Grapheme oxide quantum dot function sphere nanoparticle, polyamide reverse osmosis membrane/nanofiltration membrane modified by nanoparticle and preparation method

A technology of graphene quantum dots and nanoparticles, applied in the field of membrane separation, to achieve the effects of improving water flux, increasing membrane desalination rate, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

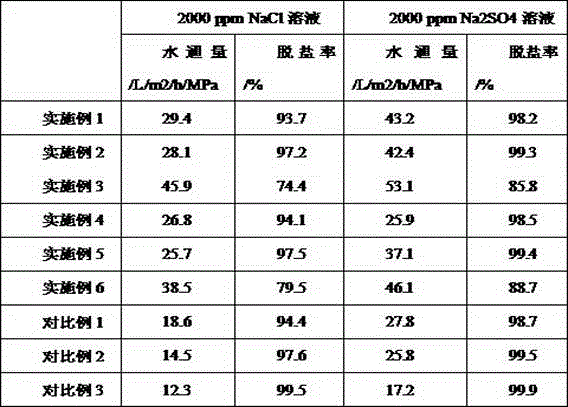

Examples

preparation example Construction

[0015] The preparation method of the graphene oxide quantum dot functional ball is as follows: slowly adding the graphene quantum dot dispersion liquid into the positively charged nano particle dispersion liquid, and then centrifuging, precipitating, separating and purifying.

[0016] Further, the positively charged nanoparticles are aminated nano-silver particles, aminated nano-zinc particles, aminated nano-copper particles, aminated nano-gold particles, aminated nano-silica particles, amine-based One or more of nano titanium dioxide particles and aminated nano chitosan particles.

[0017] The modified polyamide reverse osmosis membrane / nanofiltration membrane based on the above-mentioned functional spherical nanoparticles involved in the present invention is to inlay the above-mentioned graphene oxide quantum dot functional spherical nanoparticles in the polyamide separation layer of the reverse osmosis / nanofiltration membrane.

[0018] The preparation method of the polyamid...

Embodiment 1

[0022] Take 0.5g of silver nanoparticles and disperse them in 100mL of absolute ethanol, add 1mL of 3-aminopropyltriethoxysilane under the condition of stirring at room temperature, continue to react for 6 hours, centrifuge and wash for many times to obtain aminated nano-particles Silver particle dispersion (about 0.5g / 100mL); disperse graphite oxide in ultrapure water, ultrasonically disperse for 5 hours, and centrifuge to take the supernatant to obtain graphene oxide quantum dots; Slowly add about 0.001mg / mL graphene oxide quantum dot dispersion solution 50mL dropwise into the silver particle dispersion liquid, after continuous vigorous stirring for 1 hour, gradually reduce the stirring speed until it stops, centrifuge and wash with water to obtain graphene oxide dispersed in the water phase Quantum dot functional spherical nanoparticles. Soak the porous bottom film in the water phase for 0.5 minutes, the concentration of phenylenediamine in the water phase is 0.5wt%, and th...

Embodiment 2

[0024] Take 0.5g of silver nanoparticles and disperse them in 100mL of absolute ethanol, add 1mL of 3-aminopropyltriethoxysilane under the condition of stirring at room temperature, continue to react for 6 hours, centrifuge and wash for many times to obtain aminated nano-particles Silver particle dispersion (about 0.5g / 100mL); disperse graphite oxide in ultrapure water, ultrasonically disperse for 5 hours, and centrifuge to take the supernatant to obtain graphene oxide quantum dots; Slowly add about 0.001mg / mL graphene oxide quantum dot dispersion solution 50mL dropwise into the silver particle dispersion liquid, after continuous vigorous stirring for 1 hour, gradually reduce the stirring speed until it stops, centrifuge and wash with water to obtain graphene oxide dispersed in the water phase Quantum dot functional sphere nanoparticles; soak the porous bottom film in the water phase for 0.5 minutes, the concentration of phenylenediamine in the water phase is 1.5wt%, and the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com