Thermally conductive silicone composition

A silicone and thermal conductivity technology, which is applied in the field of thermal conductive silicone compositions, can solve the problems of high thixotropy and poor fluidity, and achieve the effects of low thixotropy, low specific gravity and excellent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

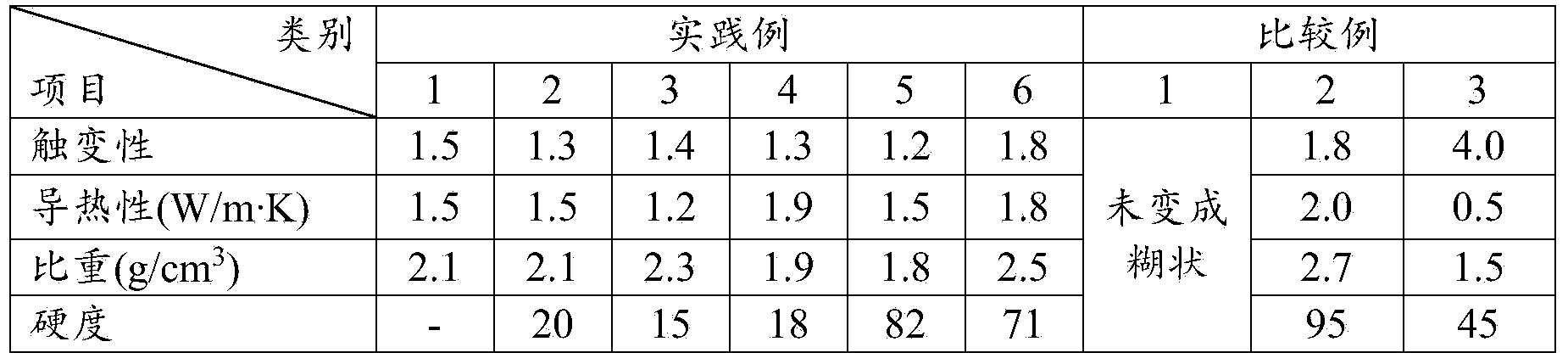

[0034] The following usage examples give a detailed description of the thermally conductive silicone composition of the present invention. It should be noted that the properties cited in the examples are values obtained at 25°C. In addition, the characteristics of the thermally conductive silicone composition were measured as follows.

[0035] [Hardness of silicone rubber]

[0036] A thermally conductive silicone rubber was prepared by heating the thermally conductive silicone rubber composition at 150° C. for one hour. The hardness of the silicone rubber was measured using a type A durometer in accordance with the regulations described in JIS K 6253-1997 (hardness testing method for rubber, vulcanized and thermoplastic (hardness testing method for vulcanized and thermoplastic rubber)).

[0037] [Viscosity and Thixotropy of Thermally Conductive Silicone Composition]

[0038] The viscosity of the thermally conductive silicone composition was measured using a rheometer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com