Patterned transparent electrode fabrication method

A transparent electrode and patterning technology, applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of limited selection of conductive materials and lack of controllability of patterns, so as to improve conductivity and light transmittance, and broaden the range , to ensure the effect of controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

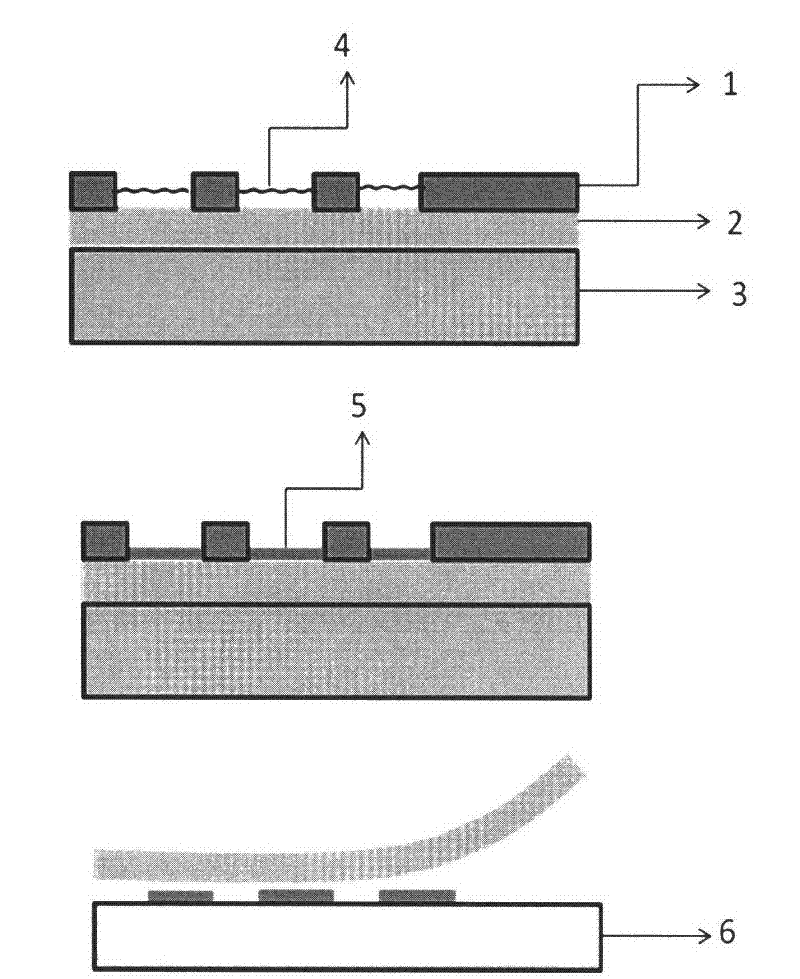

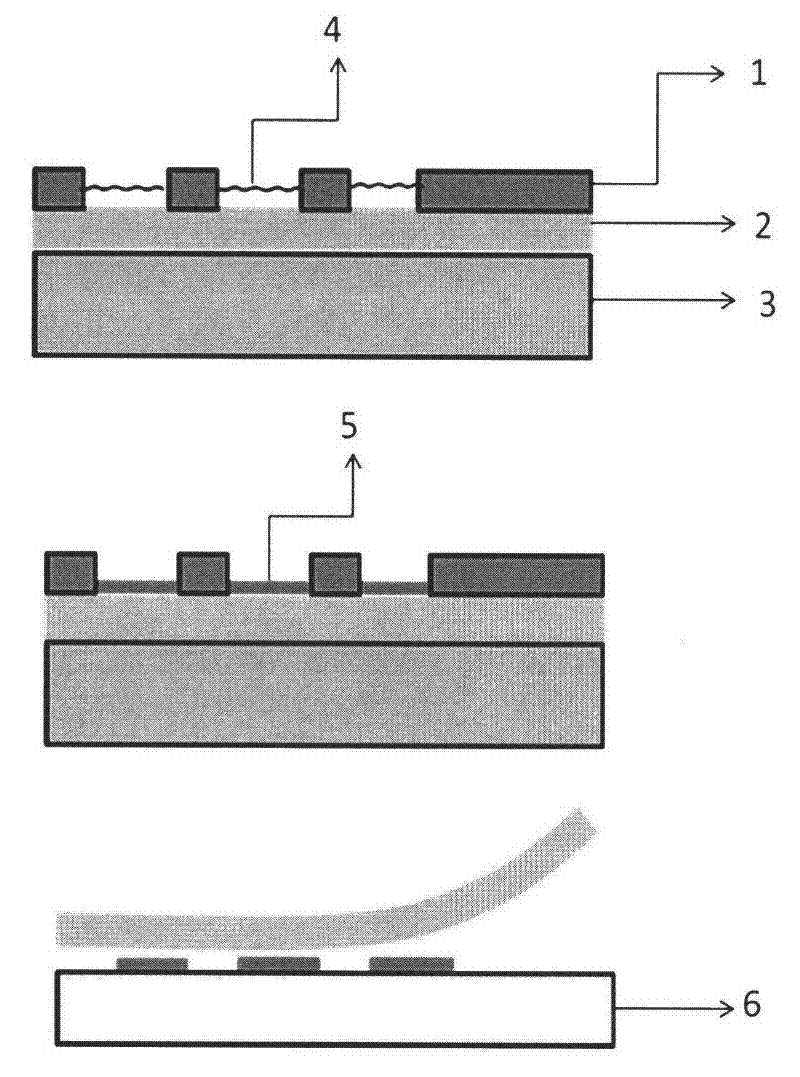

[0018] Such as figure 1 As shown, the 200nm cellulose acetate filter membrane is selected as the porous filter membrane (1) with a pore size of 200nm. The filter membrane 1 is covered with a mask 2, and the bottom is provided with a porous sand core 3, and the mask 2 has a required pattern. negative pattern. First get single-walled carbon nanotube powder 0.1mg and join in the water of 200ml, and add the surfactant sodium dodecylsulfonate (SDS) of 20g, form carbon nanotube dispersion liquid through ultrasonic stirring then, this dispersion liquid is passed through After high-speed centrifugation at a rate of 4000 rpm for 40 minutes, the supernatant was taken, namely the desired carbon nanotube monodispersion 4, and the concentration of the monodispersion was 0.5 wt%. Take 0.1ml of the carbon nanotube monodispersion and dilute it to 10ml with deionized water, add the carbon nanotube monodispersion 4 into the porous filter membrane 1 and filter through the porous sand core 3 unt...

Embodiment 2

[0020] Preparation of graphene monodispersion: take 3g of layered graphite and place it in a 250ml three-necked flask, add 70ml of concentrated sulfuric acid and 1.6g of NaNO 3 . The three-neck flask was cooled to 0°C in an ice-water bath, and then 9.0 g of potassium permanganate was slowly added to keep the temperature of the mixture not exceeding 20°C. Then the mixture was heated at 35°C, stirred and kept for 60 min, then 140 ml of water was added dropwise within 15 min, and after cooling to room temperature, 400 ml of water and 3 ml of H were added. 2 o 2 The mixture obtained by mixing and stirring evenly was filtered through a PTEF porous filter membrane with a pore size of 200nm, and the obtained filtrate was washed 3 times with deionized water, and the collected liquid was dispersed into 200ml of deionized water to obtain a graphene oxide dispersion. Take 100ml of the above dispersion into a 250ml three-necked bottle, add 1ml of hydrazine hydrate and 5g of SDS, place t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com