Polyamide acid dispersion liquid and preparation method thereof as well as polyimide film

A polyamic acid and dispersion technology, applied in the field of nanomaterials, can solve the problems of molecular chain embrittlement, material shrinkage stress, poor corona resistance, etc., and achieve good corona resistance and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

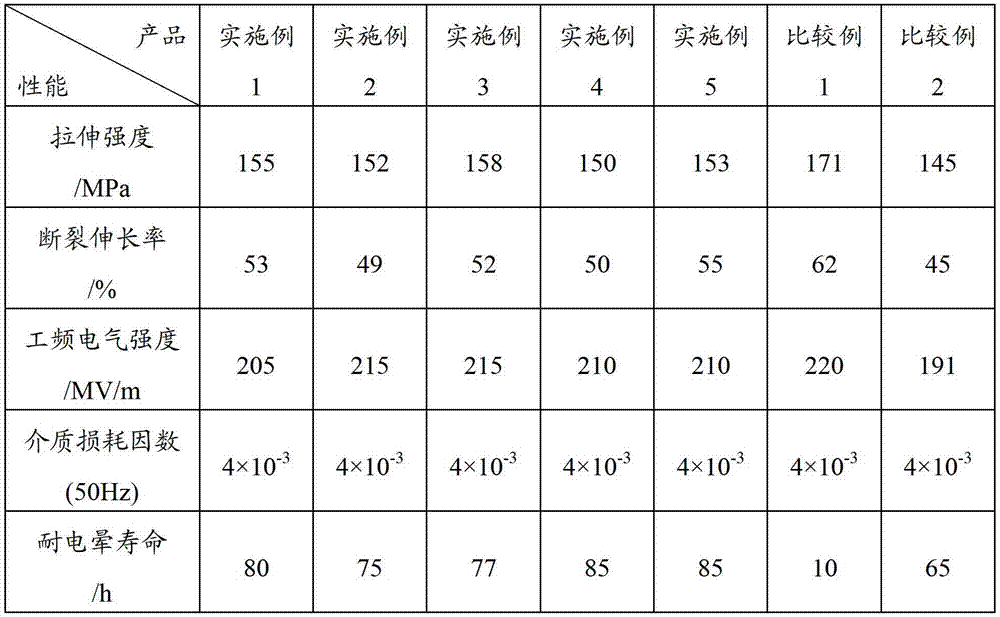

Examples

preparation example Construction

[0020] The invention provides a kind of preparation method of polyamic acid dispersion liquid, comprising:

[0021] A) dispersing the metal oxide nanoparticles whose surface is modified by a coupling agent into an organic solvent to obtain a nanoparticle dispersion;

[0022] B) Mixing and reacting the nanoparticle dispersion obtained in step A) with dianhydride and diamine to obtain a polyamic acid dispersion.

[0023] The present invention firstly modifies the surface of the metal oxide nanoparticles, and then disperses the nanoparticles in an organic solvent with a low viscosity, so that the nanoparticles can be uniformly and stably dispersed, and avoids the problem of the high viscosity of the polyamic acid solution causing the Disadvantage of inhomogeneous dispersion, the final polymerization reaction is carried out to prepare polyamic acid dispersion liquid, and the polyimide film prepared by it not only has good corona resistance performance, but also has good mechanical...

Embodiment 1

[0038] Disperse 9 g of zirconia nanoparticles with a particle size of 10 nm in 20 mL of ethanol, heat to 30 ° C, then add 1 g of silane coupling agent to react for 5 h, then filter the reaction product, wash the solid with ethanol for 3 times, and the obtained The solid is dried to obtain zirconia nanoparticles whose surface is modified by a silane coupling agent.

[0039] At room temperature (25°C), 5 g of zirconia nanoparticles whose surface was modified by a silane coupling agent were uniformly dispersed in 40 g of N-methylpyrrolidone to obtain a zirconia nanoparticle dispersion, and then pyromellitic dianhydride was added 7.8g and 7.2g of 4,4'-diaminodiphenyl ether, the temperature of the reaction system was raised to 30°C, after the dianhydride and diamine were fully dissolved, the reaction was continued for 2h, and the reaction system was cooled to room temperature to obtain poly Amic acid dispersion.

[0040] Add the prepared polyamic acid dispersion into a casting mac...

Embodiment 2

[0043] Disperse 5 g of zinc oxide nanoparticles with a particle size of 30 nm in 20 mL of ethanol, heat to 50 ° C, then add 1 g of silane coupling agent to react for 3 h, then filter the reaction product, wash the solid with ethanol for 3 times, and the obtained The solid is dried to obtain zinc oxide nanoparticles whose surface is modified by a silane coupling agent.

[0044] At room temperature (25°C), uniformly disperse 1 g of zinc oxide nanoparticles whose surface is modified by a silane coupling agent in 83 g of N-methylpyrrolidone to obtain a zinc oxide nanoparticle dispersion, and then add pyromellitic dianhydride 14.6g and 13.4g of 4,4'-diaminodiphenyl ether, the temperature of the reaction system was raised to 40°C, after the dianhydride and diamine were fully dissolved, the reaction was continued for 5h, and the reaction system was cooled to room temperature to obtain poly Amic acid dispersion.

[0045] Add the prepared polyamic acid dispersion into a casting machin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com