Method for reinforcing and restoring belt tyres

A technology of radial tires and tires, which is applied to tires, other household appliances, household appliances, etc., can solve problems such as tire bursts, achieve the effects of small carcass damage, low dependence on operating skills, and improved safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

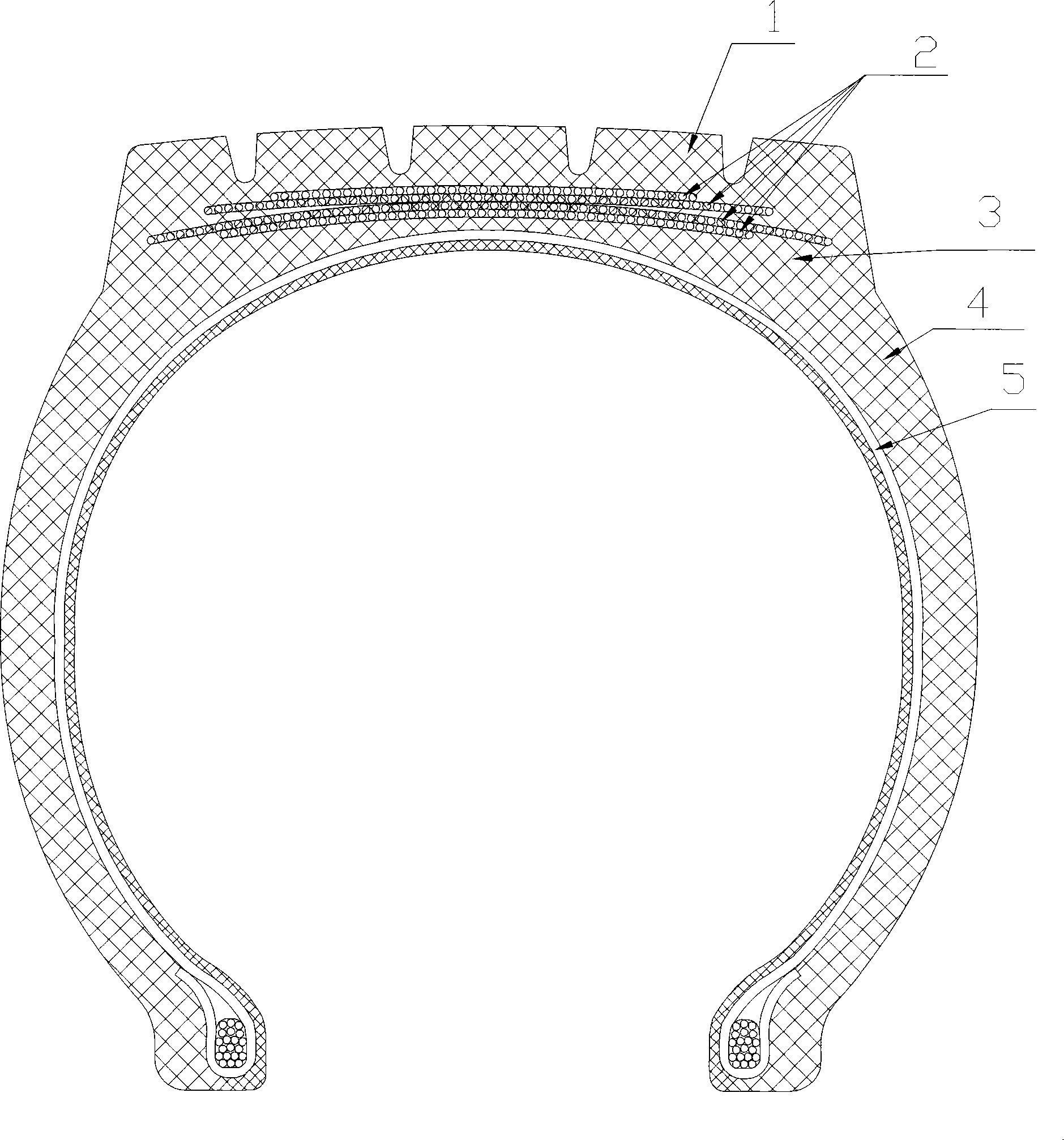

[0018] Embodiment 1, the carcass that has use value and the steel wire radial tire that the belt layer is damaged carry out reinforcement restoration, main method and step of the present invention are: 1, as shown in the accompanying drawing, start from tire tread 1 side According to the peeling position 3, cut between the tire carcass steel wire 5 and the belt layer 2, and stick to the belt layer 2, and peel off the worn tread 1 together with the belt layer 2, and the peeled off It is a ring-shaped tread; 2. Grinding the joint surface peeled off by the carcass 4; 3. Brushing the glue on the joint surface; 4. Applying adhesive glue; 5. Pre-vulcanized annular tire with belt layer 6. Carry out pressing, so that the carcass 4 and the precured annular tread containing the belt layer are combined well; 7. Put the pressed tire into the envelope, and put the vulcanized inner tube in the tire, and put it in the Vulcanized rim; 8. Put it into the vulcanization tank for vulcanization; 9...

Embodiment 2

[0019] Embodiment 2, the carcass that has use value and the steel wire radial tire that the belt layer is damaged is strengthened and restored, the main method and step of the present invention are: 1, as shown in the accompanying drawing, start from tire tread 1 side According to the peeling position 3, cut between the tire carcass steel wire 5 and the belt layer 2, and stick to the belt layer 2, and peel off the worn tread 1 together with the belt layer 2, and the peeled off It is a ring-shaped tread; 2. Grinding the combined surface of the carcass 4; 3. Brushing the glue on the combined surface; 4. Applying adhesive glue; 5. According to the belt layer material and specification of the original tire , Cord arrangement angle, number of layers blanking, sticking on the carcass 4 layer by layer, can also improve the belt layer of the original tire, such as changing the cord specification, arrangement angle, form, number of layers, etc.; 6, Apply adhesive glue on the belt layer...

Embodiment 3

[0020] Embodiment 3, the carcass is better and the steel wire radial tire of belt ply local damage is lighter is strengthened and refurbished, main method and step of the present invention are: 1, polish off old tread 1 on tire grinding machine; 2 1. Peel off the damaged belt layer 2; 3. Grind the stripped surface; 4. Apply glue; 5. Apply adhesive glue; 7. Brush glue on the whole tire grinding surface; 8. Apply adhesive glue; 9. Paste pre-vulcanized strip tread or set pre-vulcanized annular tread; 10. Press 11. Put the pressed tire into the enveloping sleeve, and put the vulcanized inner tube into the tire. On the vulcanized rim; 12. Put it into the vulcanization tank for vulcanization; 13. Finish. Complete the intensive reconditioning process of used tires.

[0021] In the above embodiments, if the vulcanization mold is used for vulcanization, the enveloping sleeve and the vulcanized rim are not used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com