UV-curing adhesive as well as preparation method and application thereof

An adhesive and curing technology, which is applied in the direction of adhesives, ester copolymer adhesives, film/sheet adhesives, etc., can solve problems such as long reaction time, complicated process, and harsh curing conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Weigh 60 g of butyl acrylate, 20 g of isooctyl acrylate, 12 g of vinyl acetate, 8 g of acrylamide, 0.3 g of azobisisobutyronitrile, and 100 g of ethyl acetate (40% solid content) and mix them uniformly. Take half of the mixed solution and pour it into a four-necked flask equipped with nitrogen, a mechanical stirrer, a condenser and a thermometer, and heat it to 78°C to start the reaction. In the system, after heat preservation and reaction for 3 hours, it was cooled.

[0028] (2) 5 g of glycidyl methacrylate was added into the reaction system, stirred and refluxed at 75° C. for 4 h, cooled and discharged.

[0029] (3) Fully mix the prepared glue solution with 1 g of 4-acryloyloxybenzophenone photoinitiator, apply it on the BOPET film with a thickness of 20-30 μm, and place it in an oven at 78° C. for 5 minutes.

[0030] (4) Then pass through UV light curing machine (wavelength 355nm, UV curing time is 180s. Curing machine UV radiation dose 180mJ / cm 2 ) for curing....

Embodiment 2

[0032] (1) Weigh 65g of sec-butyl acrylate, 20g of n-propyl acrylate, 5g of vinyl acetate, 10g of acrylamide, 0.1g of azobisisobutyronitrile, and 100g of ethyl acetate (40% solid content) and mix well. Take half of the mixed solution and pour it into a four-necked flask equipped with nitrogen, a mechanical stirrer, a condenser and a thermometer, and heat it to 78°C to start the reaction. In the system, keep warm for 3 hours and then cool down.

[0033] (2) Add 4.9 g of glycidyl methacrylate into the reaction system, stir and reflux at 75° C. for 4 hours, and cool and discharge.

[0034] (3) Fully mix the synthesized UV-curable adhesive glue and 1g of 4-acryloyloxybenzophenone photoinitiator, and apply it on the BOPET film with a thickness of 20-30μm. ℃ oven for 5min.

[0035] (4) Then pass through UV light curing machine (wavelength 355nm, UV curing time is 180s. Curing machine UV radiation dose 180mJ / cm 2 ) for curing. After curing, take it out, use a film laminating mach...

Embodiment 3

[0037] (1) Weigh 70g methyl acrylate, 20g ethyl methacrylate, 5g methacrylic acid, 5g acrylamide, 0.3g dibenzoyl peroxide, 150g ethyl acetate (50% solid content) and mix well. Take half of the mixed solution and pour it into a four-necked flask equipped with nitrogen, a mechanical stirrer, a condenser and a thermometer, and heat it to 78°C to start the reaction. In the system, after heat preservation and reaction for 3 hours, it was cooled.

[0038] (2) Add 7g of glycidyl methacrylate into the reaction system, stir and reflux at 75°C for 4h, and cool and discharge.

[0039] (3) Fully mix the synthesized UV-curable adhesive glue and 1.5g of phenyl-(1-acryloyloxy)-cyclohexyl ketone photoinitiator, and apply it on the BOPET film with a thickness of 20 ~30 μm, put it in a 78°C oven for 5 minutes.

[0040] (4) Then pass through UV light curing machine (wavelength 355nm, UV curing time is 180s. Curing machine UV radiation dose 180mJ / cm 2 ) for curing. After curing, take it out, ...

PUM

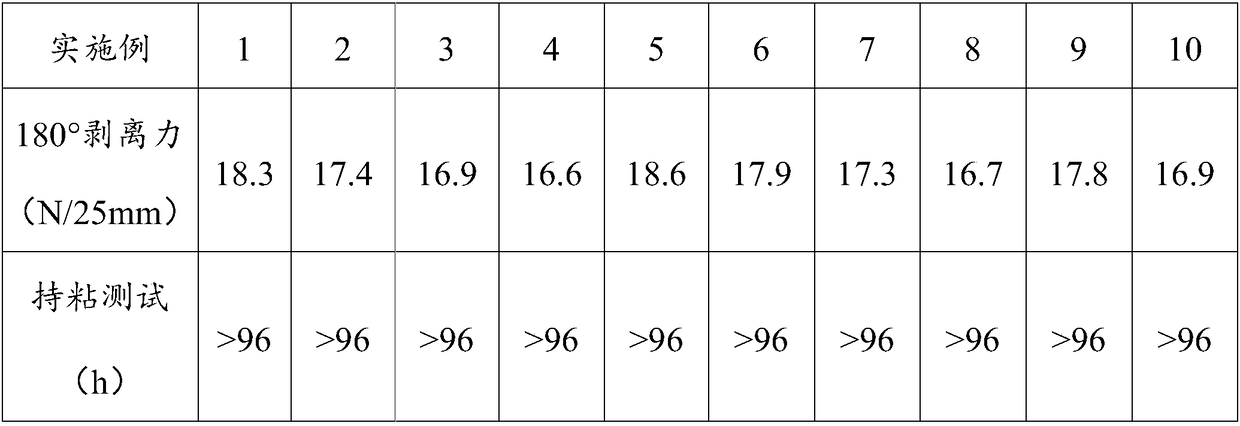

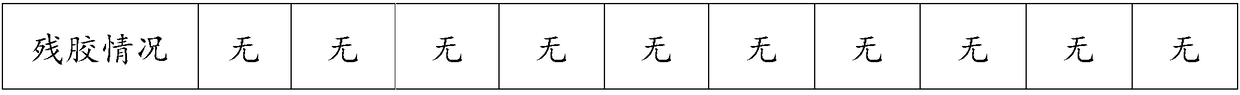

| Property | Measurement | Unit |

|---|---|---|

| Peel force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com