Multiband terahertz filter and manufacture method of multiband terahertz filter

A manufacturing method and terahertz technology, which are applied in the terahertz field to achieve the effects of large polarization insensitivity, good out-of-band suppression performance, and ingenious design ideas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

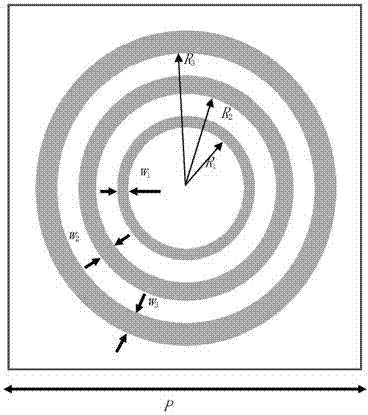

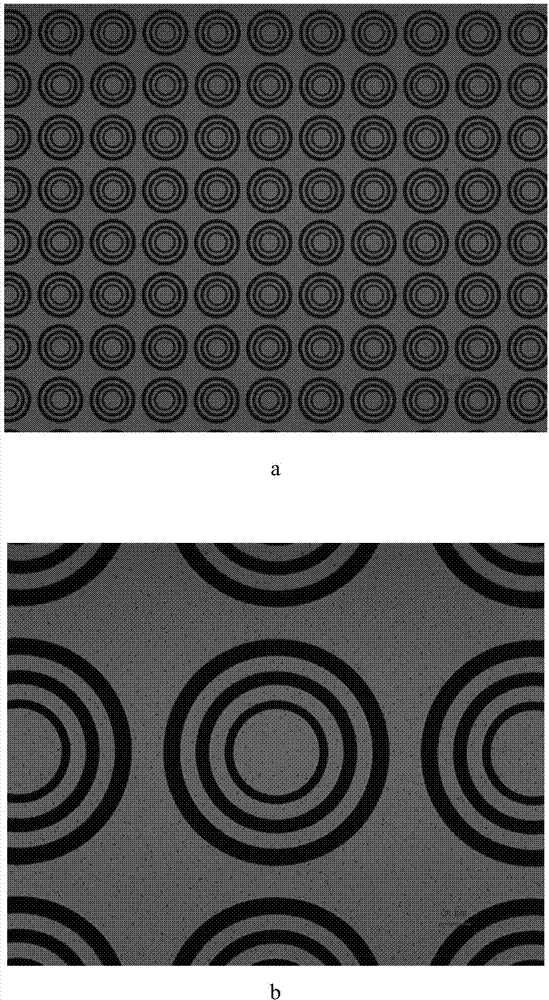

[0067] A 3-band terahertz filter made by the following method:

[0068] Step 1: cleaning the single crystal Z-cut quartz substrate;

[0069] In this step, the cleaning process is as follows:

[0070] (1) Put the quartz substrate into the acetone solution, and ultrasonically clean it for 5-10 minutes;

[0071] (2) Take out the substrate and put it into isopropanol (IPA) for ultrasonic cleaning for 5-10 minutes;

[0072] (3) Take out the substrate and clean it with deionized water, and dry the substrate with a nitrogen gun;

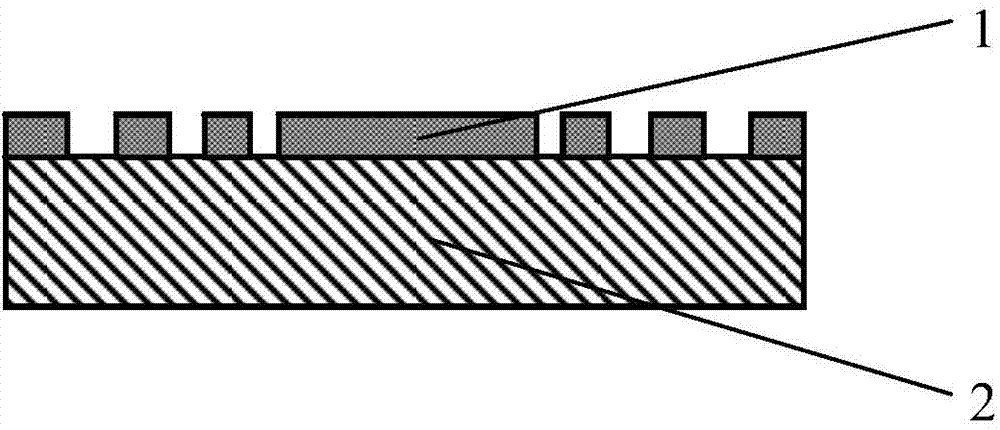

[0073] Step 2: depositing a metal aluminum (Al) film layer on the cleaned quartz substrate;

[0074] In this step, magnetron sputtering technology is used to deposit a 200nm thick metal aluminum film layer on the cleaned quartz substrate at room temperature; a metal film with a thickness of more than 200nm can ensure that it does not pass through electromagnetic waves; magnetron sputtering is a new technology in the field Routine operation, no more deta...

Embodiment 2

[0091] A 3-band terahertz filter made by the following method:

[0092] Step 1: cleaning the quartz substrate;

[0093] In this step, the cleaning process is as follows:

[0094] (1) Put the quartz substrate into the acetone solution, and ultrasonically clean it for 5-10 minutes;

[0095] (2) Take out the substrate and put it into isopropanol (IPA) for ultrasonic cleaning for 5-10 minutes;

[0096] (3) Take out the substrate and clean it with deionized water, and dry the substrate with a nitrogen gun;

[0097] Step 2: Spin-coat optical photoresist on the quartz substrate and bake;

[0098] In this step, first place the sample on a hot plate and bake at 120°C for 10 minutes to remove the moisture on the surface, then spin-coat S1813 photoresist with a thickness of about 1 μm, and place it in an oven for 40 minutes at 110°C;

[0099] Step 3: Exposure and development to obtain a periodic 3-ring structure pattern of the photoresist;

[0100] In this step, the S1813 photoresis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com