Carbonization furnace capable of recycling biomass pyrolysis gas and biomass carbonization method

A technology of biomass pyrolysis and gas recirculation, applied in fixed carbonization furnaces, coke ovens, special forms of dry distillation, etc., can solve the problems of waste of carbonization products, difficulty in controlling the carbonization process, and consumption of external energy, so as to avoid waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

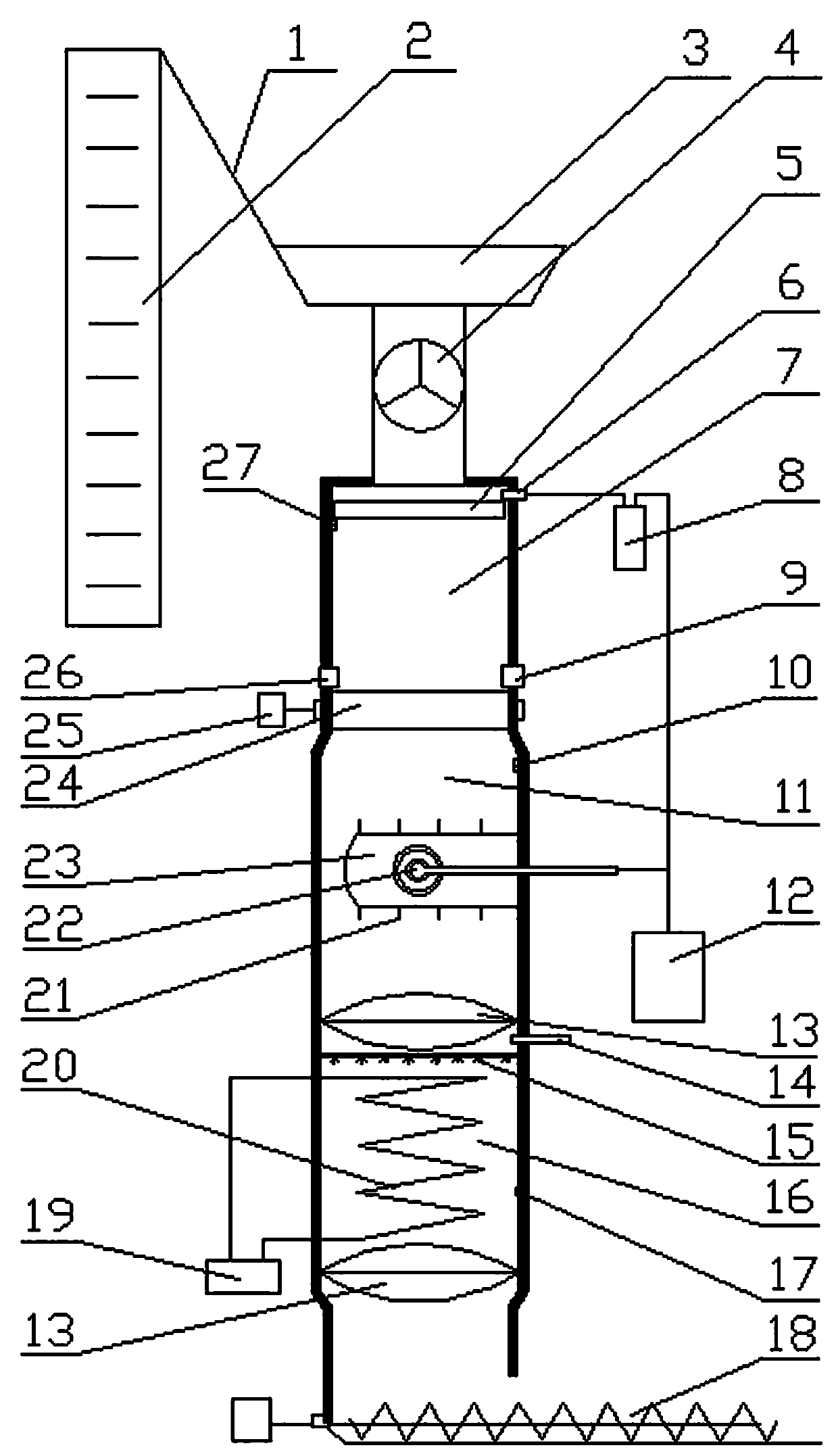

[0025] Such as figure 1 As shown, a carbonization furnace for biomass pyrolysis gas recycling of the present invention includes a furnace body and a feeding mechanism connected to the top of the furnace body and used to put biomass raw materials into the furnace body and arranged under the furnace body and used The discharge mechanism 18 is used to discharge the biomass charcoal generated in the furnace body. Furnace is figure 1 The middle black filled part is divided into three chambers from top to bottom, which are dry pyrolysis chamber 7 , carbonization chamber 11 and cooling chamber 16 . A first temperature sensor 27 is provided in the drying pyrolysis chamber 7 , a second temperature sensor 10 is provided in the carbonization chamber 11 , and a third temperature sensor 17 is provided in the cooling chamber 16 .

[0026] The feeding mechanism of the present invention includes an elevator 2 , a hopper 3 and a slide plate 1 connected between the elevator 2 and the hopper 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com