Ultra-thin polyester double-sided adhesive tape, glue thereof, and preparation method thereof

A technology of double-sided tape and polyester, applied in the direction of adhesives, ester copolymer adhesives, film/sheet adhesives, etc., can solve the problems of non-differentiation, thick thickness, thick overall thickness of the tape, etc., to achieve Good temperature resistance and weather resistance, the effect of promoting polymerization reaction and speeding up the polymerization speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

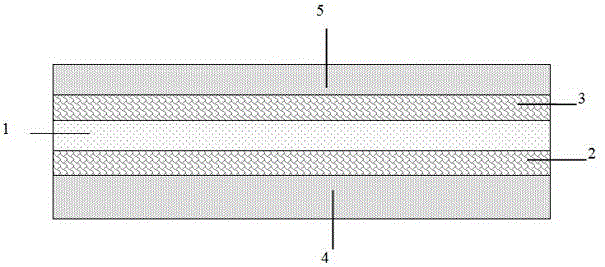

Image

Examples

preparation example Construction

[0051] The preparation method of the glue for the above ultra-thin polyester double-sided tape includes the following steps:

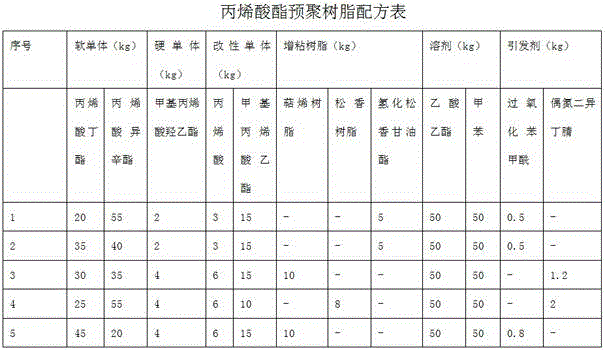

[0052] (1) Preparation of acrylate prepolymerized resin: accurately weigh each component raw material required for preparing acrylate prepolymerized resin, mix them uniformly to obtain a mixed solution, and first add 15-20% of the mixed solution to the reactor. Under the protection of nitrogen, heat to 80-90℃ to initiate the polymerization reaction, then slowly add the remaining mixture dropwise at a constant speed, and finish the dripping in 3-5h. During the whole dripping process, the temperature is controlled at 80-90℃; after the dripping is finished Keep the temperature for 2-4h, and control the temperature at 75-85℃; finally add ethyl acetate and mix evenly so that the solid content of the mixed liquid after the reaction reaches 30% to obtain an acrylic prepolymer resin with a solid content of 30%;

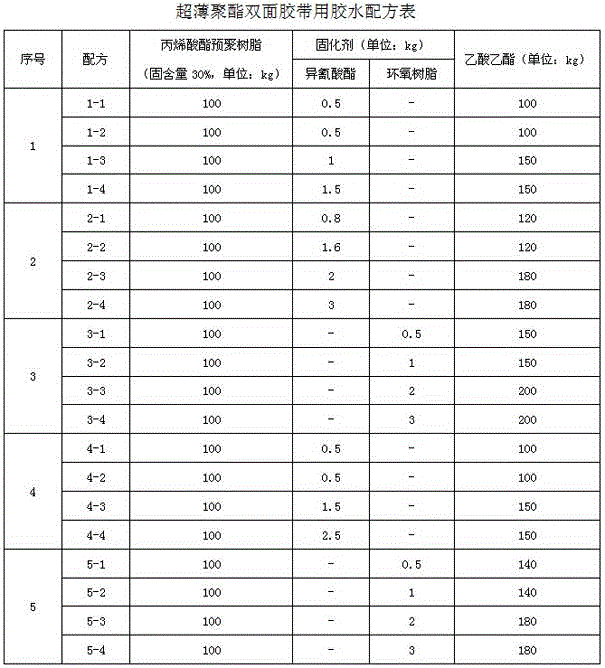

[0053] (2) Add 100 parts by weight of the acrylic pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com