Machine-washable wool suit and sewing method

A technology for washing wool and suits, which is applied in the field of machine-washable wool suits and sewing, and can solve the problems of easy deformation of suits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The application will be described in further detail below in conjunction with the accompanying drawings.

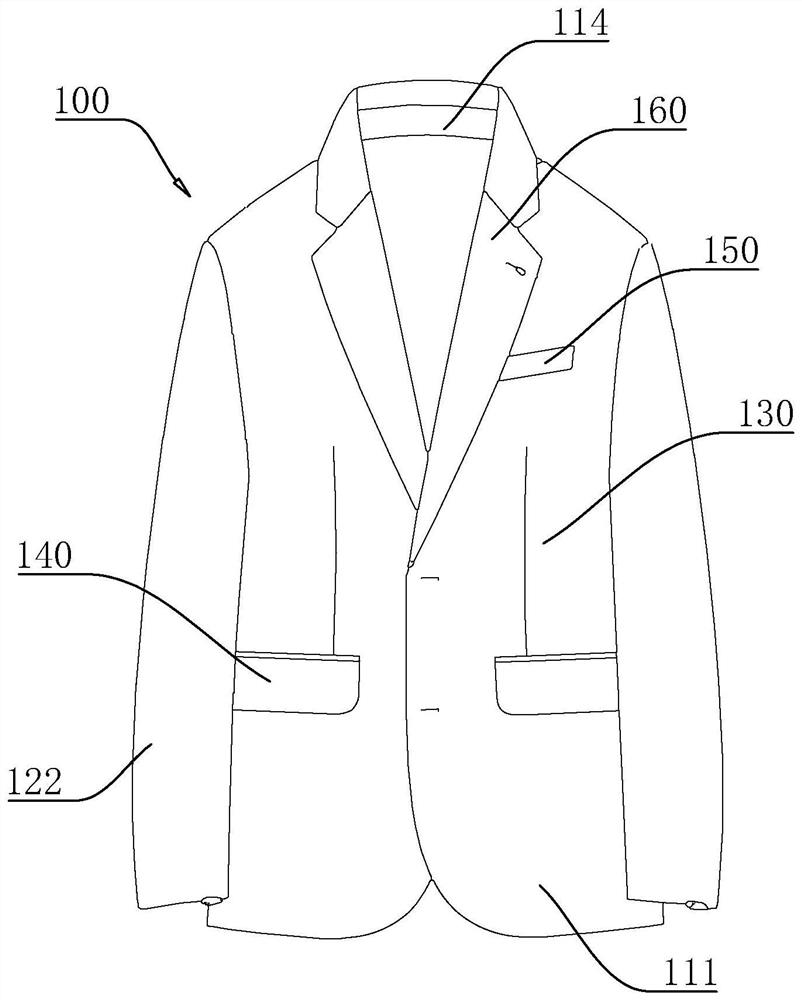

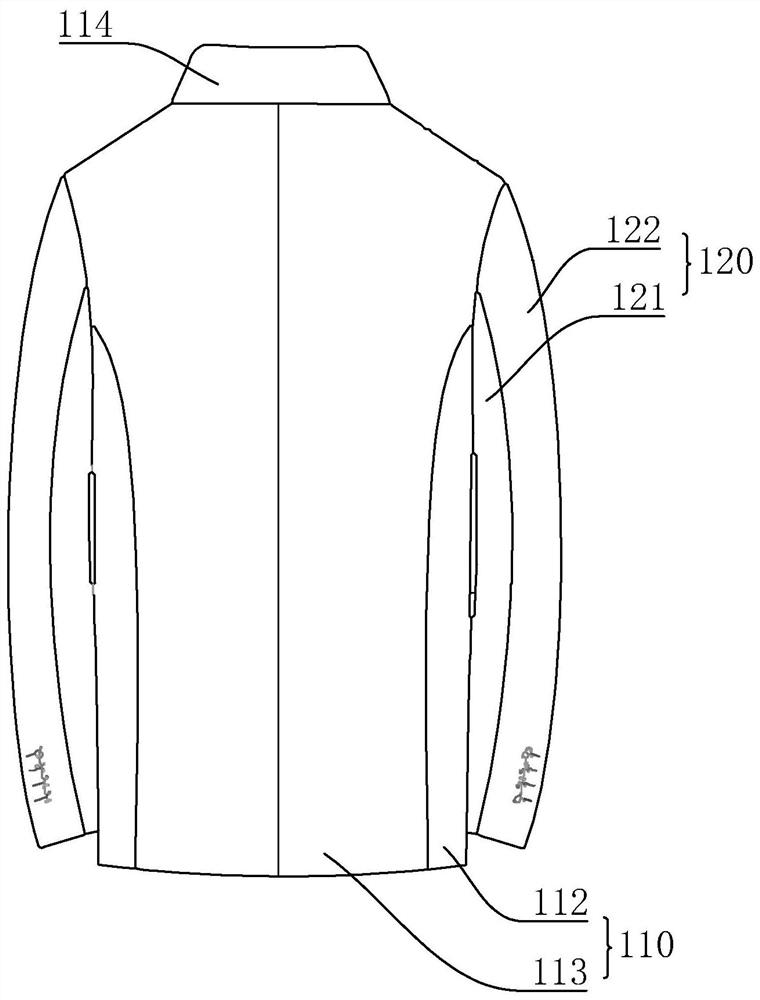

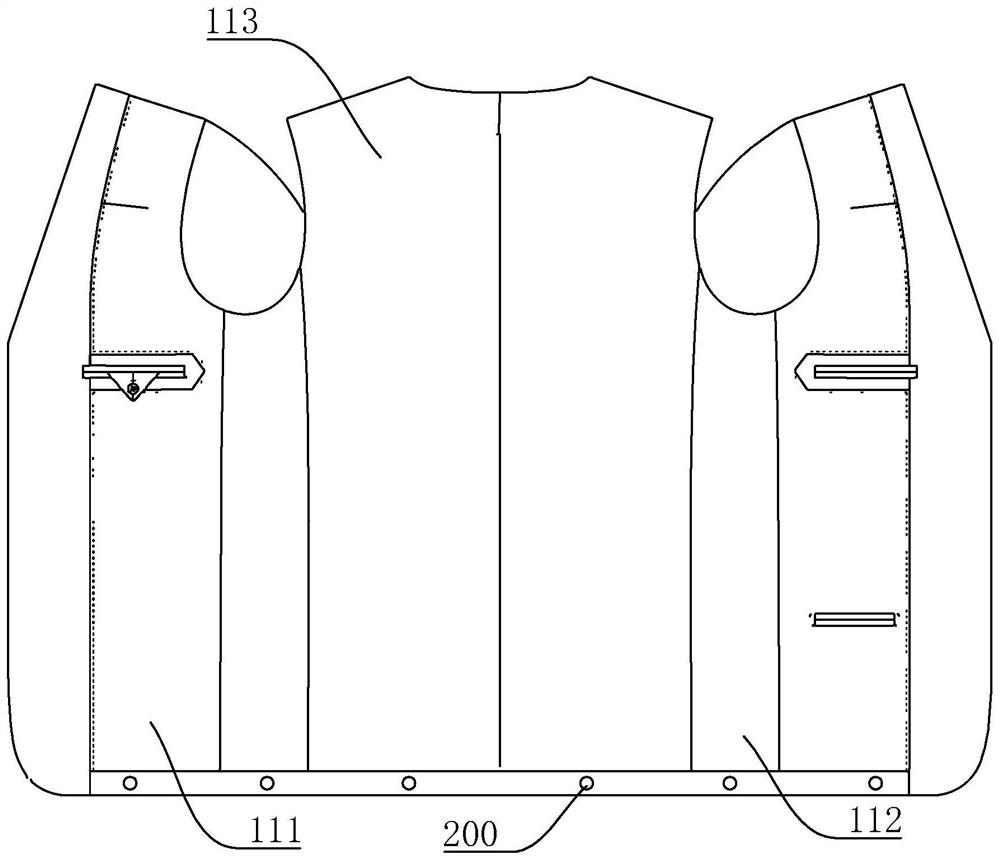

[0043] The embodiment of the present application discloses a machine washable suit, refer to figure 1 , figure 2 , comprising a suit body 100, the suit body 100 comprises a main body 110 and sleeves 120, wherein the main body 110 comprises a front garment piece 111, a side panel 112, a rear garment piece 113 and a collar 114, and the sleeve 120 comprises a small sleeve piece 121 and a large sleeve piece 122, the front garment piece 111 is symmetrically arranged with two pieces, the rear garment piece 113 is symmetrically arranged with two pieces, the side piece 112 is located between the front garment piece 111 and the rear garment piece 113 on each side, and the two rear garment pieces 113 pass through the back Seams are connected, and the front garment piece 111, the side panels 112, and the rear garment panel 113 are sewn sequentially. At the same time, the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com