Filter core

A filter and filter element technology, applied in the field of filter element, can solve the problems of cumbersome processing technology, complex structure, easy degumming, etc., and achieve the effect of simplifying processing technology, reducing product weight, and simplifying product structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

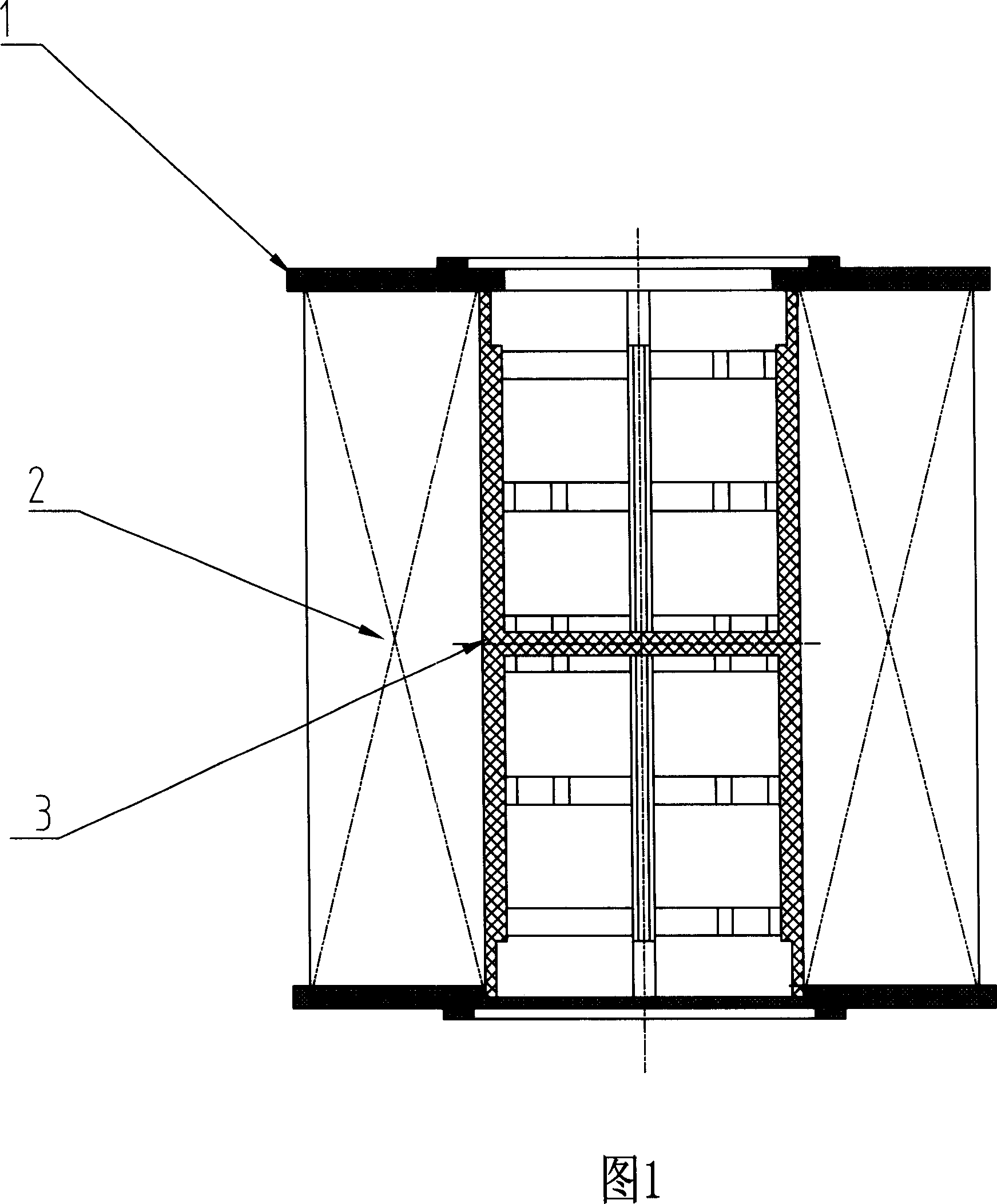

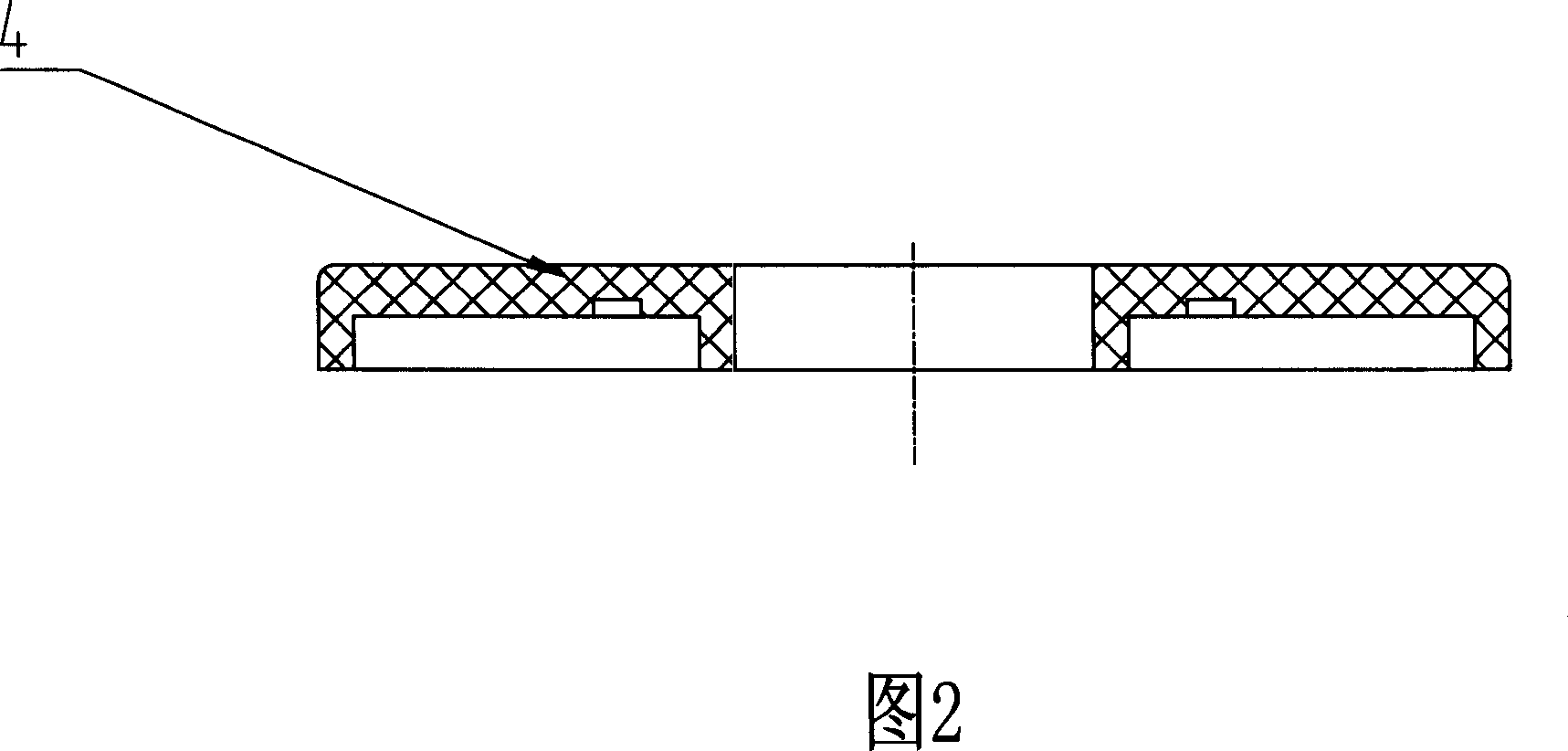

[0009] In Figure 1, mix the epoxy resin and curing agent evenly to make the epoxy resin into a liquid state, pour the liquid epoxy resin into the mold 4 in turn, and after a few minutes, insert the central tube 3 and the filter paper tube 2 into the liquid state In the epoxy resin, the epoxy resin is cured naturally to form the upper and lower end caps 1, 1' of the epoxy resin. The element is pulled out of mold 4, which replaces the end cap, adhesive and end cap seal with epoxy. In addition, an accessory O-ring is included in the accessory bag, so that the sealing ring on the assembly can be replaced when the filter element is replaced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com