Quick-setting two-component polyurethane structural adhesive as well as preparation method and application thereof

A two-component polyurethane and structural adhesive technology, which is applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve problems such as long service life, difficulty in meeting actual needs, and product explosion, and achieve improvement Toughness and adhesiveness, long balance operation time, and excellent fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

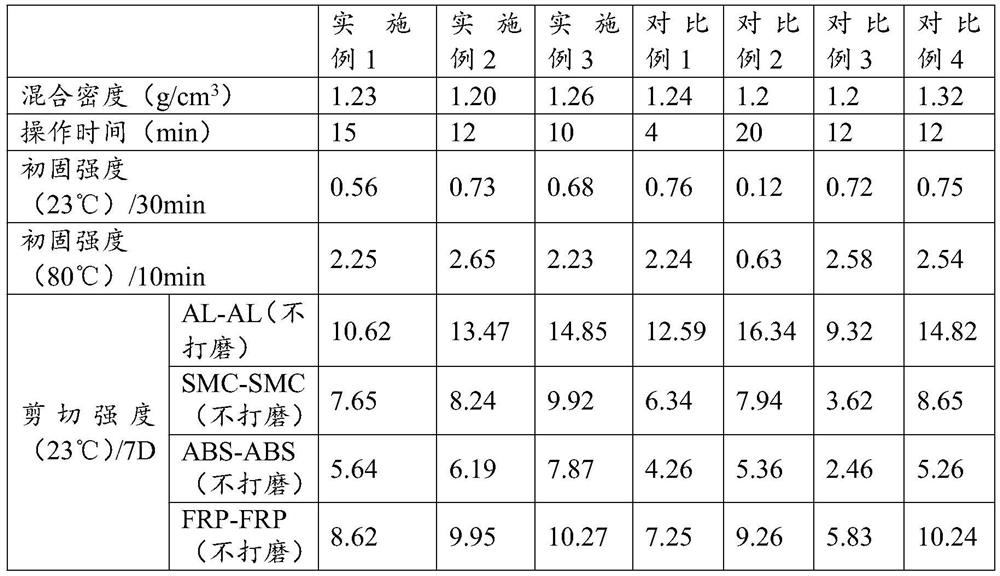

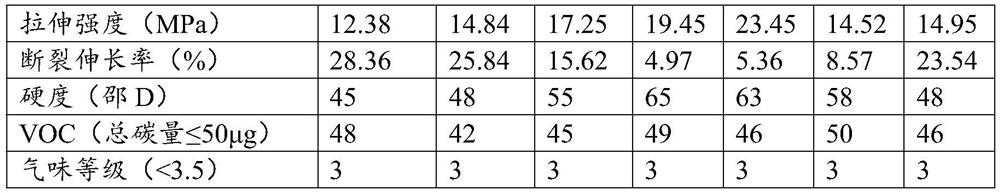

Examples

Embodiment 1

[0031] This embodiment provides a two-component polyurethane structural adhesive, including component A and component B, wherein component A is prepared from the following raw materials in parts by weight: 30 parts of castor oil, 5 parts of autocatalytic polyol (hydroxyl Value 712, relative molecular weight 394), 8 parts of liquid terpene resin (Guangzhou Songbao Chemical Co., Ltd.), 3 parts of coupling agent KH570, 0.1 part of thermal catalyst SA-1 (Evonik Chemical), 9 parts of carbon black N774 ( Cabot), 40 parts of nano calcium carbonate (Qingzhou Yuxin calcium industry), 2.4 parts of 4A molecular sieve and 2.5 parts of fumed silica H20 (Wacker). Component B is prepared from the following raw materials in parts by weight: 8 parts of plasticizer DINP, 30 parts of hydroxyl-terminated polybutadiene, 25 parts of MDI-100 (Wanhua Chemical), 10 parts of PM200 (Wanhua Chemical), 20 parts of nano calcium carbonate (Qingzhou Yuxin calcium industry), 1.2 parts of glass microspheres (p...

Embodiment 2

[0037] This embodiment provides a two-component polyurethane structural adhesive, including component A and component B, wherein component A is prepared from the following raw materials in parts by weight: 40 parts of castor oil, 10 parts of self-catalyzed polyol (hydroxyl Value 712, relative molecular weight 394), 6 parts of liquid terpene resin (Guangzhou Songbao Chemical Co., Ltd.), 2 parts of coupling agent KH570, 0.06 parts of thermal catalyst SA-1 (Evonik Chemical), 9.94 parts of carbon black N774 ( Cabot), 28 parts of nano-calcium carbonate, 3 parts of 4A molecular sieve, and 1 part of fumed silica H20 (Wacker). Component B is prepared from the following raw materials in parts by weight: 10 parts of plasticizer DINP, 20 parts of oil-modified polyester polyol PRIPLAST 3190, 25 parts of MDI-100 (Wanhua Chemical), 15 parts of PM200 (Wanhua Chemistry), 22 parts of nano-calcium carbonate, 1.5 parts of glass microspheres (particle size 10 μm), 3 parts of 4A molecular sieve an...

Embodiment 3

[0040] This embodiment provides a two-component polyurethane structural adhesive, including component A and component B, wherein component A is prepared from the following raw materials in parts by weight: 35 parts of castor oil, 15 parts of autocatalytic polyol (hydroxyl Value 712, relative molecular weight 394), 10 parts of liquid terpene resin (Guangzhou Songbao Chemical Co., Ltd.), 2.47 parts of coupling agent KH570, 0.03 parts of thermal catalyst SA-1 (Evonik Chemical), 7 parts of carbon black N774 ( Cabot), 25 parts of nano-calcium carbonate, 2 parts of 4A molecular sieve, and 3.5 parts of fumed silica H20 (Wacker). Component B is prepared from the following raw materials in parts by weight: 7 parts of plasticizer DINP, 25 parts of oil-modified polyester polyol PRIPLAST 3190, 30 parts of MDI-100 (Wanhua Chemical), 20 parts of PM200 (Wanhua Chemistry), 13 parts of nano-calcium carbonate, 1 part of glass microspheres (particle size 10 μm), 2 parts of 4A molecular sieve and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com