Casing pipe well cementing cement slurry system

A cement slurry and system technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., to achieve good thixotropic effect, reduce density, and control water loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

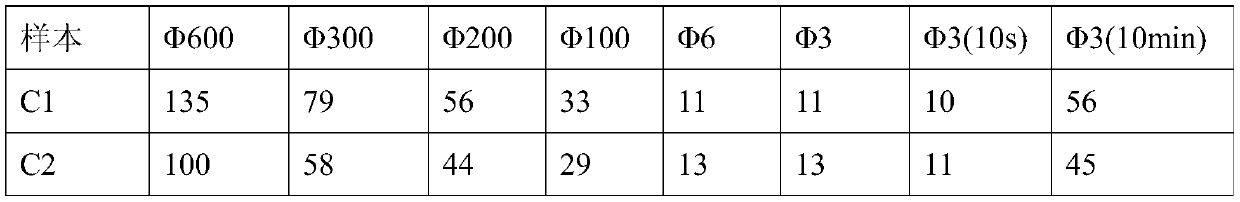

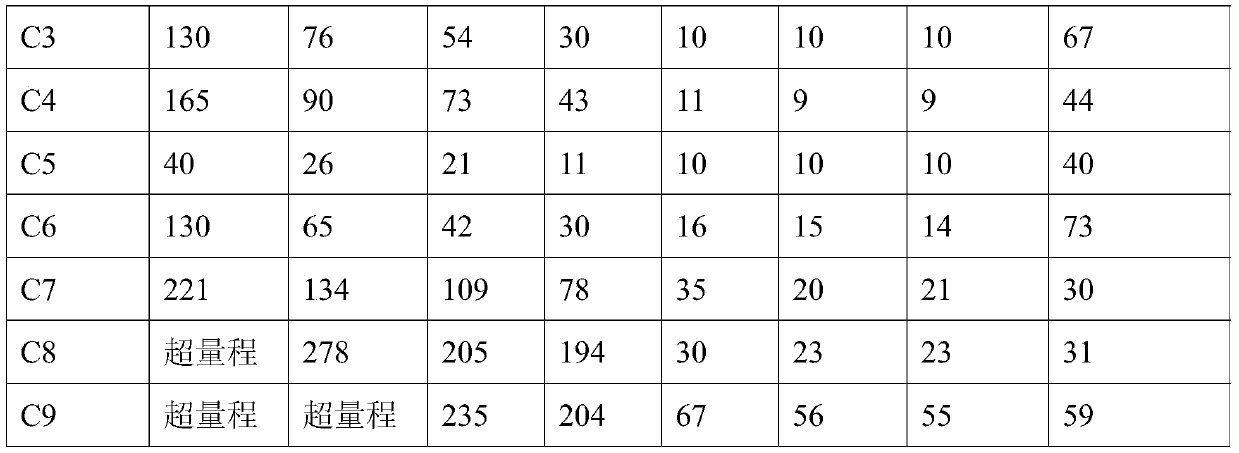

[0030] Embodiment 1 A kind of cement slurry system for casing cementing

[0031] The cement slurry system consists of the following components:

[0032] Gelling system: 4 parts of G-grade oil well cement, 3 parts of fly ash, 3 parts of slag; 2.5% of polyvinyl alcohol type fluid loss reducer in the weight of the gelling system, 0.16% of the oxidizing agent in the weight of the gelling system Zinc, a sulfonated aldehyde-ketone type dispersant accounting for 0.25% by weight of the gelling system, a spherical hydrogel accounting for 20% by weight of the gelling system, and adding water at a ratio of 0.56 by mass ratio of water to the gelling system. The cement slurry system is denoted as C1

[0033] The preparation method of described cement slurry system is:

[0034] Dry mix G-grade oil well cement, slag, fly ash, polyvinyl alcohol type fluid loss reducer, sulfonated aldehyde ketone type dispersant and zinc oxide, and wet mix the mixing water and spherical polyacrylamide hydrog...

Embodiment 2

[0035] Embodiment 2 A cement slurry system for casing cementing

[0036] The cement slurry system consists of the following components:

[0037] Gelling system: 4 parts of G-grade oil well cement, 3 parts of fly ash, 3 parts of slag; 2.5% of polyvinyl alcohol type fluid loss reducer in the weight of the gelling system, 0.16% of the oxidizing agent in the weight of the gelling system Zinc, a sulfonated aldehyde-ketone type dispersant accounting for 0.25% by weight of the gelling system, and a spherical hydrogel accounting for 30% by weight of the gelling system, adding water at a ratio of 0.56 by weight of water to the gelling system. The cement slurry system is recorded as C2

[0038] The preparation method of the cement slurry system is as described in Example 1.

Embodiment 3

[0039] Embodiment 3 A cement slurry system for casing cementing

[0040] The cement slurry system consists of the following components:

[0041] Gelling system: 4 parts of G-grade oil well cement, 3 parts of fly ash, 3 parts of slag; 2.5% of polyvinyl alcohol type fluid loss reducer in the weight of the gelling system, 0.32% of the oxidizing agent in the weight of the gelling system Zinc, a sulfonated aldehyde-ketone type dispersant accounting for 0.25% by weight of the gelling system, a spherical hydrogel accounting for 20% by weight of the gelling system, and adding water at a ratio of 0.56 by mass ratio of water to the gelling system. The cement slurry system is recorded as C3

[0042] The preparation method of the cement slurry system is as described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com