Flexible and pneumatic polishing method of silicon wafers

A silicon wafer polishing and flexible technology, used in surface polishing machine tools, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of fragile and high hardness of silicon wafers, and achieve the effect of easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

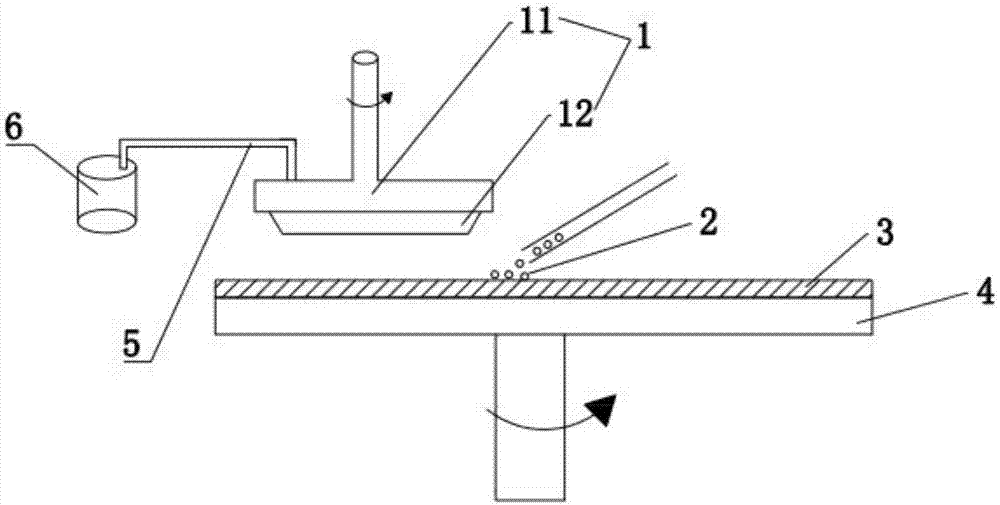

[0021] Embodiment: a kind of flexible pneumatic polishing method of silicon wafer, comprises the following steps: (1), silicon wafer 3 is fixed on the workbench 4 by waxing machine; Air, the air pressure is 10kpa; (3), rotate the flexible pneumatic polishing disc 1, inject polishing liquid 2 between the flexible pneumatic polishing disc 1 and the silicon wafer 3 simultaneously, and rotate the silicon wafer 3 to polish the silicon wafer 3; (4 ), repeat step (3) to polish, and the polishing time is 12min. The flexible pneumatic polishing disc plays the role of flexible polishing, improving the surface precision and flatness of silicon wafer polishing.

[0022] The polishing of the silicon wafer 3 is as follows: the silicon wafer 3 is rotated and polished with the rotation of the working table 4; the rotating speed of the flexible pneumatic polishing disc 1 is 45 rpm. The rotation speed of 45rpm is a suitable polishing speed during the polishing process of silicon wafers, which ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com