Art renewal lacquer and preparation method thereof

A radiant and artistic technology, applied in the field of artistic radiant paint and its preparation, can solve the problems of poor acid and alkali resistance, low hiding power, poor wear resistance, etc., achieve good barrier effect, smooth construction effect, and prolong drying time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

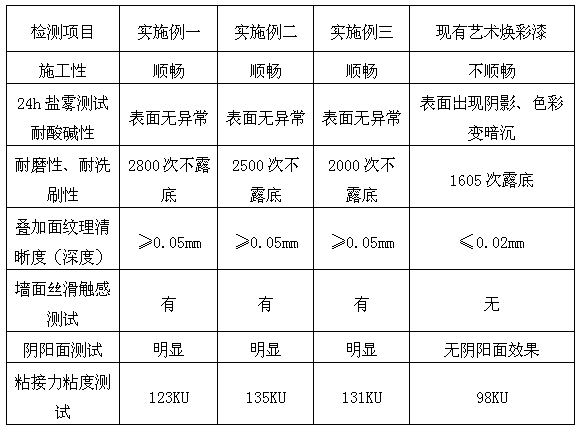

Examples

Embodiment 1

[0030] Example 1: 1 gram per serving

[0031] A kind of art rejuvenating paint, it is made according to weight part by following component: deionized water: 480 grams, dispersant: 3 grams, wetting agent 3 grams, preservative 3 grams, defoamer 6 grams , 22 grams of propylene glycol, 3 grams of slow drying agent, 3 grams of inorganic bentonite, 7 grams of film-forming aids, 4 grams of cellulose, mica powder: 82 grams, frosting powder: 10 grams, pearl powder: 240 grams, multifunctional additives : 3g, floating liquid 258g, wax emulsion 22g, antiseptic and antifungal agent: 2g, mixed thickener 15g.

[0032] In one embodiment, the dispersant is acrylic acid homopolymer.

[0033] In one embodiment, the wetting agent is a surfactant.

[0034] In one of the embodiments, the preservative is a Cathone type preservative.

[0035] In one embodiment, the defoamer is a mineral oil defoamer.

[0036] In one embodiment, the slow drying agent is made of glycerin with a purity of 99%.

[0...

Embodiment 2

[0046] Example 2: 1 catties per serving

[0047] An artistic glow paint, which is made of the following components in parts by weight: deionized water: 485 catties, dispersant: 8 catties, wetting agent 6 catties, preservative 4 catties, defoamer 9 catties , 24 catties of propylene glycol, 4 catties of slow-drying agent, 2 catties of inorganic bentonite, 11 catties of film-forming aids, 7 catties of cellulose, mica powder: 84 catties, frosting powder: 13 catties, pearl powder: 265 catties, multi-functional additives : 7 jin, floating liquid 263 jin, wax emulsion 23 jin, anticorrosion and antifungal agent: 5 jin, mixed thickener 18 jin.

[0048] In one embodiment, the dispersant is acrylic acid homopolymer.

[0049] In one embodiment, the wetting agent is a surfactant.

[0050] In one of the embodiments, the preservative is a Cathone type preservative.

[0051] In one embodiment, the defoamer is a mineral oil defoamer.

[0052] In one embodiment, the slow drying agent is made ...

Embodiment 3

[0062] Embodiment three: 1 kilogram per serving

[0063] An artistic glow paint, which is made of the following components in parts by weight: deionized water: 488 kg, dispersant: 5 kg, wetting agent: 5 kg, preservative: 2 kg, defoamer : 7 kg, propylene glycol: 21 kg, slow drying agent: 2 kg, inorganic bentonite: 4 kg, film-forming aid: 9 kg, cellulose: 6 kg, mica powder: 81 kg, frosting powder: 8 kg, pearl powder : 296 kg, multifunctional additives: 5 kg, floating liquid: 268 kg, wax emulsion 24 kg, anti-corrosion and anti-mold agent: 8 kg, mixed thickener 18 kg.

[0064] In one embodiment, the dispersant is acrylic acid homopolymer.

[0065] In one embodiment, the wetting agent is a surfactant.

[0066] In one of the embodiments, the preservative is a Cathone type preservative.

[0067] In one embodiment, the defoamer is a mineral oil defoamer.

[0068] In one embodiment, the slow drying agent is made of glycerin with a purity of 99%.

[0069] In one embodiment, the mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com