Mesoporous silica nanomotor, and preparation method and application thereof

A kind of mesoporous silica and nanotechnology, which is applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problem of large motor size, etc., and achieve the effect of large synthesis amount, simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

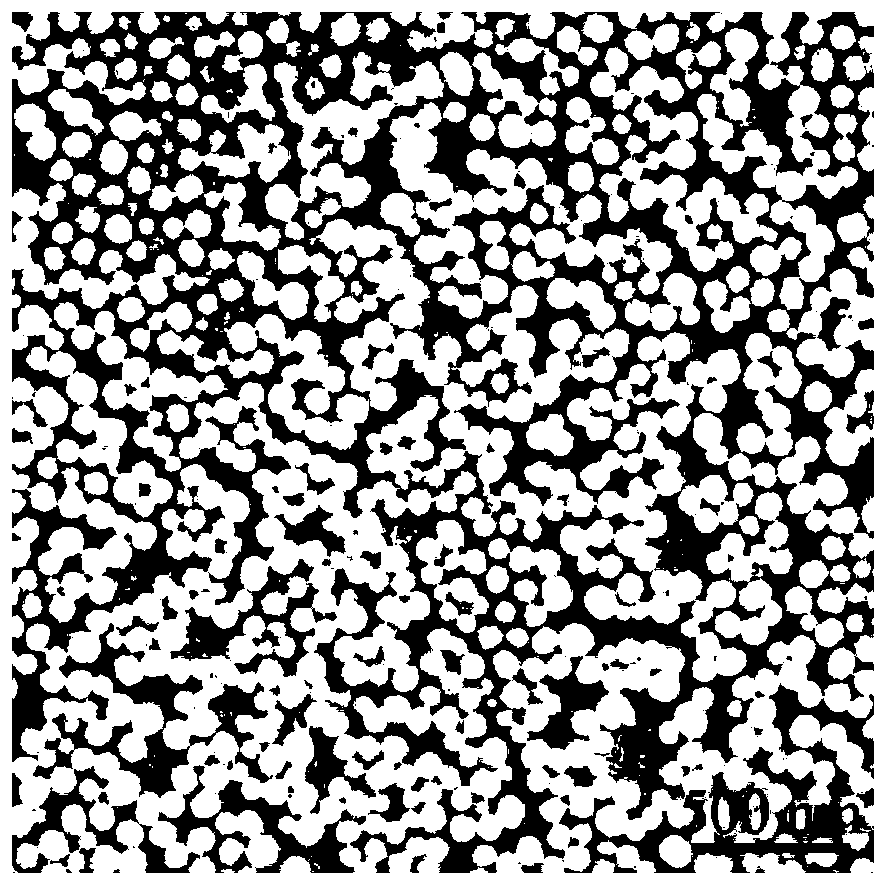

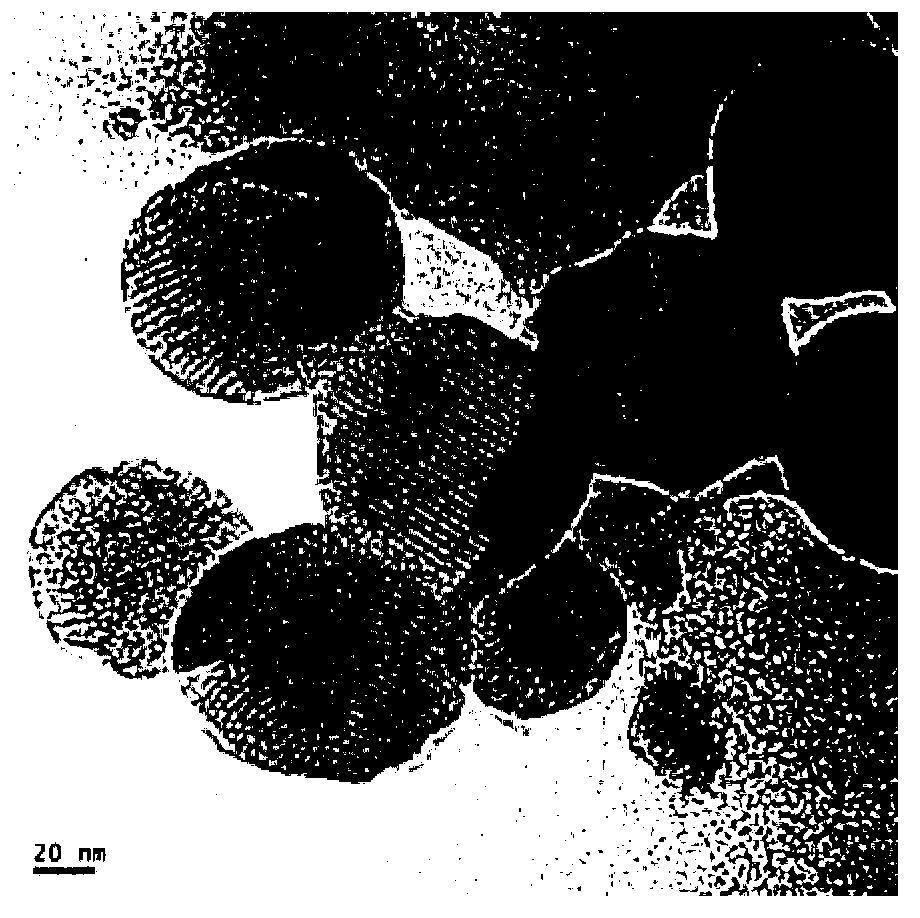

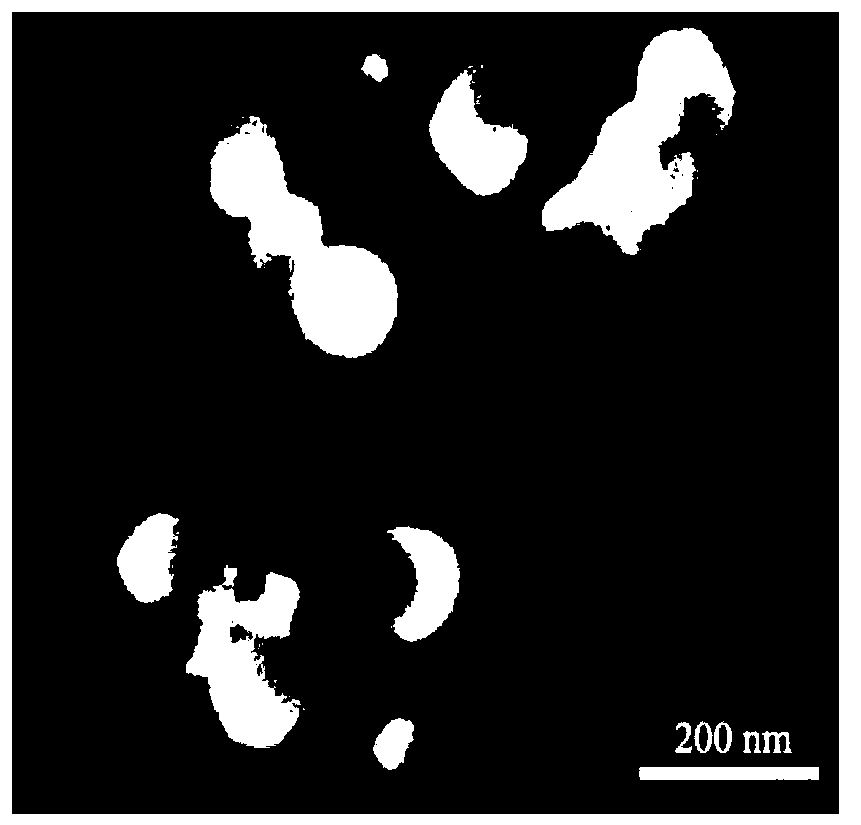

[0026] Embodiment 1: The mesoporous silica nanomotor of this embodiment is a mesoporous silica particle with a particle diameter of 50-90 nm and partially covered with a metal platinum layer.

[0027] The mesoporous silica nanomotor of this embodiment not only has an asymmetric mesoporous silica structure, but also has obvious yin and yang characteristics, a part of which has a metal layer with a catalytic function, and the other part has a mesoporous structure. The loaded substances can be loaded in the mesopores of silica nanoparticles, and hydrogen peroxide is catalyzed to generate oxygen bubbles as a driving force, so that they can move in the solution containing hydrogen peroxide and transport the loaded substances to the destination. The mesoporous silica nanomotor can not only be used to transport materials, but also has spontaneous transport power.

specific Embodiment approach 2

[0028] Embodiment 2: The preparation method of the mesoporous silica nanomotor described in Embodiment 1 is carried out in the following steps:

[0029] 1. Synthesis of mesoporous silica nanoparticles with a particle size of 50-90nm;

[0030] 2. Silicon wafer cleaning and hydrophilic treatment: first place the silicon wafer in acetone and alcohol for ultrasonic cleaning, then rinse it with deionized water, dry it with nitrogen, and then put the silicon wafer into concentrated sulfuric acid In a mixed solution with hydrogen peroxide, heat to a temperature of 60°C to 70°C and keep it for 2 to 3 hours, then take out the silicon wafer, rinse it with deionized water and dry it to obtain a hydrophilic silicon wafer, in which concentrated sulfuric acid The mixed solution with hydrogen peroxide is formed by mixing concentrated sulfuric acid with a mass concentration of 95% to 98% and hydrogen peroxide with a mass concentration of 20% to 30% in a volume ratio of (2 to 3): 1 ;

[0031...

specific Embodiment approach 3

[0035] Specific embodiment three: the difference between this embodiment and specific embodiment two is that the preparation method of step one mesoporous silica particles is carried out according to the following steps: first dissolve 0.25g~0.5g cetyltrimethylammonium bromide In 150mL~180mL of deionized water, add 1mL~2.0ml of sodium hydroxide solution with a concentration of 2mol / L~4mol / L, mix well and heat to 60~80℃, then add 1.5~2.0mL of ethyl orthosilicate After the reaction mixture was stirred at 60-80°C for 2-4 hours, the product was washed with methanol and deionized water, and vacuum-dried at 40-70°C for 10-12 hours to obtain mesoporous silica particle. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com