Patents

Literature

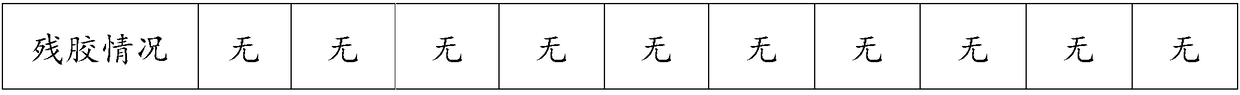

86results about How to "No degumming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

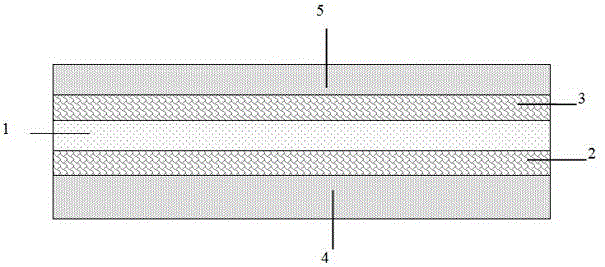

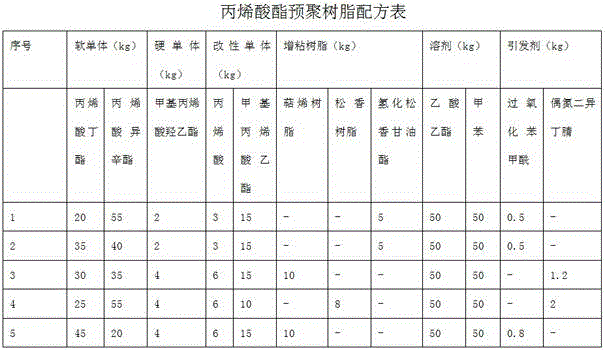

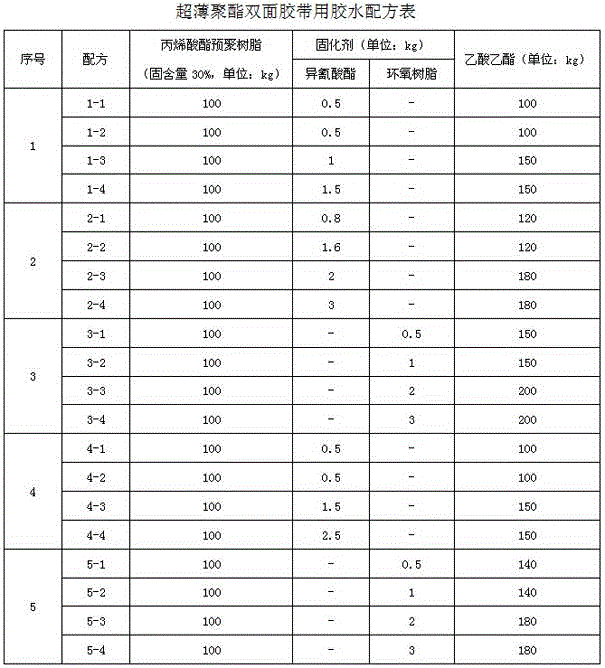

Ultra-thin polyester double-sided adhesive tape, glue thereof, and preparation method thereof

ActiveCN104152077AHigh bonding strengthImprove cohesionFilm/foil adhesivesEster polymer adhesivesPolyesterAdhesive

The invention discloses an ultra-thin polyester double-sided adhesive tape comprising a polyester thin film layer and two glue layers formed by glue coated on front and back sides of the polyester thin film. The thickness of the polyester thin film is 0.001-0.0012mm. The thickness of the glue layer is 0.002mm. Therefore, the thickness of the double-sided adhesive tape is only 0.005mm, such that electronic product development trends of thin and light can be satisfied. The total thickness of adhesive is 0.004mm, such that the tape has ultra-low thermal resistance, and heat generated by electrical components can be conducted in time. Therefore, electrical component damage caused by long-term working under high temperature is avoided. Also, the invention discloses a formula for the glue used in the ultra-thin polyester double-sided adhesive tape. The glue comprises the raw materials of, by weight, 100 parts of acrylate prepolymer resin, 0.5-3 parts of a curing agent, and 100-200 parts of ethyl acetate. With the glue, a single side thickness is 0.002mm, and high adhesive performance can be provided.

Owner:四川羽玺新材料股份有限公司

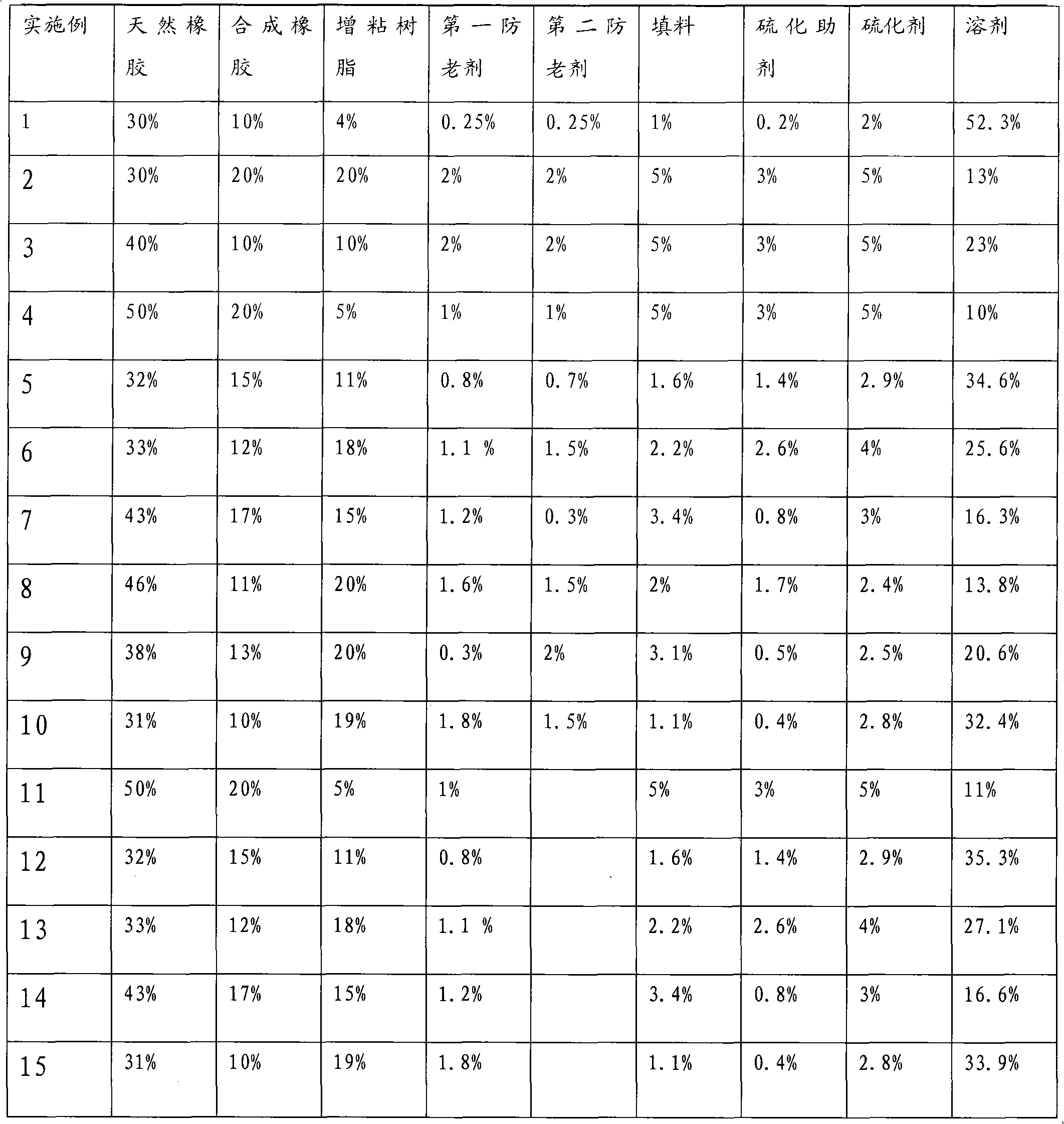

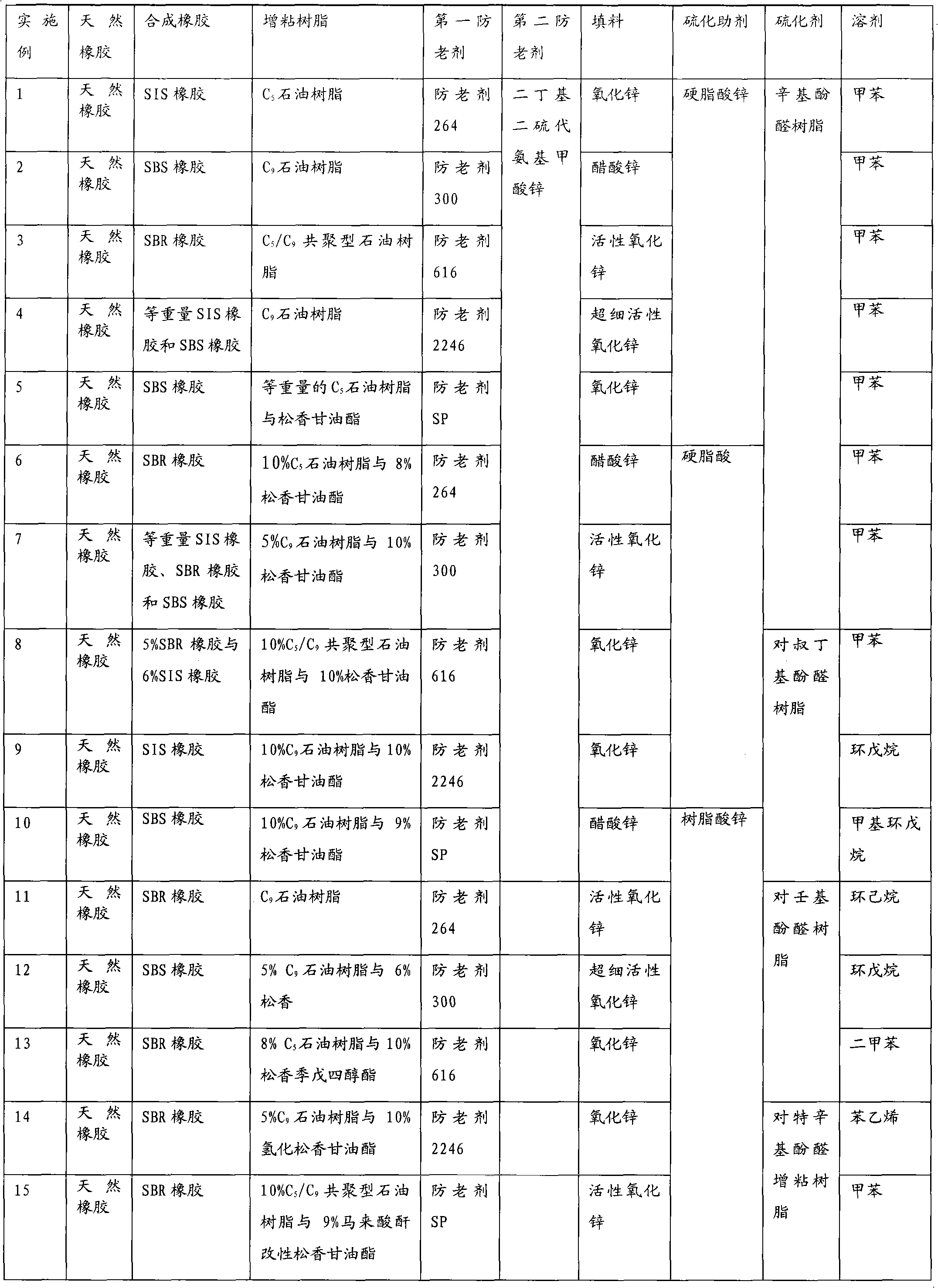

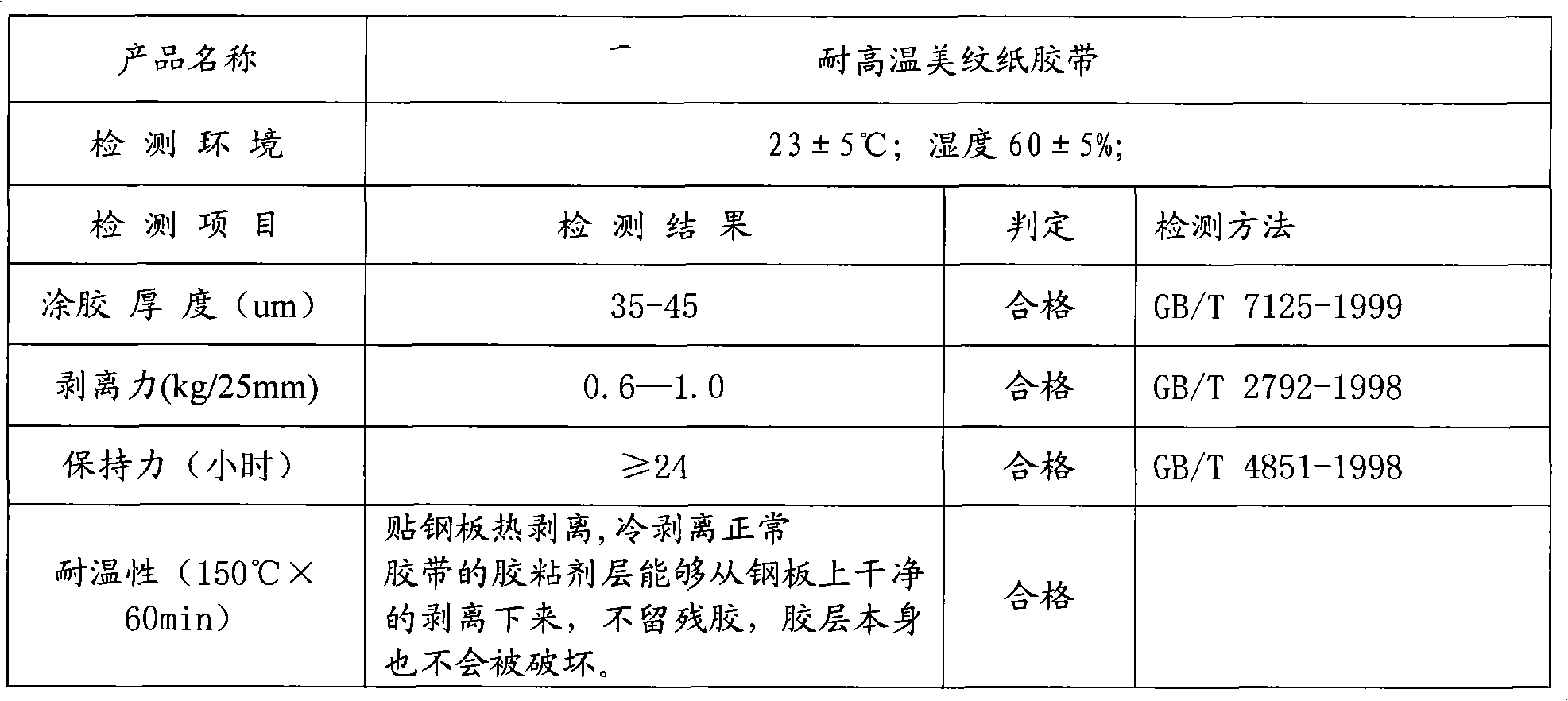

Adhesive for high-temperature-resistant masking tape and high-temperature-resistant masking tape

ActiveCN102120922AThermal peeling is normalCold peeling index is normalMineral oil hydrocarbon copolymer adhesivesNatural rubber adhesivesVulcanizationMasking tape

The invention discloses an adhesive for a high-temperature-resistant masking tape. The adhesive for the high-temperature-resistant masking tape is characterized by comprising the following components in percentage by weight: 30 to 50 percent of natural rubber, 10 to 20 percent of synthetic rubber, 4 to 20 percent of viscous resin, 0.5 to 4 percent of anti-aging agent, 1 to 5 percent of filler, 0.2 to 3 percent of vulcanization auxiliary agent, 2 to 5 percent of vulcanizing agent and the balance of solvent. The adhesive for the high-temperature-resistant masking tape has high temperature resistance and normal hot stripping and cold stripping indexes after being used continuously at the temperature of 150 DEG C for 60 minutes. The adhesive is applied to adhesion at the temperature of 150 DEG C without degumming and cracking and is particularly applied to high-temperature environments such as automobile baking varnish, an electronic circuit board and the like.

Owner:SHANGHAI SMITH ADHESIVE NEW MATERIAL

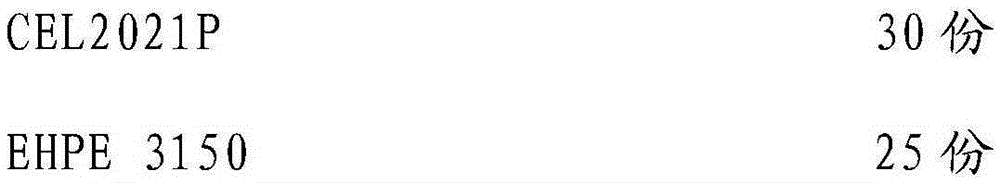

Self-adhesive EVA (Ethylene-Vinyl Acetate) protective film and manufacturing process thereof

ActiveCN103640288AModerate adhesionEasy to pasteSynthetic resin layered productsForeign matterPolymer science

The invention relates to the technical field of protective films and particularly relates to a self-adhesive EVA (Ethylene-Vinyl Acetate) protective film and a manufacturing process thereof. The self-adhesive EVA protective film is formed by a film which is coextruded and adhered by a base film layer, a middle layer and a self-adhesive layer. Especially, due to the self-adhesive layer, adhesive force of the EVA self-adhesive protective film is moderate, so that the self-adhesive EVA protective film is easily stuck and torn; after the film is stuck, the change of the adhesive force along with the time is small, the self-adhesive EVA protective film can be stuck repeatedly without adhesive failure and residual foreign matters, and can be used in special and large-corner surfaces with a radian and without upwarping; since the specific material combination of the base film layer, the middle layer and the self-adhesive layer is adopted, the impact resistance is also greatly improved; the manufacturing process of the self-adhesive EVA protective film is low in cost and is simple.

Owner:东莞市尼的科技股份有限公司

Termination adhesive tape and manufacture method thereof

InactiveCN102250562AMeet application needsLow costFilm/foil adhesivesEster polymer adhesivesIsooctyl acrylateBenzoyl peroxide

The invention relates to the technical field of adhesive tapes, and particularly relates to a termination adhesive tape and a manufacture method thereof. The termination adhesive tape comprises a base tape and a glue layer located on the base tape, wherein the glue layer is an acrylic glue layer, which is composed of the following raw materials in parts by weight: 1-5 parts of butyl acrylate, 5-12 parts of vinyl acetate, 40-60 parts of ethyl acetate, 20-35 parts of iso-octyl acrylate, 0.5-2 parts of hydroxyethyl methacrylate, 1-3 parts of acrylic acid, 2-4 parts of toluene and 0.1-0.4 part of benzoyl peroxide. The manufacture method sequentially comprises the following steps: A. preparing the acrylic glue: titrating toluene-dissolved benzoyl peroxide used as an initiator to a mixed solution of butyl acrylate, vinyl acetate, ethyl acetate, iso-octyl acrylate, hydroxyethyl methacrylate and acrylic acid at the temperature of 80 DEG C, and ensuring the titration time of 2 hours and self-reaction time of 2.5 hours; and B. applying the acrylic glue on the base tape, sequentially drying, cooling and coiling. The termination adhesive tape provided by the invention has the advantages of low cost, beautiful appearance, simple manufacture process and good electrolyte resistance.

Owner:东莞市苏粤电子包装材料有限公司

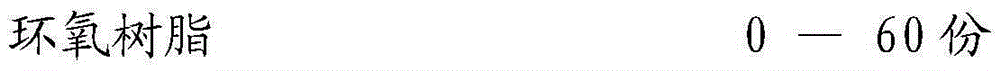

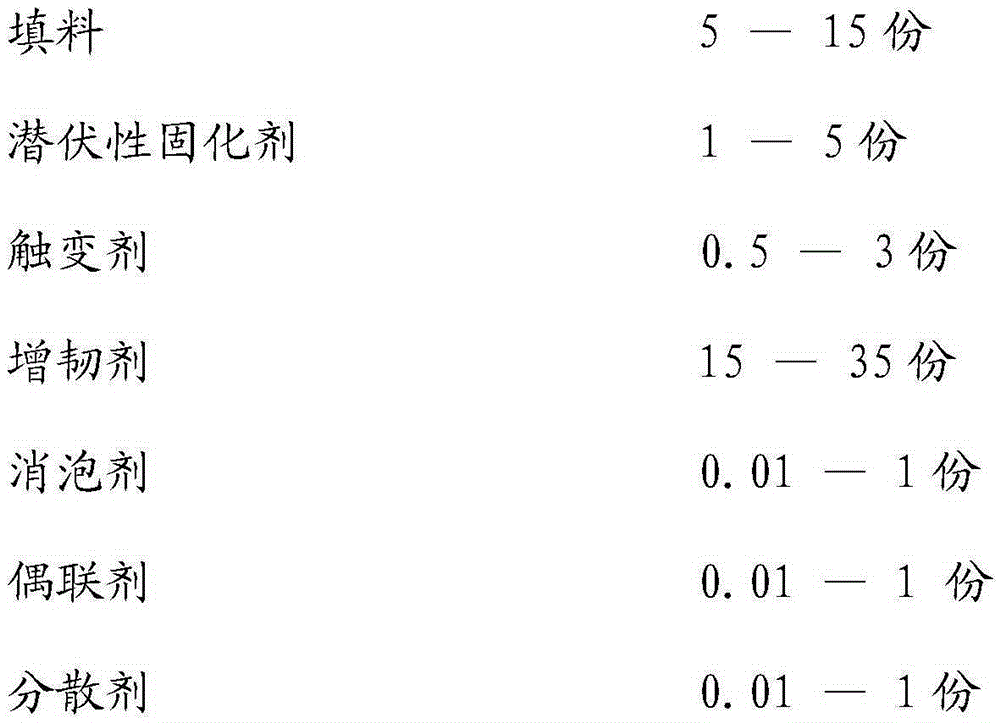

Halogen-free thermosetting epoxy adhesive and application thereof

ActiveCN105385396AThere will be no excessive halogenHalogen-free requirements meetNon-macromolecular adhesive additivesMacromolecular adhesive additivesHalogenHeat resistance

The invention provides a halogen-free thermosetting epoxy adhesive. The halogen-free thermosetting epoxy adhesive comprises, by weight, 0-60 parts of epoxy resin, 5-15 parts of a filler, 1-5 parts of a latent curing agent, 0.5-3 parts of a thixotropic agent, 15-35 parts of a flexibilizer, 0.01-1 part of an antifoaming agent, 0.01-1 part of a coupling agent and 0.01-1 part of a dispersant. The halogen-free thermosetting epoxy adhesive can be applied in E-Paper edge sealing. The epoxy adhesive provided by the invention has the advantages of no halogen, realization of low-temperature rapid solidification, excellent bonding strength and flexibility, high heat resistance, low heat expansion coefficient and high water resistance.

Owner:深圳百丽春新材料科技有限公司

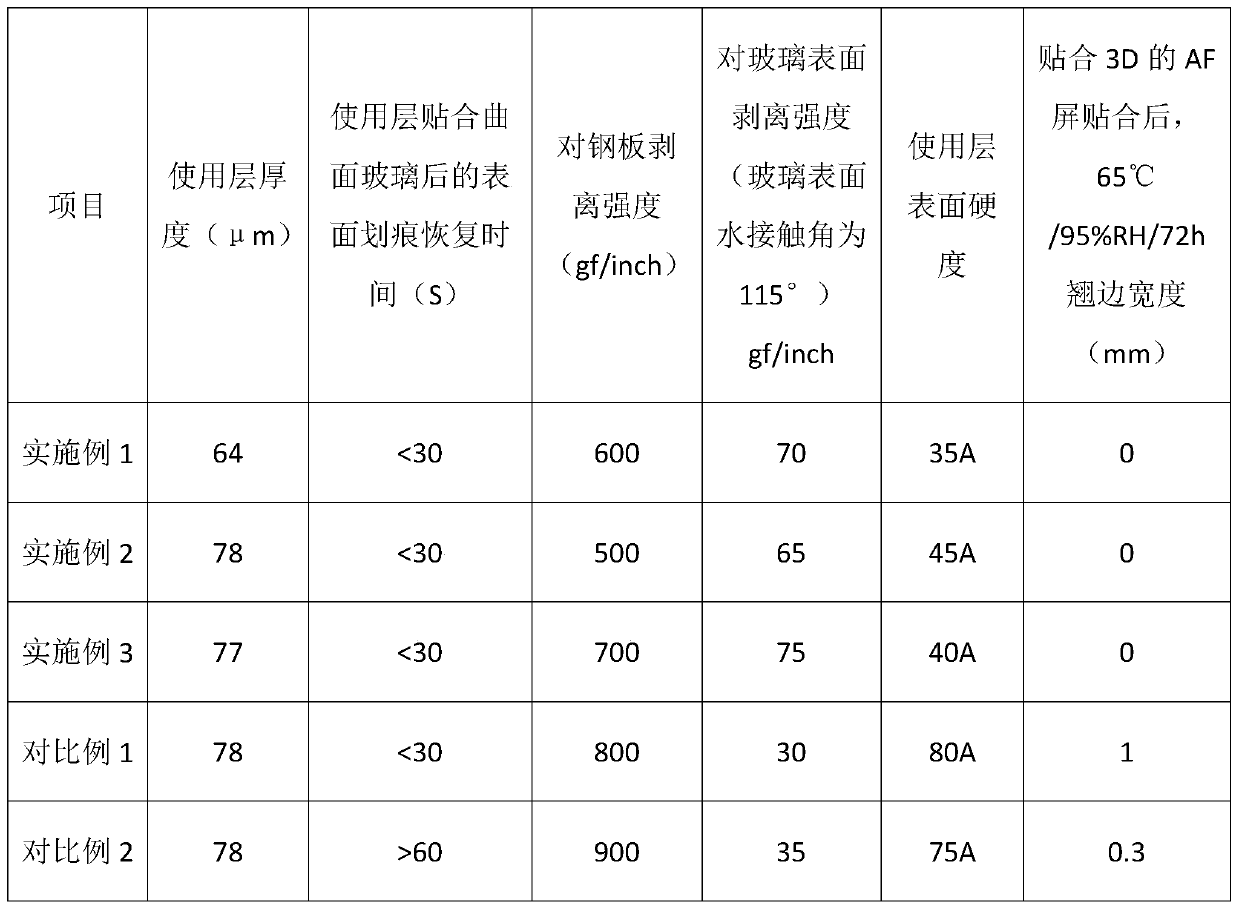

Flexible silica gel screen protection film and preparation method thereof

InactiveCN111440551AEasy to adjust softnessEasy to adjust the thicknessEster polymer adhesivesPolyurea/polyurethane coatingsColloidal silicaPolymer science

The invention discloses a flexible silica gel screen protection film, and belongs to the technical field of protection films. The flexible silica gel screen protection film mainly structurally comprises a PETrelease film, a hardened coating coated on the release surface of the PET release film, an organic silica gel layer coated on the hardened coating, an organic silicon pressure-sensitive adhesive layer coated on the organic silica gel layer, and a fluorine release film adhered on the organic silicon pressure-sensitive adhesive layer, wherein the hardened coating, the organic silica gel layer and the organic silicon pressure-sensitive adhesive layer are compounded into a use layer; the surface hardness of the use layer is HB-2H, the light transmittance is greater than or equal to 91%, the haze is less than or equal to 1%, and the softness is 25A-60A; and the thickness ratio of the hardened coating to the organic silica gel layer to the organic silicon pressure-sensitive adhesive layer in the use layer is (2-4): (40-50): (20-30). The flexible silica gel screen protection film has better flexibility and has more excellent fitting performance for curved edge amplitudes of an AF screen and a 2.5 D / 3D screen and is not degummed during die cutting and can be directly fit with a curved screen for use without hot-pressing preforming, and can play a better role in protecting existingcurved screen electronic equipment.

Owner:太仓斯迪克新材料科技有限公司

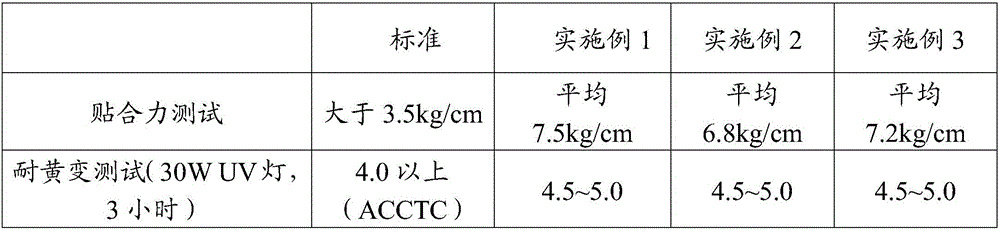

High temperature-resistant and UV (Ultraviolet)-resistant protective film and preparation method thereof

InactiveCN108707432AReduced shrinkage performancePrevent high temperature deformationNon-macromolecular adhesive additivesEster polymer adhesivesTectorial membraneDisplay device

The invention discloses a high temperature-resistant and UV (Ultraviolet)-resistant protective film and a preparation method thereof. The high temperature-resistant and UV-resistant protective film comprises a PE (Polyethylene)-based film layer and an adhesive layer, wherein the adhesive layer is formed by coating the surface of the PE-based film layer with a heat-resistant and UV-resistant pressure-sensitive adhesive and drying; the pressure-sensitive adhesive is prepared from the following raw materials in parts by weight: 25 to 35 parts of acrylate resin, 55 to 70 parts of ethyl acetate, 1to 2 parts of isocyanate curing agent, 0.1 to 0.5 part of UV absorbent and 0.4 to 0.7 part of free radial collecting agent. Compared with the prior art, the preparation method disclosed by the invention is reasonable in raw material proportioning and simple in preparation technology, and a release force of the high temperature-resistant and UV-resistant protective film provided by the invention ranges from 7N / m to 9N / m; after long-time irradiation under high temperature and UV, the release force of the high temperature-resistant and UV-resistant protective film changes within + / -35 percent, and the high temperature-resistant and UV-resistant protective film has no wrinkling, no degumming, no adhesive residue and no chromatic aberration after long-time irradiation under the UV; the high temperature-resistant and UV-resistant protective film can be used for protecting the surfaces of backlight displays in electronic products such as a computer, a television and a mobile phone and can beused for protecting an overlaid shipment transportation process of the backlight displays.

Owner:芜湖夏鑫新型材料科技有限公司

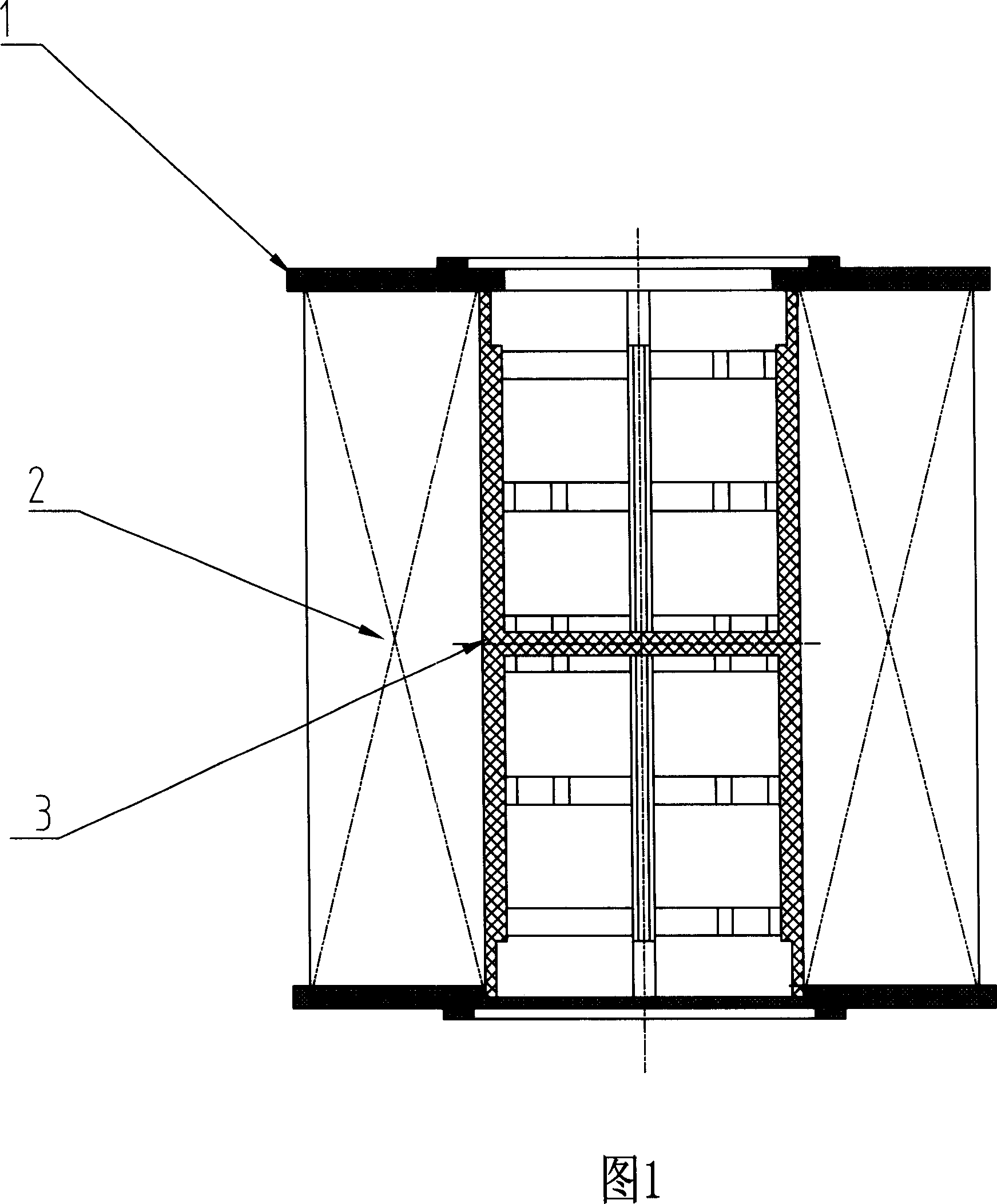

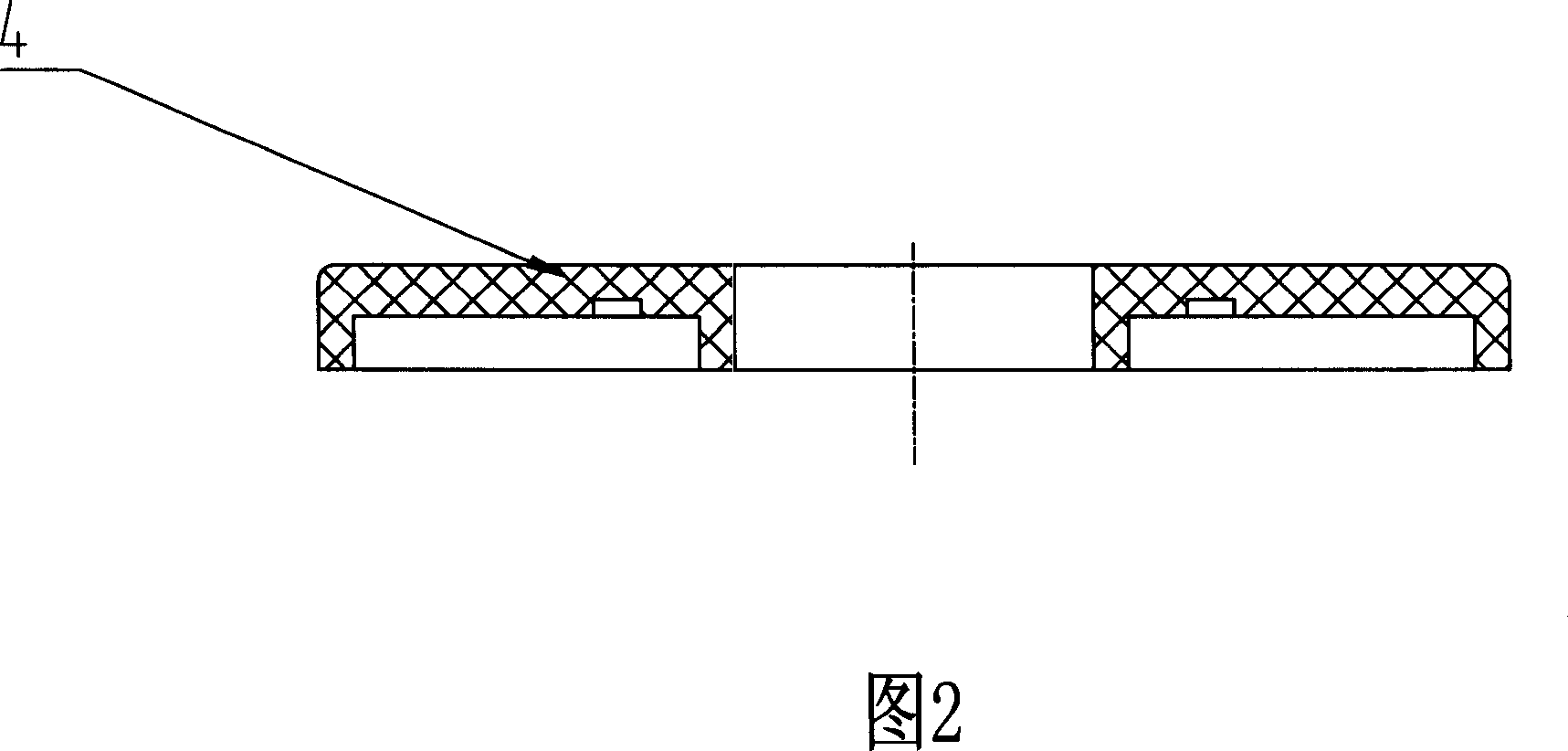

Filter core

InactiveCN101024132ASimplify process structureSimplify product structureMachines/enginesPressure lubricationEpoxyPulp and paper industry

The invention discloses a filter cleaner filter core, including upper and lower cover(1, 1 '), filter paper web(2), the center tube(3), in filter paper web(2) Set in the out of center tube(3), characterized the described upper and lower cover(1,1 ') used epoxy material production, epoxy curing period after solidifying with center tube(3) and filter paper web(2) at the same time connected to the two ends of one. Instead of using epoxy Cover, binder, Seal, it has a simple structure, reduce weight, no longer need punch, bonding, curing and heating, as long as the resin into the mold, let it filter paper web and the center tube integration can be cured with natural, it significantly reduced processes and equipment, based on the same size filter specifications and performance, simplified streamline processing and product mix, reducing the weight of the product, without unglued phenomenon, reduced processing equipment.

Owner:浙江赫嘉汽配有限公司

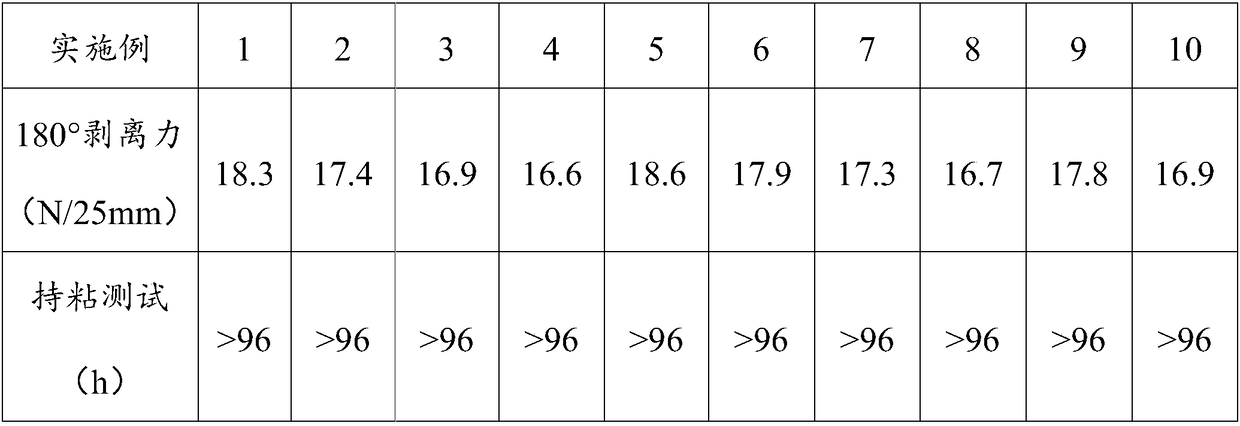

UV-curing adhesive as well as preparation method and application thereof

InactiveCN109233664ASimple manufacturing processGood adhesionFilm/foil adhesivesAmide/imide polymer adhesivesFunctional monomerSolvent

The invention discloses a UV-curing adhesive as well as a preparation method and an application thereof. The UV-curing adhesive is prepared from the following raw materials in parts by weight: 80-95 parts of adhesive monomers, 4-12 parts of functional monomers, 1-10 parts of acrylamide, 0.1-0.5 parts of an initiator, 100-150 parts of a solvent and 2-7 parts of glycidyl methacrylate. The preparation process of the UV-curing adhesive is simple, the UV-curing adhesive has excellent adhesive performance, avoids adhesive failure in the peeling process, and is convenient to store and transport and suitable for handicraft, glass products, electronic and electrical appliances, optical fields and digital optical disc manufacturing.

Owner:HARBIN INST OF TECH WUXI RES INST OF NEW MATERIALS +1

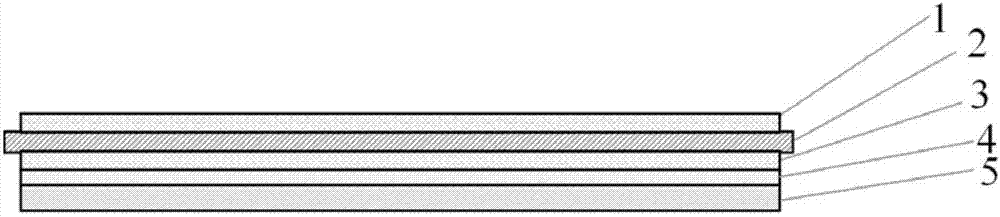

Touch panel, touch screen and preparation method thereof

PendingCN107153476AIncrease productivityReduce rebound rateInput/output processes for data processingHigh temperature storageHardness

The invention discloses a touch panel, a touch screen and a preparation method thereof. The touch panel comprises a touch sensor, an adhesive film, a first touch screen cover, a PVB interlayer and a second touch screen cover in sequence; the softening points of the first touch screen cover and the second touch screen cover are both at Above 250°C. The touch panel of the present invention has high production efficiency; excellent performance in the head-touch test; excellent performance in the environmental reliability test; , Low temperature storage (‑40℃×500h) and other environmental reliability test, there is no degumming phenomenon, no bubble generation, and the bubble rebound rate is low; because the safety problem of the head-touch test is solved, the touch screen can adopt the G+G structure, The touch screen has high hardness, wear resistance, long service life and high touch sensitivity.

Owner:SHANGHAI COPIOUS OPTICAL S & T CO LTD

Two-component solvent-free polyurethane adhesive for rock wool boards and preparation method of adhesive

InactiveCN110305614ALow viscosityEasy to operate manuallyNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAdhesive cementPolyurethane adhesive

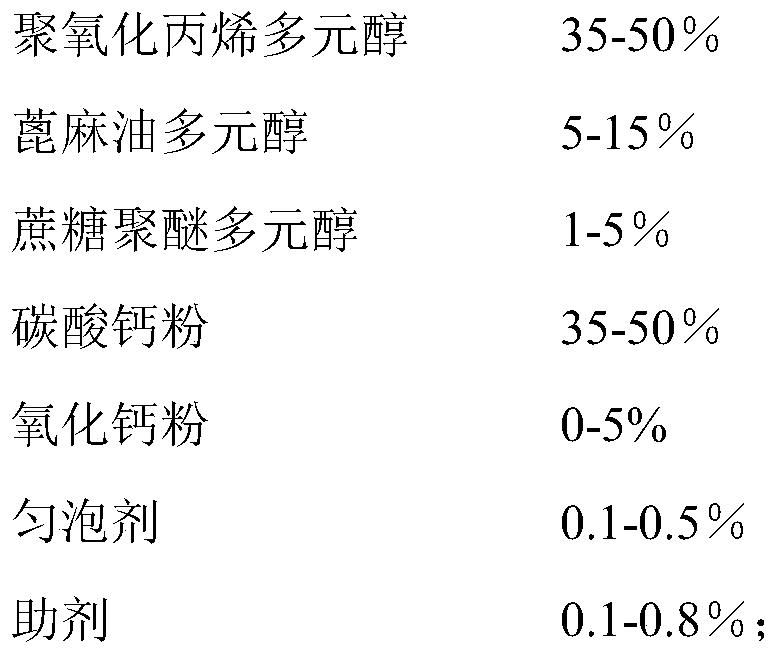

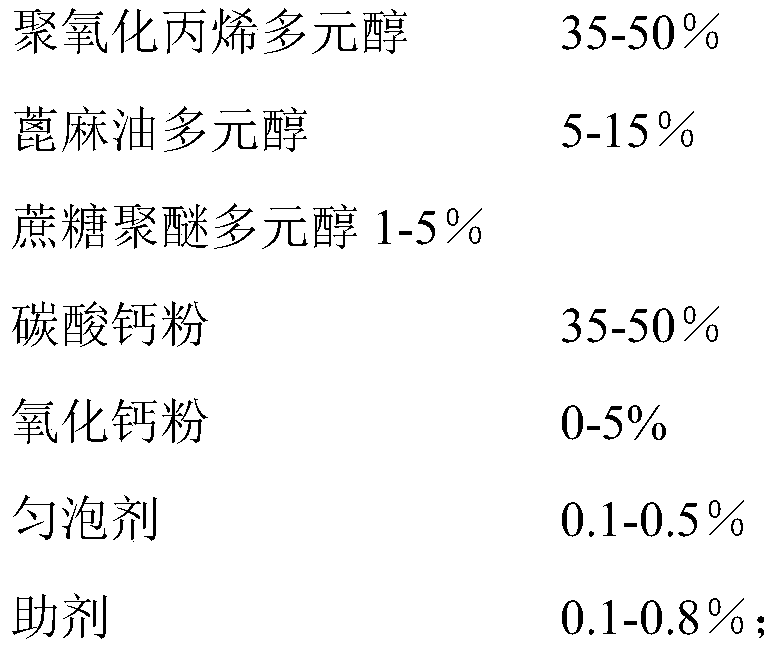

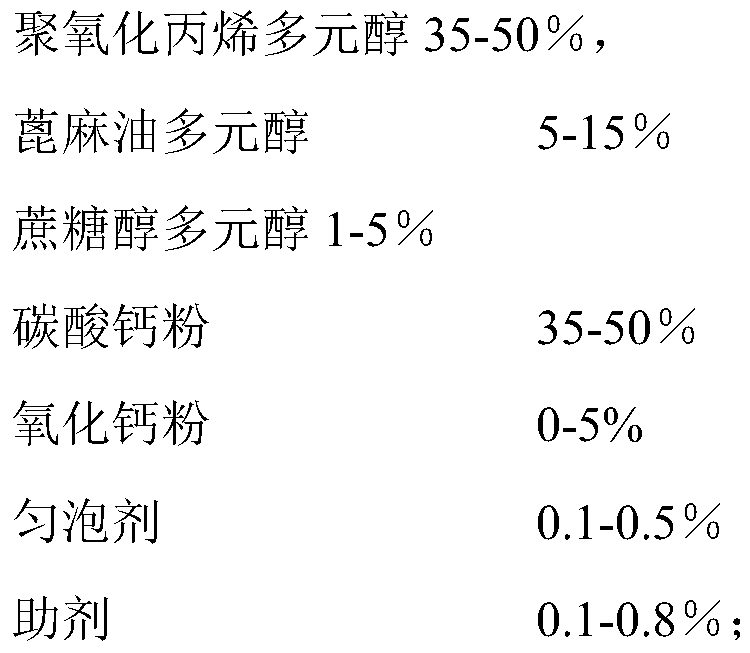

The invention belongs to the technical field of adhesives, in particular to a two-component solvent-free polyurethane adhesive for rock wool boards and a preparation method of the adhesive. The two-component polyurethane adhesive is prepared from a polyol component and an isocyanate component, wherein the weight ratio of the polyol component to the isocyanate component is 4-6: 1, and the polyol component comprises 35-50% of polyoxypropylene polyol, 5-15% of castor oil polyol, 1-5% of sucrose polyether polyol, 35-50% of calcium carbonate powder, 0-5% of calcium oxide powder, 0.1-0.5% of a foamstabilizer and 0.1-0.8% of an auxiliary agent; and the isocyanate component comprises 91-96% of polymethylene polyphenyl isocyanate and 4-9% of polyol-modified diphenylmethane diisocyanate. The adhesive has the advantages of low viscosity, simple and convenient operation, uniform and controllable foaming, can be combined and bonded with multiple building materials, has high strength, strong toughness and good fastness, has high temperature resistance, cold resistance, excellent water resistance, good durability, no cracking, no degumming and the like.

Owner:南京威邦新材料有限公司

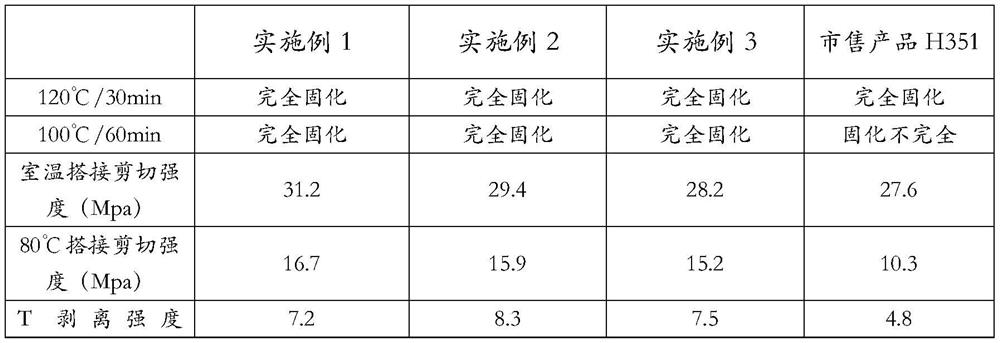

High-performance medium-temperature cured single-component epoxy structural adhesive and preparation method thereof

PendingCN112646523AImprove temperature resistanceHigh bonding strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceAdhesive

The high-performance medium-temperature cured single-component epoxy structural adhesive comprises the following components in parts by weight: 100 parts of epoxy resin; 0-30 parts of a diluent; 10-15 parts of a latent curing agent; 30-40 parts of a toughening agent; 3-7 parts of an accelerant; 3-7 parts of a thixotropic reinforcing agent; 3-5 parts of a coupling agent; 20-30 parts of filler. The invention also provides a preparation method of the structural adhesive. The preparation method comprises the following steps: 1) proportionally taking the epoxy resin, diluent, flexibilizer, filler and thixotropic reinforcing agent, and uniformly stirring; and 2) carrying out vacuum dehydration in an environment with a temperature of more than 100 DEG C, cooling to room temperature, taking the latent curing agent, the accelerator and the coupling agent in proportion, uniformly stirring in an environment with a temperature of less than 40 DEG C, and carrying out vacuum defoamation to obtain the structural adhesive. The structural adhesive disclosed by the invention is high in toughness, high in bonding strength, long in storage life and capable of resisting high temperature (as high as 280 DEG C) for a short time, and can effectively meet the use requirements of the market on the single-component epoxy structural adhesive.

Owner:重庆德天汽车新材料研究院有限公司

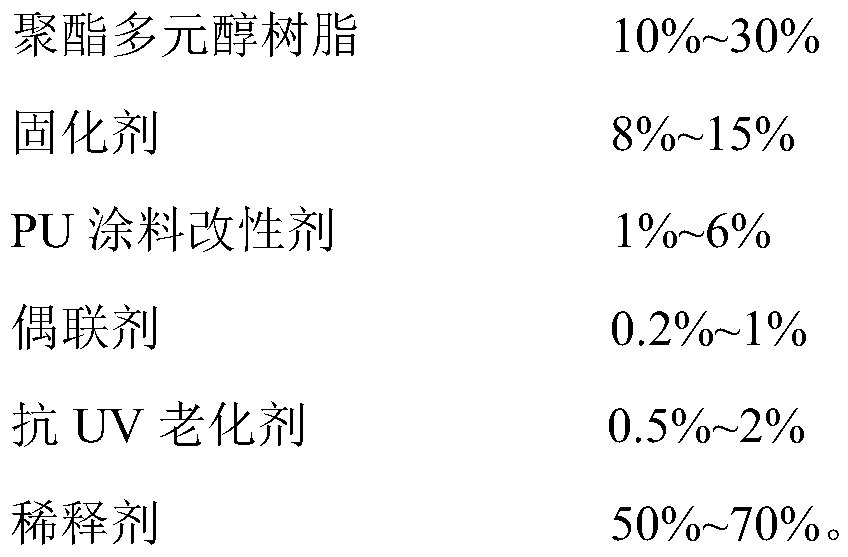

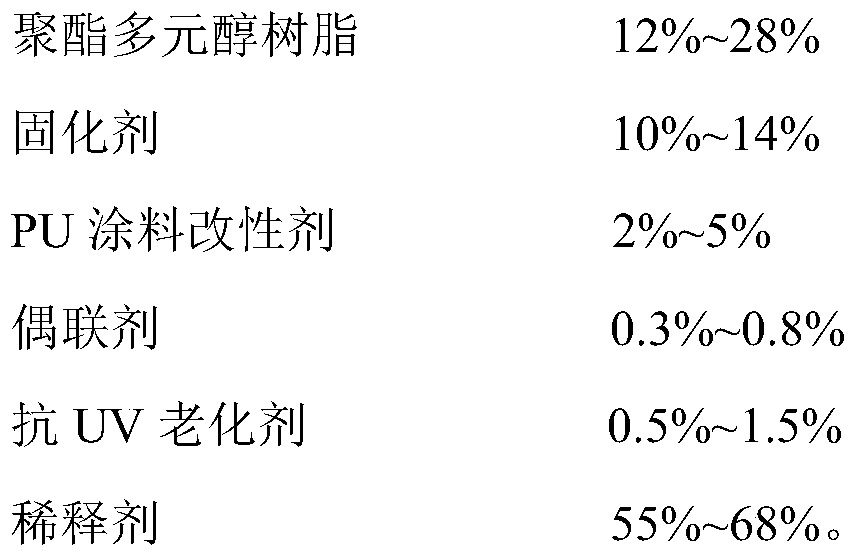

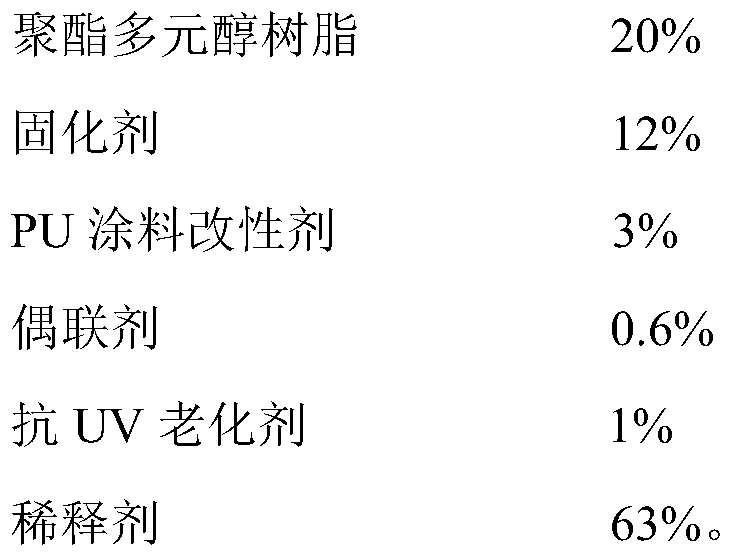

High light, wear resistant and aging resistant silica gel PU printing ink and preparation method and application method thereof

The invention relates to the technical field of printing ink, in particular to high light, wear resistant and aging resistant silica gel PU printing ink and a preparation method and application methodthereof. The high light, wear resistant and aging resistant silica gel PU printing ink prepared from polyester polyol resin, a curing agent, a PU coating modifier, a coupling agent, an an anti-UV (ultraviolet) aging agent and a diluting agent has the advantages of good light and excellent adhesion, wear resistance and aging resistance, and can pass through adhesion test, friction test, cold and hot shock test, cosmetic resistance test, hand perspiration test, UV aging test and light resistance test. The preparation method includes the steps of 1, weighing; 2, dispersing and mixing. The application method includes the steps of A, spraying; B, baking. The preparation method and the application method have the advantages of simple process and low production cost, and can be suitable for large-scale production.

Owner:DONGGUAN SINCO ELECTRONICS

PVC (Polyvinyl Chloride) low-viscosity self-adhesive static protective film

InactiveCN103171226AReduce adhesionNo degummingSynthetic resin layered productsPolyvinyl chlorideViscosity

The invention discloses a PVC (Polyvinyl Chloride) low-viscosity self-adhesive static protective film comprising a first base material layer, a second base material layer and a third base material layer, wherein the second base material layer is arranged between the first base material layer and the third base material layer; the second base material layer is a PVC resin thin film layer; and the first base material layer and the third base material layer are PVC resin self-adhesive layers. With the adoption of the manner, the static protective film disclosed by the invention can be adhered to a product through static adsorption to have the surface protection and antistatic functions; the PVC low-viscosity self-adhesive static protective film is low in adhesive force, can be repeatedly fitted and stripped, is not degummed in a stripping process, has no residual rime fog, and is soft; and the PVC low-viscosity self-adhesive static protective film can be used for arc-shaped surfaces with a special shape, a large corner and the like, and can not raise.

Owner:KUNSHAN HANBAO TAPE TECH

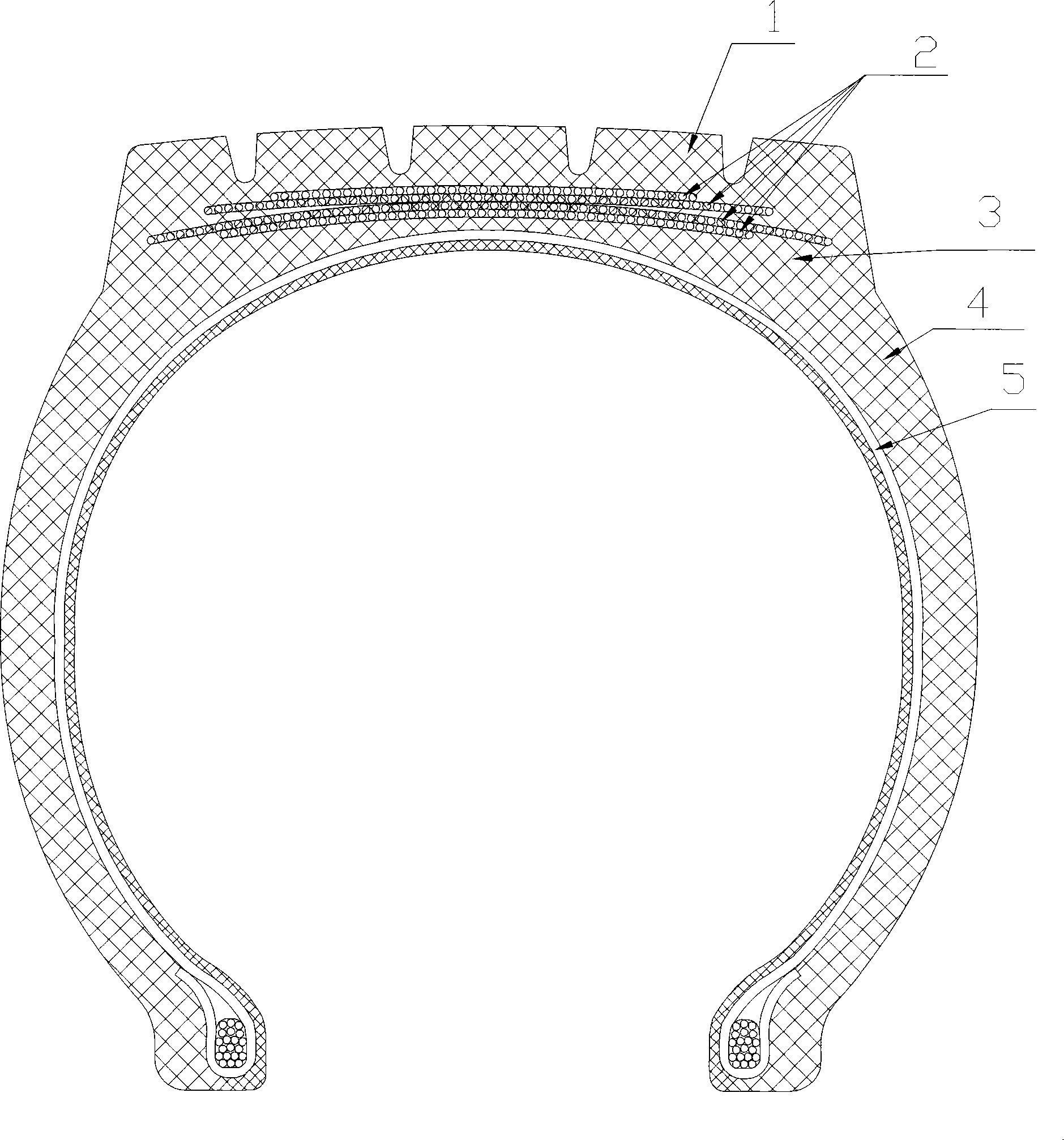

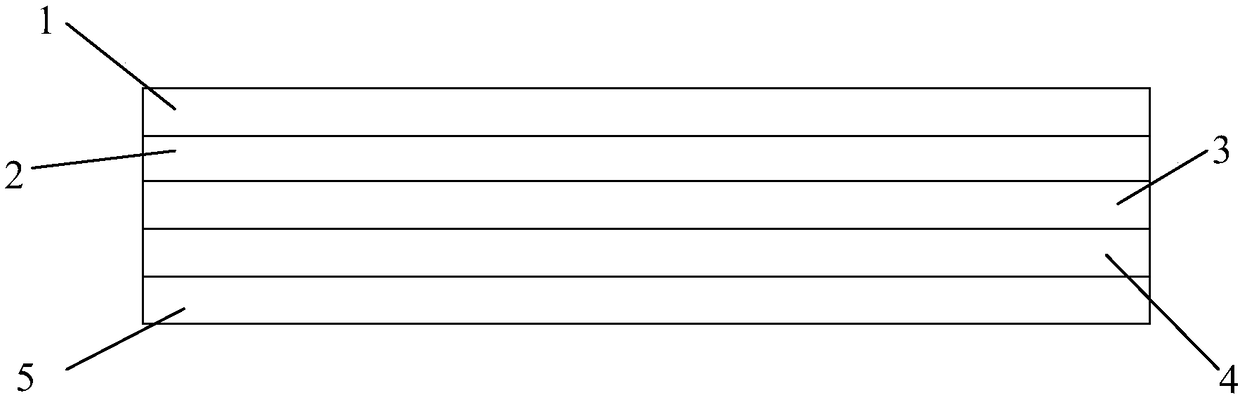

Method for reinforcing and restoring belt tyres

The invention relates to a method for strengthening and revamping a radial ply tire. The method is used for strengthening and revamping a steel wire radial ply tire which has fetal body with useful value and damaged stabilizer ply. The method includes: 1, the steel wire 5 of the fetal body of the tire and the stabilizer ply 2 are cut off according to a peeling off position 3 from the side face of the tire tread 1 of the tire, the worn out tire tread 1 which is clung below the stabilizer ply 2 is peeled off along with the stabilizer ply; 2, the junction surface where the fetal body 4 is peeled is polished; 3, plasmagel is painted on the junction surface; 4, bonding glue is applied; 5, a precure tire tread is sheathed; 6, stitching is carried out, thus the tire tread 4, the stabilizer ply 2 and the annular precure tire tread are well combined; 7, the tire is packed into an outer envelope after the stitching, a vulcanized inner tube is loaded in the tire, then the tire is put on a vulcanizing wheel felloe; 8 the tire is vulcanized in a vulcanizing tank; 9, finishing. By the method, the worn out tire can be strengthened and revamped.

Owner:钟爱民

Hot melt adhesive for artificial turf coating and preparation method thereof

ActiveCN103205221AMeet environmental protection requirementsHigh peel strengthMonocarboxylic acid ester polymer adhesivesAdhesive cementPolymer science

The invention relates to hot melt adhesive technical field, and particularly discloses a hot melt adhesive for artificial turf coating and a preparation method thereof. The hot melt adhesive for the artificial turf coating comprises, by weight, 15-50 parts of ethylene-vinyl acetate copolymers, 20-80 parts of propylene-vinyl copolymers, 20-80 parts of polyolefin plastomers and 5-30 parts of amorphous a-olefin copolymers; and the hot melt adhesive is premixed by a high-speed mixer and then squeezed by a twin-screw extruder. The hot melt adhesive is free of solvents and odor, is environmental-friendly, has strong wettability to adherends and can be used for adhering grass tightly, has high peel strength, and has high pullout force of lawn when used as the adhesive resin of the artificial turf coating.

Owner:GUANGZHOU LUSHAN NEW MATERIALS +1

Production process of polyethylene (PE) protective film

The invention relates to the technical field of protective films, in particular to a production process of a polyethylene (PE) protective film. The PE protective film produced by the production process has high / low temperature resistance, reduces the phenomenon of warping during use, can avoid the phenomenon of degumming during peeling, and is convenient to peel. A preparation method comprises thefollowing steps of S1, film blowing: melting and plasticizing a plastic raw material in an extruder, extruding the plastic raw material into a film tube through an annular die head, and blowing, cooling and sizing the film tube with compressed air to form a PE film; S2, preparation of a pressure-sensitive adhesive: mixing water-based acrylic acid and cross-linked polyacrylic acid, adding the mixture into a fuse machine, melting and stirring the mixture uniformly to obtain an adhesive; S3, glue coating: uniformly coating the surface of the PE film with the adhesive by a coating machine; S4, curing treatment: curing the PE film coated with the adhesive by ultraviolet light irradiation; S5, irradiation cross-linking modification treatment: performing cross-linking modification treatment on asemi-finished product obtained after curing; S6, winding; and S7, slitting.

Owner:昆山恒永昌电子科技有限公司

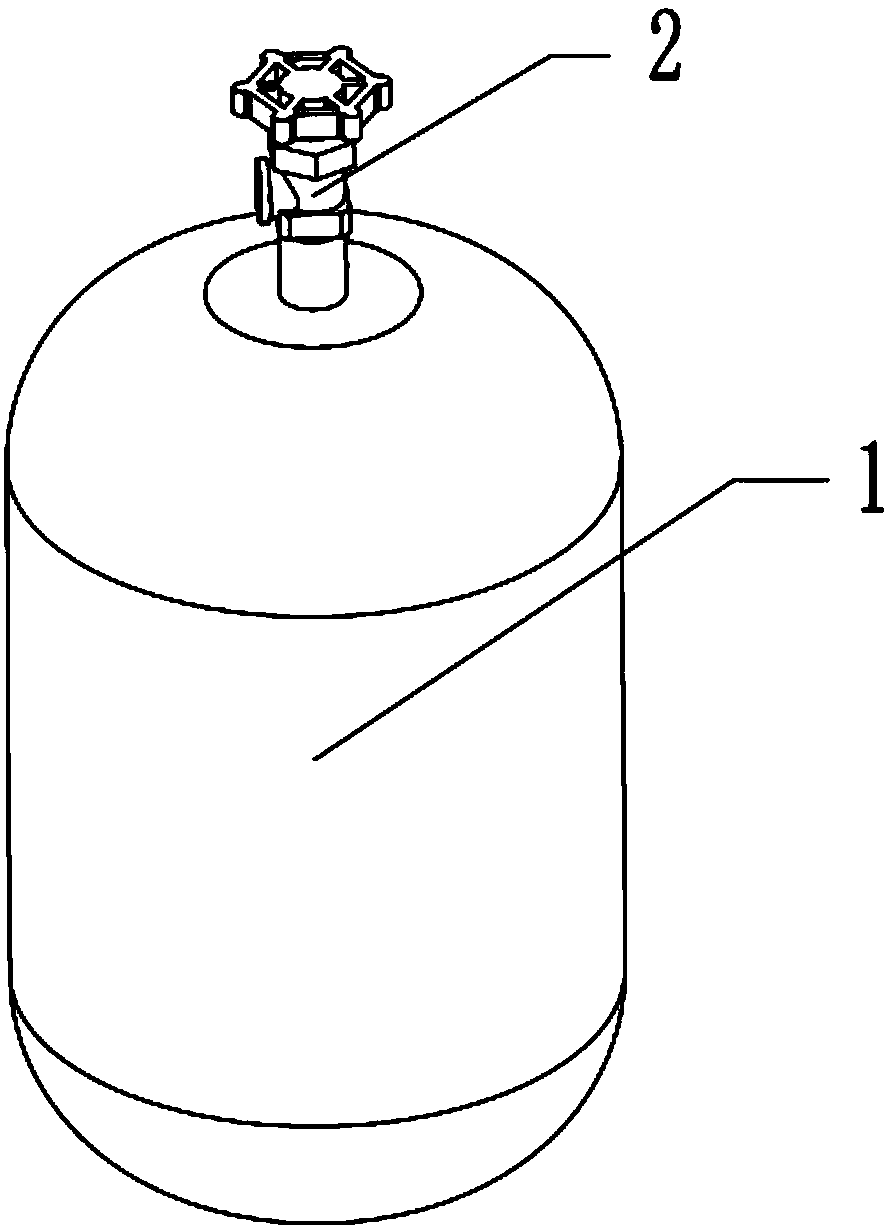

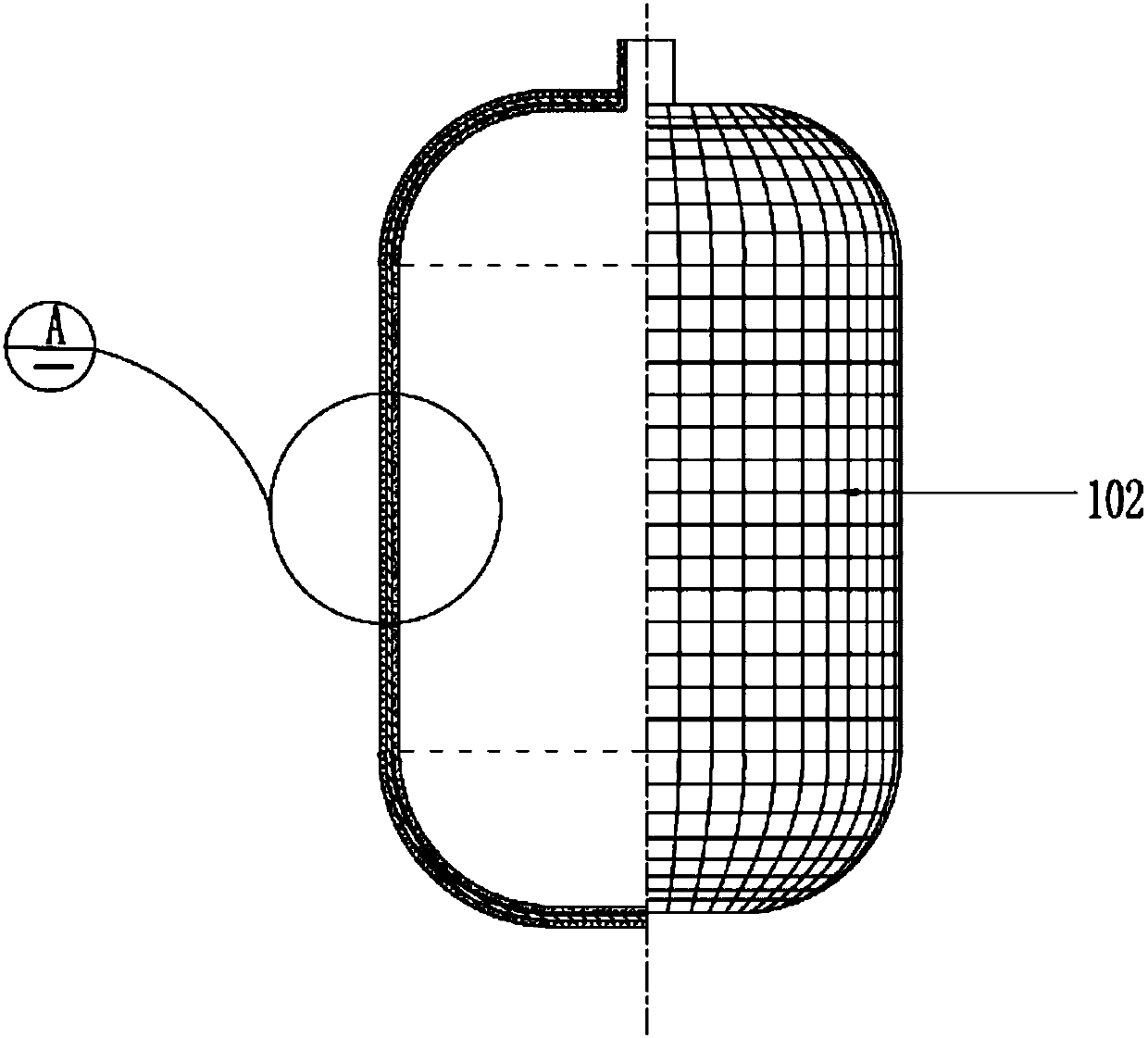

Storage and transport gas cylinder with fiber wound plastic liner, and manufacturing method thereof

ActiveCN109681770AEasy to prepareImprove bindingVessel manufacturingPressure vesselsFiber bundleGas cylinder

The invention discloses a storage and transport gas cylinder with a fiber wound plastic liner. The storage and transport gas cylinder comprises a plastic liner, a fiber-reinforced layer and a fiber reticular bonding layer, and the fiber reticular bonding layer is fused into the plastic liner; the fiber-reinforced layer is wound the exposed part of the fiber reticular bonding layer and the outer wall of the plastic liner; and resins are filled among the fiber-reinforced layer, the fiber reticular bonding layer and the outer wall of the plastic liner. The invention further discloses a manufacturing method of the gas cylinder, and the manufacturing method comprises the steps that fiber mesh cloth is prearranged in a plastic liner die, and plastic particles are heated so that the plastic particles are fused and extruded into a semi-fluid baggy semi-finished product; air is blown into the semi-finished product for manufacturing the plastic liner, and the fiber mesh cloth is hot fused into the wall of the plastic liner so that the fiber reticular bonding layer is formed; and fiber bundles are socked with the resins and wound on the fiber reticular bonding layer so that the fiber-reinforced layer is formed. According to the storage and transport gas cylinder, the problem of bonding between the plastic liner and the fiber winding layer can be solved effectively, and the debonding phenomenon is not generated after vacuum circulating detection and when temperature, pressure and other environmental conditions are changed greatly.

Owner:HAIKONG COMPOSITE MATERIALS TECH CO LTD

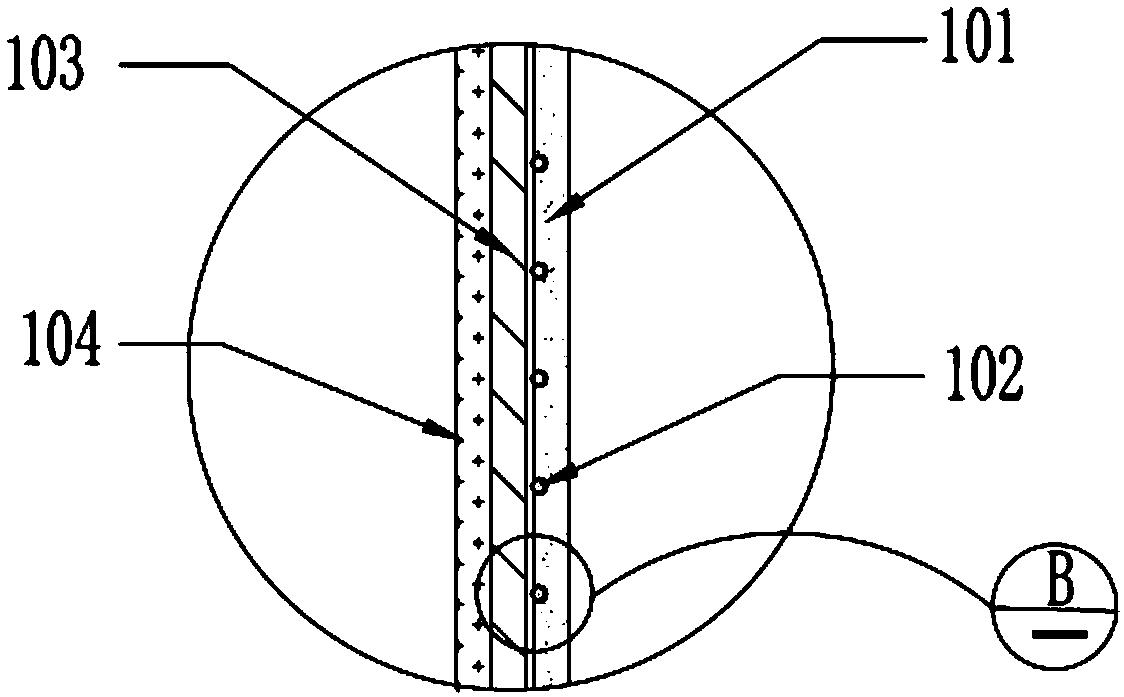

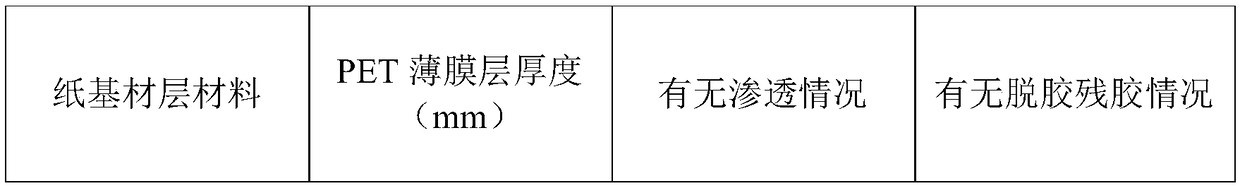

Anti-penetration paper-based adhesive tape

PendingCN108753194AHigh strengthImprove toughnessPressure sensitive film/foil adhesivesPaper basedEngineering

The invention provides an anti-penetration paper-based adhesive tape. The anti-penetration paper-based adhesive tape sequentially comprises a surface treatment layer, a paper substrate layer, a pressure-sensitive adhesive layer A, a PET film layer and a pressure-sensitive adhesive layer B. According to the anti-penetration paper-based adhesive tape provided by the invention, through embedment of the PET film layer between the paper substrate layer and the adhesive layer, the problems that during paint spraying and brushing or long-time use of a solvent on the back side of the adhesive tape, the solvent penetrates and adhesion of adhesive to paper is affected after solvent penetration, and during peeling again, the adhesive remains on the surface of an adhered object and the solvent causespollution and loss to the surface of the adhered object after penetration into the surface of the adhered object can be effectively improved; the PET film layer also can enhance the strength and the toughness of the paper, so that the paper does not break when applied to a large bent position and a corner; meanwhile, adhesion of the paper to a substrate can be enhanced; the surface of a paper material is generally an uneven porous surface and the adhesive difficultly completely penetrates therein, so that during using, point-type and sheet-type adhesive failure is easily caused; when PET is used as a carrier, the PET has relatively high surface energy and a smooth surface and has excellent bonding to the adhesive, so that the problems such as the adhesive failure and adhesive residual areavoided.

Owner:SHANGHAI SMITH ADHESIVE NEW MATERIAL

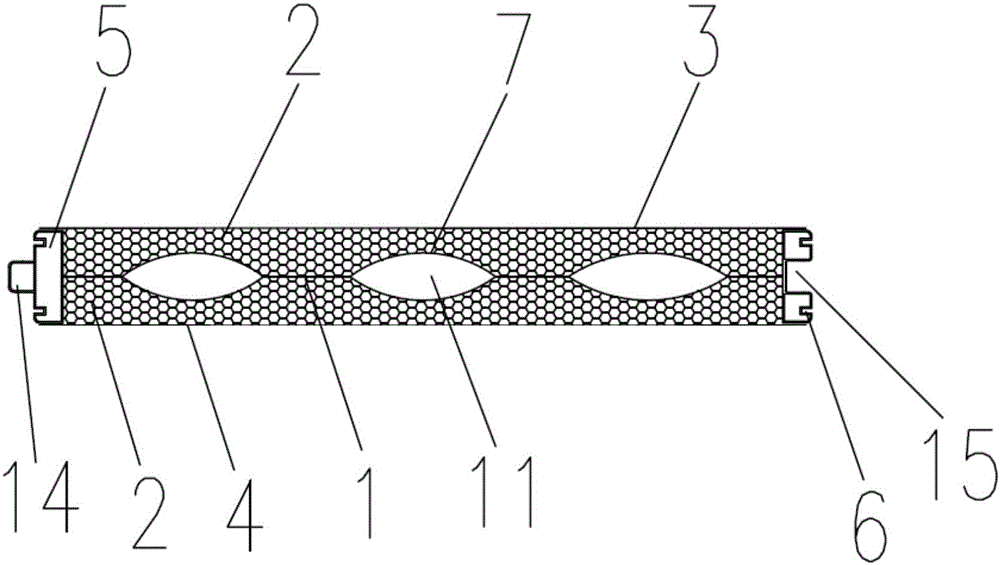

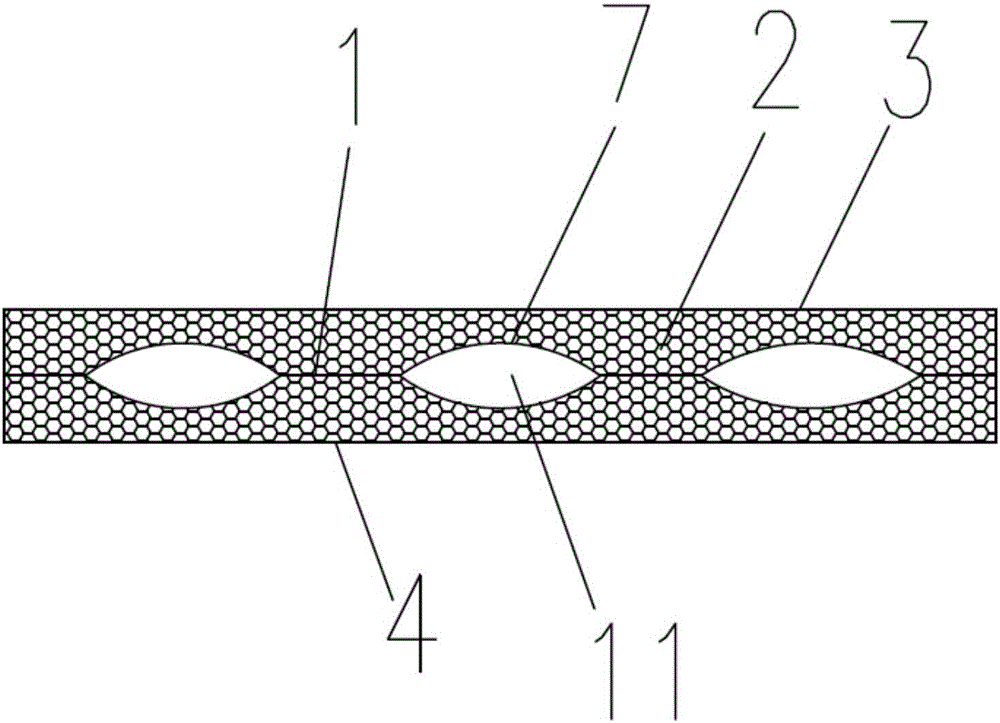

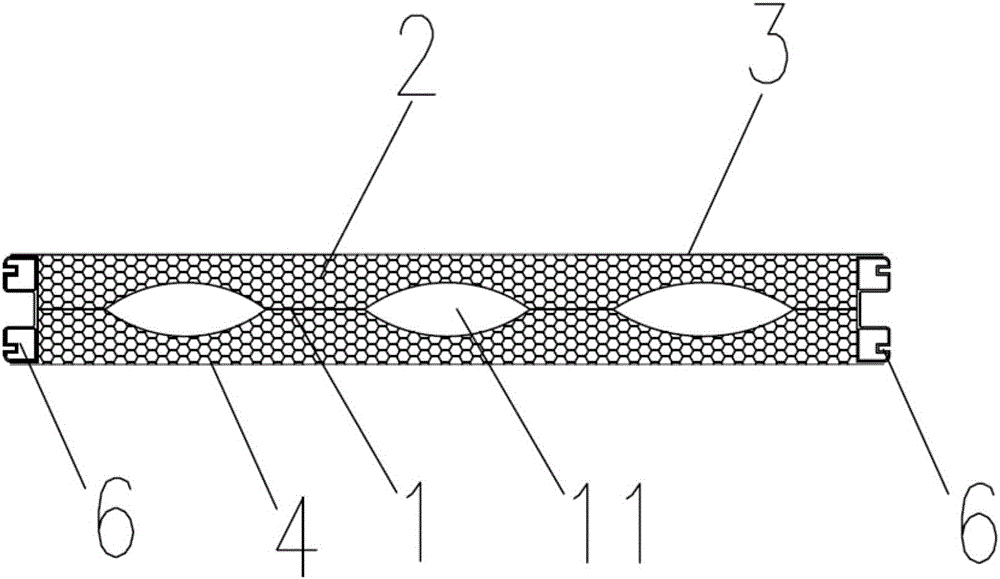

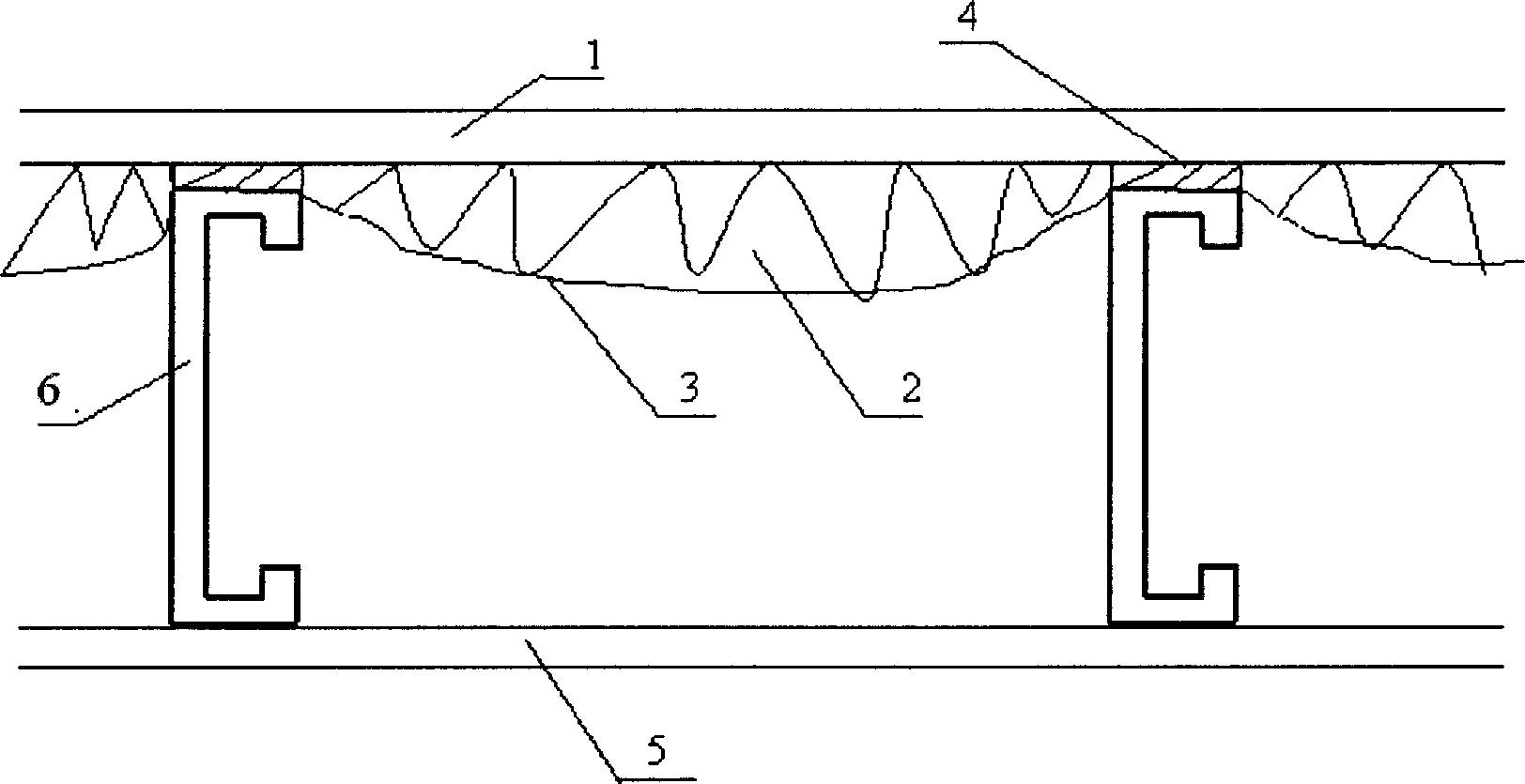

Keel-free lightweight partition board

PendingCN106639141AImprove fire performancePermeableBuilding componentsFailure preventionThermal insulation

The invention relates to a keel-free lightweight partition board, which comprises a board core unit, the board core unit at least consists of two magnesium oxysulfate plates, one side of each magnesium oxysulfate plate is provided with a plurality of grooves, the sides, which are provided with the grooves, of the two adjacent magnesium oxysulfate plates are attached together, central holes of the partition board are formed after the grooves are jointed, a first veneer is stuck on one side of the board core unit, a second veneer is stuck on the other side, a male groove is stuck on one end of the board core unit, the male groove is provided with an embossment, a female groove is stuck on the other end, and the female groove is provided with a slot corresponding to the embossment. The partition board disclosed by the invention has outstanding advantages and effects in terms of fireproofness, dampproofness, adhesive failure prevention, high strength, thermal insulation, heat insulation, sound absorption, etc.; and since the male groove is stuck on one end of the board core unit and the female groove is stuck on the other end, during construction, only the embossment of the male groove of one partition board needs to be inserted into the slot of the female groove of another partition board, so installation is highly convenient.

Owner:BLUETOP JIANGSU NEW MATERIAL

Method for sealing vacuum glass by using polyethylene hot-melt adhesive films for adhesion

The invention discloses a method for sealing vacuum glass by using polyethylene hot-melt adhesive films for adhesion. The method comprises the steps of: preparing the hot-melt adhesive films, cutting an upper flat glass sheet and a low flat glass sheet, clamping aluminum alloy frames between surrounding edges of the upper and lower glass sheets, forming a sealed cavity body through enclosing the aluminum alloy frames, the upper flat glass sheet and the low flat glass sheet, forming an exhausting hole in one aluminum alloy frame, placing hot-melt adhesive film strips on joints between the aluminum alloy frames and the upper and lower glass sheets, clamping through pressurizing, feeding to a heating furnace, keeping the temperature of 110-125 DEG C for 4-5 minutes, taking out and cooling; coating glass cement on junctions between outer sides of the aluminum alloy frames and the glass sheets; and vacuumizing, plugging the exhausting hole, and mounting frames on the periphery of the vacuum glass. According to the method, the prepared hot-melt adhesive films are adopted to seal the glass sheets and the aluminum alloy frames, and the effect is good; and shown by detection on a vacuum glass window which is manufactured by the method and is used more than two years, sealed portions are in good condition and are free of degumming phenomena, the vacuum degree of the interior of an interlayer still maintains a high level, the interior of the interlayer is free of situations, such as condensation and mildewing, and the heat preservation and insulation effects are good.

Owner:HEFEI KANGLING HEALTH TECH

Structure of multifunction double-layer pressing steel plate roofing and laying method thereof

InactiveCN1773046ALeakage GuaranteeNo degummingRoof covering using slabs/sheetsBuilding roofsPurlinGlass fiber

The present invention discloses a multifunctional double-layer pressed steel plate roof and its laying method. Its structure is characterized by that its top layer is pressed steel plate, between steel purlin and pressed steel plate a steel wire-mesh is set, between the pressed steel plate and steel wire-mesh a glass-fiber felt is set, between the steel wire-mesh on the steel purlin and pressed steel plate also is set a heat-insulating plate, and under the steel purlin a pressed steel plate is connected. Besides, said invention also provides the concrete steps of its laying method.

Owner:GUIYANG AL-MG DESIGN & RES INST

Outsole, method for attaching outsole to mid-sole and made shoe sole

ActiveCN106235513AAvoid deformationGuaranteed aestheticsSolesDomestic footwearBiochemical engineeringStock solution

The invention provides an outsole. The outsole sequentially comprises an outsole substrate, a rubber stock solution film layer attached on the outsole substrate and a release film layer attached on the rubber stock solution film layer. The outsole surface is smooth and clean, and the cumbersome surface treatment processes such as polishing and treating agent adding are omitted. The invention further discloses a method for attaching the outsole to a mid-sole. In the attaching process, a hardening glue type thin film is added, cohesiveness is good, when the outsole is attached to the mid-sole, cohesiveness-increasing post treatment processes such as gluing, glue spraying and pressing are not needed, mold and time cost is reduced, and the production efficiency is greatly improved. Meanwhile, the invention discloses a shoe sole made through the method for attaching the outsole to the mid-sole. The outsole and the mid-sole of the shoe sole are closely attached, and the shoe sole is attractive and durable.

Owner:刘银实

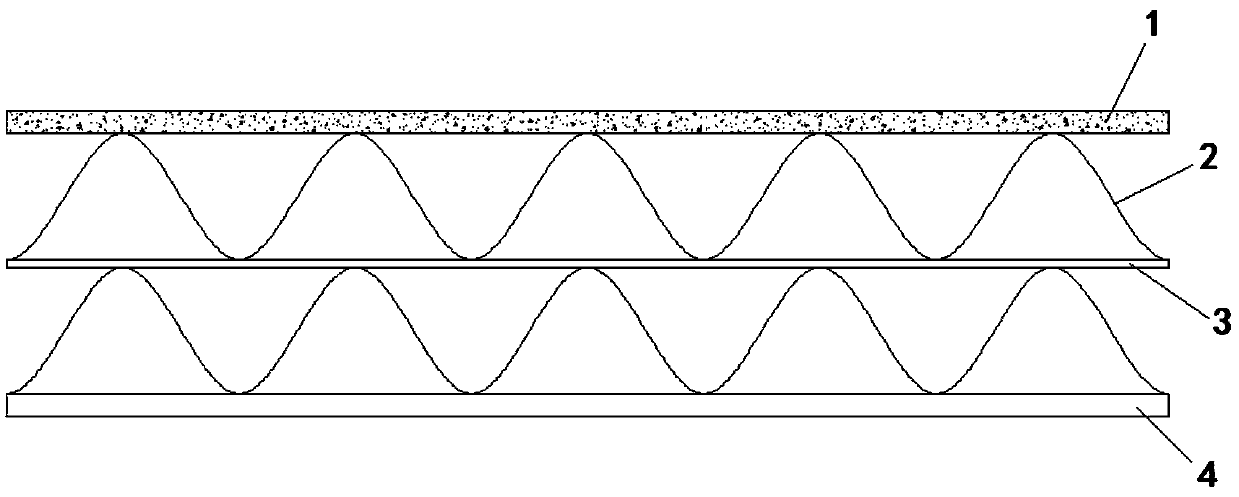

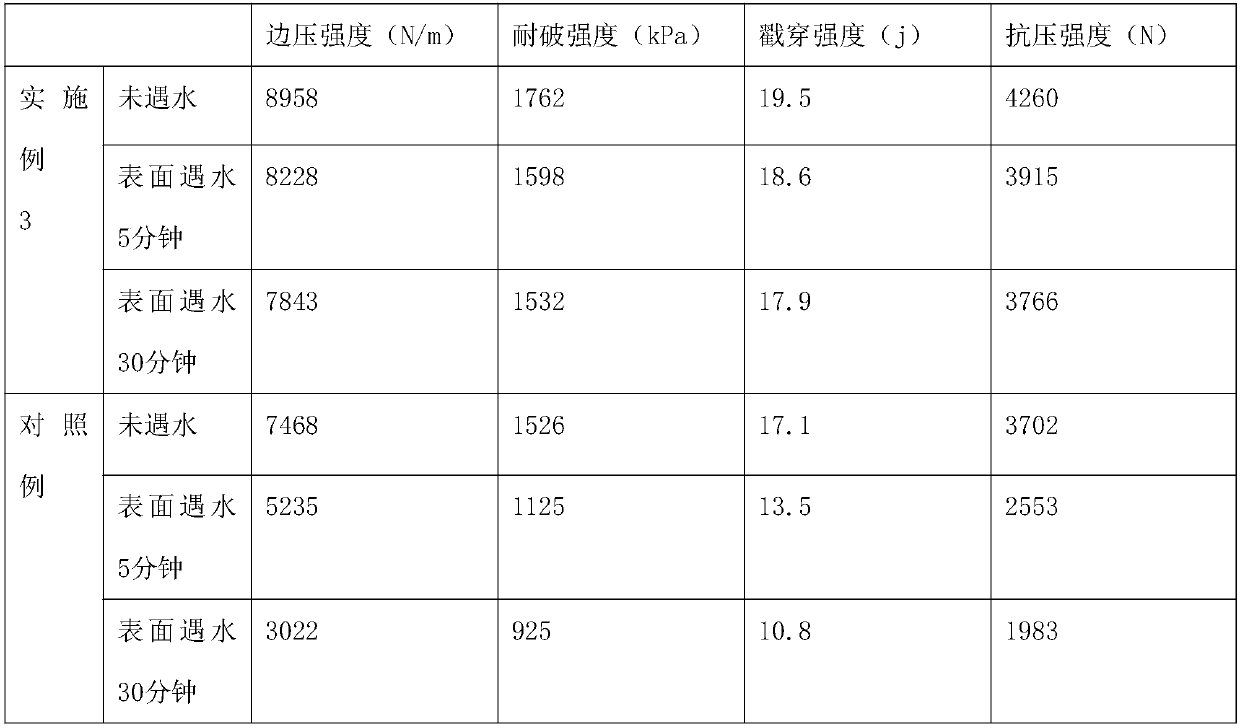

Corrugated cardboard core material

InactiveCN107892786AHigh strengthStrong service lifeNon-macromolecular adhesive additivesSpecial paperCarboxymethyl-chitosanBauxite

The invention discloses a corrugated cardboard core material which includes the raw materials in parts by weight: 50-80 parts of modified natural rubber, 15-30 parts of cis-1,4-polybutadiene rubber, 5-8 parts of nitrile rubber, 5-15 parts of a thermoplastic elastomer SIS, 5-8 parts of ethoxylated alkyl phenol ammonium sulfate, 3-5 parts of rosin based resin acid, 2-5 parts of polyether polyol, 12-20 parts of carbon black, 8-15 parts of C9 petroleum resin, 5-8 parts of tricaprate, 5-10 parts of polydiphenylmethane diisocyanate, 2-5 parts of carboxymethyl chitosan, 2-5 parts of zinc oxide, 2-6 parts of sodium based bentonite, 2-5 parts of bauxite, 1-2 parts of sepiolite fibers, 5-8 parts of a sericin solution, 3-5 parts of epoxidized soybean oil, 2-8 parts of stearic acid, 4-8 parts of a plasticizer, 2-5 parts of an accelerant, 6-12 parts of a softener, 2-5 parts of a toughening agent, and 10-15 parts of a vulcanizing agent. The core material adopts reasonable raw material and proportion, and all the components are complementary with each other and have synergistic effect, so that the prepared core material has the advantages of strong anti-aging property, high temperature resistanceand long service life.

Owner:BENGBU SHENHUI COLOR PRINTING & PACKAGING LIMITED

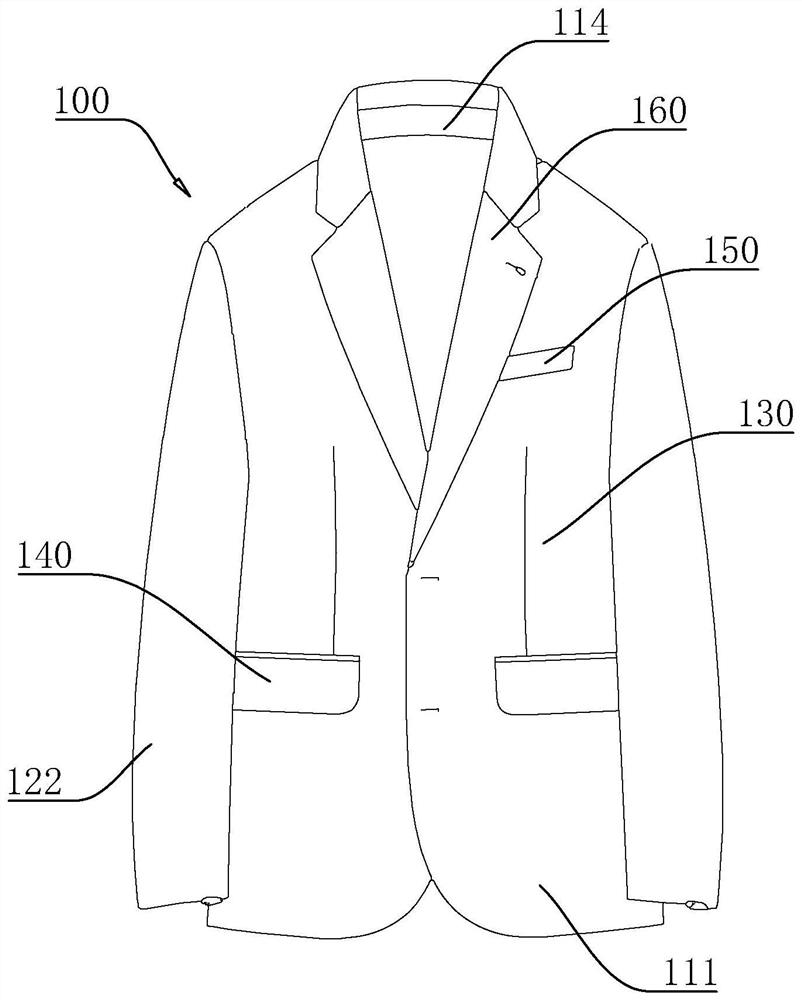

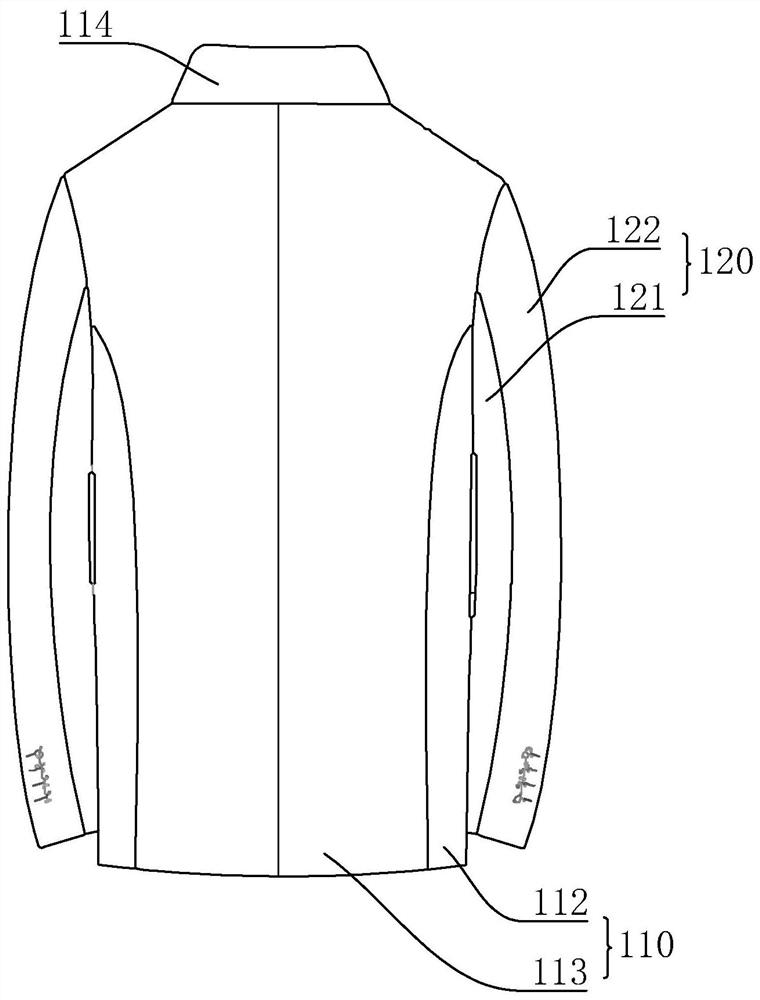

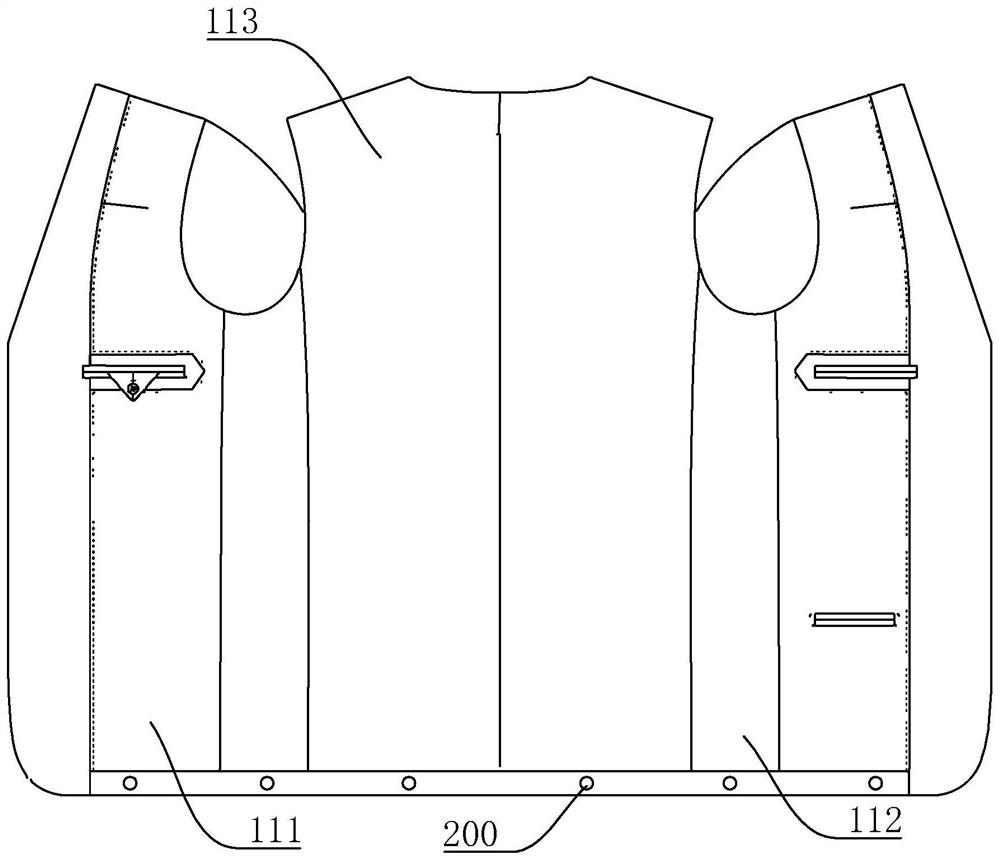

Machine-washable wool suit and sewing method

PendingCN111743218APlay a supporting roleReduce the possibility of deformationJacketsMechanical engineeringIndustrial engineering

The invention relates to the technical field of suit manufacturing processes, in particular to a machine-washable wool suit and a sewing method. The machine-washable wool suit is mainly characterizedby comprising a suit body, wherein the suit body is formed by tailoring machine-washable wool fabric, the suit body comprises a main body and sleeves, water permeable holes are formed in the welt of the inner side of the lower hem of the main body, thin linings are arranged on the lower edge of the main body and the cuff edges of the sleeves, and the thin linings are made of machine-washable lining cloth. The machine-washable wool suit has the following effects that: during machine washing, the adhesive lining cloth can effectively stabilize the style structure and the stereoscopic impressionof the suit; meanwhile, after the water permeable holes are formed, the possibility that the suit deforms and the lining cloth breaks due to the fact that water is accumulated between the fabric and the lining cloth in the machine washing process can be effectively reduced, water is drained through the water permeable holes, and all-around safety guarantee is provided for no deformation after machine washing.

Owner:深圳名盾服饰科技有限公司

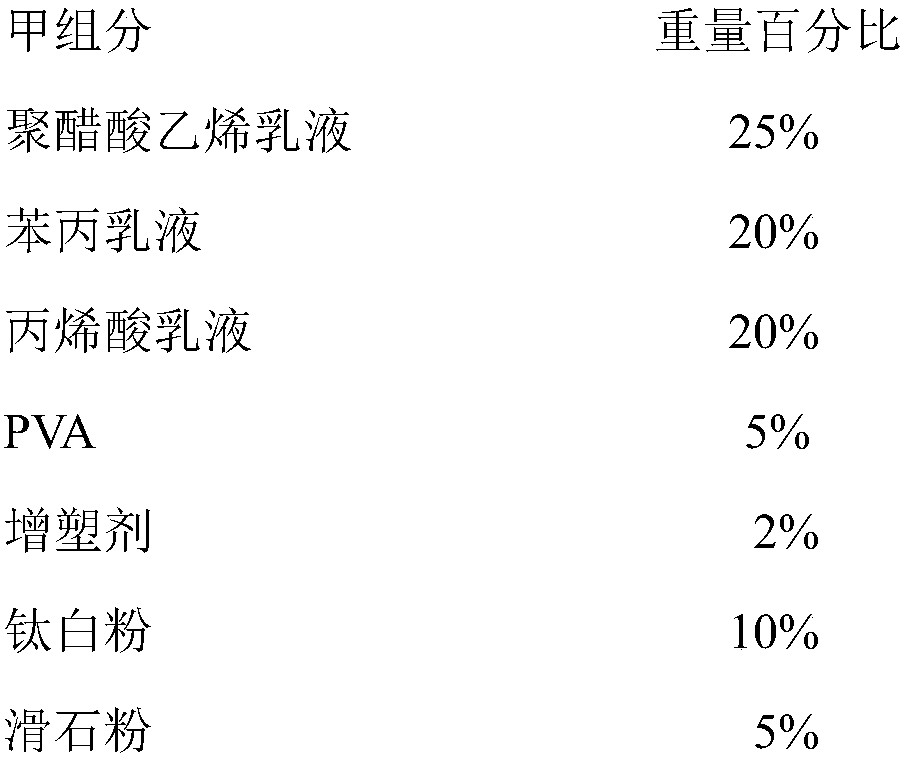

Water-based wood toothing glue and preparation method thereof

InactiveCN107793964AAvoid condensationImprove water resistanceMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesWater basedEmulsion

The invention discloses a water-based wood toothing glue, which is prepared from the following raw materials in percentage by weight: 20 to 30 percent of polyvinyl acetate emulsion, 20 to 30 percent of styrene-acrylic emulsion, 20 to 30 percent of acrylic emulsion, 3 to 5 percent of PVA, 1 to 2 percent of plasticizer, 10 to 20 percent of filler, 10 to 20 percent of deionized water, 0.2 to 0.5 percent of defoaming agent, and 0.2 to 0.5 percent of preservative. The invention also discloses a preparation method of the water-based wood toothing glue. The water-based wood toothing glue provided bythe invention is low in cost, good in stability, fast in drying speed, high in gluing strength, and good in water fastness and durability, and cannot degum or craze under high-temperature or extremelycold weathers.

Owner:JIANGMEN DINGSHI ADHESIVE INDAL

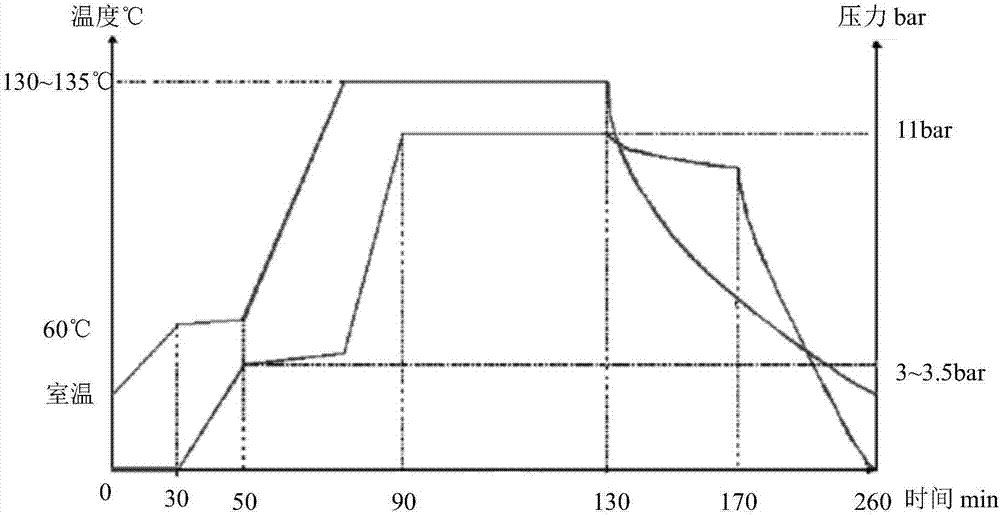

Method for sealing vacuum glass by using hot-melt adhesive films for adhesion

The invention discloses a method for sealing vacuum glass by using hot-melt adhesive films for adhesion. The method comprises the steps of: preparing the hot-melt adhesive films, cutting an upper flat glass sheet and a low flat glass sheet, clamping aluminum alloy frames between surrounding edges of the upper and lower glass sheets, forming a sealed cavity body through enclosing the aluminum alloy frames, the upper flat glass sheet and the low flat glass sheet, forming an exhausting hole in one aluminum alloy frame, placing hot-melt adhesive film strips on joints between the aluminum alloy frames and the upper and lower glass sheets, clamping through pressurizing, feeding to a heating furnace, keeping the temperature of 130-135 DEG C for 4-5 minutes, taking out and cooling; coating glass cement on junctions between outer sides of the aluminum alloy frames and the glass sheets; and vacuumizing, plugging the exhausting hole, and mounting frames on the periphery of the vacuum glass. According to the method, the prepared hot-melt adhesive films are adopted to seal the glass sheets and the aluminum alloy frames, and the effect is good; and shown by detection on a vacuum glass window which is manufactured by the method and is used more than two years, sealed portions are in good condition and are free of degumming phenomena, the vacuum degree of the interior of an interlayer still maintains a high level, the interior of the interlayer is free of situations, such as condensation and mildewing, and the heat preservation and insulation effects are good.

Owner:HEFEI KANGLING HEALTH TECH

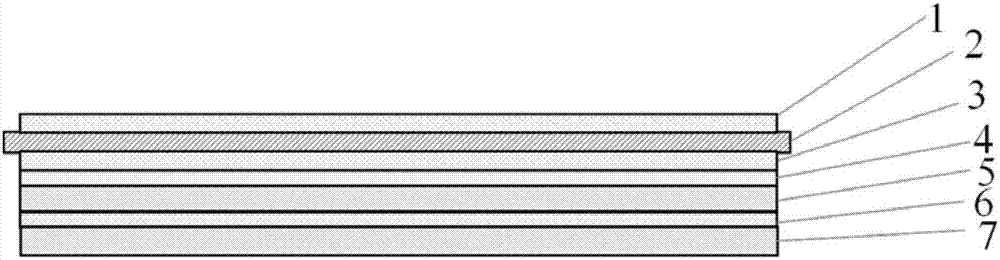

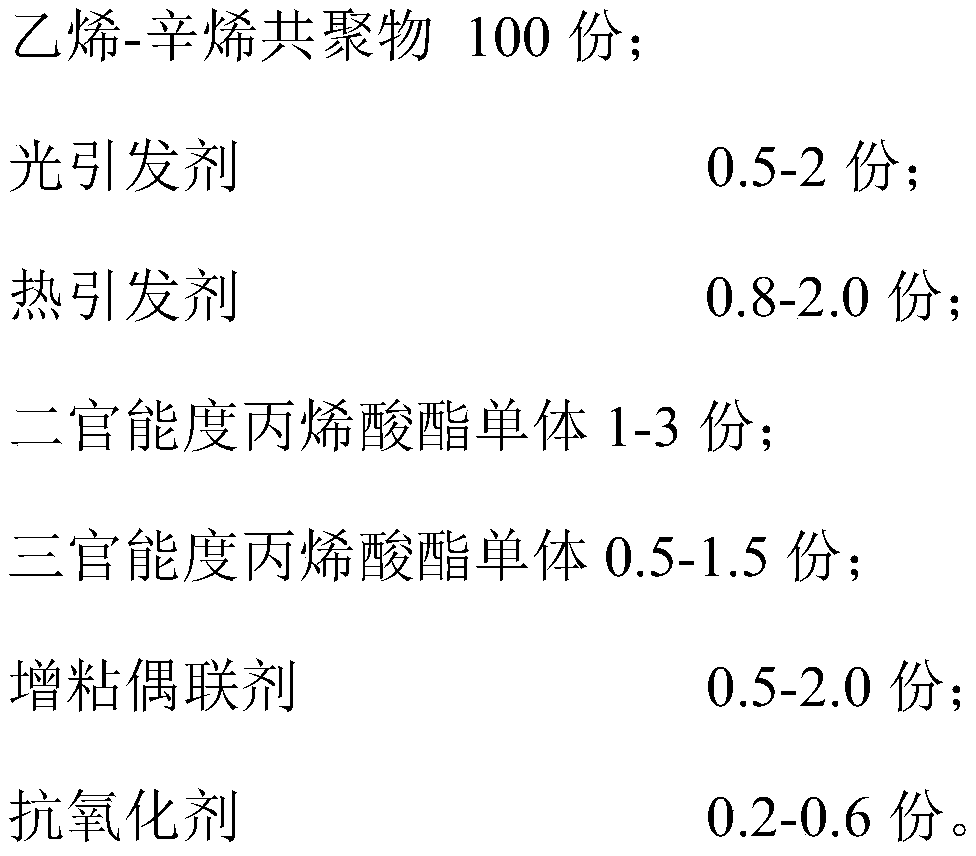

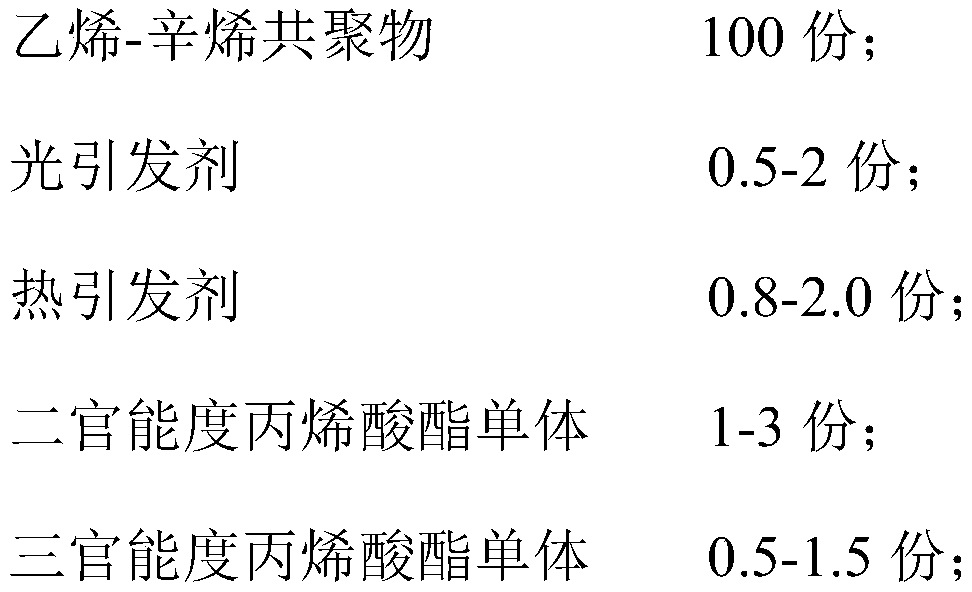

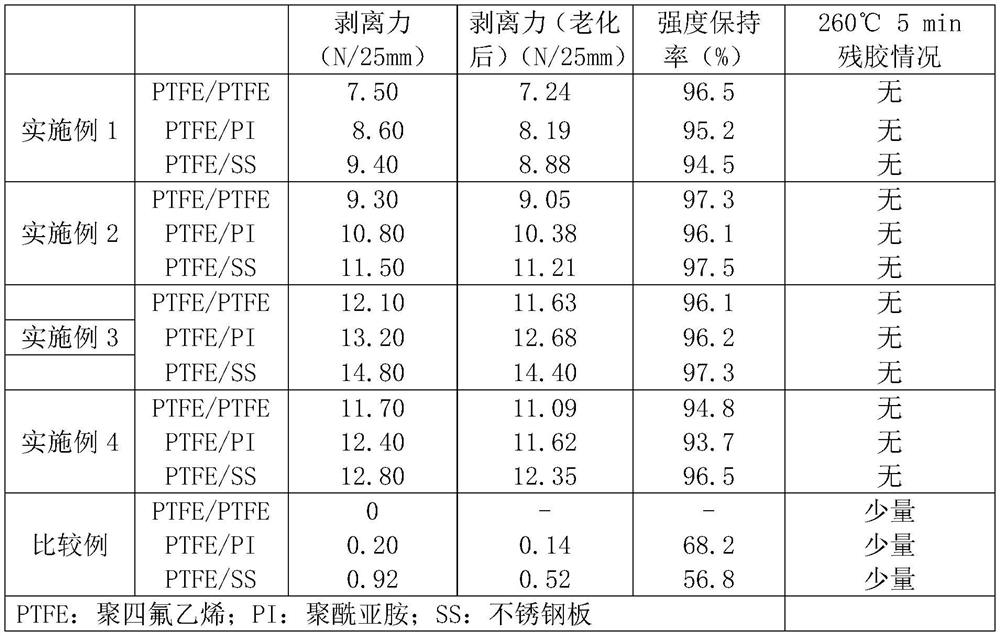

Photo-thermal dual-curing polyolefin packaging adhesive film and preparation method thereof

ActiveCN111534237ASolve the problem of photothermal dual curingHigh activityNon-macromolecular adhesive additivesOrganic non-macromolecular adhesivePolymer sciencePolyolefin

The invention discloses a photo-thermal dual-curing polyolefin packaging adhesive film. The film is prepared from the following components in parts by weight: 100 parts of an ethylene-octene copolymer, 0.5 to 2 parts of a photoinitiator, 0.8 to 2.0 parts of a thermal initiator, 1 to 3 parts of a difunctional acrylate monomer, 0.5 to 1.5 parts of a trifunctional acrylate monomer, 0.5 to 2.0 parts of a tackifying coupling agent and 0.2 to 0.6 part of an antioxidant. According to the invention, the ethylene-octene copolymer is adopted, the mixing of a difunctional acrylate monomer and a trifunctional acrylic acid monomer is combined, meanwhile, the photoinitiator and the thermal initiator are matched for use, so that the polyolefin photovoltaic packaging adhesive film can be prepared throughtwo-time curing of light and heat, the curing temperature is relatively low, the weather resistance is good, bubbles are avoided, the degumming phenomenon cannot occur after long-term use, and the phenomenon of poor appearance of the thin-film solar cell is reduced.

Owner:SUN YAT SEN UNIV

High-temperature-resistant fluorine-containing acrylate pressure-sensitive adhesive capable of being used for adhering fluorine-containing materials

PendingCN114479723AImprove wettabilityStrong adhesionAmide/imide polymer adhesivesEster polymer adhesivesAdhesive cementPolymer chemistry

The invention discloses a high-temperature-resistant fluorine-containing acrylate pressure-sensitive adhesive capable of being used for adhering fluorine-containing materials. The high-temperature-resistant fluorine-containing acrylate pressure-sensitive adhesive is prepared from the following components in parts by mass: 75 parts of a soft monomer; 10 parts of a hard monomer; 5 to 30 parts of a fluorine-containing acrylate monomer; 0.6 to 2.6 parts of a heat-resistant monomer; 0.345 part of a thermal initiator; and 100 to 130 parts of a solvent. The fluorine-containing acrylate monomer is introduced into an acrylate polymerization system to reduce the surface energy of a polymer so as to improve the wettability of the polymer on the surface of a low-surface-energy base material. The glass transition temperature of the pressure-sensitive adhesive is controlled by adjusting the proportion of soft and hard monomers in the polymer so as to meet the requirements under different use conditions.

Owner:HARBIN INST OF TECH WUXI RES INST OF NEW MATERIALS +1

Process for manufacturing vacuum glass

The invention discloses a process for manufacturing vacuum glass. The process comprises the steps of: preparing the hot-melt adhesive films, cutting an upper flat glass sheet and a low flat glass sheet, clamping aluminum alloy frames between surrounding edges of the upper and lower glass sheets, forming a sealed cavity body through enclosing the aluminum alloy frames, the upper flat glass sheet and the low flat glass sheet, forming an exhausting hole in one aluminum alloy frame, placing hot-melt adhesive film strips on joints between the aluminum alloy frames and the upper and lower glass sheets, clamping through pressurizing, feeding to a heating furnace, keeping the temperature of 130-145 DEG C for 4-5 minutes, taking out and cooling; coating glass cement on junctions between outer sides of the aluminum alloy frames and the glass sheets; and vacuumizing, plugging the exhausting hole, and mounting frames on the periphery of the vacuum glass. According to the process, the prepared hot-melt adhesive films are adopted to seal the glass sheets and the aluminum alloy frames, and the effect is good; and shown by detection on a vacuum glass window which is manufactured by the method and is used more than two years, sealed portions are in good condition and are free of degumming phenomena, the vacuum degree of the interior of an interlayer still maintains a high level, the interior of the interlayer is free of situations, such as condensation and mildewing, and the heat preservation and insulation effects are good.

Owner:佛山晨阳玻璃科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com