Flexible silica gel screen protection film and preparation method thereof

A screen protection film and protective film technology, applied in the direction of adhesives, pressure-sensitive films/sheets, film/sheet-shaped adhesives, etc., can solve problems such as easy degumming of die-cutting, warping of curved surfaces, and affecting user experience , to achieve the effect of easy adjustment of softness and thickness, fast rebound speed and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

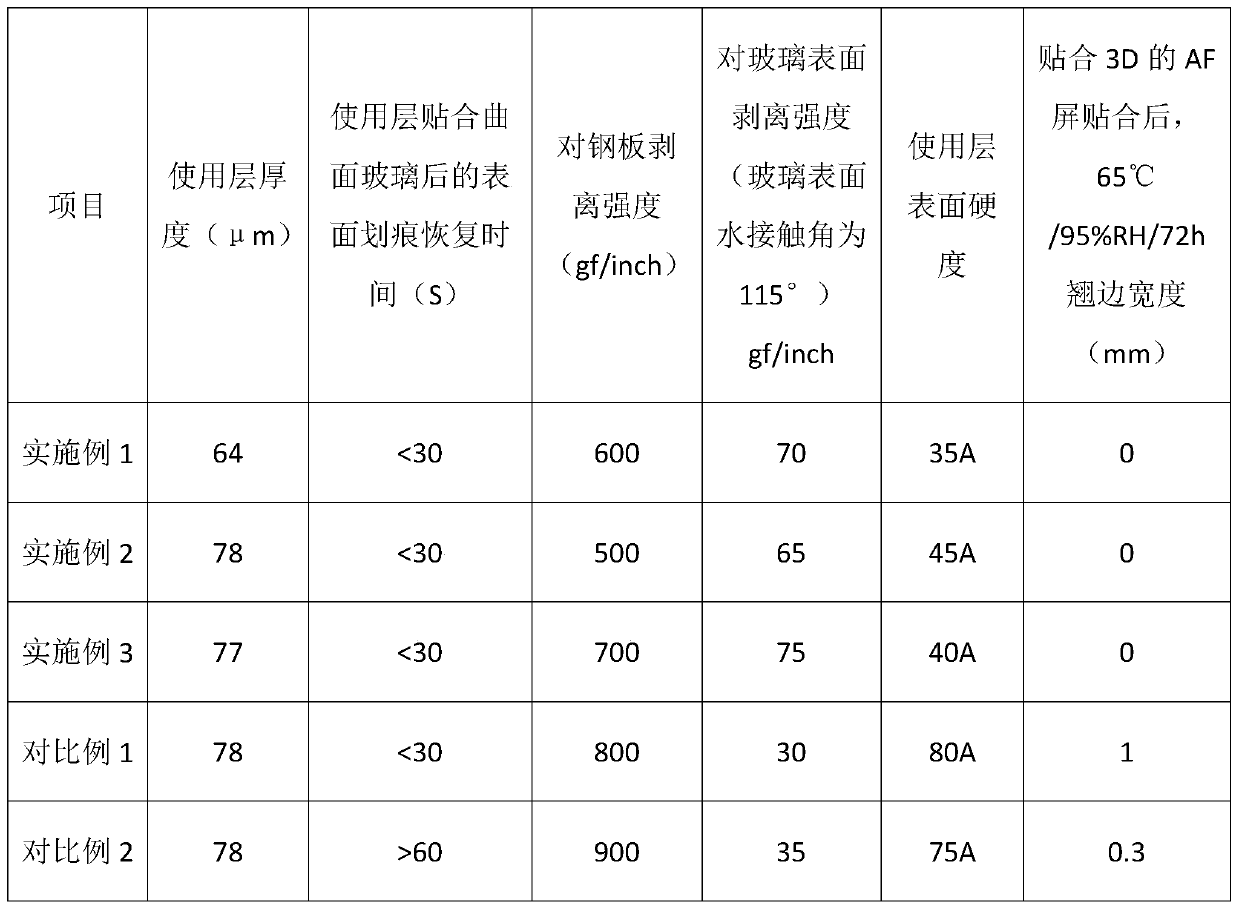

Examples

Embodiment 1

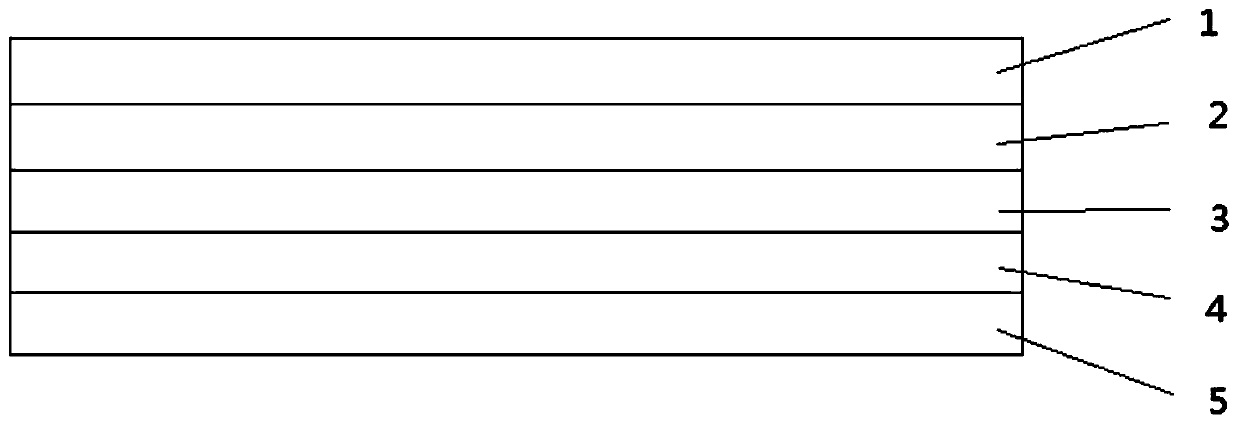

[0122] First, select a 50 μm thick PET release film 1, apply a 4 μm thick hardened coating solution on the release surface, bake at 80°C for 30s, and use a UV lamp of 500mJ / cm 2 After irradiating for 30s and curing, a hardened coating 2 is formed, and then the sample structure I is obtained;

[0123] Then, 40 μm of organic silica gel was coated on the hardened coating surface of the sample structure I, and the thickness of the glue was baked in an oven at 160 ° C for 30 seconds to form an organic silica gel layer 3 to obtain the sample structure II;

[0124] Then apply 20 μm silicone pressure-sensitive adhesive on the surface of the silicone layer 3 of the sample structure II, bake in an oven at 160°C for 30 seconds, and then irradiate with ultraviolet light (500mJ / cm 2 , irradiated for 50s) and then out of the oven to form a silicone pressure-sensitive adhesive layer 4, and then obtain the sample structure III, and then attach a 0.05mm fluorine release film 5. A finished str...

Embodiment 2

[0129] First, select a 50 μm thick PET release film 1, apply a 3 μm thick hardened coating solution on the release surface, bake at 80°C for 30s, and use a UV lamp of 500mJ / cm 2 After irradiating for 30s and curing, a hardened coating 2 is formed, and then the sample structure I is obtained;

[0130] Then, 50 μm of organic silica gel was coated on the hardened coating surface of the sample structure I, and the thickness of the glue was baked in an oven at 160 ° C for 30 seconds to form an organic silica gel layer 3 to obtain the sample structure II;

[0131] Then apply 25 μm silicone pressure-sensitive adhesive on the surface of the silicone layer 3 of the sample structure II, bake in an oven at 160°C for 30 seconds, and then irradiate with ultraviolet light (500mJ / cm 2 , irradiated for 50s) and then out of the oven to form a silicone pressure-sensitive adhesive layer 4, and then obtain the sample structure III, and then attach a 0.05mm fluorine release film 5. A finished str...

Embodiment 3

[0136] First, select a 50 μm thick PET release film 1, apply a 2 μm thick hardened coating solution on the release surface, bake at 80°C for 30s, and use a UV lamp of 500mJ / cm 2 After irradiating for 30s and curing, a hardened coating 2 is formed, and then the sample structure I is obtained;

[0137] Then, 45 μm of organic silica gel was coated on the hardened coating surface of the sample structure I, and the thickness of the glue was baked in an oven at 160 ° C for 30 seconds to form an organic silica gel layer 3 to obtain the sample structure II;

[0138] Then apply a 30 μm silicone pressure-sensitive adhesive on the surface of the silicone layer 3 of the sample structure II, bake in an oven at 160°C for 30 seconds, and then irradiate with ultraviolet light (500mJ / cm 2 , irradiated for 50s) and then out of the oven to form a silicone pressure-sensitive adhesive layer 4, and then obtain the sample structure III, and then attach a 0.05mm fluorine release film 5. A finished s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com