Movement method of micro-nano motor and directional movement model of micro-nano motor

A directional motion, micro-nano technology, applied in nanotechnology, nanotechnology, nanotechnology for sensing, etc., can solve problems such as the inability to realize directional motion of micro-nano motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This embodiment provides a micro-nano motor, and the preparation process of the micro-nano motor is as follows:

[0043] (1) Take an appropriate amount of SiO with a diameter of 1 μm 2 Microsphere solution in a centrifuge tube, centrifuge;

[0044] (2) Add appropriate amount of ethanol and ultrasonically disperse to obtain SiO 2 ethanol dispersion;

[0045] (3) The dispersed SiO 2 The ethanol dispersion was spread flat on the glass slide, and after the ethanol volatilized, it was placed in a plasma sputtering apparatus for magnetron sputtering. The target material was Au, and the SiO 2 One side surface of the microsphere is sputtered to form an Au layer, the sputtering pressure is 2.0Pa, and the time is 3min;

[0046] (4) After the sputtering is completed, take out the glass slide and ultrasonically obtain the Au-SiO with Janus structure 2 micro-nanomotor.

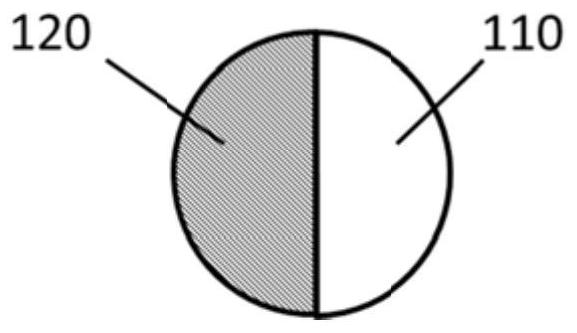

[0047] The structure of the micro-nanomotor is as follows figure 1 As shown, it includes a microsphere 110...

Embodiment 2

[0054] This embodiment provides a micro-nano motor, and the preparation process of the micro-nano motor is as follows:

[0055] (1) Take an appropriate amount of SiO with a diameter of 3 μm 2 Microsphere solution in a centrifuge tube, centrifuge;

[0056] (2) Add appropriate amount of ethanol and ultrasonically disperse to obtain SiO 2 ethanol dispersion;

[0057] (3) The dispersed SiO 2 The ethanol dispersion was spread flat on the glass slide, and after the ethanol volatilized, it was placed in a plasma sputtering apparatus for magnetron sputtering. The target material was Au, and the SiO 2 One side surface of the microsphere is sputtered to form an Au layer, the sputtering pressure is 2.0Pa, and the time is 5min;

[0058] (4) After the sputtering is completed, take out the glass slide and ultrasonically obtain the Au-SiO with Janus structure 2 micro-nanomotor.

[0059] The structure of the micro-nanomotor is as follows figure 1 As shown, it includes a microsphere 110...

Embodiment 3

[0066] This embodiment provides a micro-nano motor, and the preparation process of the micro-nano motor is as follows:

[0067] (1) Take an appropriate amount of SiO with a diameter of 5 μm 2 Microsphere solution in a centrifuge tube, centrifuge;

[0068] (2) Add appropriate amount of ethanol and ultrasonically disperse to obtain SiO 2 ethanol dispersion;

[0069] (3) The dispersed SiO 2 The ethanol dispersion was spread flat on the glass slide, and after the ethanol volatilized, it was placed in a plasma sputtering apparatus for magnetron sputtering. The target material was Au, and the SiO 2 One side surface of the microsphere is sputtered to form an Au layer, the sputtering pressure is 2.0Pa, and the time is 7min;

[0070] (4) After the sputtering is completed, take out the glass slide and ultrasonically obtain the Au-SiO with Janus structure 2 micro-nanomotor.

[0071] The structure of the micro-nanomotor is as follows figure 1 As shown, it includes a microsphere 110...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com