Anti-penetration paper-based adhesive tape

An anti-penetration and adhesive tape technology, which is applied in the direction of adhesives, film/sheet adhesives, pressure-sensitive films/sheets, etc., can solve the problems of poor bonding force, residue, and low deformability of adhesive tape, and achieve enhanced Strength and toughness, excellent adhesion, and the effect of enhancing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

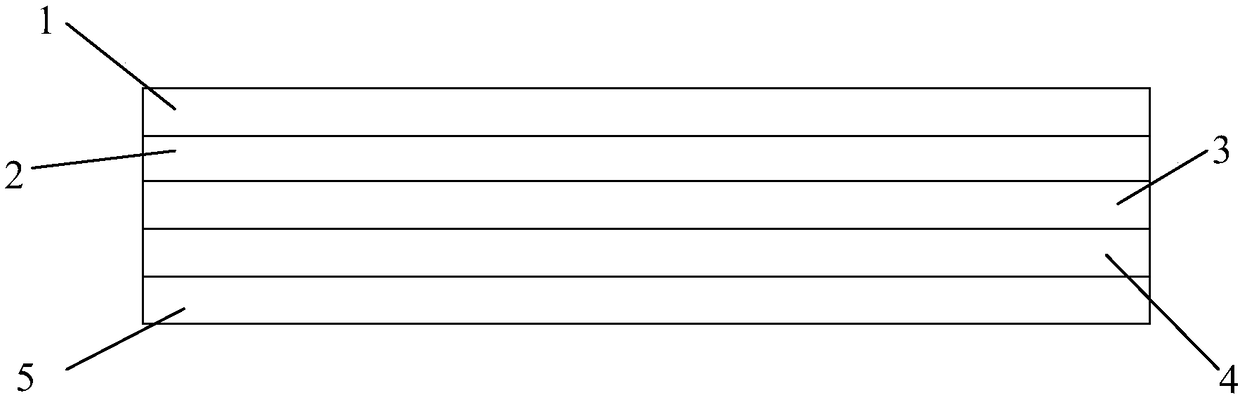

Image

Examples

Embodiment 1

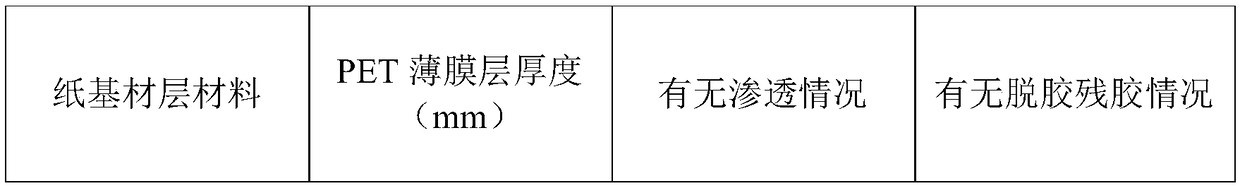

[0023] Preferably, the surface treatment layer is selected from an organic silicon release layer, the pressure-sensitive adhesive layer A and the pressure-sensitive adhesive layer B are selected from rubber adhesives, and the thickness of the paper substrate layer is 0.05mm, and the dry glue thickness of the pressure-sensitive adhesive layer A is 0.01 mm. mm, the dry glue thickness of the pressure-sensitive adhesive layer B is 0.03mm, the experiment is carried out, and several sets of specific experimental data are provided below:

[0024] Table 1

[0025]

[0026]

[0027] The test method for the penetration and degumming residue in the above table is to randomly take a piece of 10cm×10cm tape from the tape, attach it to a smooth steel plate washed with alcohol, roll it with a 2.5kg roller for 3 times, and then put it on the tape After 48 hours of painting on the surface, pull the tape at an angle of 180° to the steel plate and observe whether there is paint penetration...

Embodiment 2

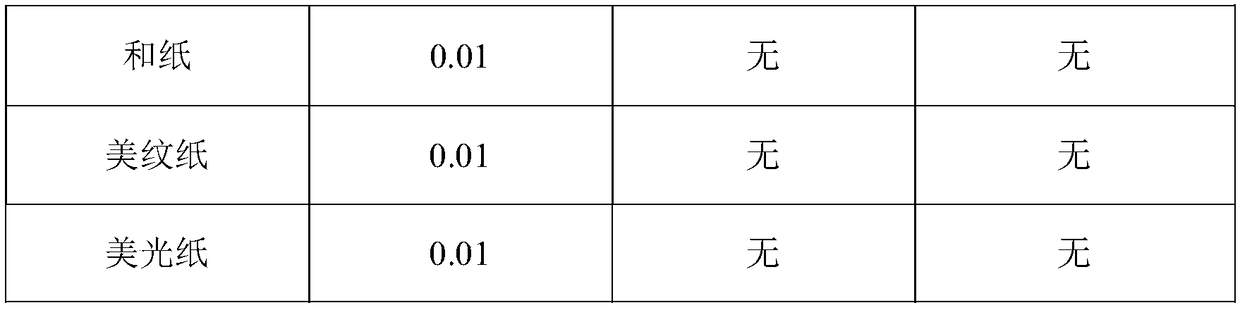

[0029] Preferably, the surface treatment layer is selected from a non-silicon release layer, the pressure-sensitive adhesive layer A and the pressure-sensitive adhesive layer B are selected from an acrylic adhesive, and the thickness of the paper substrate layer is 0.05mm, and the dry glue thickness of the pressure-sensitive adhesive layer A is 0.01 mm. mm, the dry glue thickness of the pressure-sensitive adhesive layer B is 0.03mm, the experiment is carried out, and several sets of specific experimental data are provided below:

[0030] Table 2

[0031]

[0032] The test method for the penetration and degumming residue in the above table is to randomly take a piece of 10cm×10cm tape from the tape, attach it to a smooth steel plate washed with alcohol, roll it with a 2.5kg roller for 3 times, and then put it on the tape After 48 hours of painting on the surface, pull the tape at an angle of 180° to the steel plate and observe whether there is paint penetration and degumming...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com