Automatic online phase measuring device for crankshaft connecting rod neck

A technology of crankshaft connecting rod and measuring device, which is used in grinding machine parts, workpiece feed motion control, metal processing equipment and other directions, can solve problems such as workpiece breakage, flying out, grinding wheel fragmentation, etc. , the effect of less investment and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

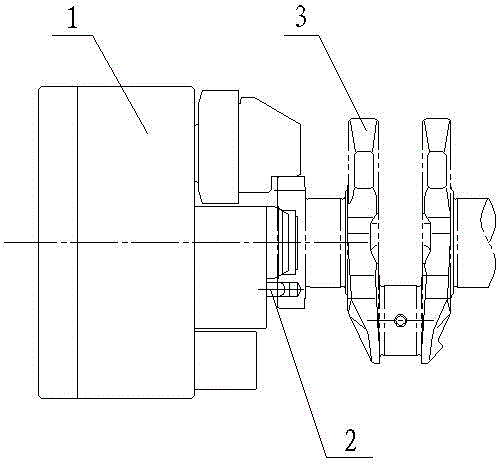

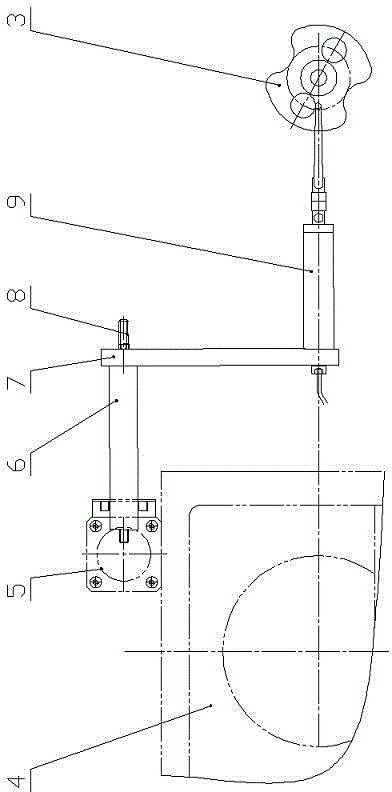

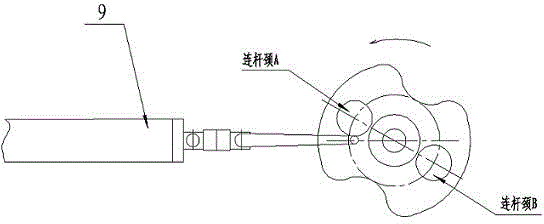

[0030] The present invention provides an automatic on-line phase measurement device (abbreviated as the measurement device) of the crankshaft pin neck, as an embodiment, such as figure 2 As shown, it includes a contact sensor 9, a contact sensor driving device 5, a rotating arm 6, a bracket 7, a screw mandrel 8, a main rotating shaft for clamping the crankshaft 3 and coaxial with the main journal of the crankshaft, the main rotating shaft driving device and the main rotating shaft Corner sensor. The rotating arm is vertically and fixedly connected to the rotating shaft of the touch sensor driving device through one end thereof, the other end of the rotating arm is provided with a central screw hole, the upper end of the bracket is provided with a light hole, and a rod passes through the The light hole is screwed into the central screw hole, the upper end of the bracket is locked and fixed on the other end of the rotating arm by a nut, and the end of the contact sensor away fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com