High-performance medium-temperature cured single-component epoxy structural adhesive and preparation method thereof

An epoxy structural adhesive, a single-component technology, applied in the direction of epoxy resin glue, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problems of insufficient toughness and short storage time, and achieve Excellent toughness, high bonding strength, and the effect of improving the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

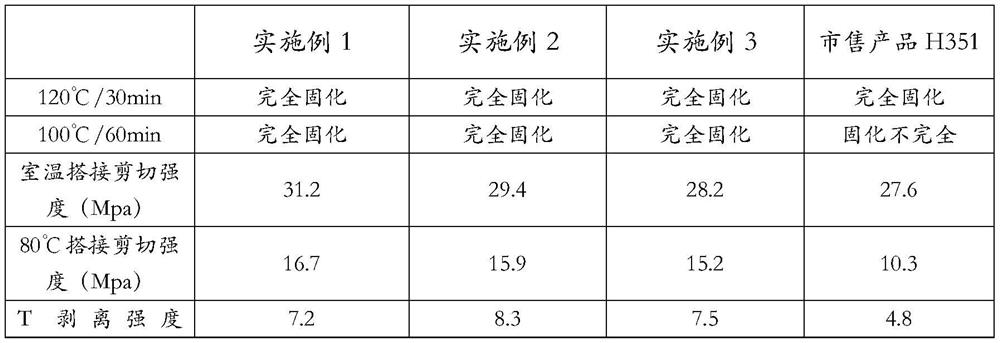

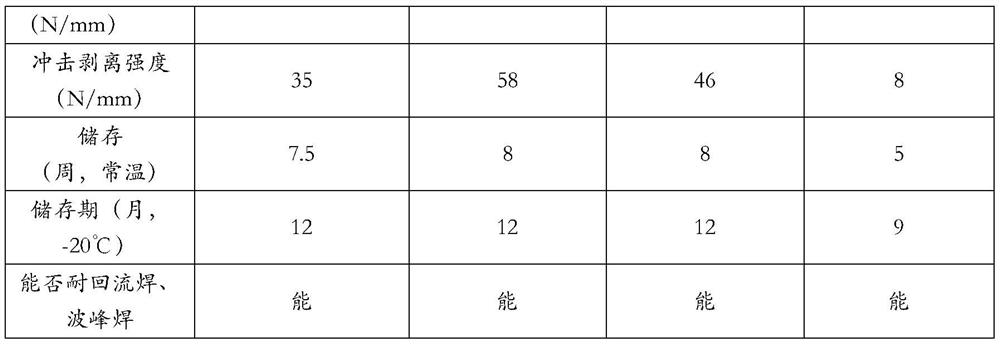

Examples

Embodiment 1

[0035] The components and component weights of structural adhesives are shown in the table below:

[0036] component name Parts by mass / Kg NPEL-128 80 NPER-133L 25 102C-5 20 MX-153 33 XA-297 2 DDA5 12 U52M 4 PN-23 1.5 Nano calcium carbonate 20 H18 7 KH-560 4

Embodiment 2

[0038] The components and component weights of structural adhesives are shown in the table below:

[0039] component name Parts by mass / Kg NPES-901 55 622 25 NPER-133L 25 102C-5 20 MX-153 33 XA-290 2 DDA5 12 U52M 4 PN-23 1.5 Nano calcium carbonate 20 H18 7 KH-560 4

Embodiment 3

[0041] The components and component weights of structural adhesives are shown in the table below:

[0042] component name Parts by mass / Kg E44 80 NPER-133L 25 102C-5 20 MX-153 33 CTBN 1.5 DDA5 12 U52M 4 PN-23 1.5 Nano calcium carbonate 20 H18 7 KH-560 4

[0043] Each structural glue of embodiment 1-3 is prepared according to the following method:

[0044] 1) Take epoxy resin, diluent, toughening agent, filler and thixotropic reinforcing agent in proportion, add it to a planetary mixer, and stir at a high degree until it is completely dispersed and uniform;

[0045] 2) Vacuum dehydration at 110°C for 10 minutes, then cool to room temperature, take latent curing agent, accelerator, and coupling agent in proportion, stir at 30°C until completely dispersed, and vacuumize for 30 minutes to obtain Structural glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com