Water-based wood toothing glue and preparation method thereof

A wood and water-based technology, applied in the field of wood adhesives, can solve the problems of poor durability, low bonding strength and high price, and achieve the effects of good durability, fast drying speed and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

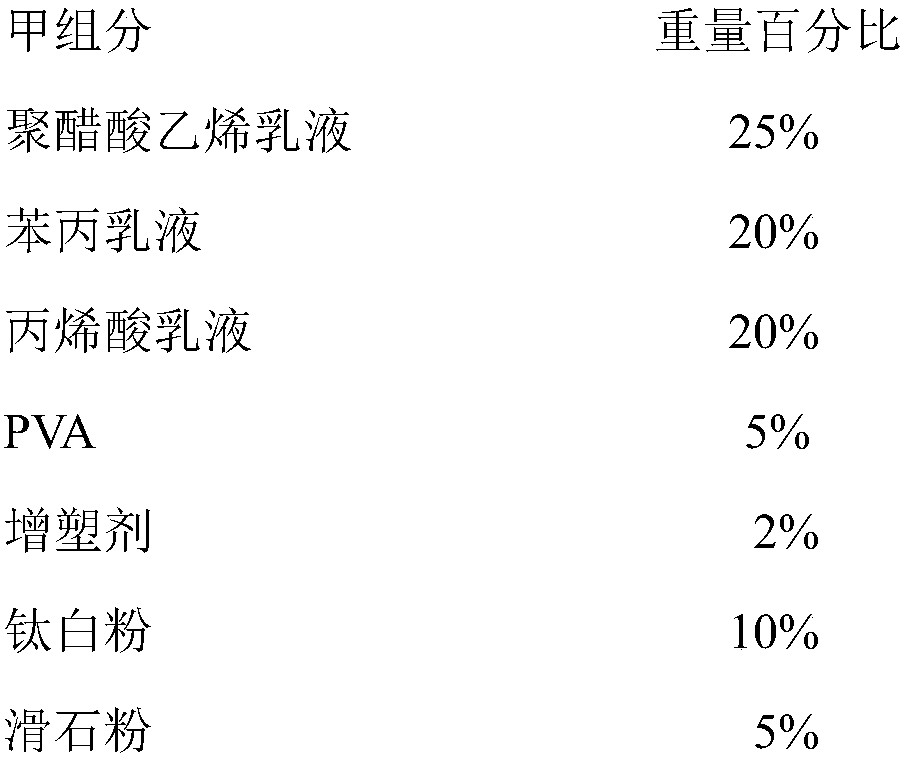

Embodiment 1

[0032]

[0033]

[0034] The above raw materials are all commercially available, wherein the plasticizer is polyamide resin, the defoamer is mineral oil, and the preservative is isothiazolinones.

[0035] Weigh the raw materials according to the above weight ratio, add deionized water into the reactor, slowly add defoamer and PVA at a stirring rate of 100r / min, keep the stirring rate constant, raise the temperature to 80°C, and stir at a constant temperature and speed for 2h , then lower the temperature to 60°C, add polyvinyl acetate emulsion, styrene-acrylic emulsion, and acrylic emulsion, stir for 30 minutes at a stirring speed of 500r / min, then add titanium dioxide and talcum powder, and then add plasticizers and preservatives. Stir for 2h at a stirring rate of 1000r / min, take a sample for detection, filter, and discharge for packaging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com