuinolineTriazine

A pigment dispersing agent wherein a quinophthalone structure is bonded to a triazine structure through an arylene group or a heteroaromatic ring and a basic functional group is bonded to triazine ring through a connecting group which pigment dispersing agent improves an ink or a coating in fluidity and is effective for preparing a product having a low viscosity and low thixotropic properties and having excellent properties such as tinting strength, transparency and viscosity stability with the passage of time, and a pigment composition and a pigment dispersion containing the same.

Owner:TOYO INK SC HOLD CO LTD

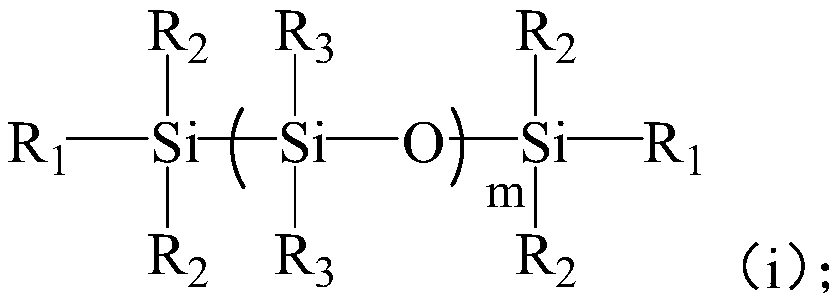

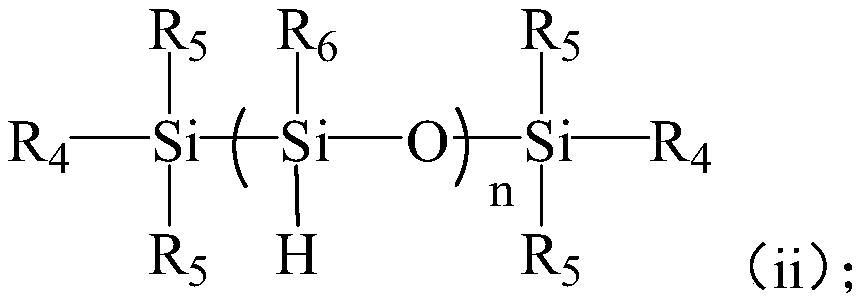

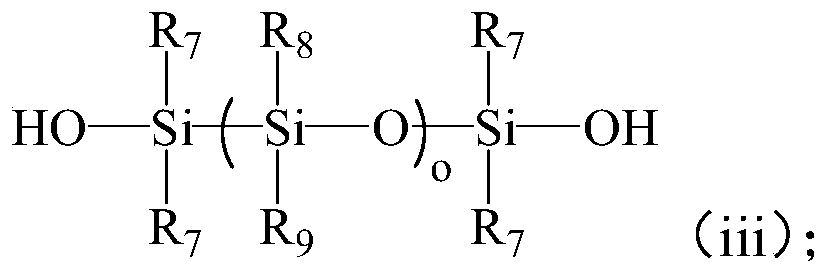

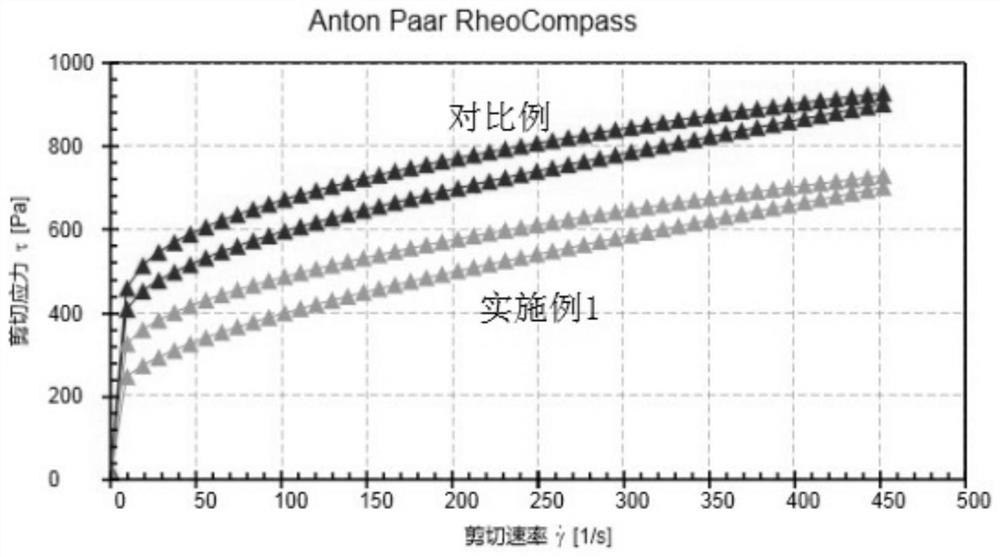

Pre-foamed organic silicone foam material as well as preparation method and application thereof

The invention provides a pre-foamed organic silicone foam material as well as a preparation method and application thereof. The pre-foamed organic silicone foam material disclosed by the invention comprises the following raw materials: methyl and / or vinyl-terminated organopolysiloxane, hydrogen-containing polysiloxane, hydroxyl silicone oil, a pre-foaming agent, an alcohol substance, a surfactant, a filler, a catalyst and a vulcanization inhibitor. According to the pre-foamed organic silicone foam material disclosed by the invention, the pre-foaming agent and the alcohol substance are adopted for performing auxiliary foaming on the basis of dehydrogenation foaming of hydroxyl silicone oil, foaming can be performed before a dehydrogenation reaction, tiny bubble nucleuses are formed, gas volumes and foaming ratios can be effectively increased, the dosage of the hydroxyl silicone oil is reduced, thixotropy is reduced, and processability is improved. Meanwhile, by adding aids such as the surfactant, compatibility of the components can be improved, and stability in the foaming process is improved, so that the prepared foam material is fine and uniform in pore and low in density.

Owner:ZHEJIANG XINAN CHEM INDAL GROUP

Adhesive with energy storage function and application thereof

ActiveCN113355045AReduce contentReduce thixotropyNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAdhesive cementPolymer science

The invention discloses an adhesive with an energy storage function and application thereof. The adhesive comprises an adhesive matrix and an energy storage microcapsule; the energy storage microcapsule comprises a wall material and a core material; the wall material is a terpolymer of resorcinol, urea and aldehyde; the core material is a phase change energy storage material; the content of nitrogen in the wall material is less than or equal to 12 wt%. According to the adhesive with the energy storage function and the application thereof provided by the technical schemes of the invention, phenol serves as a third monomer to be copolymerized with the urea and aldehyde to prepare the microcapsule wall material, meanwhile, the content of nitrogen in the microcapsule wall material is reduced, and a prepared energy storage microcapsule can be applied to preparation of the adhesive; the prepared adhesive with the energy storage function has the advantages of low thixotropy, good flowing property, high phase change material content, good energy storage effect and the like.

Owner:富乐(苏州)新材料有限公司

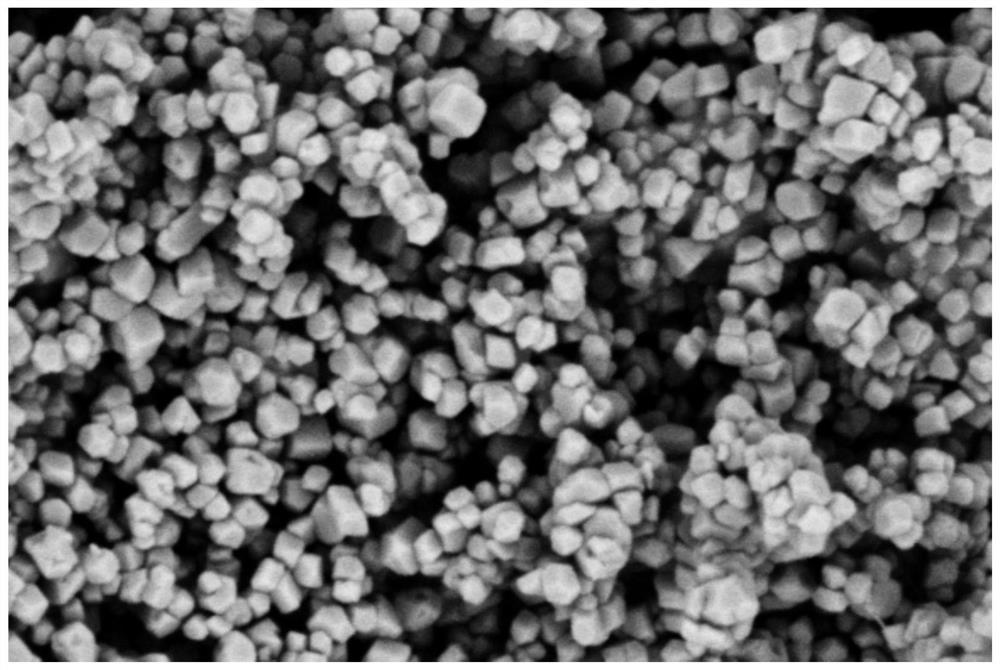

Surface treatment method of nano calcium carbonate for impact-resistant automobile chassis coating

ActiveCN112724708AHigh viscoelasticityImprove rheologyCalcium/strontium/barium carbonatesMaterial nanotechnologySodium stearateCarbonization

The invention discloses a surface treatment method of nano calcium carbonate for an impact-resistant automobile chassis coating, which comprises the following steps of diluting lime milk to obtain slurry, regulating the specific gravity, and carbonating the slurry in a carbonating tower, measuring conductivity through an instrument, adding a crystal form control agent at the lowest point of gelatinization conductivity at the initial stage of carbonization, and stirring to react until the pH value is less than or equal to 7 to obtain calcium carbonate suspension, carrying out oleophylic surface treatment on the calcium carbonate suspension, stirring, and adding a compound treatment agent consisting of a sodium stearate saponification solution and flaxseed gum, polyhexamethylene glycol, sodium dodecyl benzene sulfonate and isopropyl triisostearoyl titanate for surface treatment, and carrying out filter pressing, microwave vacuum drying and sieving to obtain the nano calcium carbonate. The nano calcium carbonate particles prepared through the method are regular in morphology, have the advantages of being good in stability, good in rheological property, high in impact resistance, low in moisture absorption capacity and the like, and can improve the impact resistance and sagging resistance of PVC paste when applied to filling of the automobile chassis coating PVC paste.

Owner:GUANGXI HUANA NEW MATERIALS TECH CO LTD

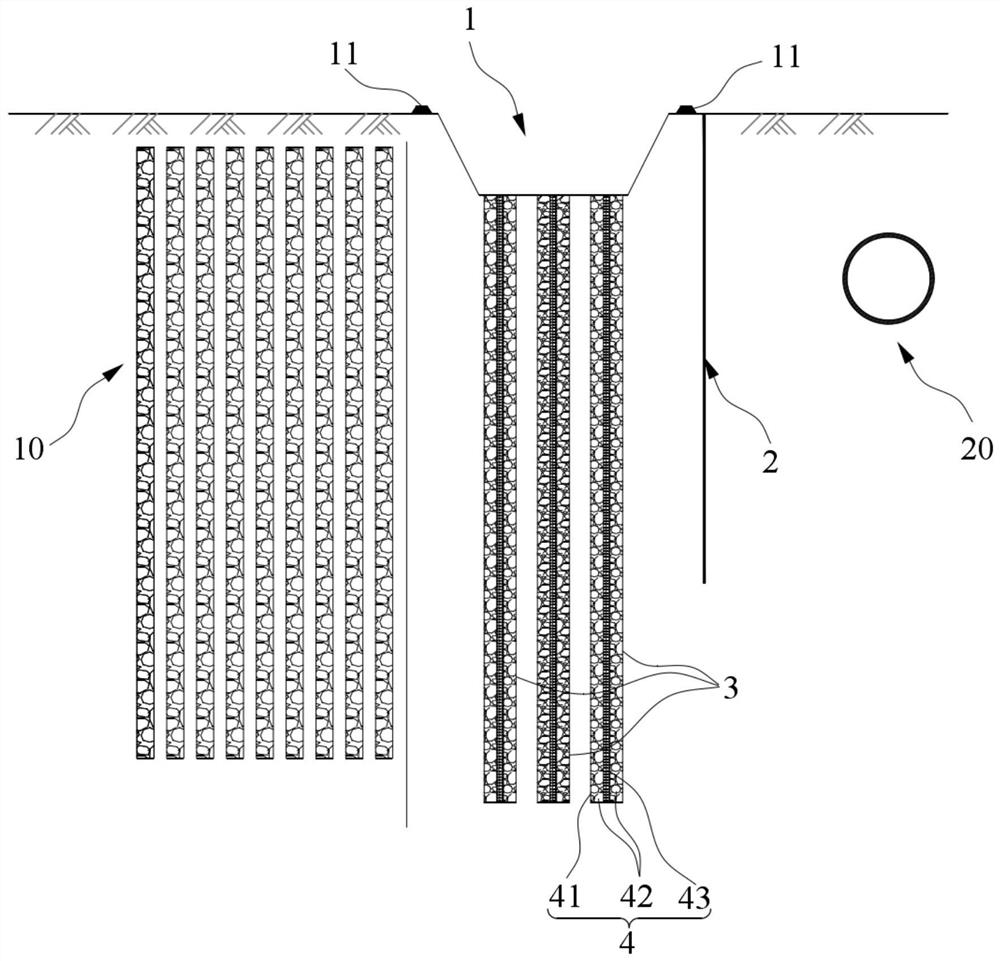

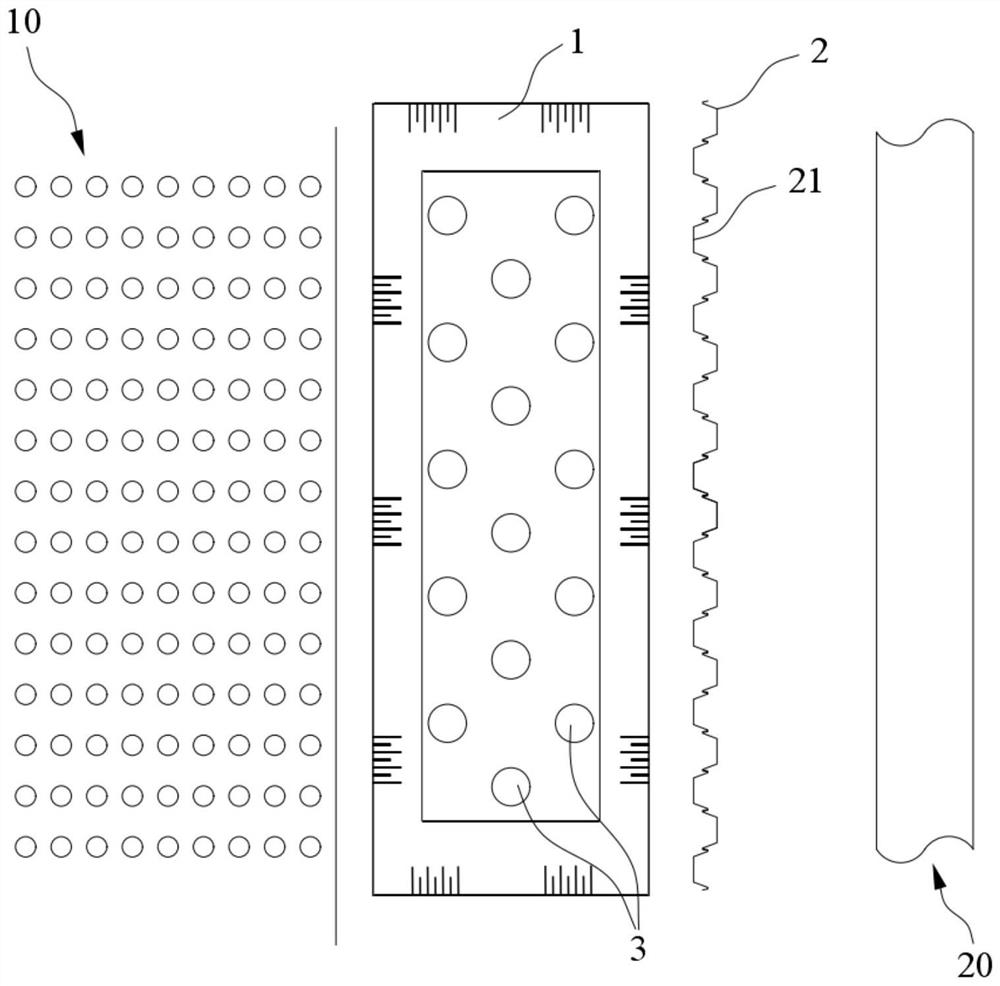

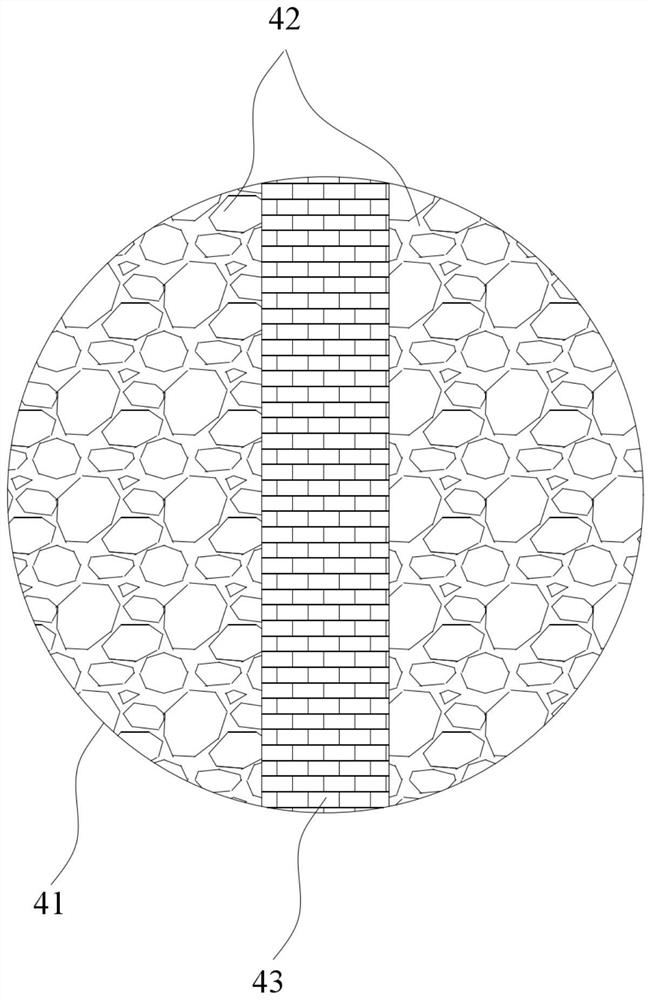

Construction method for reducing soil squeezing effect of pile group

PendingCN113107022AReduce vibrationReduce deliveryProtective foundationGeotextilesResidual vibrationPore water pressure

The invention relates to the technical field of pipe pile construction methods, in particular to a construction method for reducing the soil squeezing effect of a pile group. The construction method for reducing the soil squeezing effect of the pile group comprises the following steps of S1, measuring the positions of an isolation ditch and a steel sheet pile between a pile group construction area and an external building area; S2, driving the steel sheet pile into the ground; S3, digging the isolation ditch; S4, drilling a plurality of stress release holes at the bottom of the isolation ditch, and immersing a vibration isolation assembly in each stress release hole; and S5, carrying out construction on the pile group construction area. According to the construction method for reducing the soil squeezing effect of the pile group, vibration wave transmission and surface upheaval caused by static pressure pile sinking of a pipe pile are effectively weakened through the isolation ditch; the stress release holes are matched with the vibration isolation assembly to isolate surrounding soft soil vibration and thixotropy caused by pipe pile sinking, horizontal and vertical displacement of soft soil is reduced, and excess pore water pressure generated in the soft soil is discharged; the steel sheet pile can block residual vibration of the stress release holes and refract and return vibration waves, so that sensitive buildings are protected.

Owner:上海南汇水利市政工程有限公司

Acrylate adhesive for cementing skirting line ofhigh-speed train

PendingCN106752984AAvoid loss of shear and peel strengthReduce thixotropyNon-macromolecular adhesive additivesMacromolecular adhesive additivesParaffin waxChemistry

The invention discloses an acrylate adhesive for cementing a skirting line of ahigh-speed train, relating to the field of acrylate structural adhesives. The acrylate adhesive contains the following components in parts by volume: 1 part of an oxidizing agent and 8-12 parts of a reducing agent, wherein the oxidizing agent contains the following components in parts by weight: 10-45 parts of dibutyl phthalate, 0-5parts of bisphenol A epoxy resin, 1-5 parts of a silane coupling agent, 10-20 parts of calcium carbonate, 15-20 parts of benzoyl peroxide and 1-5 parts of castor oil; the reducing agent contains the following components in parts by weight: 20-45 parts of methyl methacrylate, 5-20 parts of an impact-resistant modifier, 5-10 parts of chlorosulfonated polyethylene, 1-3 parts of an accelerant, 0.5-1 part of paraffin, 2-5 parts of maleic acid, 0.5-1 part of a stabilizer, 5-10 parts of calcium carbonate and 1-5 parts of the silane coupling agent. The acrylate adhesive has relatively good heat resistance and moisture resistance, the volume change is relatively small during the curing, and a high exothermic peak is avoided.

Owner:HUBEI HUITIAN NEW MATERIALS STOCK CO LTD +3

High-performance medium-temperature cured single-component epoxy structural adhesive and preparation method thereof

PendingCN112646523AImprove temperature resistanceHigh bonding strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceAdhesive

The high-performance medium-temperature cured single-component epoxy structural adhesive comprises the following components in parts by weight: 100 parts of epoxy resin; 0-30 parts of a diluent; 10-15 parts of a latent curing agent; 30-40 parts of a toughening agent; 3-7 parts of an accelerant; 3-7 parts of a thixotropic reinforcing agent; 3-5 parts of a coupling agent; 20-30 parts of filler. The invention also provides a preparation method of the structural adhesive. The preparation method comprises the following steps: 1) proportionally taking the epoxy resin, diluent, flexibilizer, filler and thixotropic reinforcing agent, and uniformly stirring; and 2) carrying out vacuum dehydration in an environment with a temperature of more than 100 DEG C, cooling to room temperature, taking the latent curing agent, the accelerator and the coupling agent in proportion, uniformly stirring in an environment with a temperature of less than 40 DEG C, and carrying out vacuum defoamation to obtain the structural adhesive. The structural adhesive disclosed by the invention is high in toughness, high in bonding strength, long in storage life and capable of resisting high temperature (as high as 280 DEG C) for a short time, and can effectively meet the use requirements of the market on the single-component epoxy structural adhesive.

Owner:重庆德天汽车新材料研究院有限公司

Quick-setting two-component polyurethane structural adhesive as well as preparation method and application thereof

ActiveCN111704885AReduce the temperatureReduced activityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer sciencePtru catalyst

The invention relates to a quick-setting two-component polyurethane structural adhesive as well as a preparation method and application thereof. The component A in the double-component polyurethane structural adhesive is prepared from castor oil, autocatalytic polyol, tackifying resin, a coupling agent, a catalyst, filler, a molecular sieve and silicon dioxide, and the component B is prepared fromtoughened polyol, a plasticizer, isocyanate, glass beads, filler, a molecular sieve and silicon dioxide. The bi-component polyurethane structure not only has enough operation time, but also can be quickly cured, is high in bonding strength and universality, does not flow during vertical surface sizing, can meet the sizing process of various complex structures, and is very suitable for quick bonding and positioning of automotive upholstery.

Owner:HUBEI HUITIAN NEW MATERIALS STOCK CO LTD +2

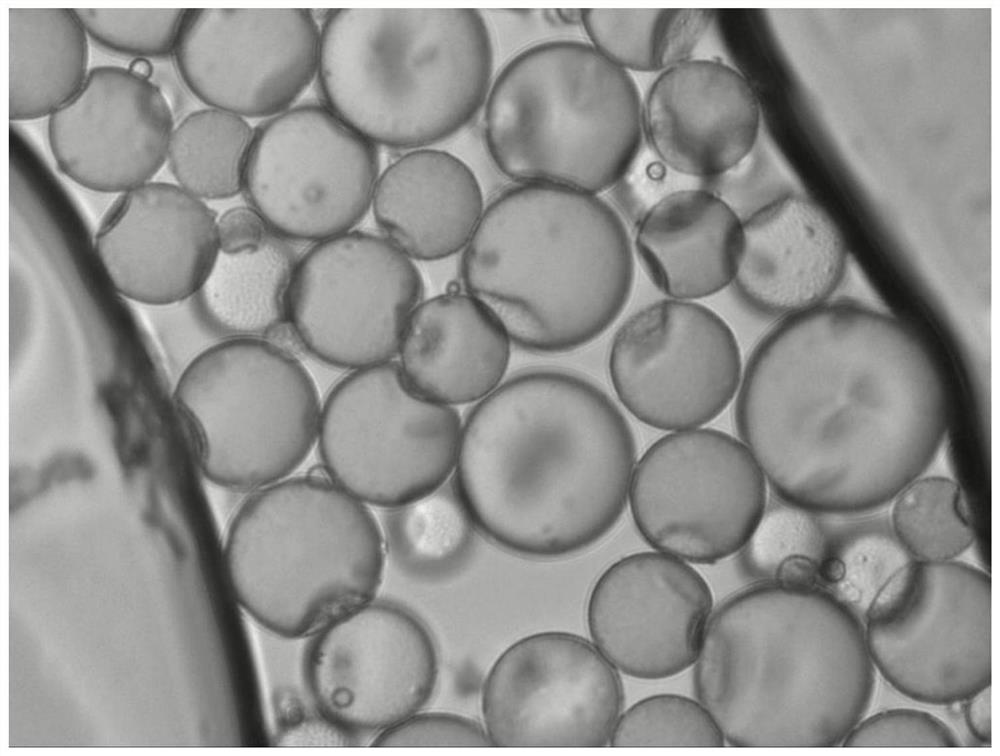

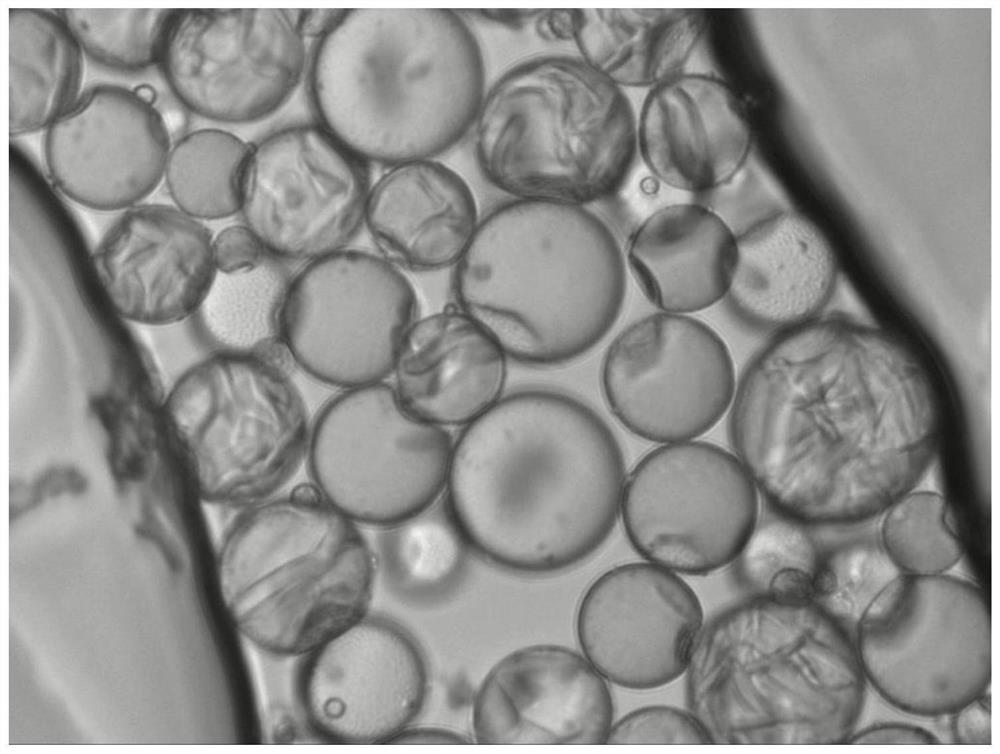

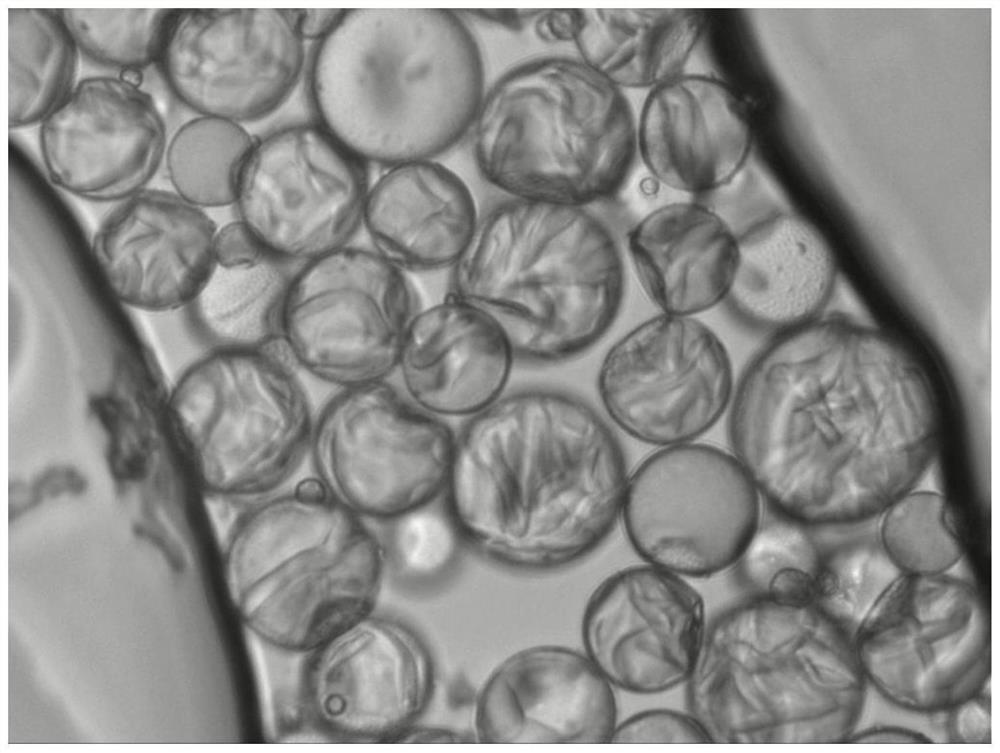

Transparent mortar mixture simulating rheological property of cement mortar and preparation method of transparent mortar mixture

InactiveCN103728166ALow costEasy to makeFlow propertiesPreparing sample for investigationDissolutionCement mortar

The invention provides a transparent mortar mixture simulating a rheological property of cement mortar and a preparation method of the transparent mortar mixture. The mixture comprises the following components by weight percentage: 92.41-94.50% of deionized water, 0.30-0.35% of carbomer 940 powder, 0.20-0.24% of neutral regulator triethanolamine and 5-7% of transparent glass bead. The transparent mortar mixture simulates the rheological property of the cement mortar at a water cement ratio of 0.45-0.5 and a sand cement ratio of 1:1. The preparation method of the mixture comprises the steps of adding the carbomer powder into the deionized water, after complete dissolution, dropwise adding triethanolamine, after uniformly stirring, standing for 5-10min, obtaining transparent carbomer gel, and then uniformly stirring after adding the transparent glass bead. The transparent mortar mixture serves as a simulating medium of the cement mortar, is low in cost, simple to prepare, good in transparency, small in thixotropy and small in rheological parameter ongoing change, and has an obvious pseudoplastic characteristic.

Owner:HOHAI UNIV

Acrylate adhesive for bonding bullet train roof reinforcing ribs

ActiveCN106590447AIncreased shear strengthHigh peel strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesDiamineChemistry

The invention discloses an acrylate adhesive for bonding bullet train roof reinforcing ribs, and relates to the field of acrylate structure adhesives. The acrylate adhesive comprises, by volume, 1 part of oxidizing agents and 7-15 parts of reducing agents. The oxidizing agent comprises, by weight, 30-50 parts of dibutyl phthalate, 1-5 parts of bisphenol-A-type epoxy resin, 15-20 parts of high-glue powder, 10-20 parts of benzoyl peroxide and 1-5 parts of castor oil. The reducing agents comprise, by weight, 20-54 parts of methyl methacrylate, 10-20 parts of impact modifiers, 10-15 parts of chlorosulfonated polyethylene, 1-3 parts of triethylene diamine, 0.5-1 part of paraffin, 1-5 parts of acrylic acid, 0.3-1 part of stabilizing agents and 1.2-1.6 parts of organic modified bentonite. The acrylate adhesive can be closely connected with bonding materials in high-frequency vibrating states and cannot peel when being used for a long time.

Owner:HUBEI HUITIAN NEW MATERIALS STOCK CO LTD +3

Method for preparing gravure composite ink

InactiveCN102585600AGood storage stabilityFull expression of metastasesInksComposite strengthLoss rate

The invention discloses a method for preparing gravure composite ink, and belongs to the field of ink preparation. The method comprises the following steps of: 1) preparing resin liquid, namely dispersing until a solvent is uniformly mixed, adding solid resin, and fully dissolving the solid resin to prepare the resin liquid; (2) feeding, namely dispersing until the resin liquid is uniformly mixed, adding a solvent, and uniformly mixing to prepare a liquid binder; and adding a pigment, and uniformly mixing the pigment and the liquid binder to obtain an ink material; (3) sanding; and (4) adjusting, namely dispersing the ink material, adding an aid, and dispersing until the aid and the ink material are uniformly mixed. The adhesion index of the ink is improved from more than or equal to 85 percent to more than or equal to 95 percent, so that the composite strength of the ink is higher; the viscosity of the ink is more stable, and the thixotropy of the ink is greatly reduced; the loss rate of the ink in the production process is reduced from about 5 percent to about 2.5 percent; and the hue of the ink is brighter, and chroma is improved by 5 to 10 percent.

Owner:洋紫荆油墨(河北)有限公司

Casing pipe well cementing cement slurry system

The invention relates to the field of oilfield chemistry and oil-gas well cementing materials, relates to a casing pipe well cementing cement slurry system, and particularly relates to a well cementing cement slurry system with low density, low viscosity, strong thixotropy and long thickening time, which is suitable for a shallow layer. The system comprises a gelling system, a dewatering agent, zinc oxide, a dispersing agent, hydrogel and water. The cement slurry system disclosed by the invention not only has low viscosity and strong thixotropic property, but also has low density and long thickening time, and can meet the requirement of an annulus rotary grouting method on secondary well cementation of a free casing section.

Owner:CHINA PETROLEUM & CHEM CORP +1

Carbon black gel ink

InactiveCN103232759AImprove dispersion stabilityReduced stabilityInksActive agentSurface-active agents

The invention provides a carbon black gel ink comprising the components of, by weight, 0.2-0.5% of xanthan gum, 1-2% of alkali-swellable acrylic acid, 20-50% of carbon black color paste, 10-15% of a surfactant, 5-20% of a moisturizing lubricant, 0.05-0.1% of a preservative and fungicide agent, 0.2-0.8% of a PH value regulator triethylamine, and 30-40% of deionized water. The invention is provided according to particle size and distribution of the pigment carbon black in the color paste, and according to the aspect of dispersion stability. An appropriate dispersing agent is selected, and water-based color paste preparation process is optimized, such that the carbon black pigment water-based color paste suitable for gel ink is developed, and guidance is provided for breaking the technical bottleneck in gel ink pen production of our nation.

Owner:李莉

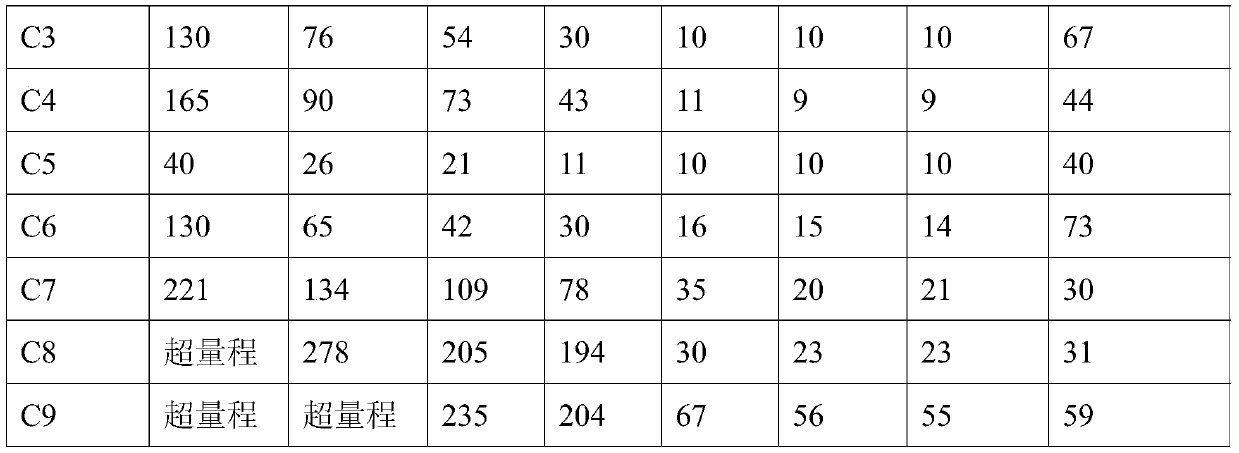

Art renewal lacquer and preparation method thereof

InactiveCN109337427AEasy to makeLong penetration timeAntifouling/underwater paintsPaints with biocidesLacquerWear resistance

The invention discloses art renewal lacquer and a preparation method thereof. The art renewal lacquer has superior adhesion, lubricating property, film-forming property, water resistance, mildew resistance, wear resistance, stain resistance, resistance to acid and base and wash resistance, so that a construction process can be more smooth, and the problem of construction difficulty is solved. A wall space applied with the art renewal lacquer has the effects that obvious male and female faces are formed, the surface has silky touch, the stacking surface has clear lines and the overall color issoft. The problems in the conventional art renewal lacquer that poor construction often occurs during construction, the covering power is low, the effect of male and female faces is avoided, the stacking surface has no clear lines, the wall space smoothness is low, the wall space is free of silky touch and poor in wash resistance, wear resistance, stain resistance and resistance to acid and base and the like are solved.

Owner:罗浮塔涂料科技有限公司

Carbomer gel medium for simulating rheological property of cement paste and preparation method thereof

InactiveCN103743605ALittle change over timeLow costFlow propertiesPreparing sample for investigationCement pasteMaterials science

The invention provides a carbomer gel medium for simulating rheological property of cement paste and a preparation method thereof. The carbomer gel medium for simulating rheological property of cement paste comprises the following components by weight percent: 99.70-99.75 percent of deionized water, 0.15-0.18 percent of carbomer resin powder and 0.10-0.12 percent of triethanolamine (serving as a neutral regulator), wherein the water cement ratio in the carbomer gel medium for simulating rheological property of cement paste is 0.45-0.5. The preparation method comprises the following steps: adding the carbomer resin powder into the deionized water, dripping the triethanolamine after the powder is completely dissolved, uniformly stirring, standing for 5-10 minutes so as to obtain transparent carbomer gel. The 940 series of carbomer gel serves as a simulation medium of the cement paste, and the carbomer gel medium is low in cost, simple to prepare, high in transparency, low in thixotropy, small in time-dependent behavior of rheological parameters and obvious in pseudoplastic characteristics.

Owner:HOHAI UNIV

Silver neutral ink

The invention provides silver neutral ink with high stability to fill up a gap of the sliver neutral ink. The silver neutral ink comprises the following components in percentage by weight: 0.2-0.3% of xanthan gum, 1-2% of alkali-swellable acrylic acid, 30-50% of water-soluble aluminum silver paste, 10-15% of surfactant, 5-20% of moisturizing and lubricating agent, 0.05-0.1% of antiseptic antimildew agent, 0.2-0.8% of pH value regulating agent and 30-40% of deionized water. The prepared silver neutral ink disclosed by the invention has good rheology and can greatly improve the writing performance.

Owner:李莉

Epoxy orange peel antiskid floor paint and preparation method thereof

InactiveCN111019475AStable thixotropyHigh activityAnti-corrosive paintsEpoxy resin coatingsComposite materialAntifoam agent

The invention discloses an epoxy orange peel antiskid floor paint and a preparation method thereof, and belongs to the technical field of paints. The floor paint comprises, by weight, 30-50 parts of epoxy resin, 20-40 parts of dolomite powder, 5-10 parts of talcum powder, 1-3 parts of white carbon black, 0.3-1 part of a dispersant, 0.5-2 parts of an antifoaming agent, 0.5-1 part of a rheological modifier, and 10-20 parts of a curing agent. The epoxy orange peel antiskid floor paint not only retains the characteristics of toughness, wear resistance, corrosion resistance and the like of common epoxy floor paints, but also has antiskid and beautiful decorative effects, and has very good constructability.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Thermally Conductive Silicone Composition

InactiveUS20150097138A1Reduce thixotropyImprove thermal conductivityHeat-exchange elementsPolymer scienceViscosity

A thermally conductive silicone composition comprising: (A) an organopolysiloxane that is liquid at 25° C. and preferably has a viscosity of from 100 to 1,000,000 mPa·s; (B) an aluminum oxide powder having an average particle size of not more than 10 μm and preferably from 1 to 8 μm; and (C) an aluminum hydroxide powder having an average particle size of greater than 10 μm and preferably not greater than 50 μm, has low thixotropy, low specific gravity, and high thermal conductivity.

Owner:DOW CORNING TORAY CO LTD

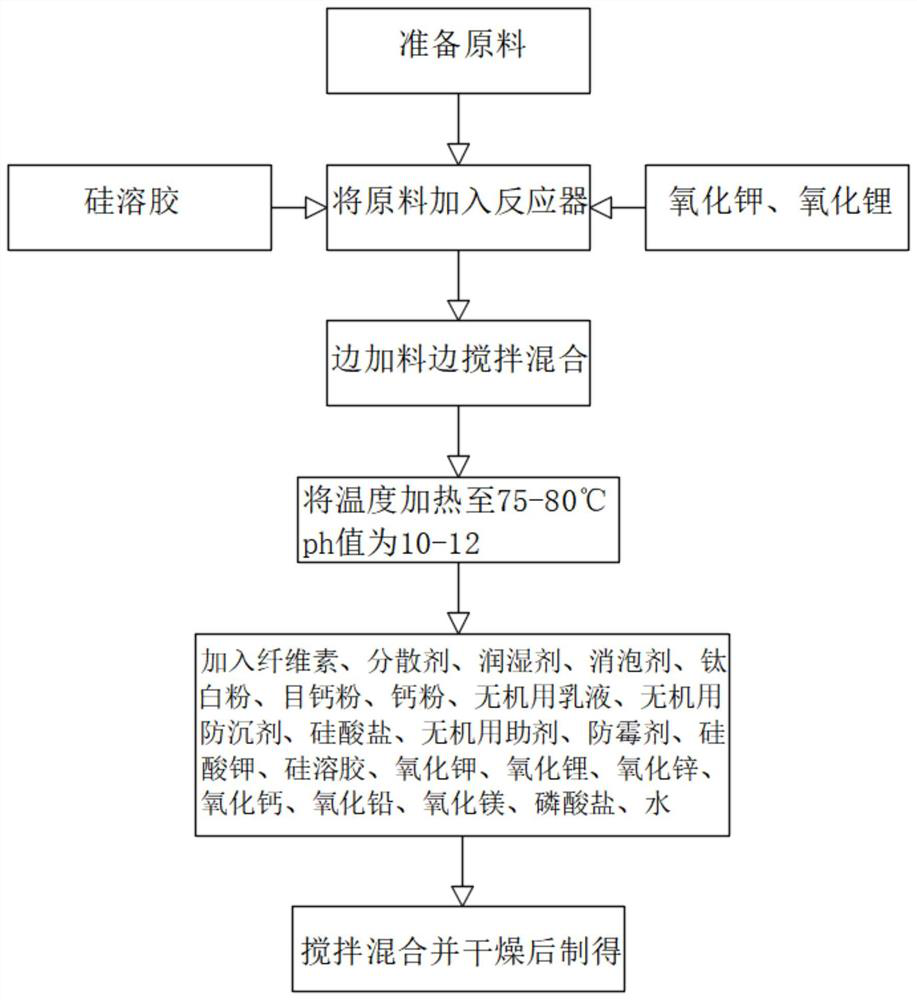

Mildew-proof antibacterial inorganic coating

PendingCN114644844ALong-lasting anti-mildew effectReaction formation blockAntifouling/underwater paintsAlkali metal silicate coatingsPhosphateEnvironmental geology

The invention discloses a mildew-proof antibacterial inorganic coating which comprises water, cellulose, a dispersing agent, a wetting agent, a defoaming agent, titanium dioxide, mesh calcium powder, calcium powder, an inorganic emulsion, an inorganic anti-settling agent, silicate, an inorganic auxiliary agent, a mildew-proof agent, potassium silicate, silica sol, potassium oxide, lithium oxide, zinc oxide, calcium oxide, lead oxide, magnesium oxide, phosphate and a thickening agent. The mildew-proof effect can be effectively improved mainly by preparing the mildew-proof agent, meanwhile, in a humid environment, through a byproduct potassium carbonate generated by reaction of added potassium silicate, carbonate of a wall body and carbon dioxide in air, the coating can present strong alkalinity, can also play a lasting mildew-proof role in the humid environment, and is convenient and practical; the inorganic auxiliary agent is formed by mixing the quaternary ammonium salt stabilizer, the poly-tertiary amine stabilizer and the organic and inorganic silicide, and the quaternary ammonium salt stabilizer, the poly-tertiary amine stabilizer and the organic and inorganic silicide are mixed, so that a relatively good synergistic effect is achieved, and the stability is improved.

Owner:福建釉时代环保涂料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com