Touch panel, touch screen and preparation method thereof

A touch panel, touch screen technology, applied in instruments, electrical digital data processing, data processing input/output process, etc., can solve the problems of insufficient viscosity, fragile cover, poor performance, etc., and achieve high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

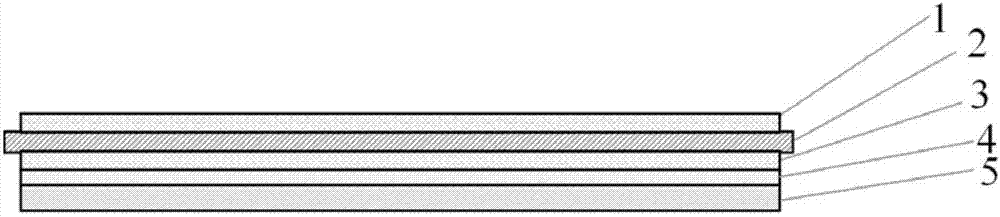

[0056] The touch panel of this embodiment includes a touch sensor (thickness 0.8mm), an adhesive film (125 μm), a second glass cover plate (0.3mm), and a PVB interlayer (0.38mm) from bottom to top. and a first glass cover (0.3mm). figure 1 It is a structural schematic diagram of the touch panel in Embodiment 1, wherein 1 is the first glass cover, 2 is the PVB interlayer, 3 is the second glass cover, 4 is the adhesive film, and 5 is the touch sensor.

[0057] The touch panel preparation method comprises the following steps:

[0058] (1) Die-cutting of PVB film: In the thousand-level dust-free workshop, according to the actual requirements, the PVB film is die-cut according to the size of the touch sensor. The average size of the glass cover plate is 0.5-1mm larger to ensure that the two layers of glass cover plates can be fully bonded during subsequent lamination;

[0059] (2) Cleaning: cleaning the first glass cover plate and the second glass cover plate with ultrasonic wave...

Embodiment 2

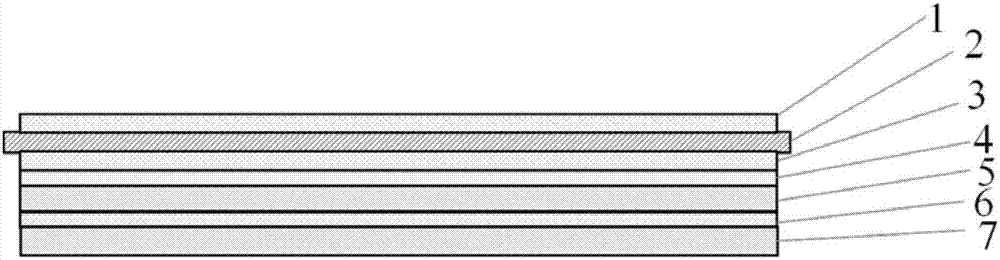

[0079] The touch panel of this embodiment includes a touch sensor (thickness 0.5mm), an adhesive film (500 μm), a second glass cover plate (0.2mm), and a PVB interlayer (1.52mm) from bottom to top. and a first glass cover (0.2mm).

[0080] The touch panel preparation method is except following parameters, and all the other are identical with embodiment 1:

[0081] In step (5), during the first preheating lamination process, the temperature is 120°C, the pressure is 4bar, the time is 4min, and the vacuum degree is 10 -3 bar; in the second stage of preheating lamination, the temperature is 220°C, the pressure is 8bar, the time is 4min, and the vacuum is 10 -3 bar; naturally cool the surface of the touch panel precursor to about 50°C;

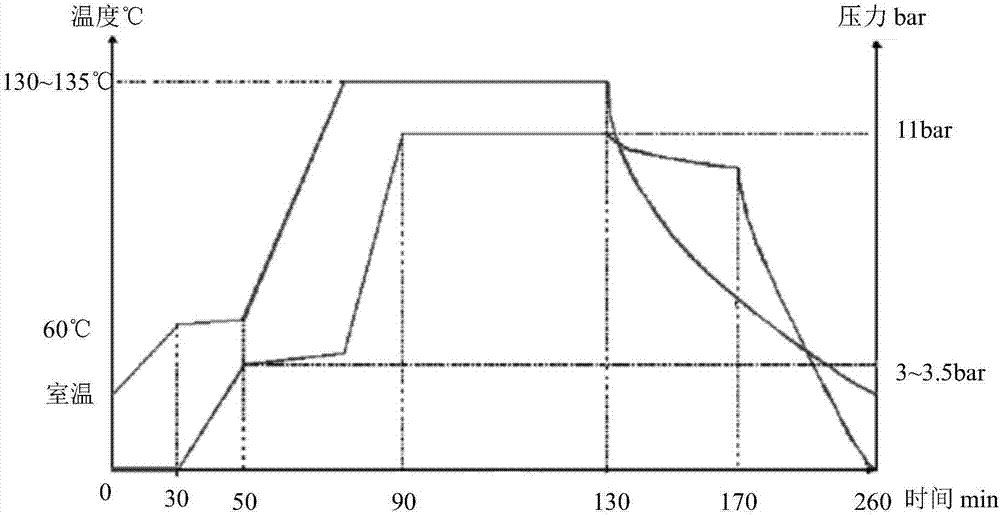

[0082] In step (7), the exhaust operation is carried out according to the following steps: within 20 minutes, the temperature is raised to 57 ° C for the first time and then the first heat preservation is carried out for 30 minutes. During the f...

Embodiment 3

[0086] The touch panel of this embodiment includes a touch sensor (thickness 0.5mm), an adhesive film (250 μm), a second glass cover plate (0.4mm), and a PVB interlayer (0.76mm) from bottom to top. and a first glass cover (0.4mm).

[0087] The touch panel preparation method is except following parameters, and all the other are identical with embodiment 1:

[0088] In step (5), in the first stage of preheating lamination process, the temperature is 70°C, the pressure is 6bar, and the time is 10min; in the second stage of preheating lamination, the temperature is 170°C, the pressure is 6bar, and the time is 10min ; Naturally cool the surface of the touch panel precursor to about 70°C;

[0089] In step (7), the exhaust operation is carried out according to the following steps: within 20 minutes, the temperature is raised to 63 ° C for the first time and then the first heat preservation is carried out for 30 minutes. During the first heat preservation process, the pressure is rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com