Sintered device

A nanoparticle and inorganic film technology, which is applied in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of difficult single-layer deposition to prepare nanoparticle films, limitations, etc., and achieve the effect of high charge mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

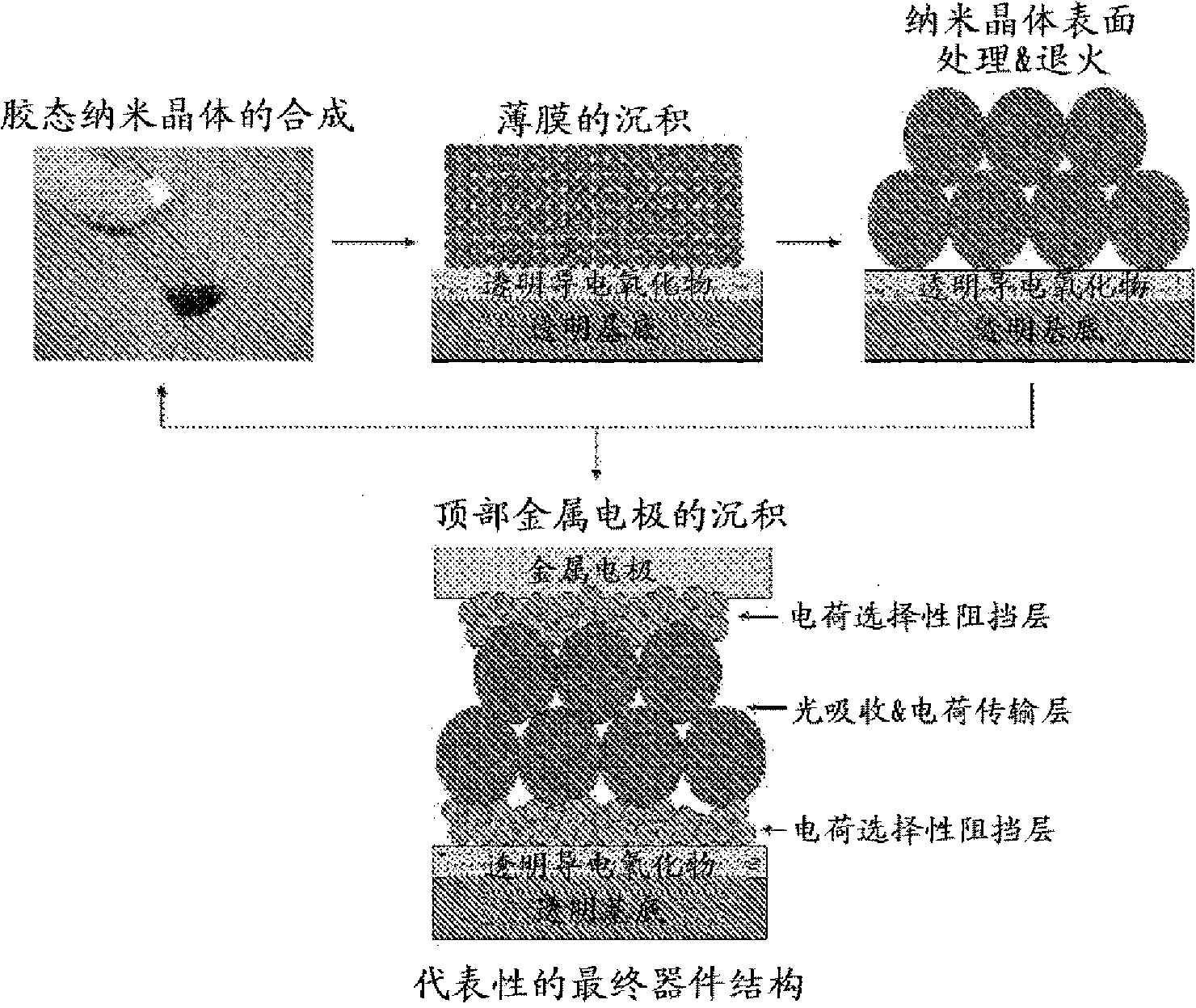

[0233] Layer-by-layer preparation method of solar cells

[0234] figure 1 A general schematic for the preparation of solution-processed inorganic solar cells using a layer-by-layer technique is shown in . This technique begins by synthesizing a dispersion of nanoparticles of the desired composition by any of the acceptable synthetic methods existing in the art. Synthetic nanoparticles dispersed in their growth solution are purified by filtration, centrifugation or extraction, and combinations thereof. After purification, it may be necessary to alter the surface chemistry of the nanoparticles to ensure dispersion in a solvent compatible with multilayer deposition. The nature of the solvent can depend on the specific processing conditions for the deposited film, but is typically toluene, chloroform, chlorobenzene, hexane, xylene, pyridine, propanol, ethanol, methanol, methyl ethyl ketone, dimethyl sulfoxide, Dimethylformamide, or water, or a mixture thereof.

[0235] Once ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com