Pigment dispersing agent, pigment composition and pigment dispersion

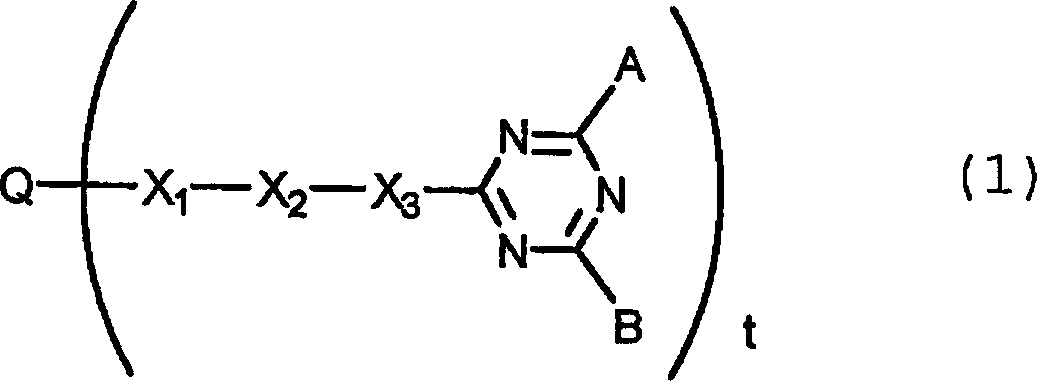

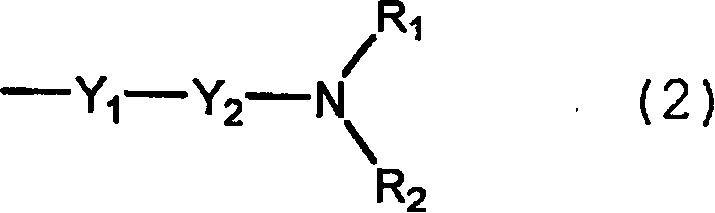

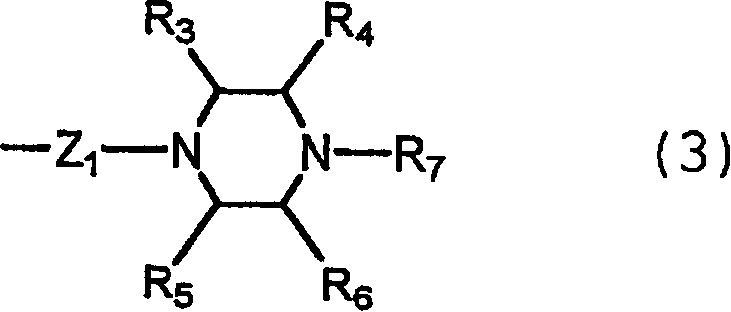

一种颜料组合物、颜料分散剂的技术,应用在颜料分散剂领域,能够解决降低商业价值、着色力降低、色调改变等问题,达到涂膜光泽和透明性低、低触变性、高透明度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0108] For the method of preparing the pigment composition of the present invention, sufficient dispersion effect can be obtained only by mixing the pigment powder and the pigment dispersant powder of formula (1). Higher dispersing effect can be obtained by the following methods: using dissolver, high-speed mixer, homogeneous mixer, kneader, rolling mill, grinder, sand mill, pulverizer, etc.; formula (1) The solution of the pigment dispersant is added to the suspension of the pigment in water or an organic solvent and the pigment dispersant is deposited on the surface of the pigment; the organic pigment and the pigment dispersant are dissolved in a solvent with strong solubility (such as sulfuric acid) , and pour the resulting solution into a weak solvent such as water for co-precipitation.

[0109] The pigment dispersion of the present invention is prepared by dispersing a mixture of a pigment, a pigment dispersant, an organic solvent, and a resin (varnish) with a disperser. ...

preparation example 1

[0117] Preparation Example 1

[0118]540 grams of benzoic acid were added to the stirred vessel, which was then heated to 130°C to melt it. 34 grams of quinaldine and 204 grams of tetrachlorophthalic anhydride were added to the molten benzoic acid. The reaction vessel was heated to 160 °C and the mixture was stirred for 10 hours. Then, the temperature was lowered to 130° C., and 950 g of 25%-sodium hydroxide aqueous solution was added. The resulting suspension was poured into 10 liters of water, which was heated to 80° C. and stirred for 1 hour. The suspension was filtered off with suction and washed with water until the filtrate became neutral. Then, drying was performed to obtain 89 g (91%) of quinolinophthalone derivative A represented by formula (16).

[0119]

preparation example 2

[0120] Preparation Example 2

[0121] 204 grams of tetrachlorophthalic anhydrides were changed into 139 grams of trimellitic anhydrides, and the heating time at 160° C. was changed to 24 hours, and 65 grams (86% ) quinolinophthalone derivative B represented by formula (17).

[0122]

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com