UV-curable strippable ink as well as production method and construction method of UV-curable strippable ink

A technology of construction method and production method, applied in the field of UV curing peelable ink, can solve the problems of poor environmental protection, pollution, easy to migrate the surface of electronic products, etc., and achieve the effects of low cost, simple process and improved curing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

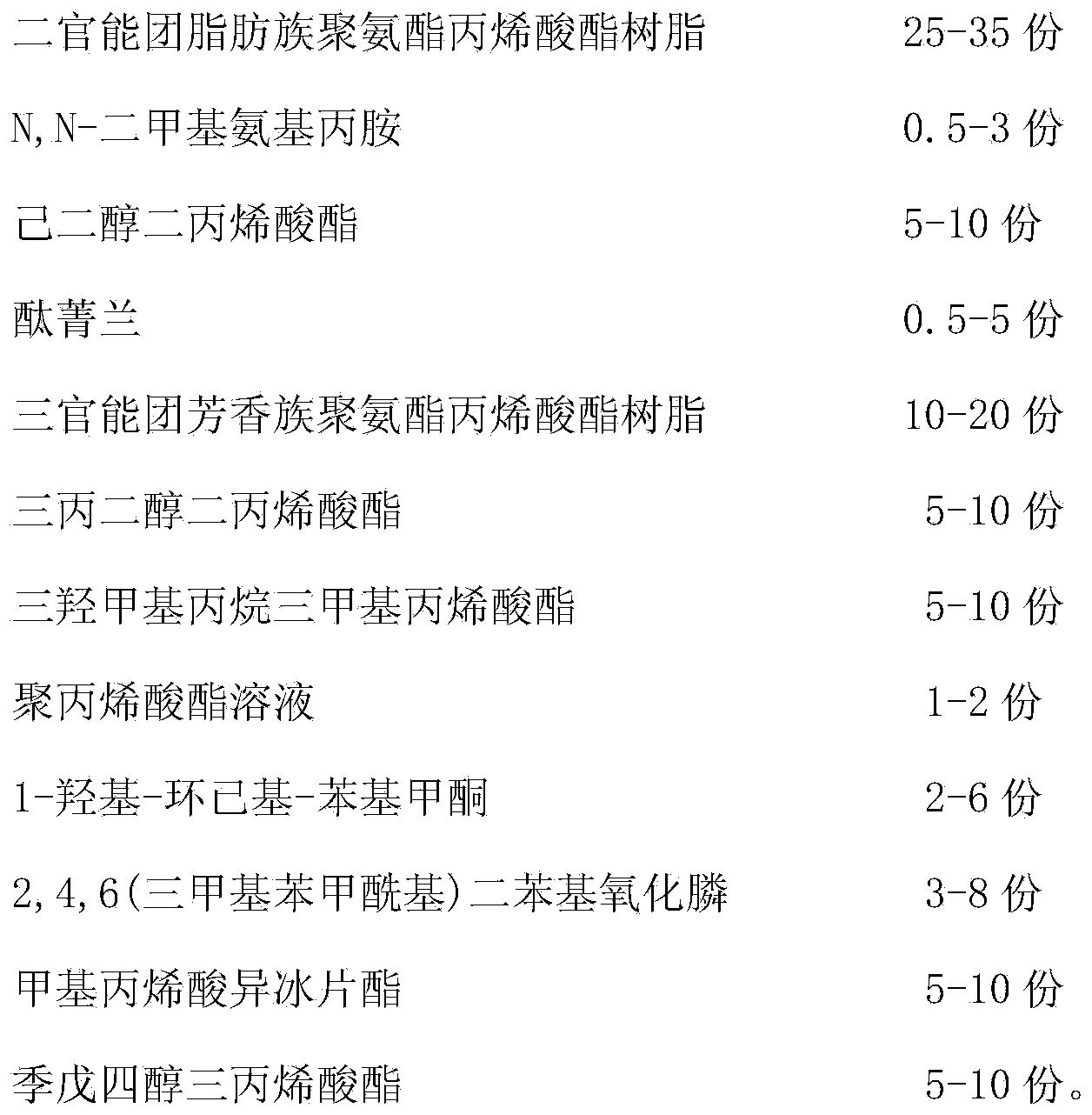

[0030] The UV curing peelable ink of the present embodiment comprises the following components by weight:

[0031] 25 parts of difunctional aliphatic urethane acrylate resin, 0.5 part of N,N-dimethylaminopropylamine, 5 parts of hexanediol diacrylate, 0.5 part of phthalocyanine blue, 10 parts of trifunctional aromatic urethane acrylate resin, three 5 parts of propylene glycol diacrylate, 5 parts of trimethylolpropane trimethacrylate, 1 part of polyacrylate solution, 2 parts of 1-hydroxy-cyclohexyl-phenyl ketone, 2,4,6 (trimethyl 3 parts of diphenylphosphine oxide, 5 parts of isobornyl methacrylate, and 5 parts of pentaerythritol triacrylate.

[0032] The production method of the UV curing peelable ink of the present embodiment comprises the following steps:

[0033] (1) Weighing components: take each component according to parts by weight, and set aside;

[0034] (2) Preparation of color paste: Mix the weighed N,N-dimethylaminopropylamine, hexanediol diacrylate, and difunctio...

Embodiment 2

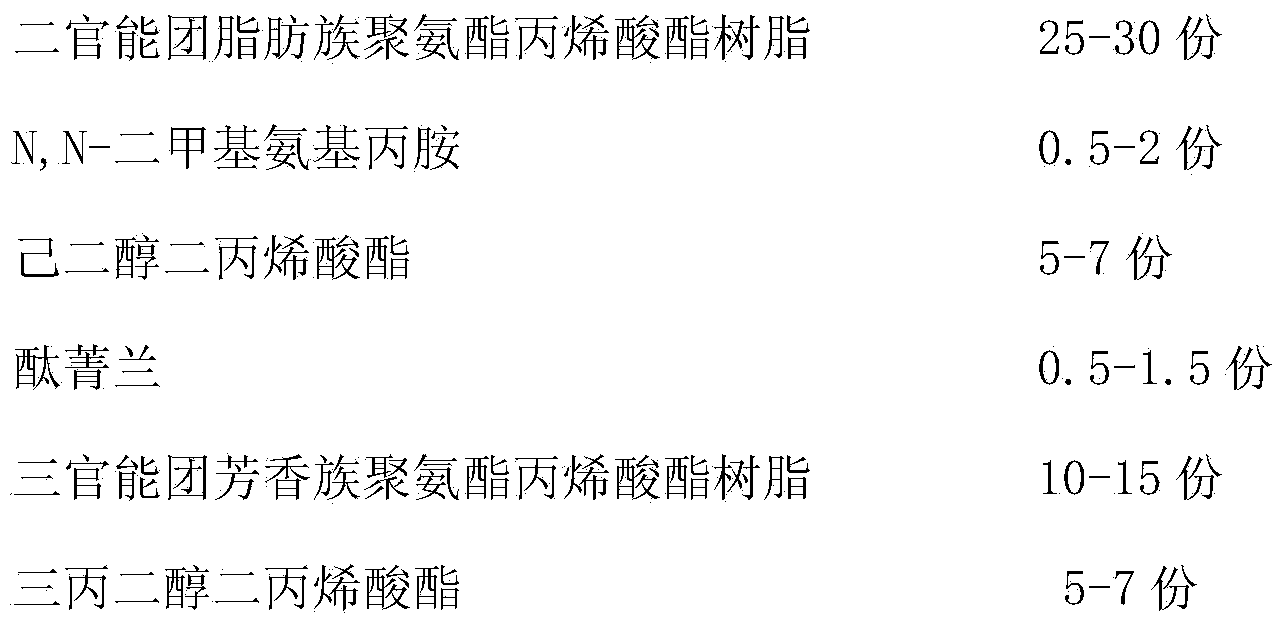

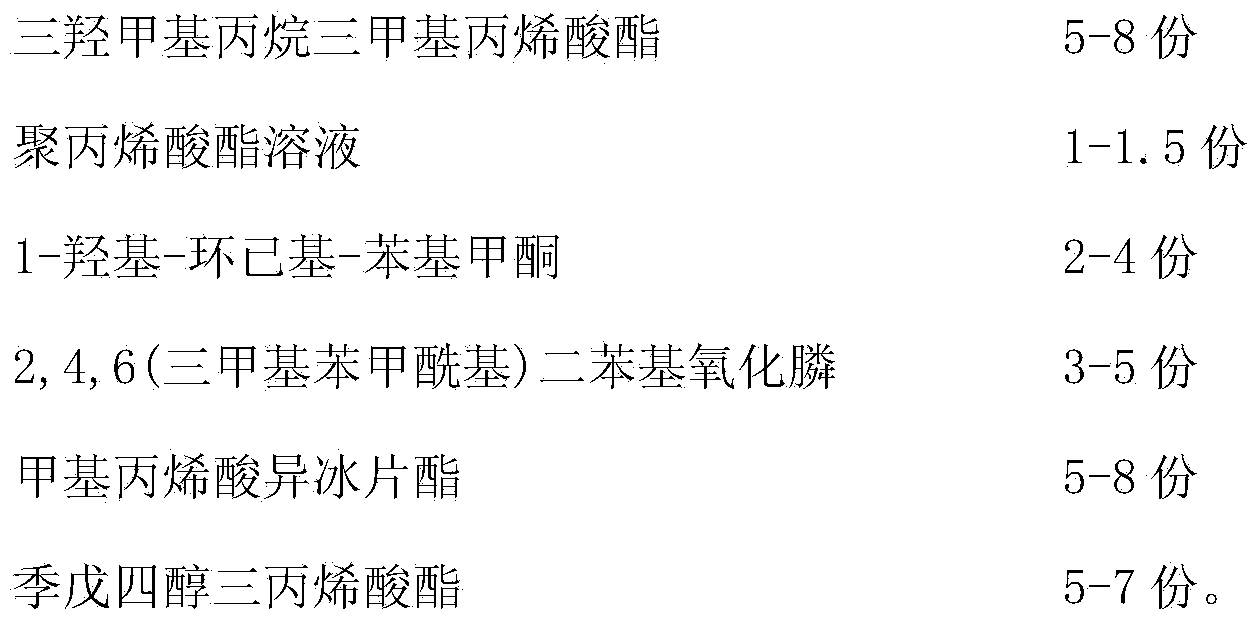

[0045] The UV curing peelable ink of the present embodiment comprises the following components by weight:

[0046] 35 parts of difunctional aliphatic urethane acrylate resin, 3 parts of N,N-dimethylaminopropylamine, 10 parts of hexanediol diacrylate, 5 parts of phthalocyanine blue, 20 parts of trifunctional aromatic urethane acrylate resin, three 10 parts of propylene glycol diacrylate, 10 parts of trimethylolpropane trimethacrylate, 2 parts of polyacrylate solution, 6 parts of 1-hydroxy-cyclohexyl-phenyl ketone, 2,4,6 (trimethyl 8 parts of diphenyl phosphine oxide, 10 parts of isobornyl methacrylate, and 10 parts of pentaerythritol triacrylate.

[0047] The production method and construction method of the UV-curable peelable ink in this embodiment are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0049] The UV curing peelable ink of the present embodiment comprises the following components by weight:

[0050] 30 parts of difunctional aliphatic urethane acrylate resin, 2 parts of N,N-dimethylaminopropylamine, 7 parts of hexanediol diacrylate, 1.5 parts of phthalocyanine blue, 15 parts of trifunctional aromatic urethane acrylate resin, three 7 parts of propylene glycol diacrylate, 8 parts of trimethylolpropane trimethacrylate, 1.5 parts of polyacrylate solution, 4 parts of 1-hydroxy-cyclohexyl-phenyl ketone, 2,4,6 (trimethyl 5 parts of diphenylphosphine oxide, 8 parts of isobornyl methacrylate, and 7 parts of pentaerythritol triacrylate.

[0051] The production method and construction method of the UV-curable peelable ink in this embodiment are the same as those in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com