Method of transporting inert particles by using micro-nano motor cluster

A micro-nano particle, inert particle technology, applied in individual particle analysis, particle and sedimentation analysis, measuring devices, etc., can solve problems such as restricting operability and practical application, and achieve a wide range of applications, high control accuracy, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

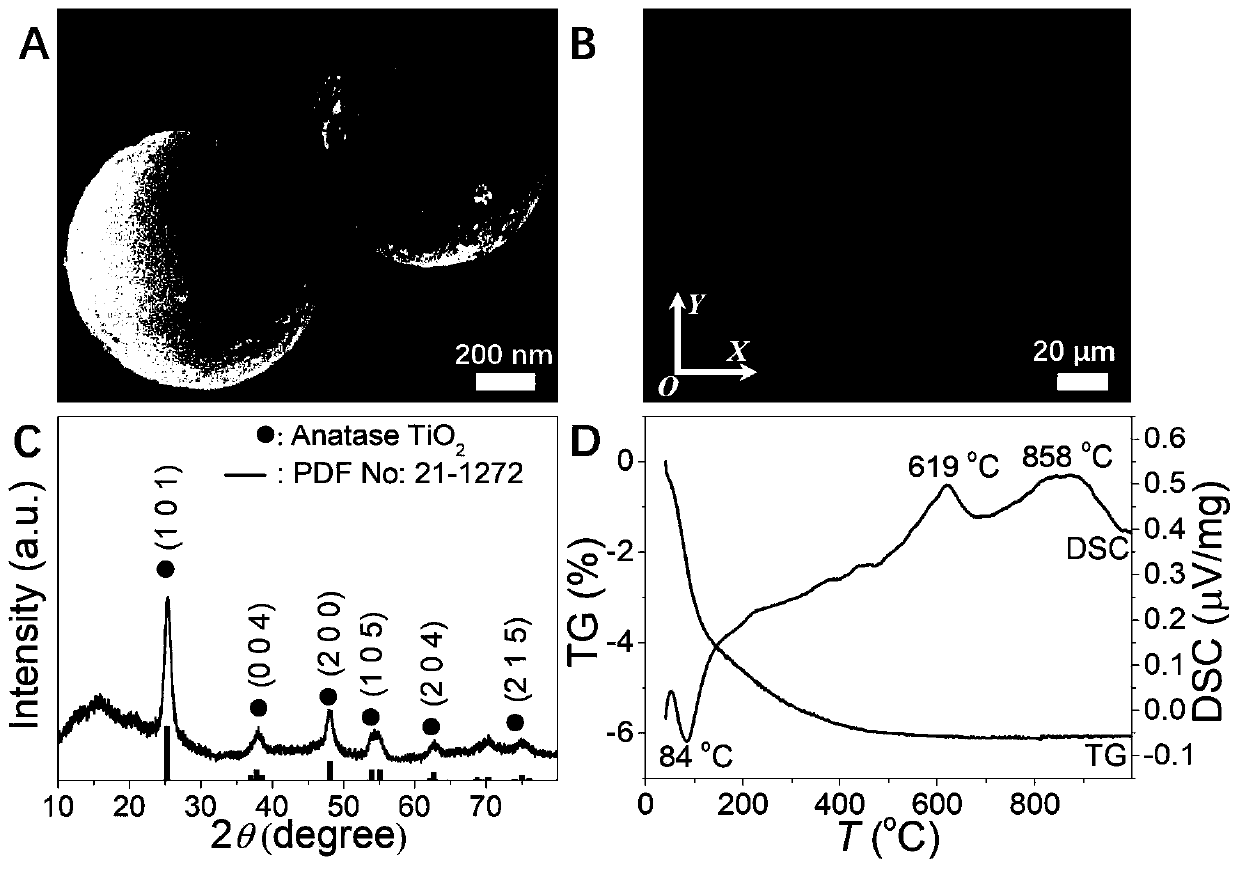

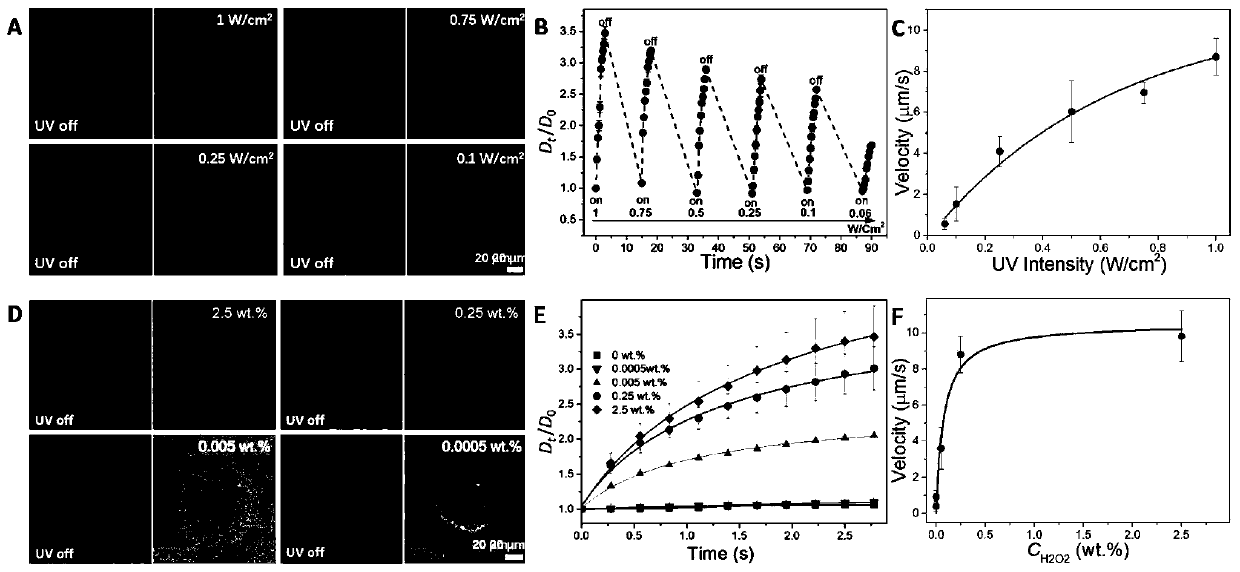

[0036] An isotropic TiO based 2 Cluster construction and phototactic motion control methods for micromotors:

[0037] Isotropic anatase TiO 2 Spherical microparticles, which are dispersed in deionized aqueous solution to form a particle suspension of 0.35mg / ml. Take a small amount of particle suspension and disperse it into a certain concentration of hydrogen peroxide fuel (0.25wt.%), and wait for about 1-5 minutes to obtain micron motor clusters formed by self-aggregation. Build a lighting platform, set the angle between the light and the horizontal plane as β (0°≤00.06W), and precisely control the TiO by controlling the light switch and light direction 2 Motion directions and trajectories of micromotor clusters.

[0038] Using a scanning electron microscope (SEM, S-4800, Hitachi Co., Ltd., Japan), an inverted fluorescence microscope (Leica DM 3000B), an X-ray diffraction analyzer (XRD Bruker D8 Advance X-ray diffractometer) and a thermogravimetric analyzer (NETZSEC, STA-...

Embodiment 2

[0051] The TiO that constructs cluster in embodiment 1 2 Micron particles were replaced by P25 (25nm) nano TiO 2 and large-sized TiO prepared by microemulsion method 2 For micron particles (5-20 μm), the two are respectively dispersed in deionized aqueous solution to form a particle suspension with a certain concentration. A small amount of particle suspension was dropped onto a glass substrate, and the particle aggregation was characterized by a fluorescence microscope (Leica DM3000B). The result is as Figure 10 shown

Embodiment 3

[0053] Adjust the particle suspension concentration in Example 1 to 0.15, 0.5, 0.75mg / ml respectively, repeat the steps of Example 1 above to obtain TiO 2 Micro-motor clusters, using a fluorescence microscope (Leica DM 3000B) to characterize particle aggregation, such as Figure 11 As shown, it shows that when the particle concentration is higher than 0.15mg / ml, clusters of different sizes can be obtained, and the higher the particle concentration, the larger the cluster size obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com