Corrugated cardboard core material

A technology for corrugated cardboard and core material, applied in the field of corrugated cardboard core material, can solve the problems of deterioration and damage of internal products, poor waterproof performance of corrugated cardboard, etc., and achieve the effects of strong aging resistance, long service life and good waterproof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A corrugated cardboard core material, the raw materials of which include by weight: 50-80 parts of modified natural rubber, 15-30 parts of butadiene rubber, 5-8 parts of nitrile rubber, 5-15 parts of thermoplastic elastomer SIS, ethoxylate Alkylated alkylphenol ammonium sulfate 5-8 parts, rosin-based resin acid 3-5 parts, polyether polyol 2-5 parts, carbon black 12-20 parts, C9 petroleum resin 8-15 parts, tridecyl ester 5- 8 parts, 5-10 parts of polydiphenylmethane diisocyanate, 2-5 parts of carboxymethyl chitosan, 2-5 parts of zinc oxide, 2-6 parts of sodium bentonite, 2-5 parts of bauxite, sea 1-2 parts of pumice fiber, 5-8 parts of sericin liquid, 3-5 parts of epoxy soybean oil, 2-8 parts of stearic acid, 4-8 parts of plasticizer, 2-5 parts of accelerator, softening 6-12 parts of curing agent, 2-5 parts of toughening agent, 10-15 parts of vulcanizing agent.

[0027] Further, the modified natural rubber is one or a combination of grafted natural rubber and epoxidized...

Embodiment 2

[0037] A method for preparing corrugated cardboard core material, comprising the following steps:

[0038](1) Mix the modified natural rubber, butadiene rubber, nitrile rubber, and thermoplastic elastomer SIS evenly, then add ethoxylated alkylphenol ammonium sulfate, rosin-based resin acid, polyether polyol, carbon black, C9 Petroleum resin, tridecyl ester, heat up to 130-135°C at a heating rate of 5°C / min, keep warm and mix for 15-30min, then add zinc oxide, sodium bentonite, bauxite, sepiolite fiber, sericin protein solution , epoxidized soybean oil, stearic acid, and continue to keep warm and mix for 5-10min to obtain material A;

[0039] (2) Add carboxymethyl chitosan and plasticizer to polydiphenylmethane diisocyanate, and heat up to 125-130°C at a heating rate of 5°C / min and mix for 10-15min, then add accelerator, Continue heat preservation and mixing for 5-10 minutes to obtain material B;

[0040] (3) Add material B, softener, and toughening agent to material A, mix t...

Embodiment 3

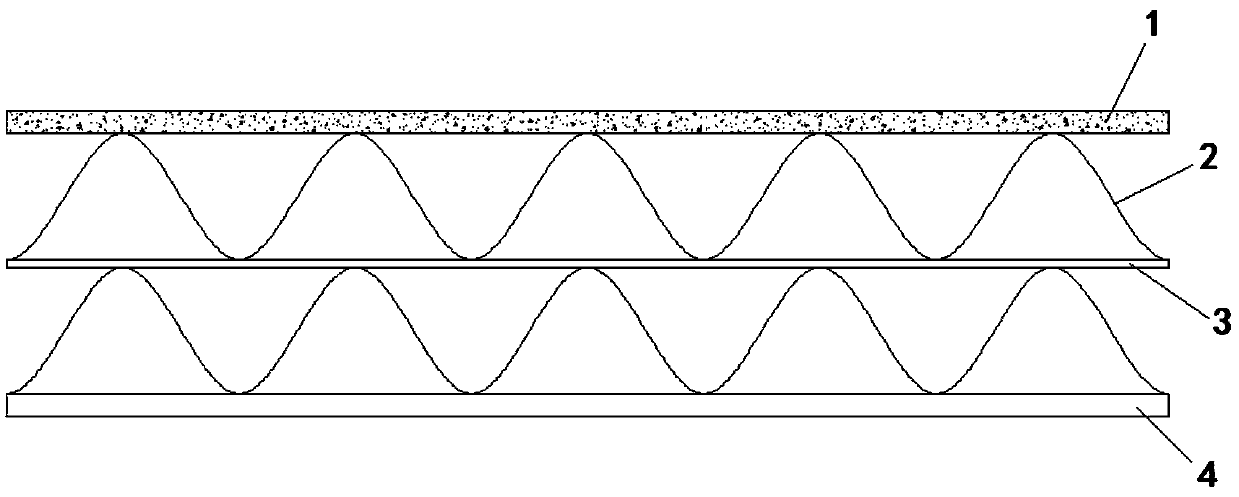

[0043] A waterproof corrugated cardboard, comprising surface paper 1, corrugated paper 2, core material 3 and inner paper 4, the corrugated paper 2 is provided with two layers in total, located on both sides of the core material 3, and the upper corrugated paper 2 is provided with a surface Paper 1, lining paper 4 is arranged below the corrugated paper 2 on the lower side, and the surface paper 1, corrugated paper 2, core material 3 and lining paper 4 are bonded by adhesive;

[0044] The core material 3 adopts the core material prepared by the present invention;

[0045] The adhesive is prepared from the following raw materials in parts by weight: 150 parts of starch, 15 parts of sodium bicarbonate, 12 parts of dodecyl dimethyl benzyl ammonium chloride, 6 parts of defoaming agent, 32 parts of bone glue, water 280 parts, 12 parts of isopropanol, 6 parts of nano-silica, 3 parts of lignocellulose, 4 parts of improver.

[0046] Further, the improving agent is formed by mixing glu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com