Patents

Literature

45 results about "Smouldering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Smouldering (British English) or smoldering (American English; see spelling differences) is the slow, low-temperature, flameless form of combustion, sustained by the heat evolved when oxygen directly attacks the surface of a condensed-phase fuel. Many solid materials can sustain a smouldering reaction, including coal, cellulose, wood, cotton, tobacco, cannabis, peat, plant litter, humus, synthetic foams, charring polymers including polyurethane foam and some types of dust. Common examples of smouldering phenomena are the initiation of residential fires on upholstered furniture by weak heat sources (e.g., a cigarette, a short-circuited wire), and the persistent combustion of biomass behind the flaming front of wildfires.

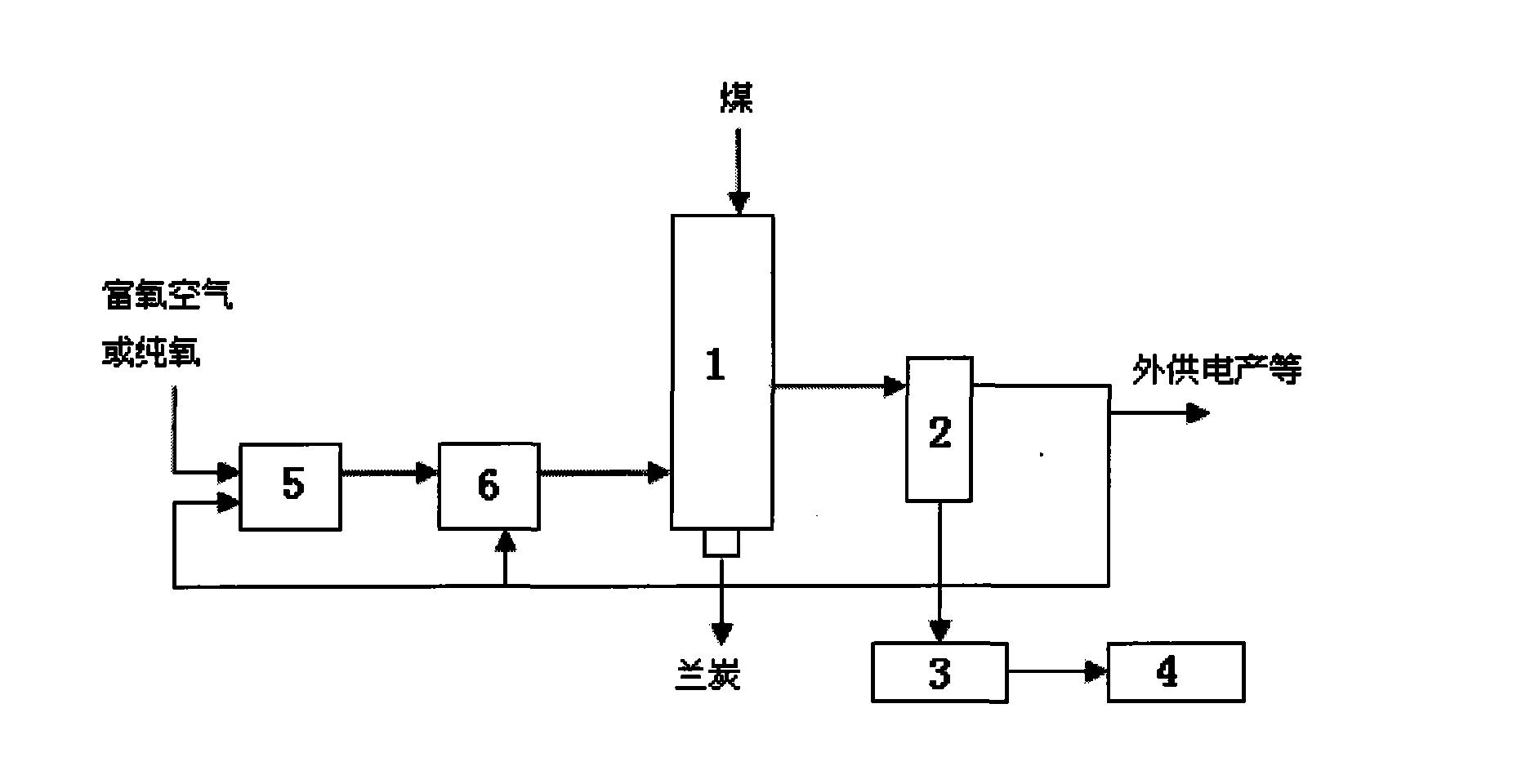

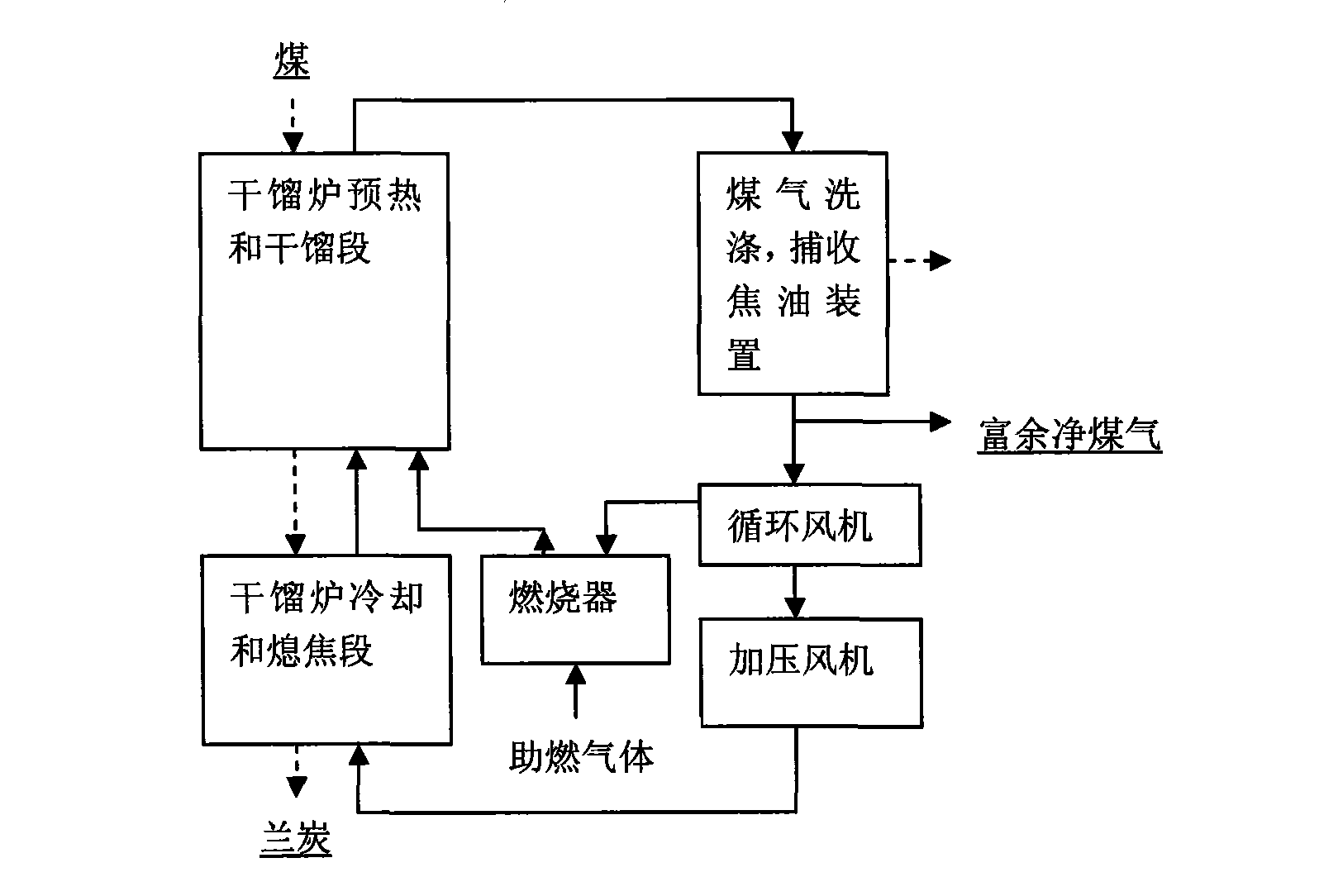

Method for coke dry quenching by coal internal heat smouldering

InactiveCN101514291ATake advantage ofImprove heat utilization efficiencyCoke quenchingIndirect heating destructive distillationCarbonizationQuenching

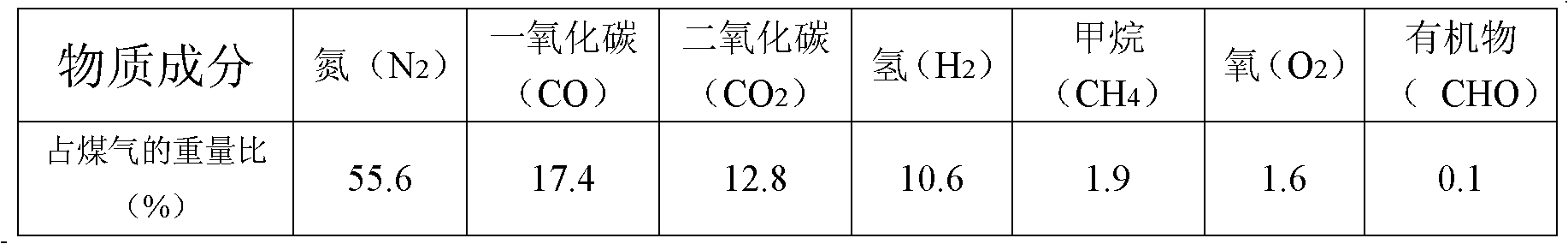

The invention discloses a method coke dry quenching by coal internal heat smouldering. In the method, high temperature carbonized coal gas produced by carbonized dry quenched coke is made into cool coal gas by washing and collecting tar; after the cool coal gas passes a circulating fan, part of the coal gas is introduced into a burner to be synthesized with high temperature waste gas into high temperature mixed gas satisfying the coal smouldering requirement; the high temperature mixed gas enters into a carbonization section of a coke oven to be used as a carbonization heat source; the other part of pure coal gas passing the circulating fan is introduced to a coke quenching and cooling section of a carbonization furnace by a booster fan to be used as an inertia medium of Ramsbottom coke and quenched coke; the cool coal gas passing the coke quenching and cooling section of the carbonization furnace absorbs the heat and then passes the carbonization section of the coke oven to carry out nonoxidation heating or weak-oxidation heating towards the coal together with the carbonization heat source to realize combustion-free circulation. The method simplifies the coke dry quenching technology, reduces the water content of the Ramsbottom coke, uses the heat of the Ramsbottom coke before coke quenching effectively, improves the utilization rate of the pure coal gas, reduces the use of combustion-supporting gas and accordingly reduces the energy consumption of the burner.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

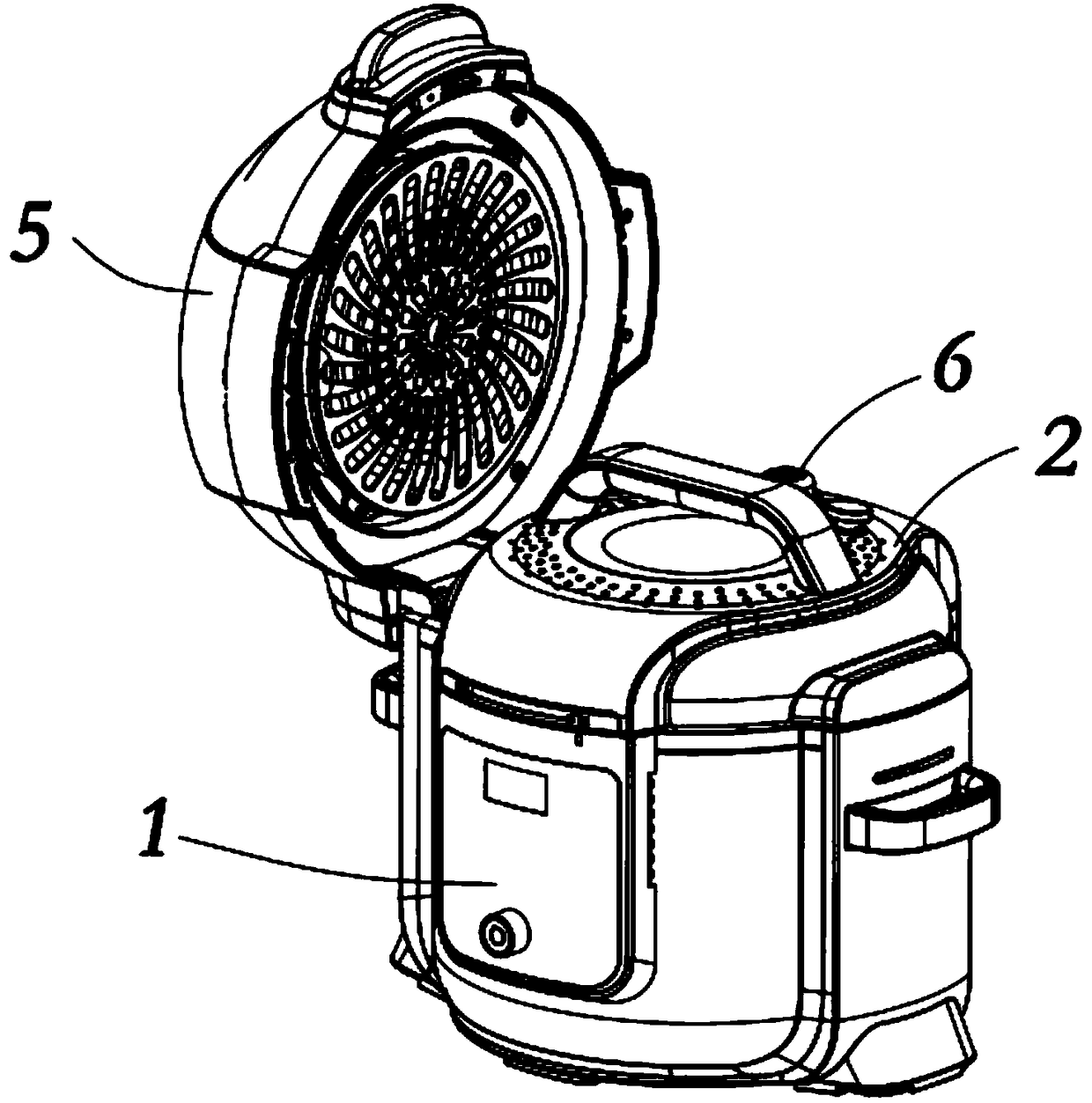

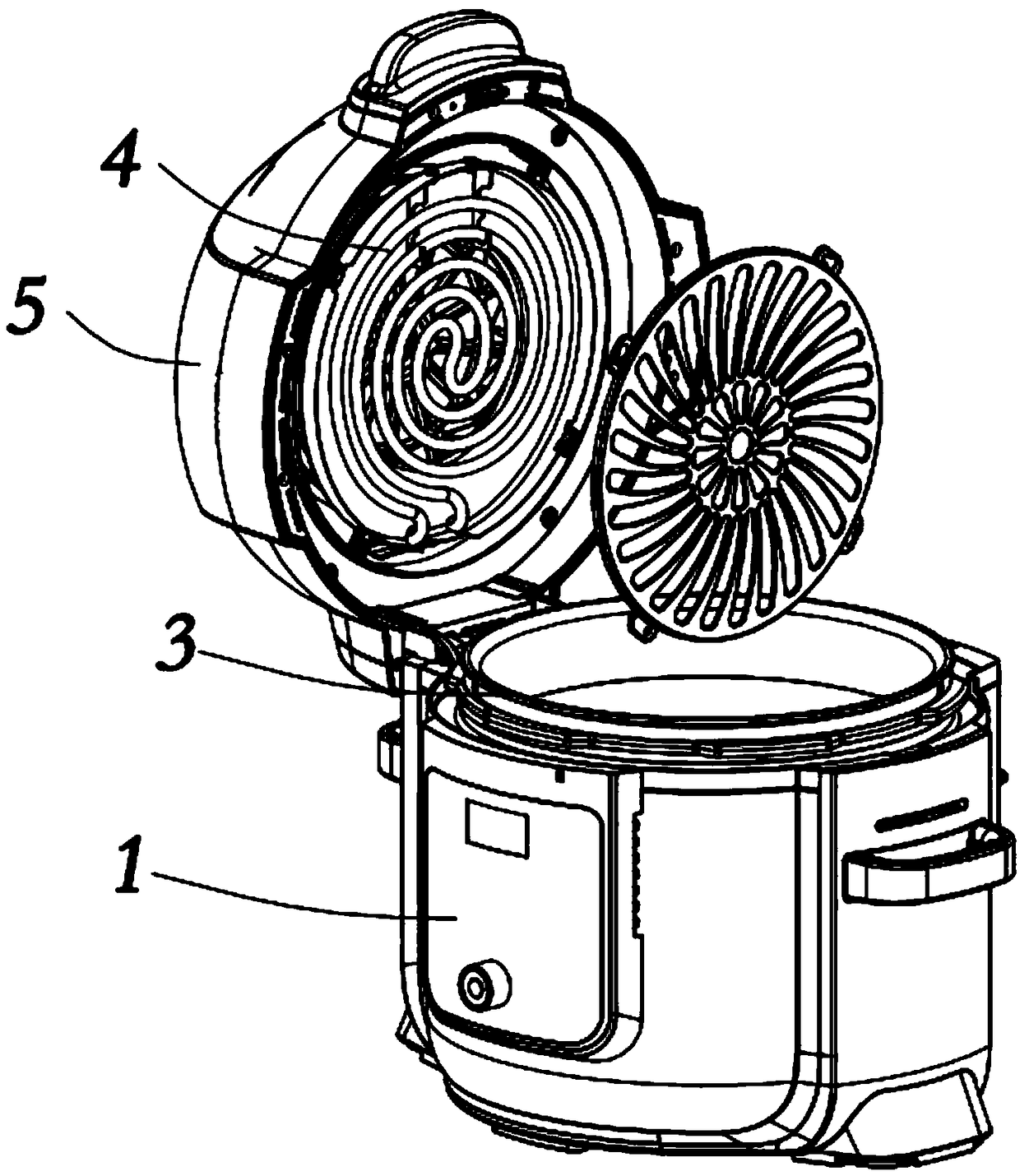

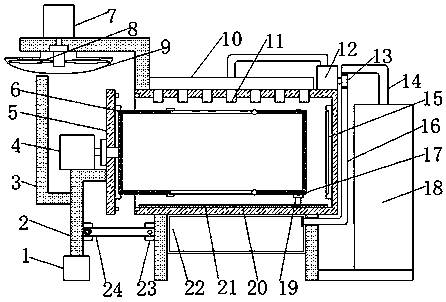

Food cooking method and cooking utensil

InactiveCN108402891AAvoid unfamiliarityGreat tasteRoasters/grillsPressure-cookersProcess engineeringCooking methods

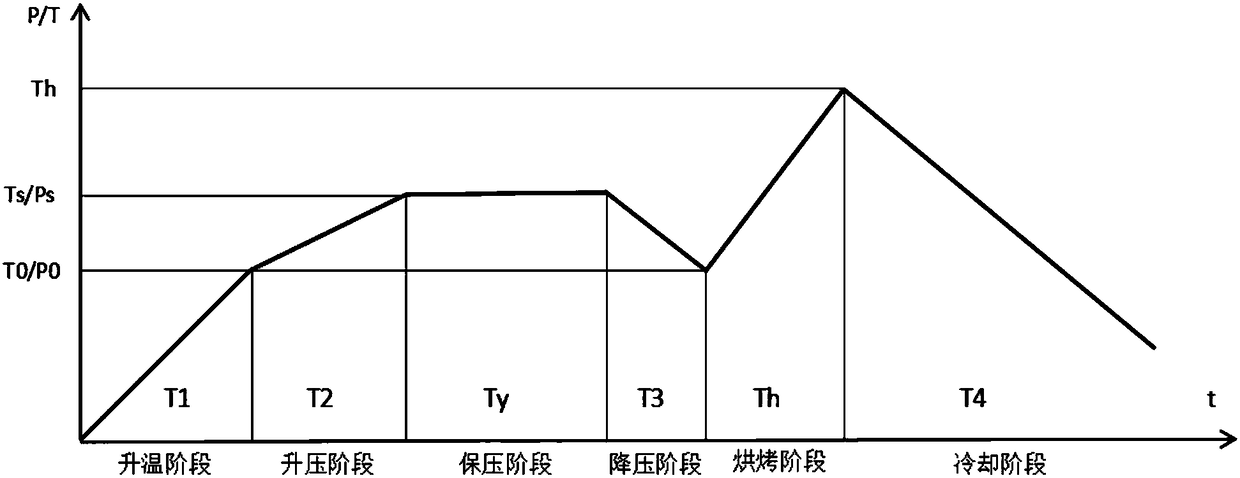

The invention provides a food cooking method. The method comprises the steps of a pressure cooking stage, wherein food is placed into a container, the container is covered with a first cooker lid, a heating device is started for heating to generate pressure, and smouldering is performed under the pressure environment for Ty time; a pressure reduction stage, wherein a pressure reduction device is started, the pressure inside the container is lowered to P0, and the first container lid is opened; a non-pressure baking stage, wherein the container is covered with a second cooker lid, a baking heater is started, food inside the container is baked, and baking is performed for Th to the end. According to the food cooking method, the pressure cooking stage and the non-pressure cooking stage are performed, so that the internal and external food cooking degrees are close. The invention further provides a cooking utensil adopting the food cooking method.

Owner:尚科宁家(香港)股份有限公司

Method for preparing coal gas, top-grade active carbon, water glass and silicate phosphate from rice hulls

ActiveCN101891189AImprove qualityOvercome absorbencyPhosphatesAlkali metal silicatesPhosphateBiological activation

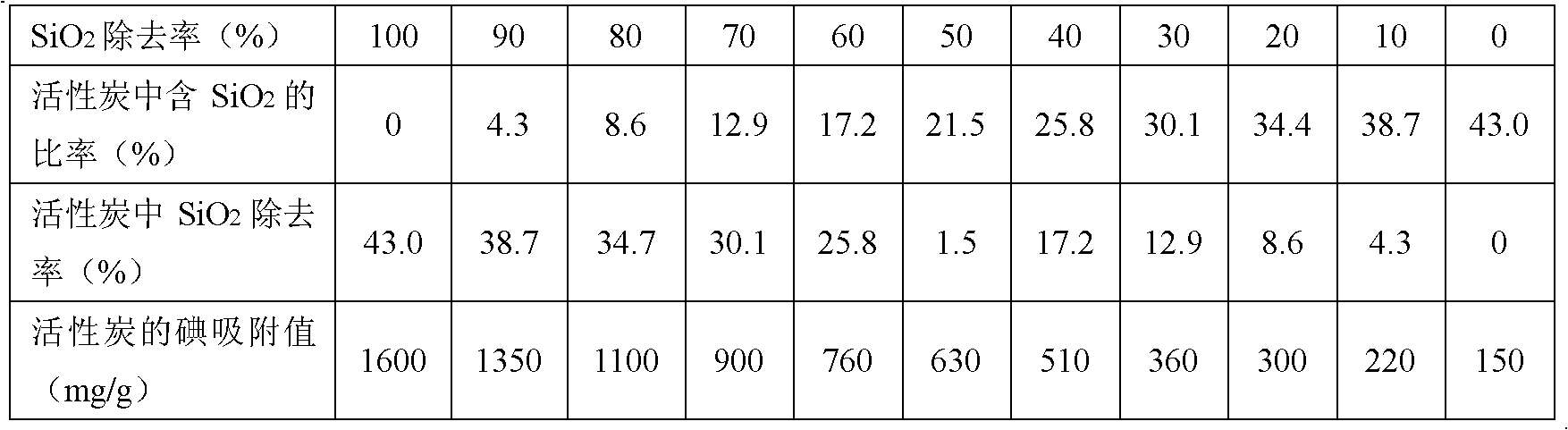

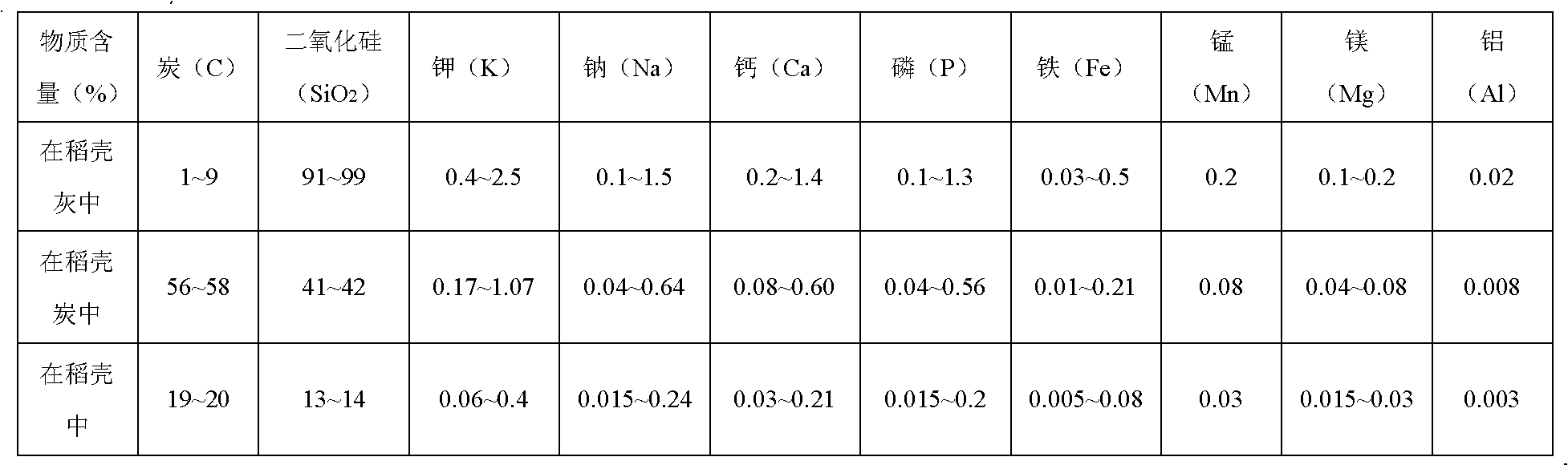

The invention relates to a method for preparing coal gas, high-grade active carbon, water glass and silicate phosphate from rice hulls, which comprises the following steps of: smouldering, carbonizing and activating the rice hulls to produce the coal gas for power generation and to obtain rice hull carbon; activating the rice hull carbon with acid and alkaline to obtain low-grade active carbon, packaging the low-grade active carbon in a dust-proof explosion-proof sealed mode, and activating at moderate temperature, secondary high temperature and high temperature to finally obtain the high-grade active carbon and produce the water glass and the silicate phosphate simultaneously. The defect of low-grade active carbon prepared from the rice hull carbon in the prior art is overcome. The invention has reasonable technological method and technological process, and solves the technical obstacles on moderate temperature and high temperature activation of the rice hull carbon. The rice hull carbon obtained after preparing the coal gas from the rice hulls can be directly used for producing the high-grade active carbon, the water glass and the silicate phosphate, and the economical benefits and the social benefits of the rice hulls are effectively increased. Large-scale industrial production can be realized, and a new approach is provided for realizing a complete industrial chain of agriculture industrialization and rice processing.

Owner:长沙稻香农业科技有限公司

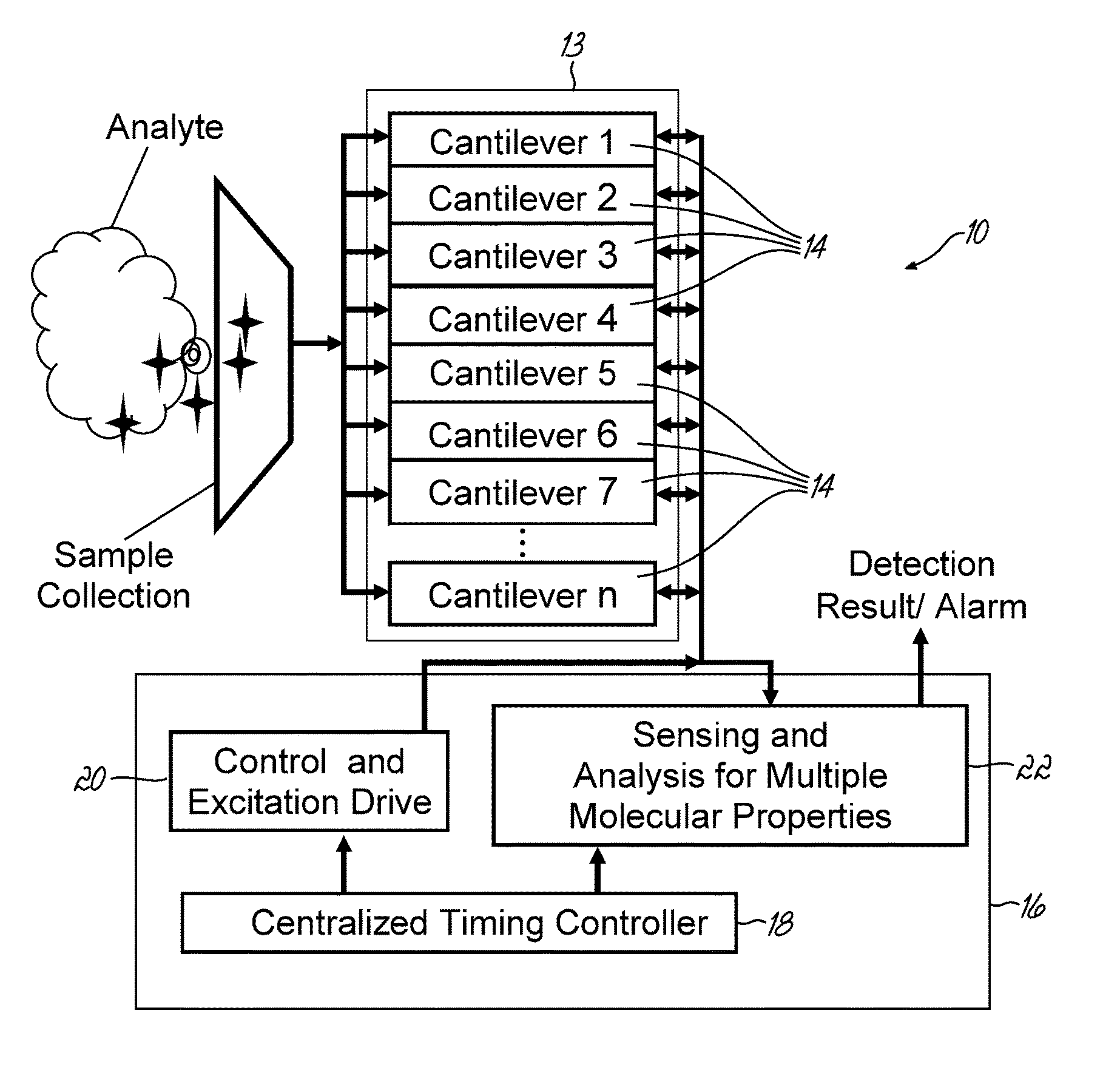

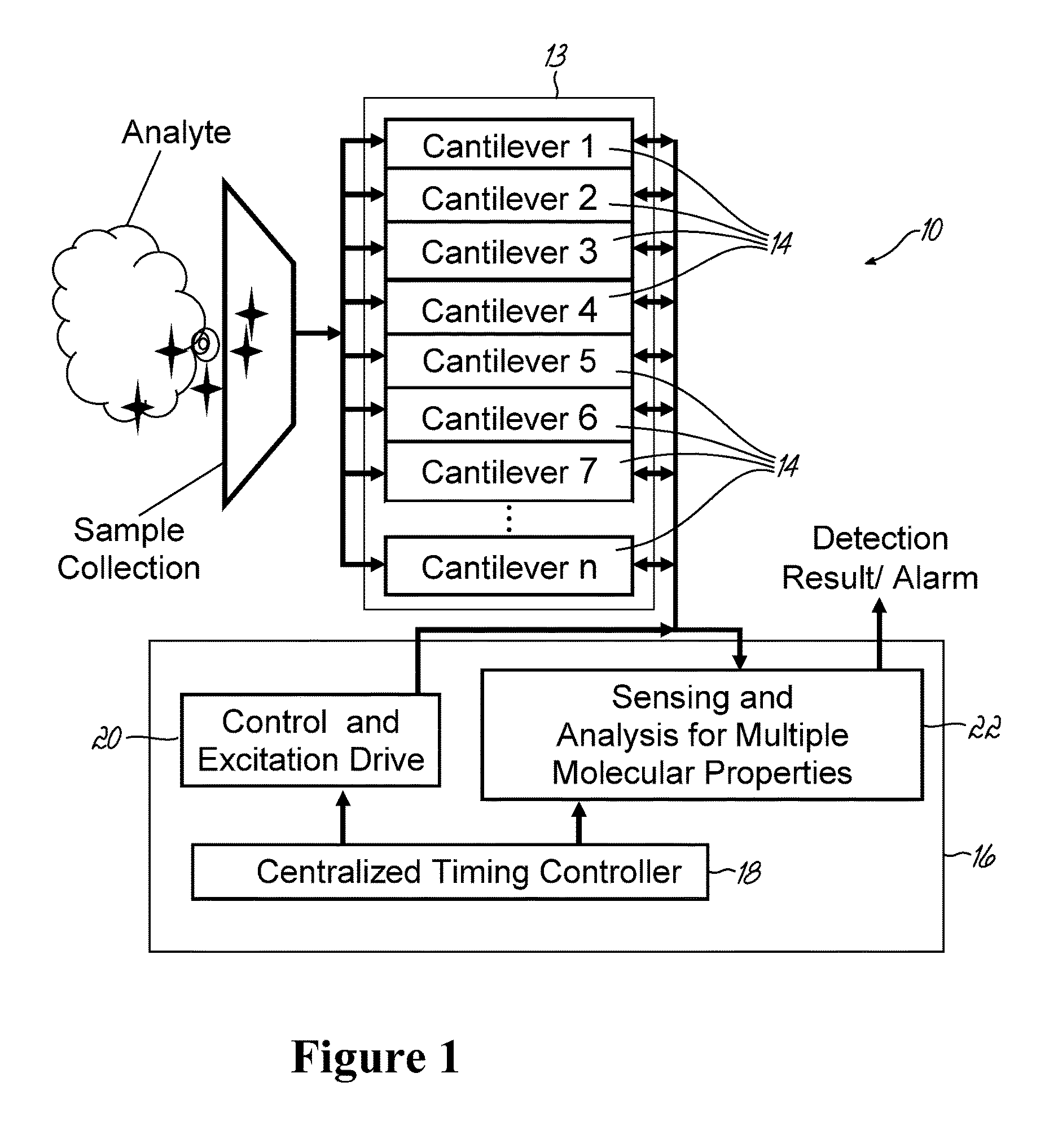

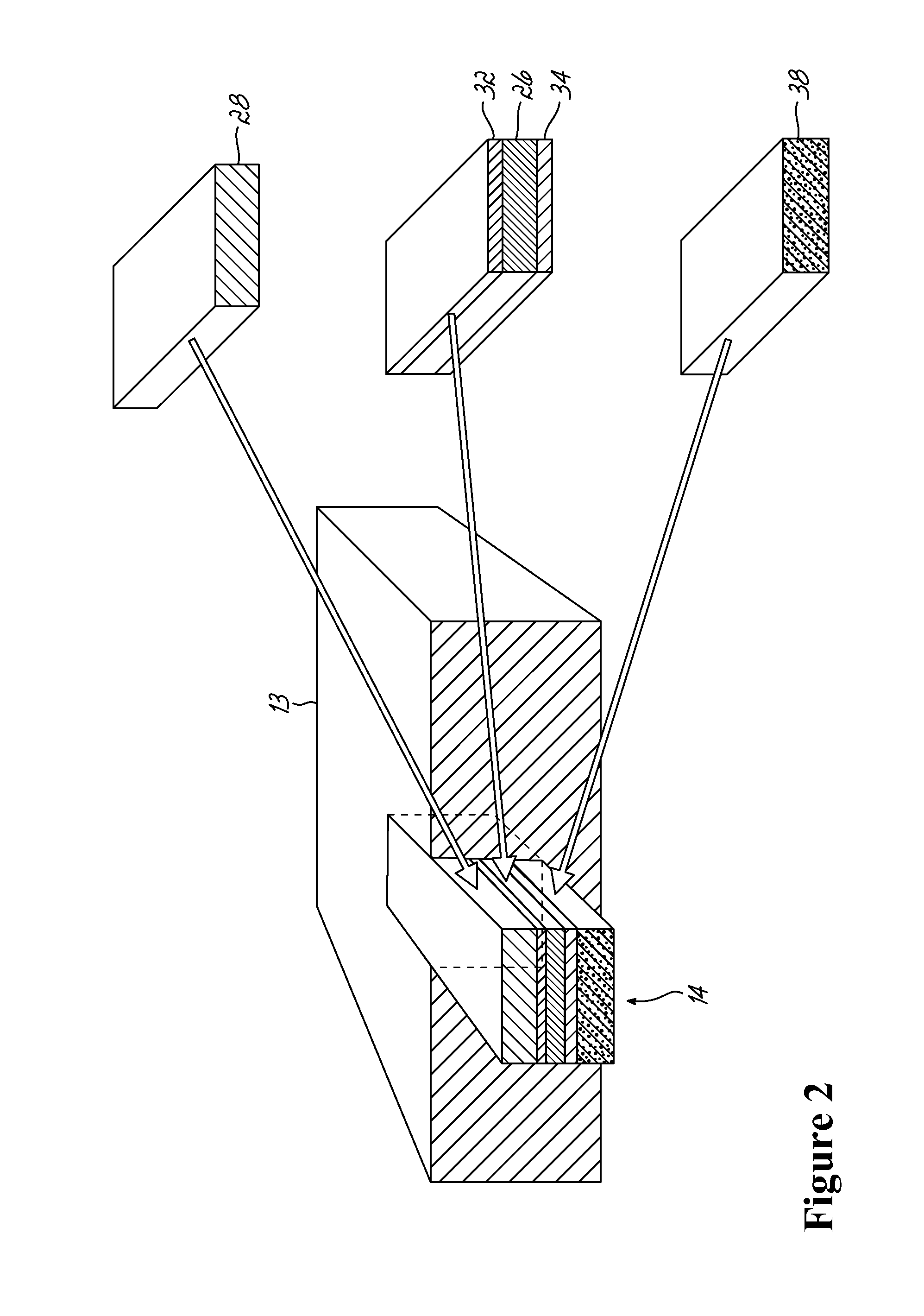

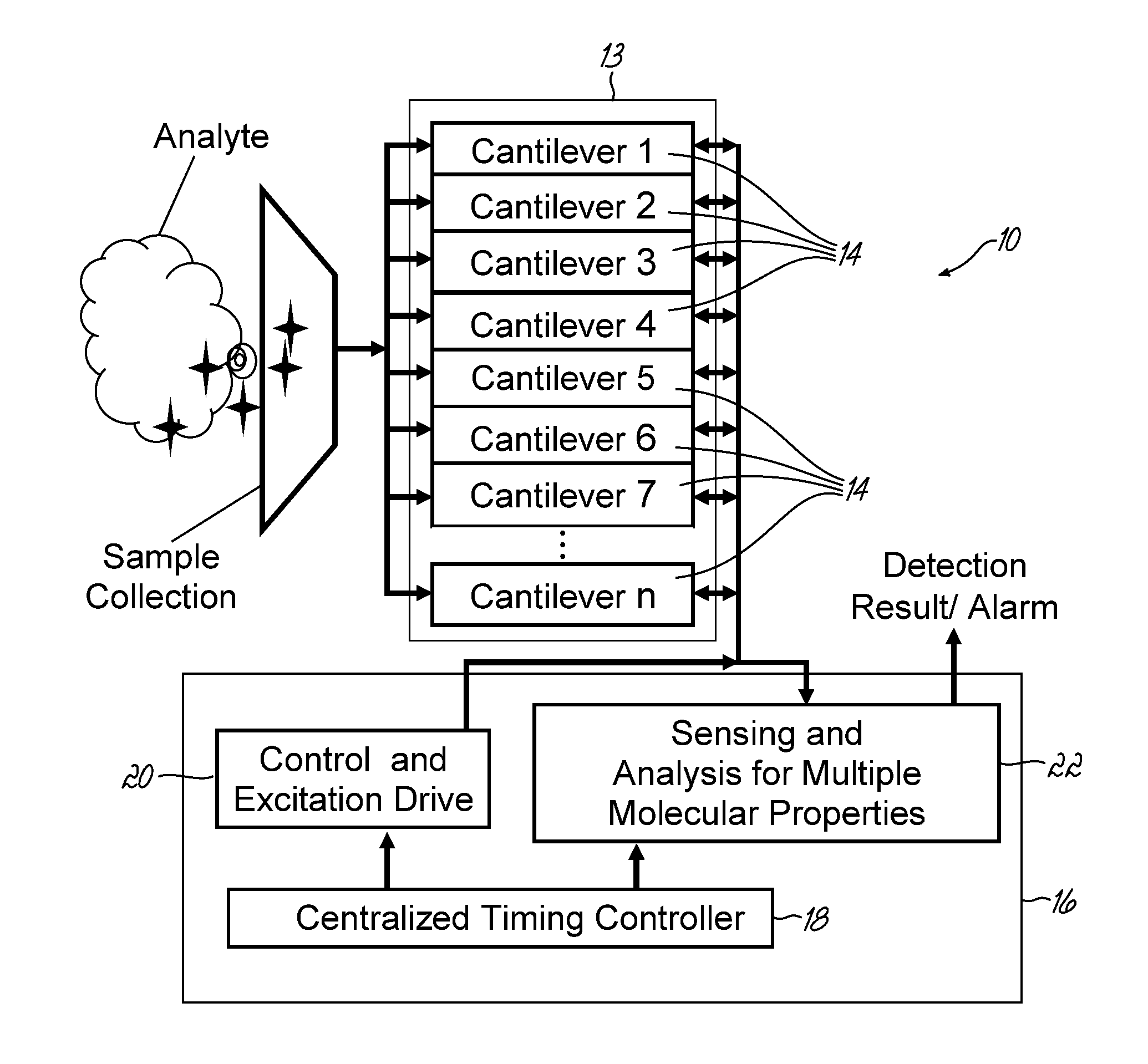

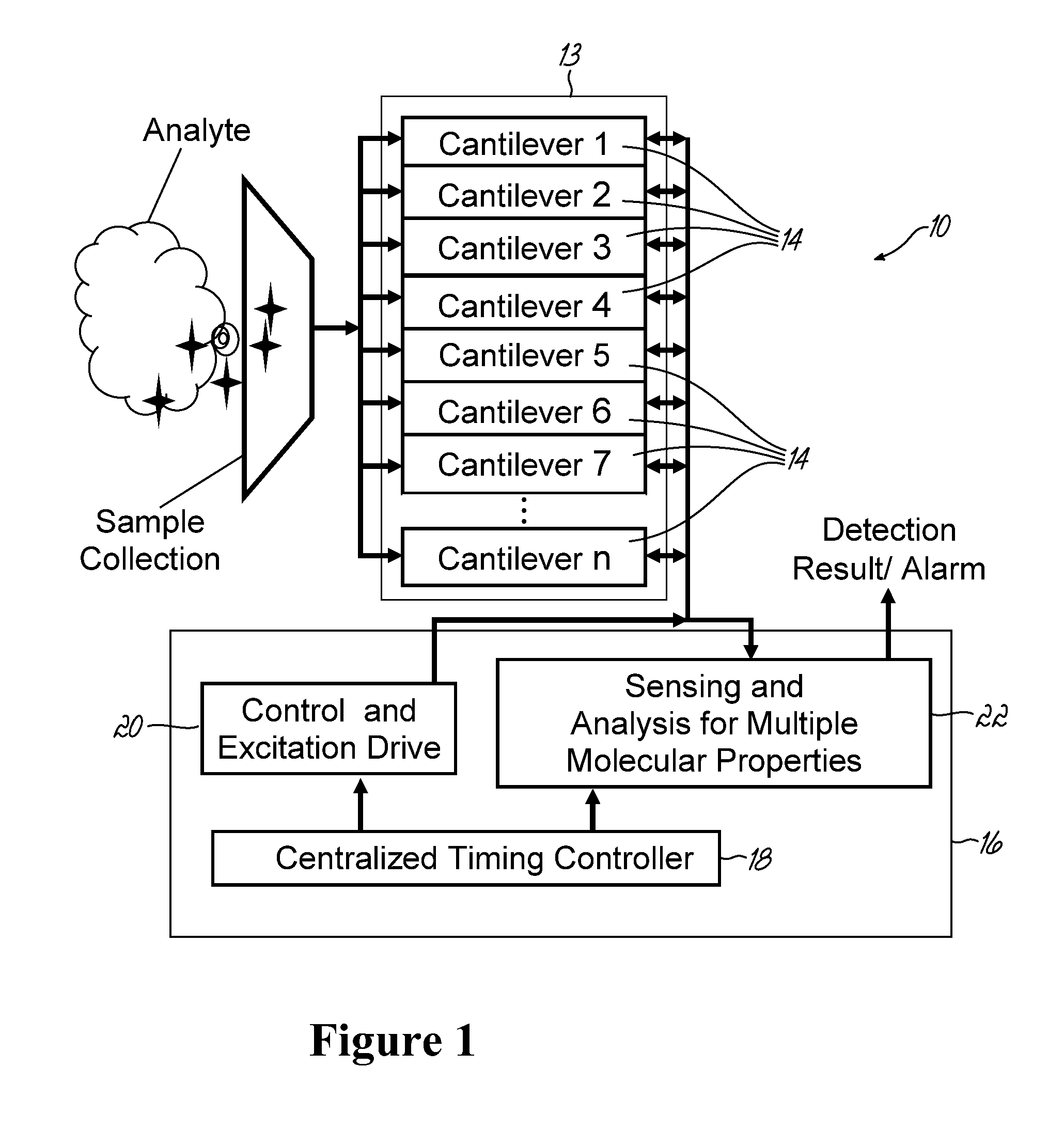

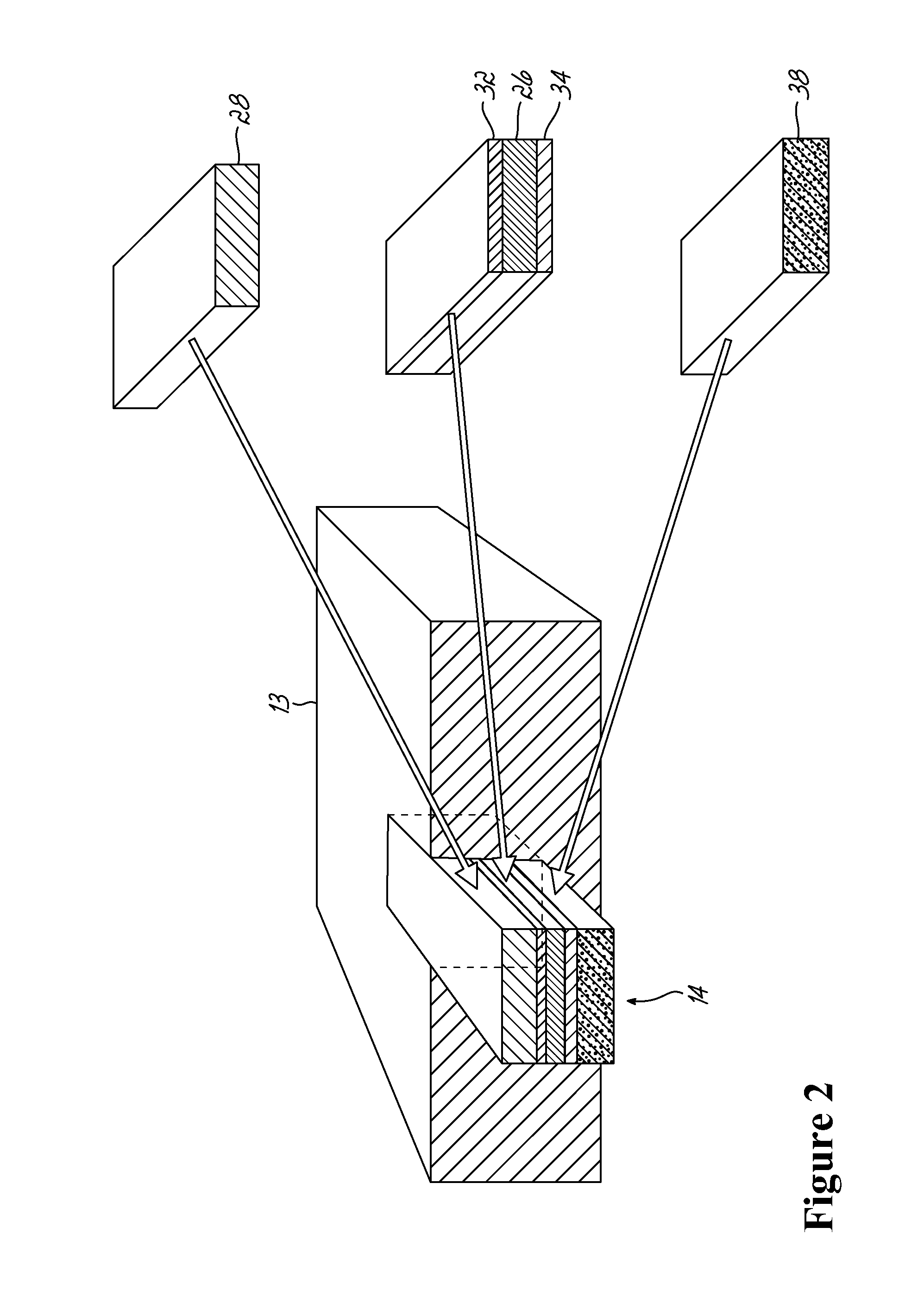

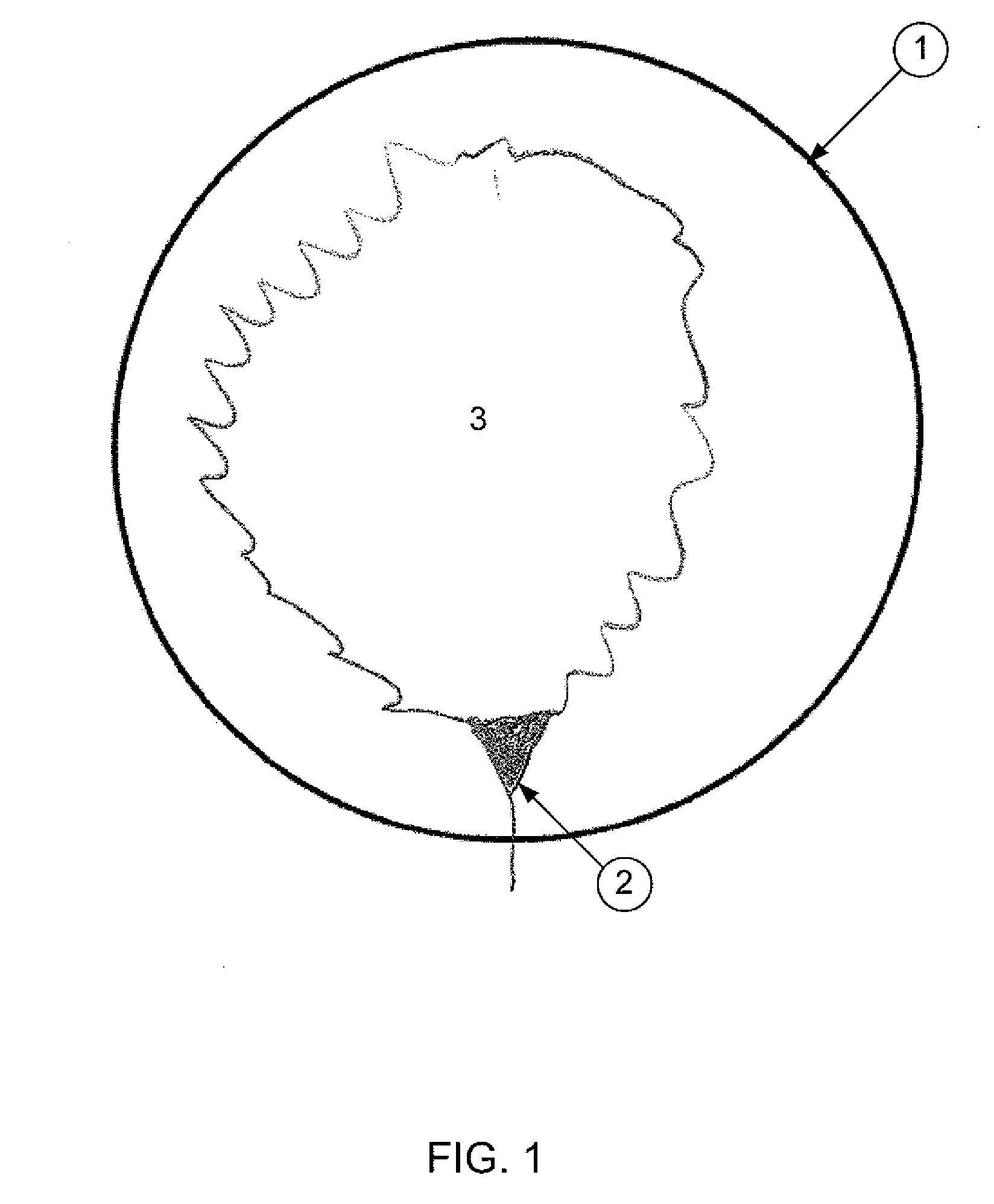

Pre-smoke detector and system for use in early detection of developing fires

ActiveUS9547968B2Reliable detectionImprove detection reliabilityAnalysing fluids using sonic/ultrasonic/infrasonic wavesWithdrawing sample devicesDecompositionFalse alarm

A pre-smoke detector and system for use in early detection of developing fires whereby vapors of marker chemicals generated during the melting and / or smoldering of common household materials are detected before detection by conventional smoke detectors. Vapors resulting from heating and resultant vaporization of substances are detected as well as vapors resulting from their breakdown, decomposition, or pyrolysis during the pre-combustion stage. Conventional smoke detectors focus on particle detection and are most effective after a developing fire has produced smoke. To minimize false alarms caused by common household odors, the pre-smoke detectors focus on detecting medium temperature pyrolysis products using sensor coatings that can be consistent with a 10 year operational lifetime and multiple orthogonal detection processes. Since virtually all marker chemicals of interest for pre-smoke detection are heavier than air, a system is described that appropriately integrates with smoke detector alarm systems present in most homes.

Owner:NEVADA NANOTECH SYST

Pre-smoke Detector and System for Use in Early Detection of Developing Fires

ActiveUS20120092175A1Reliable detectionImprove detection reliabilityFire alarmsDecompositionFalse alarm

A pre-smoke detector and system for use in the early detection of developing fires whereby vapors of marker chemicals generated during the melting and / or smoldering of common household materials are detected before detection by conventional smoke detectors. Vapors resulting from the heating and resultant vaporization of substances are detected as well as vapors resulting from their breakdown, decomposition, or pyrolysis during the pre-combustion stage. Conventional smoke detectors focus on particle detection and are most effective after a developing fire has produced smoke. To minimize false alarms caused by common household odors, the pre-smoke detectors focus on detecting medium temperature pyrolysis products using sensor coatings that can be consistent with a 10 year operational lifetime and multiple orthogonal detection processes. Since virtually all marker chemicals of interest for pre-smoke detection are heavier than air, a system is described that appropriately integrates with smoke detector alarm systems present in most homes.

Owner:NEVADA NANOTECH SYST

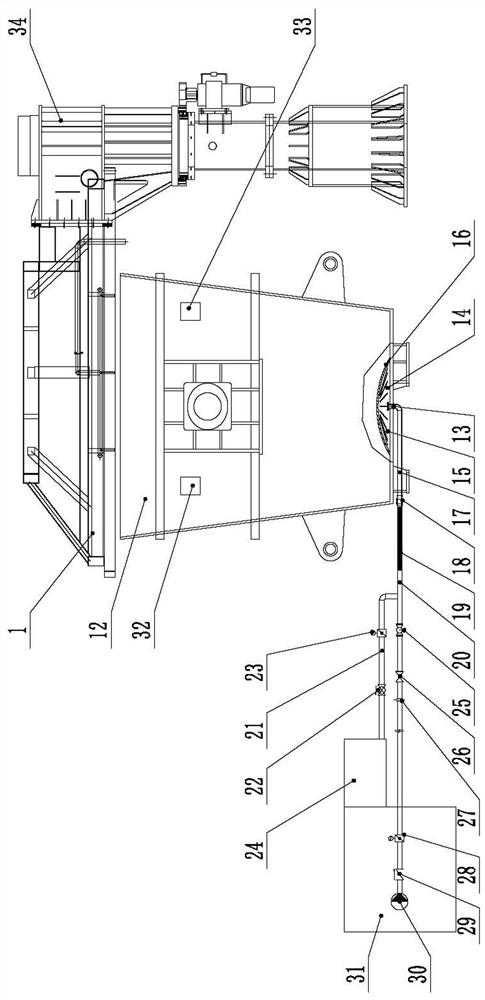

Process applicable to transfer of molten steel slag of converter and optimization of treatment of hot smouldering slag

ActiveCN103014200ASolve transshipment safety issuesGuaranteed continuityManufacturing convertersRecycling and recovery technologiesRadiation lossRefractory

The invention provides a process applicable to transfer of molten steel slag of a converter and optimization of treatment of hot smouldering slag. According to the process, a slag film of 20 to 80mm, which is formed by bringing the high-temperature molten slag tank of the converter into contact with the inner wall of the slag tank of a steel casting and then rapidly cooling, is adopted as the refractory material of a lining; the slag surface of the slag tank containing the motel steel slag of the converter is processed for 0.5 to 2 hours by spraying atomized water, so as to form a slag housing of 100 to 150mm on the slag surface, thus the loss of thermal radiation can be reduced once the steel slag is contained again, the molten slag can be prevented from being splashed during transportation, and a condition for treating the hot smouldering slag at a temperature over 800 DEG C is provided; an infrared temperature measuring gun is adopted and used for measuring the temperature of the slag tank, and the tank can be drawn when a housing of the slag tank is at a temperature below 425 DEG C and the slag housing of the upper part is at temperature below 625 DEG C, and as a result, the safety in production can be ensured.

Owner:XINJIANG BAYI IRON & STEEL

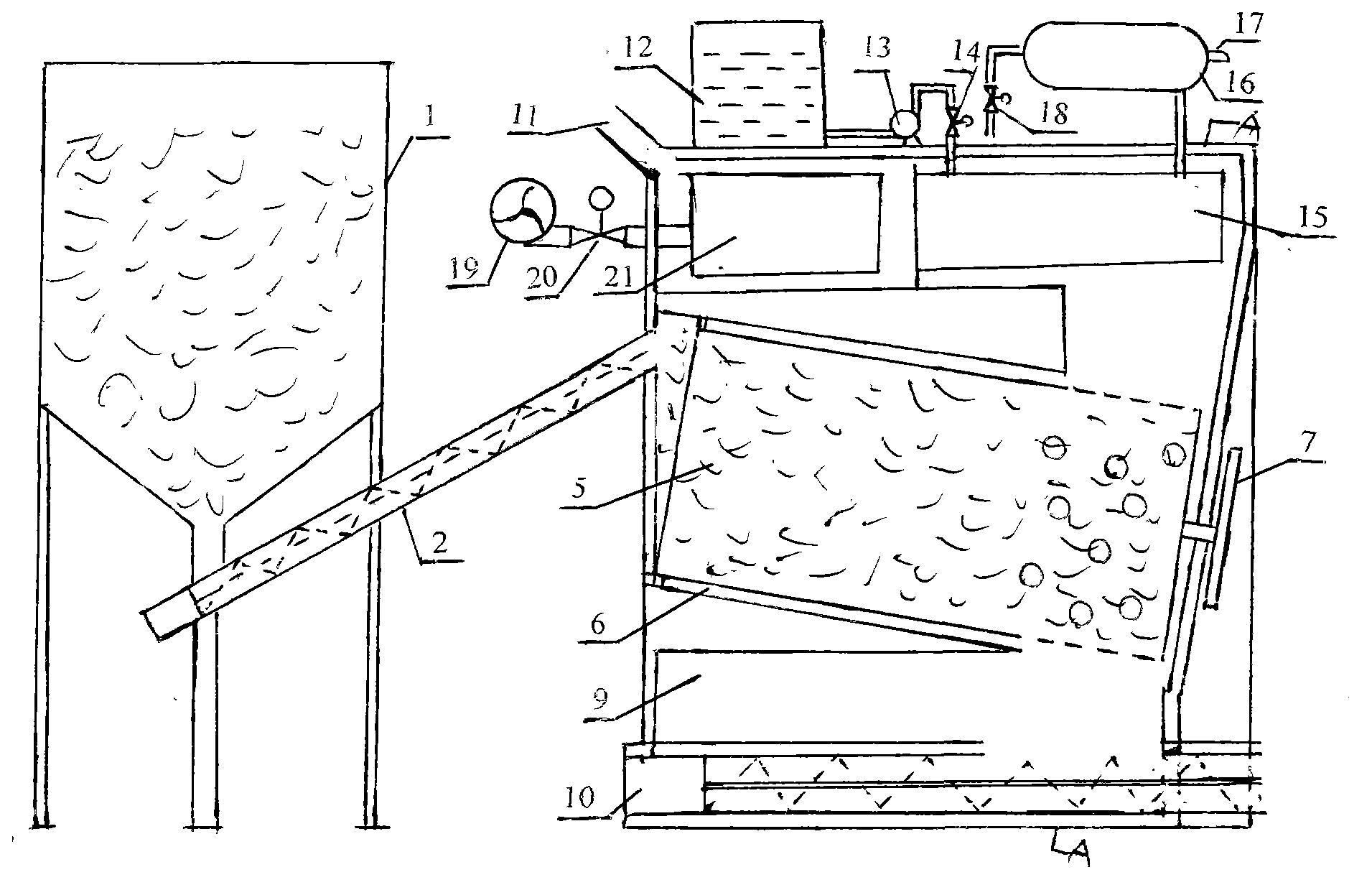

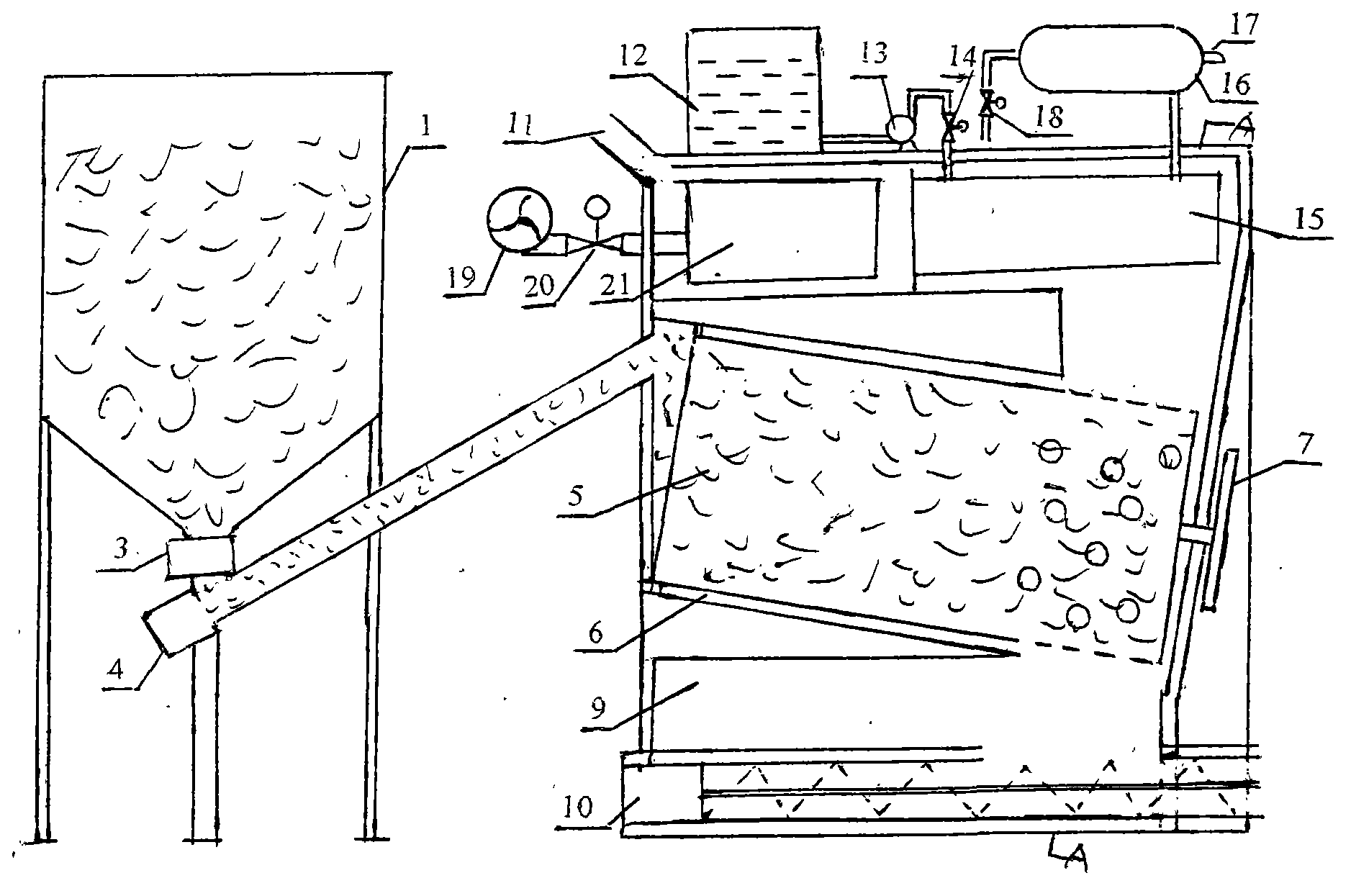

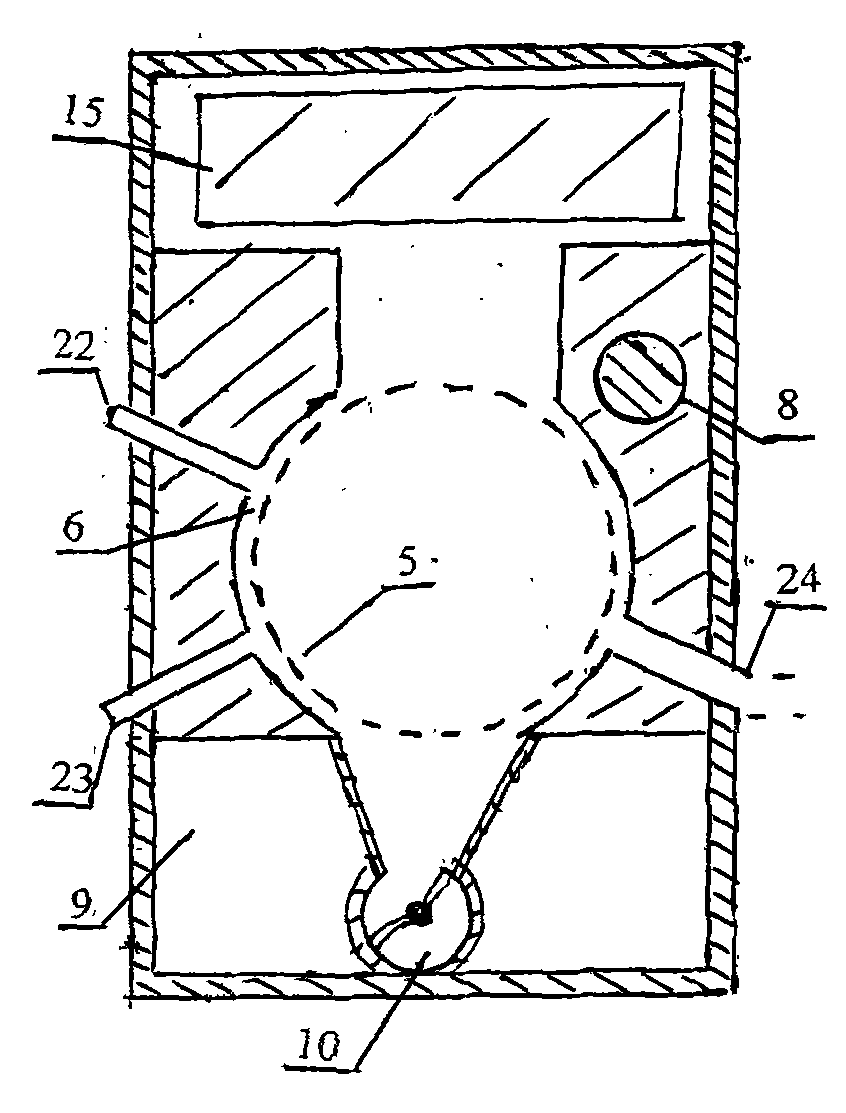

Straw gasification furnace capable of continuously producing gas

The invention discloses a straw gasification furnace capable of continuously producing gas. Straws which are cut up are fed into a material storage tank, the straws placed in the material storage tank are conveyed into a rolling tube type furnace rake by a spiral feeding machine, after the rolling tube type furnace rake is fully filled with the straws, a driving motor rotates to drive the rolling tube type furnace rake to rotate, and a plastic bottle is extruded so that diesel oil can be uniformly sprayed onto the straws in the rolling tube type furnace rake. The straws sprayed with the diesel oil are ignited by the flame of a pistol type long pipe gas ignition gun, wind blown out from a blast blower supports the smouldering of the straws in the rolling tube type furnace rake, the straws can generate a large amount of carbon monoxide during the smouldering, fireproof ceramic balls or metal balls in the rolling tube type furnace rake stir the straws so that the uniform smouldering of the straws can be realized, coal tar generated by the smouldering is heated and decomposed into low-molecule combustible gas when passing through two layers of double-layer honeycomb-shaped metal nets of the back section of the red burnt rolling tube type furnace rake, hot smoke gas heats the wind blown out from a boiler and the blast blower, the generated vapor and hot wind enter an air outlet pipe, and humid and hot air supports the smouldering of the straws, the combustible gas content in the smoke gas can be increased, and the smoke gas is cooled.

Owner:张英华

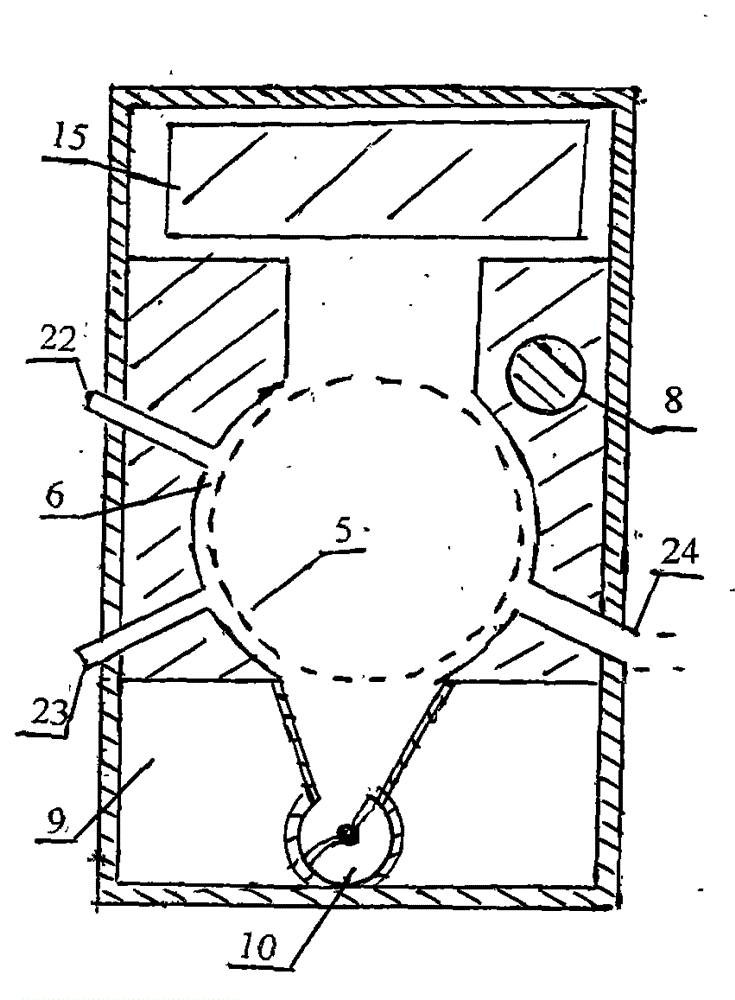

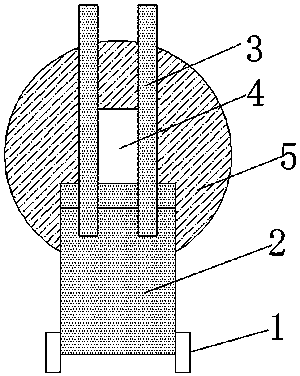

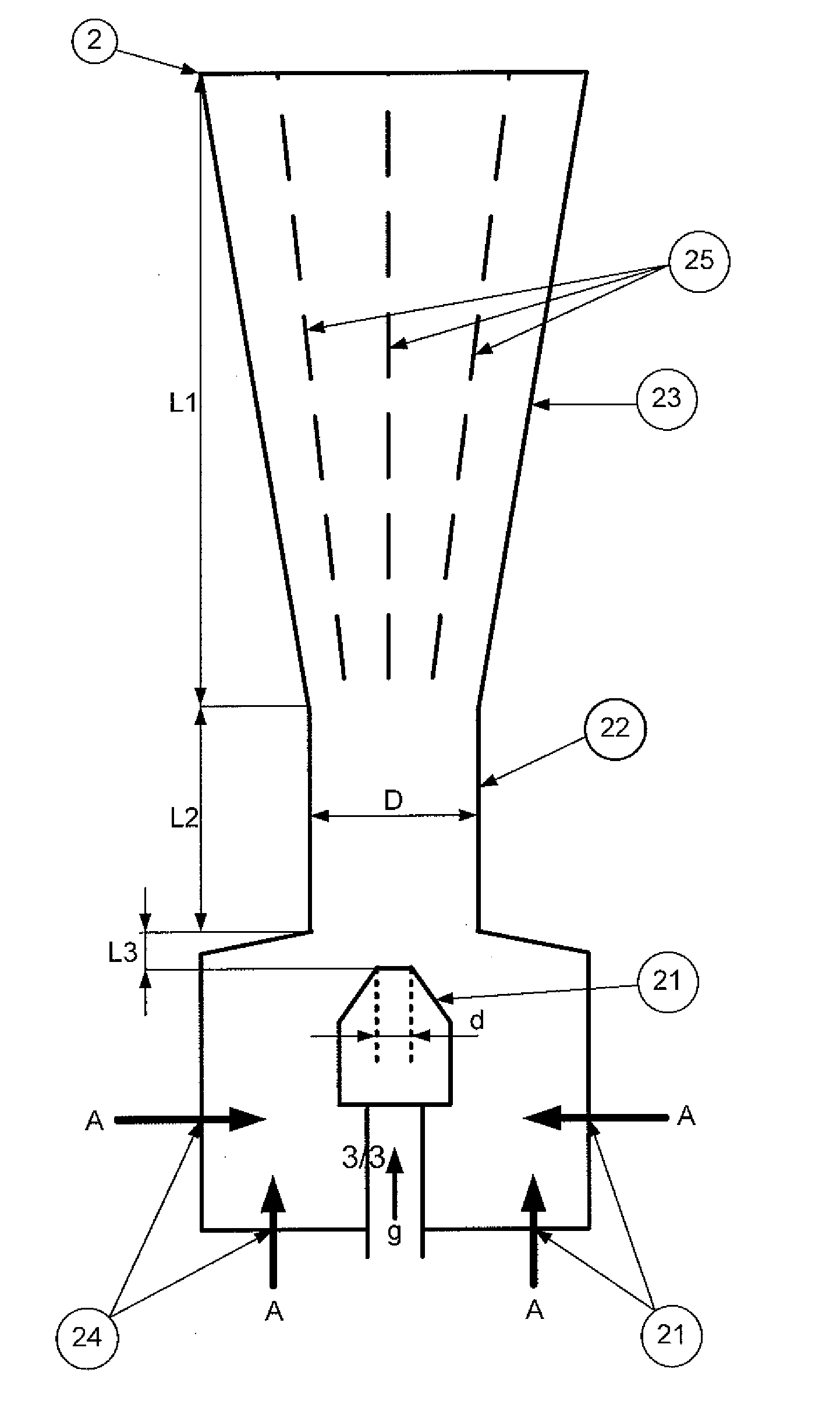

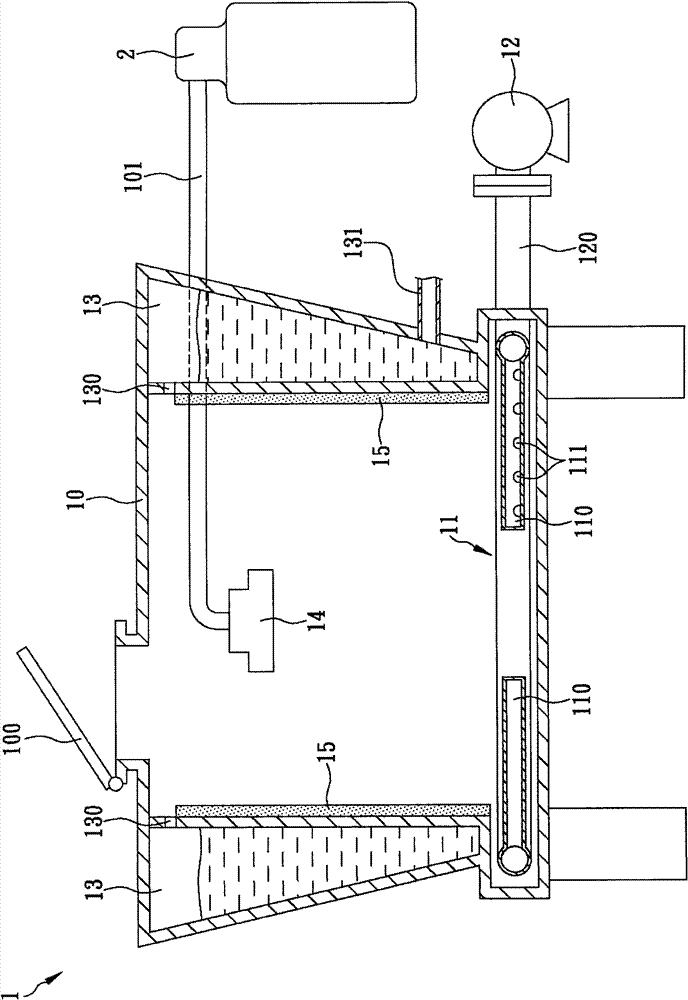

Low-temperature smouldering pyrolysis device for sludge

ActiveCN110395866AReduce settingsFully contactedSludge treatment by pyrolysisByproduct vaporizationSlagSludge

The invention discloses a low-temperature smouldering pyrolysis device for sludge and belongs to the technical field of sludge treatment. The low-temperature smouldering pyrolysis device comprises a pyrolyzing furnace body, wherein a hermetic feeder is arranged at the top of the pyrolyzing furnace body, a deslagging device is arranged at the bottom of the pyrolyzing furnace body, and a carbon residue treater is arranged at a slag tap of the deslagging device; a distributor which is located just below the hermetic feeder is arranged in the pyrolyzing furnace body, a plurality of gas sucking sets are arranged at bottoms of sidewalls of the pyrolyzing furnace body around the circumferential direction, each gas sucking set comprises a gas inlet and a gas outlet, the gas inlets are located above the gas outlets, the gas inlets and the gas outlets are located on contrary side faces of the pyrolyzing furnace body, an annular gas guide pipe is arranged on the pyrolyzing furnace body, each gasoutlet communicates with the annular gas guide pipe, and control valves are arranged corresponding to each gas inlet and each gas outlet; and a ventilating pipe is connected with the annular gas guidepipe and is connected with a dedusting and cooling mechanism. The low-temperature smouldering pyrolysis device for the sludge achieves that smouldering is thorough and is high in efficiency, and thequantity of extracted smouldering afterproducts is large.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Method for extinguishing a smouldering fire in a silo

InactiveUS20090178814A1Risk minimizationAvoid disadvantagesFire rescueBoring toolsMass ratioGas passing

The invention relates to a method for extinguishing a smouldering fire in a silo by introducing inert gas into the silo. The inert gas is introduced through a venturi-type nozzle above the stored content in the silo with a slow streaming velocity in such a way that mass ratio of the entrained surrounding gas to the incoming liquid inert gas is between 0.5 and 20. Thus a closed inert gas layer is formed above the smouldering fire.

Owner:LINDE AG

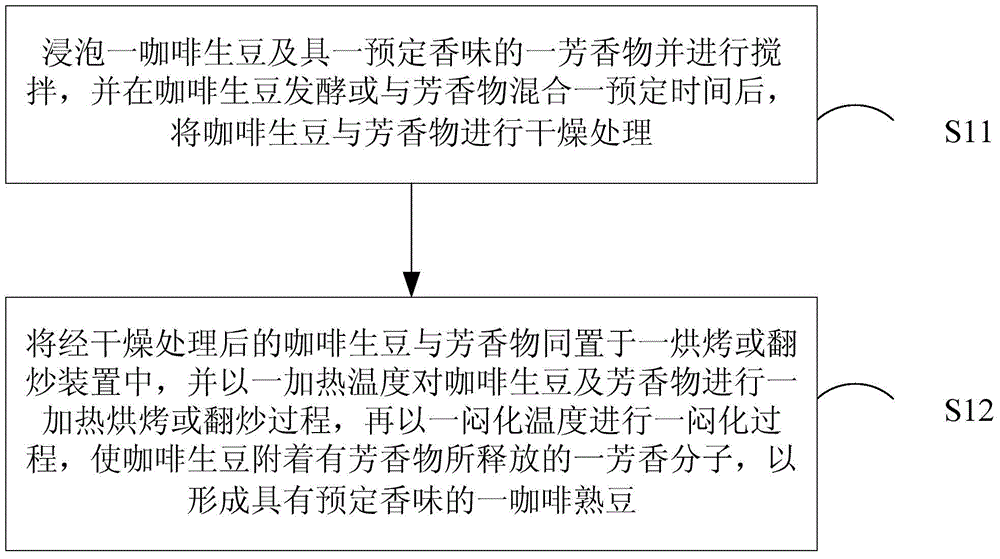

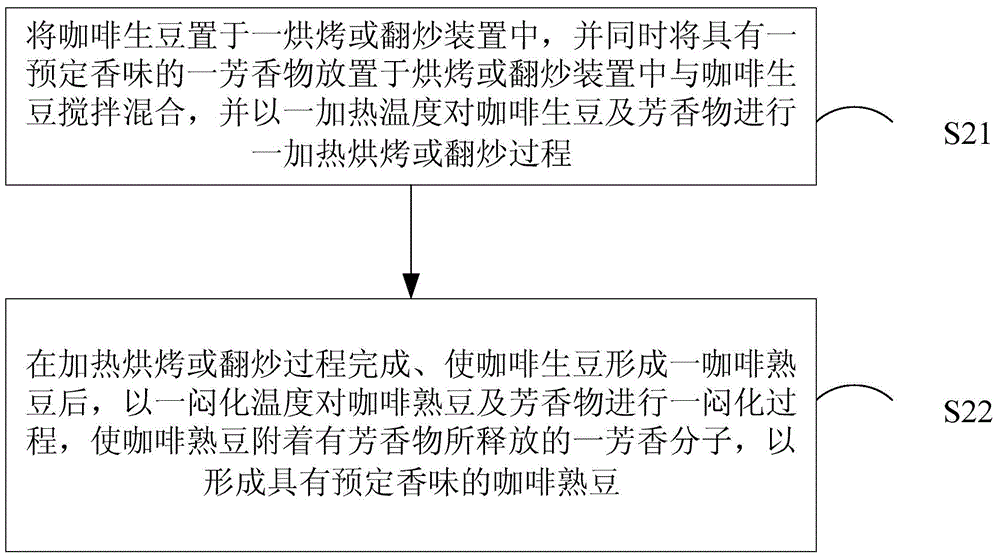

Method for preparing aromatic coffee

The present invention discloses a method for preparing aromatic coffee, comprising the following steps: soaking a green coffee bean and an aromatic substance with predetermined aroma and stirring, then drying the green coffee bean and the aromatic substance after the green coffee bean is fermented or is mixed with the aromatic substance for predetermined time; and placing the green coffee bean and the aromatic substance into a baking or stir-frying device performing a heating baking or stir-frying process on the green coffee bean and the aromatic substance at a heating temperature, and performing a smouldering process at a smouldering temperature, so that the green coffee bean can be provided with an aromatic molecule released by the aromatic substance, so as to generate a prepared coffee bean with the predetermined aroma.

Owner:史辰雄

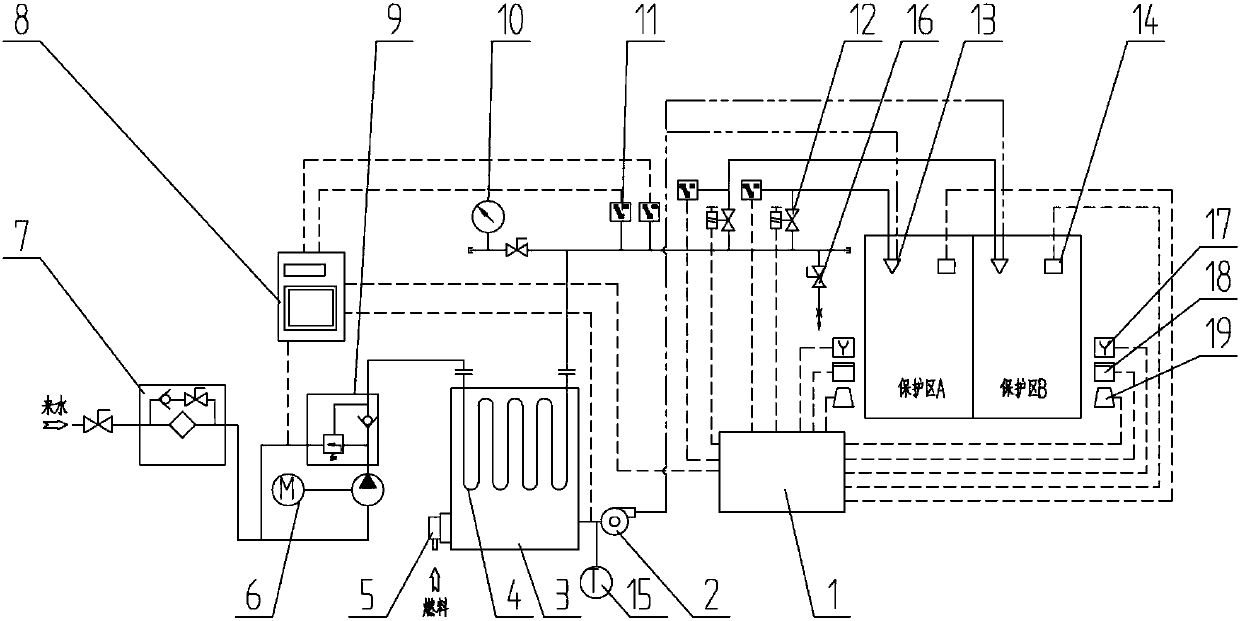

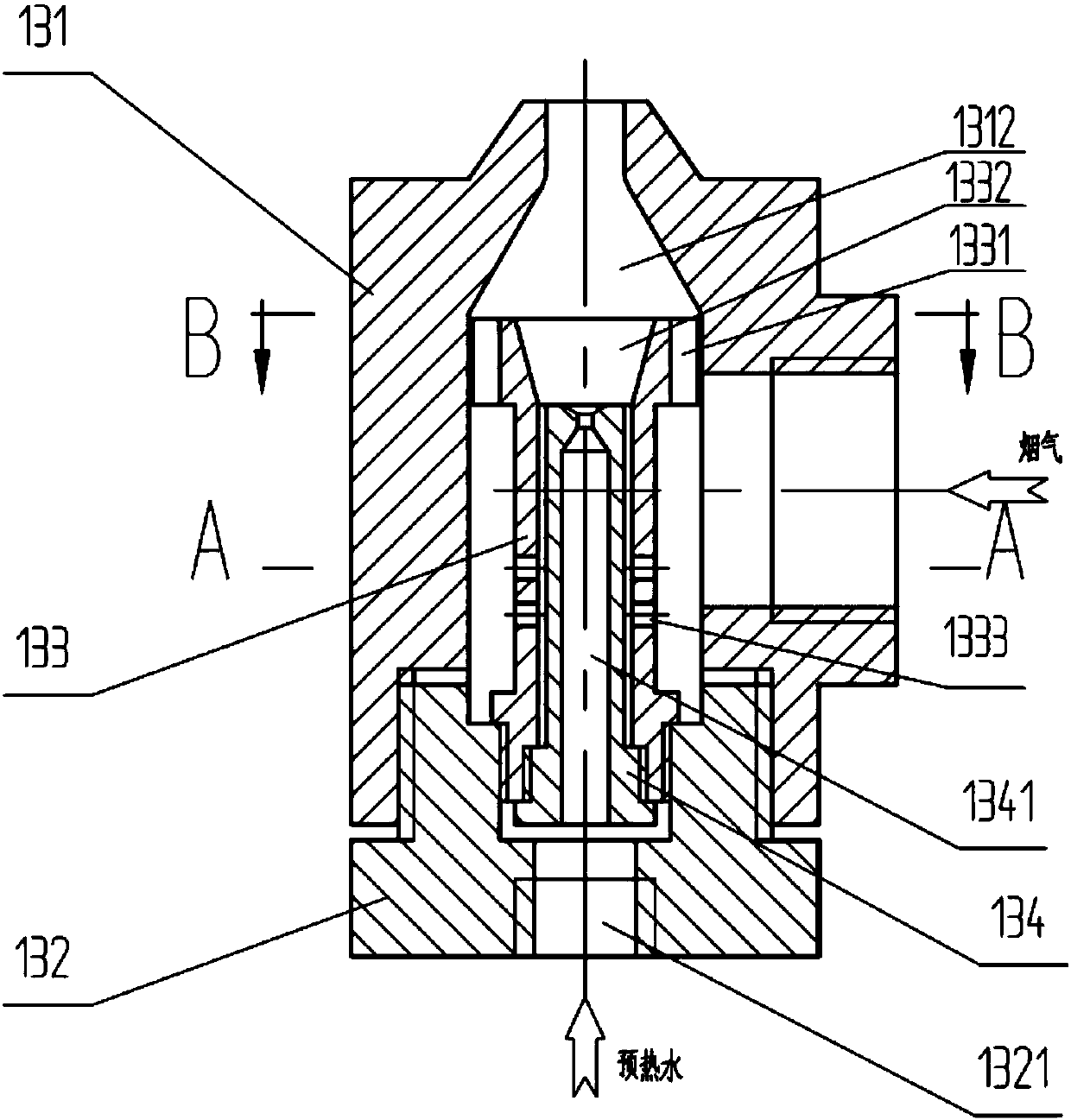

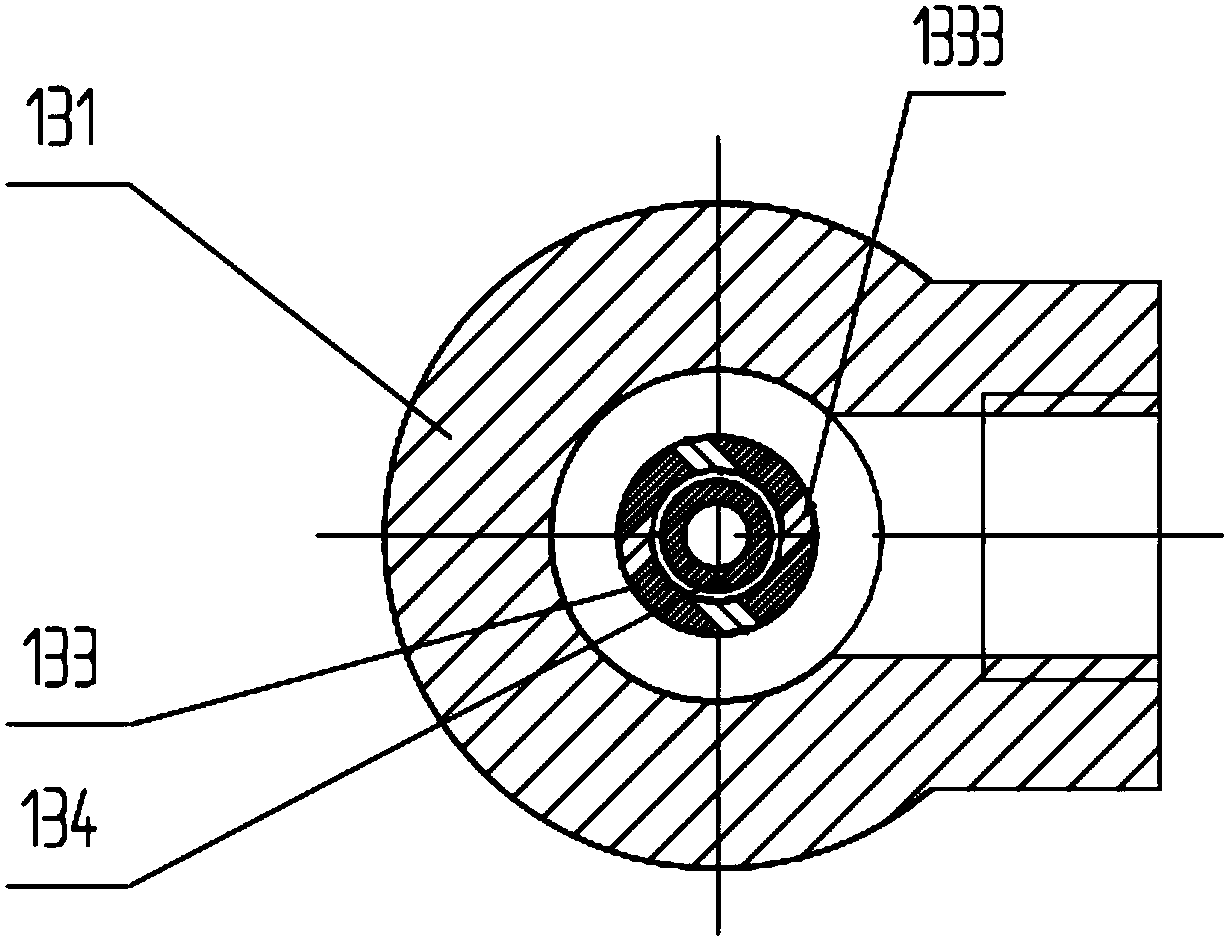

Preheating type fine water mist fire extinguishing system and fine water atomizing nozzle

ActiveCN107899167AEffectively extinguishImprove fire extinguishing effectFire rescueCombustion technology mitigationFlame detectionControl line

The invention particularly relates to a preheating type fine water mist fire extinguishing system and a fine water atomizing nozzle. The problems that because an existing fire extinguishing system cannot form an effective asphyxia environment for fire with small calorific value, difficulty in fire extinguishing of fine water mist is caused is solved. The fine water mist fire extinguishing system comprises a fire alarm device, a control device and a fire extinguishing system. The fire extinguishing system comprises a filter, a pump set, a heat exchanger and a fine water atomization nozzle whichare sequentially connected with one another through pipelines. The heat exchanger is subjected to heat exchange through a combustion machine, the combustion machine is connected with the fine water atomization nozzle through an induced draft fan, a pipeline between the heat exchanger and the fine water atomizing nozzle is provided with a signal feedback device, and the signal feedback device is connected with the control device through a control line. The fine water atomization nozzle is arranged in the protection region, a flame detection device is arranged in the protection region, and theflame detection device is connected with the fire alarm device. According to the fine water mist fire extinguishing system and the nozzle, fires with little heating capacity such as an initial small fire, a class-A fire and a smouldering fire can be effectively extinguished.

Owner:XIAN UNIV OF SCI & TECH

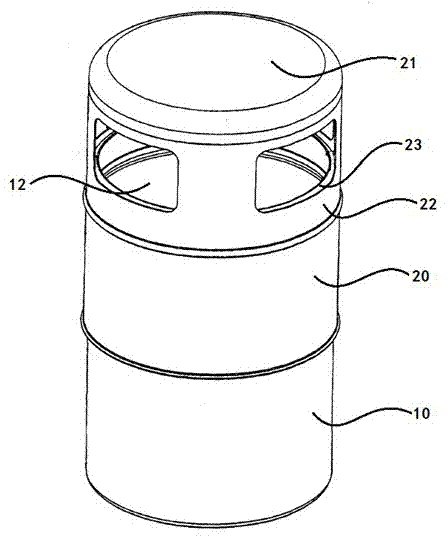

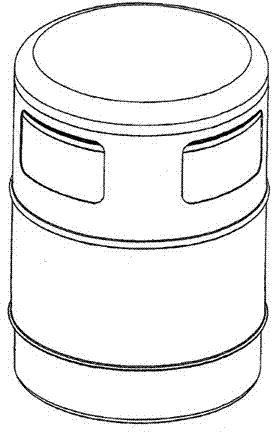

Plastic dustbin with heat-resisting and fireproofing functions

ActiveCN103569552AImprove fire safetyAvoid enteringRefuse receptaclesPolyether coatingsFireproofingEngineering

The invention relates to a plastic dustbin with heat-resisting and fireproofing functions. The plastic dustbin comprises a cylindrical plastic bin body with an upper opening and a plastic cover, wherein the plastic cover comprises a top wall and a cylindrical sleeve type side wall; at least one window is formed in the side wall; a groove is formed in the outer wall of the plastic bin body, a clamp ring is arranged in the groove, and a bulged part is formed in the side wall of the plastic cover and supported on the clamp ring, so that the plastic cover is kept in the use position; and when the temperature inside the plastic bin reaches to a set value, the clamp ring retracts and / or melts, so that the plastic cover slides downwards along the outer wall of the plastic bin body under the gravity action of the plastic cover, and a channel from the window to the upper opening of the plastic bin body is closed. According to the plastic dustbin, oxygen required by burning is prevented from entering the plastic bin body or remarkably reduced, so that spreading of naked light or smouldering fire is prevented, and the fireproofing safety of the dustbin is improved greatly.

Owner:重庆赛普实业有限公司

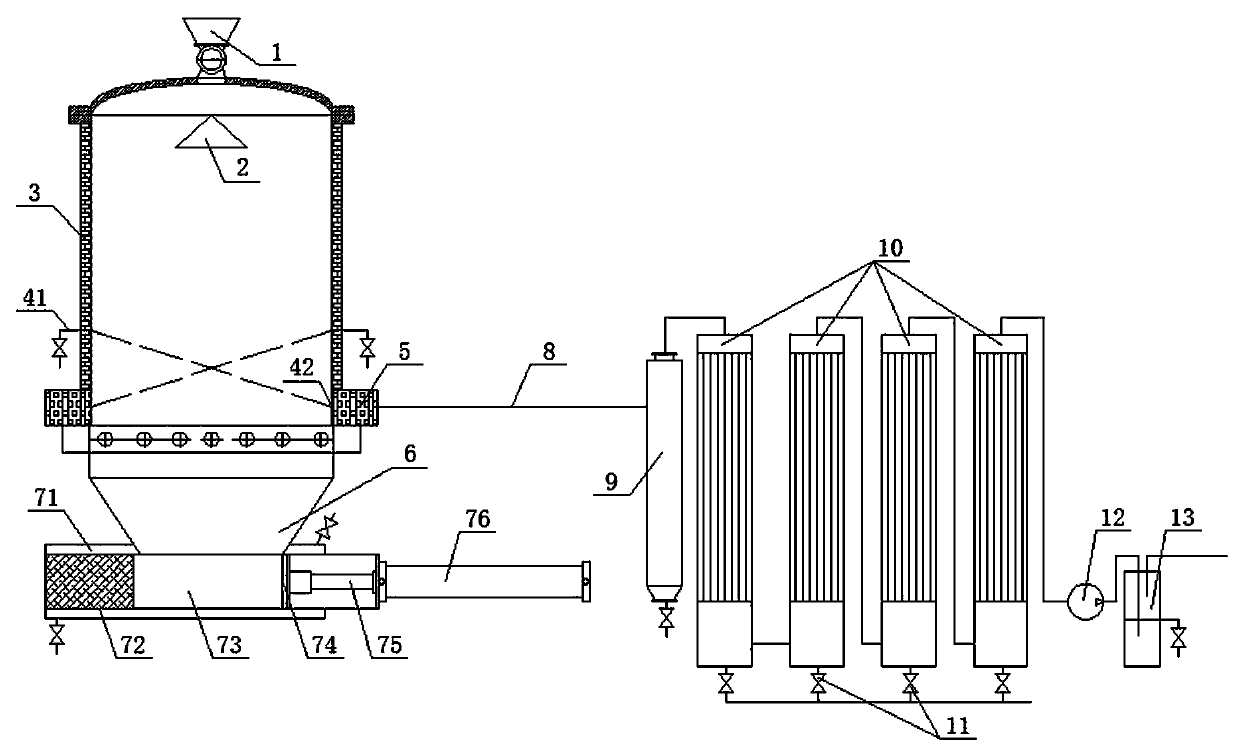

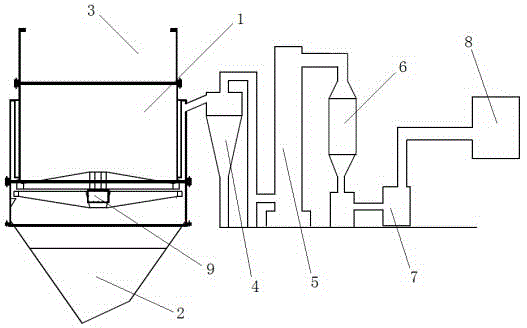

An apparatus for rice husk carbonization combustion and combustion gas collection-utilization

InactiveCN105694927AFavorably deal withAvoid pollutionBiofuelsSpecial form destructive distillationCombustorHusk

The invention discloses an apparatus for rice husk carbonization combustion and combustion gas collection-utilization. The apparatus comprises a rice husk carbonization combustion device, a cyclone dust removal column and a combustor. The rice husk carbonization combustion device is composed of a feeding open hopper, a combustion cabin and a lower ash bucket. A spraying washing column and a condenser are sequentially arranged between the cyclone dust removal column and the combustor. A blower is arranged at the front end of the combustor. Four observation holes are evenly formed in the periphery of the middle segment of the combustion cabin, so that the rice husk carbonization condition in the combustion cabin can be observed in real time, and the time when ash is discharged can be judged. A cover board of each observation hole is an inverted door installed later. According to the apparatus, unpractical components in gas generated in rice husk smouldering can be effectively removed to obtain a large amount of carbon monoxide and methane gas, and the carbon monoxide and the methane gas are recycled, reused, and used in the combustor. Waste gas can be favorably treated by the apparatus so that the gas is prevented from polluting air and the apparatus has the strong environmental protection significance.

Owner:唐长红

Environment-friendly smoke baking device for black tea processing

InactiveCN107439727AEasy to pushImprove the efficiency of smoking and roastingPre-extraction tea treatmentBlack teaEngineering

The invention discloses an environment-friendly smoking and roasting device for black tea processing, which comprises a smoking and roasting box, a combustion box is welded to the outer wall of the bottom of the smoking and roasting box, and a material inlet is opened on one side of the outer wall of the combustion box, and the inner wall of the bottom of the inlet is passed through The hinge is fixed with a feed door, a baffle is welded at the central axis position of the bottom inner wall of the smoking box, and the top of the baffle is welded on the top inner wall of the smoking box, and a smoking car is placed on the bottom inner wall of the smoking box. In addition, a second baffle plate is welded at the central axis of the top outer wall of the smoker, and smoke concentration sensors are fixed on both sides of the top outer wall of the smoker box by screws. The invention can smoke and roast a large amount of black tea at one time, improves the efficiency of black tea smoke and roast, effectively reduces pollution, and has good environmental protection effect. At the same time, the recovery tube can be used to recover excess smoke and then smoke and roast, and the smoke can be used to the greatest extent, saving resources. The cost is reduced, and the equipment is highly automated, which greatly reduces the labor intensity.

Owner:湖北金莓科技发展有限公司

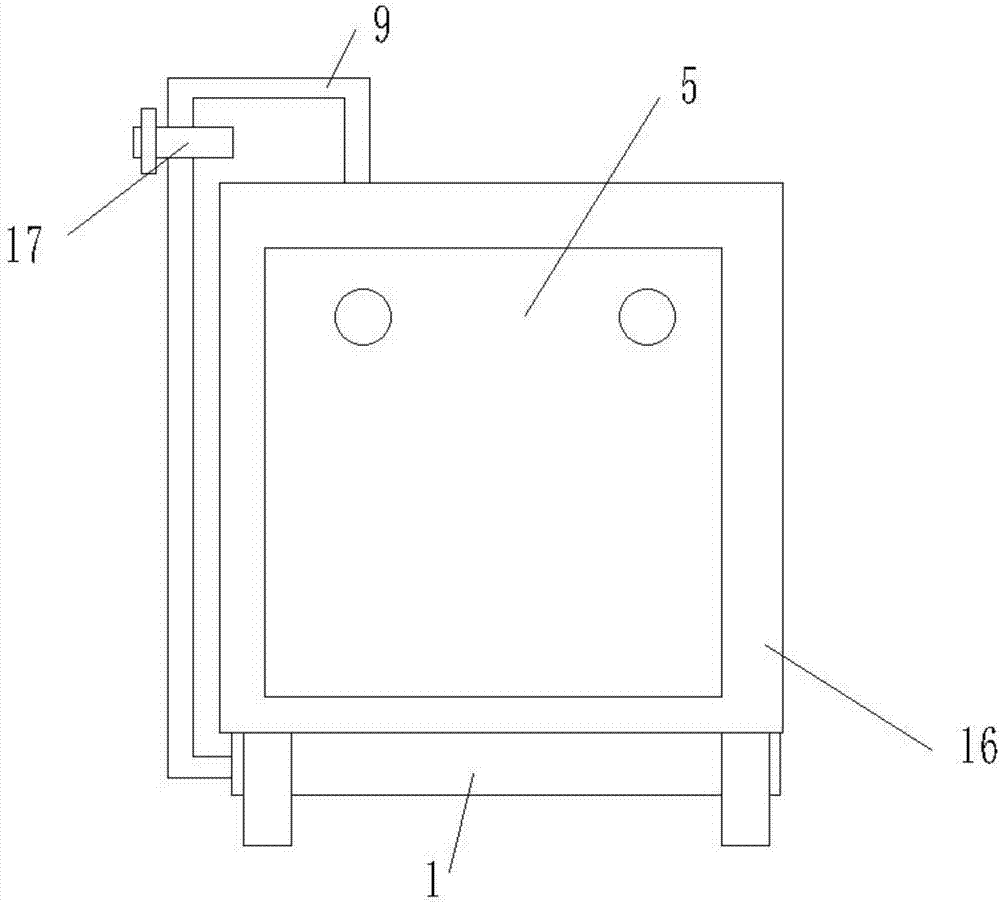

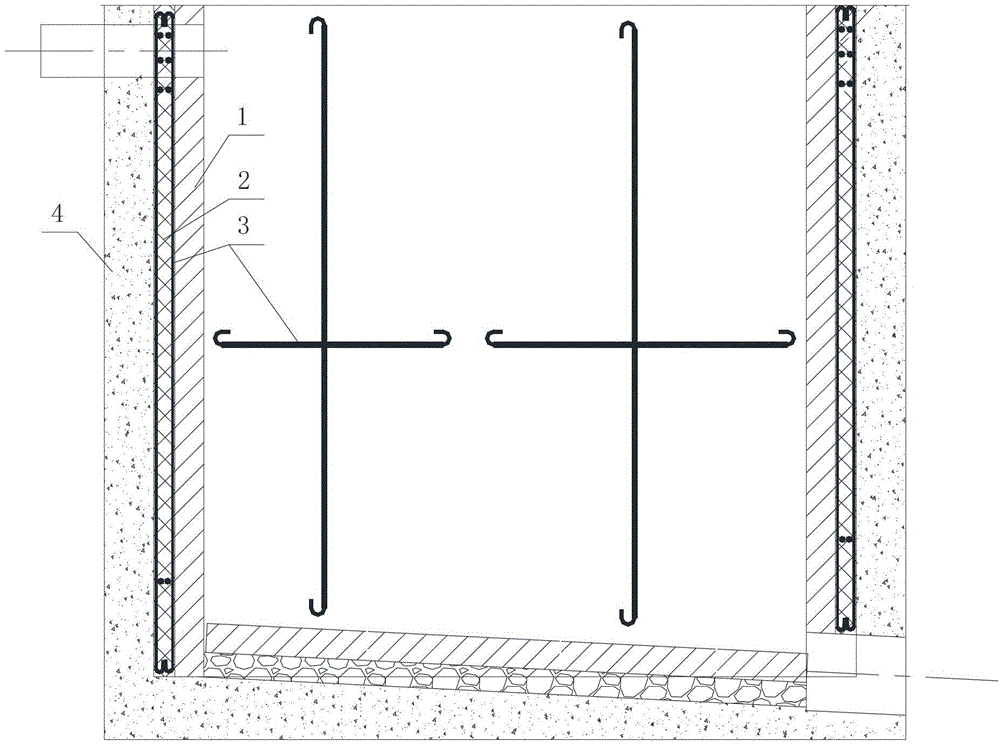

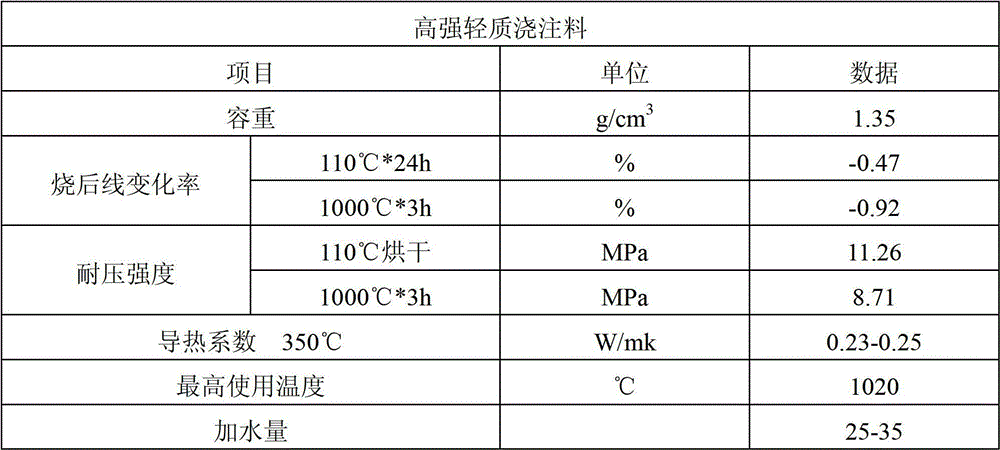

Thermal insulation construction and method used for steel slag thermal smouldering device

ActiveCN102747175AImprove securityImprove integrityRecycling and recovery technologiesSlagThermal insulation

The invention provides a thermal insulation construction and method used for a steel slag thermal smouldering device. The thermal insulation construction provided by the invention is characterized in that a thermal insulation layer of a thermal insulation device is internally provided with a constructional reinforcement and is filled with thermal insulation castable, so as to reduce the temperature of a concrete construction and protect the concrete construction. Compared with the prior art, the thermal insulation construction disclosed by the invention can be used for effectively and greatlyreducing the working temperature of the concrete construction, improving the durability of concrete, enabling the thermal insulation castable to achieve better integrity, reducing the maintenance frequency and improving the use security.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

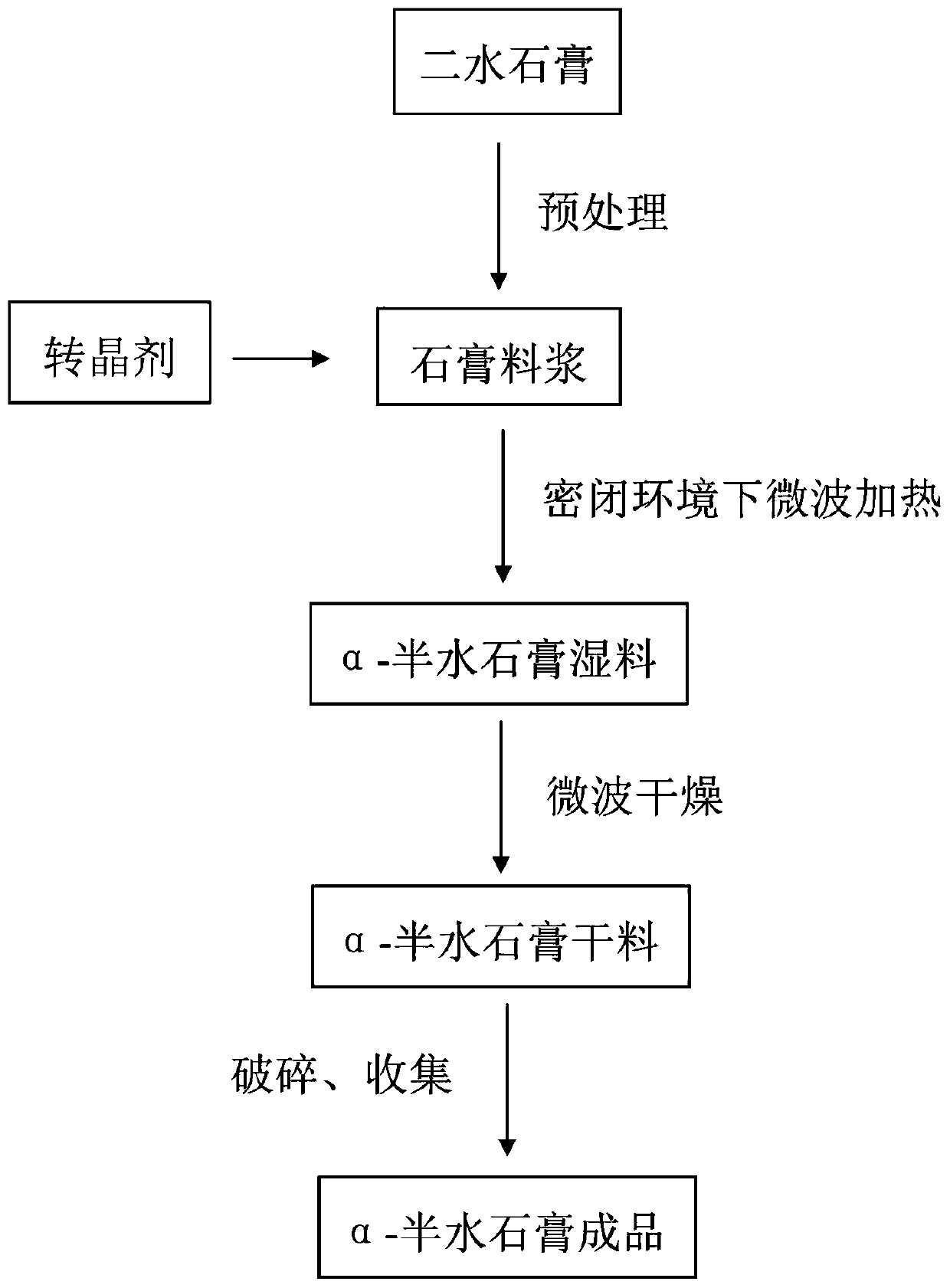

Production technology for preparing alpha-hemihydrate gypsum through microwave smouldering

The invention discloses a production technology for preparing alpha-hemihydrate gypsum through microwave smouldering. The production technology mainly comprises the steps of pre-treatment, wherein anindustrial by-product gypsum or natural gypsum is pre-treated, and dihydrate gypsum is purified; microwave heating, wherein the pretreated material is placed into a closed container and the material is heated by using a microwave field; crystal transformation, wherein under the action of a crystal transformation agent and other additives, the crystal morphology of the material is transformed underthe combination of microwave heating; microwave drying, wherein heating is continuously conducted by using the microwave field, and excessive liquid is vaporized, discharged and collected; breaking,wherein the agglomerated material is broken by using a machine; storage, wherein the broken material is hermetically stored at a certain humidity, temperature and the like. The production technology has the advantages of being environmentally friendly, efficient and controllable in cost, and the alpha-hemihydrate gypsum capable of meeting the national standards can be prepared.

Owner:云南凝创环保科技有限公司

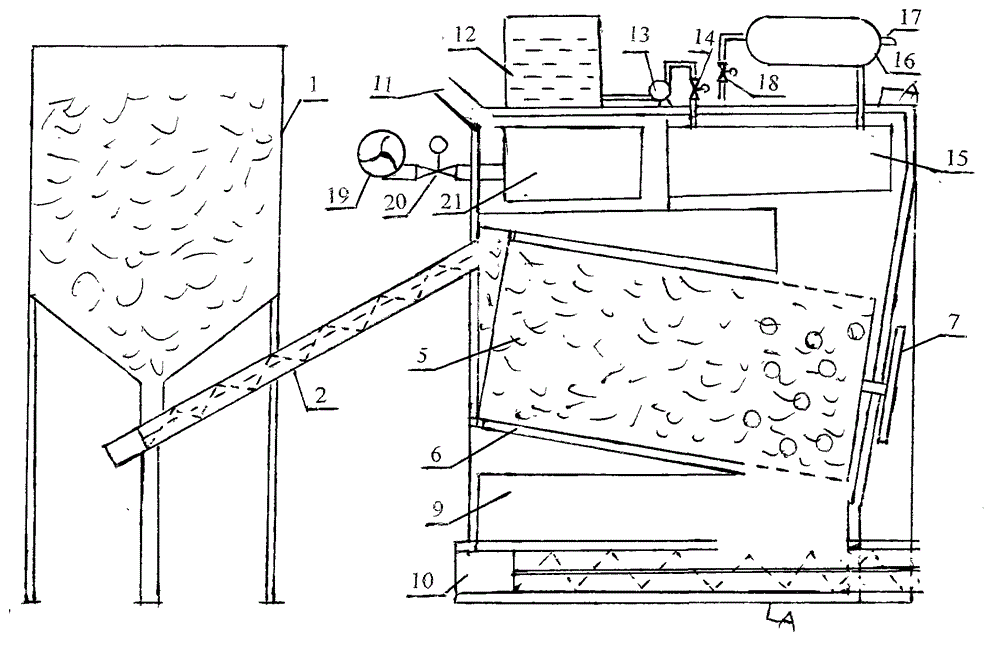

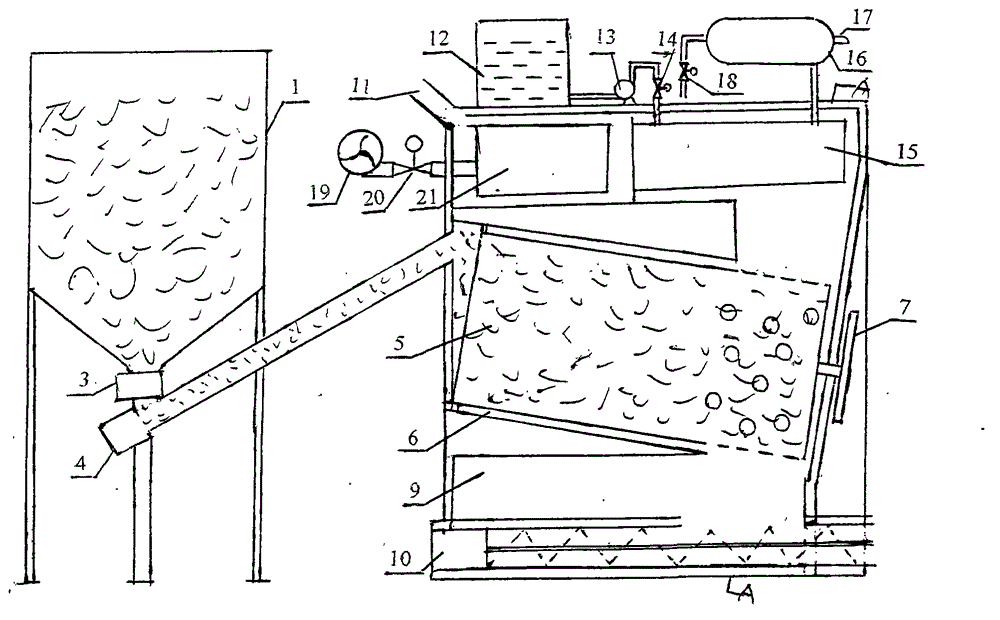

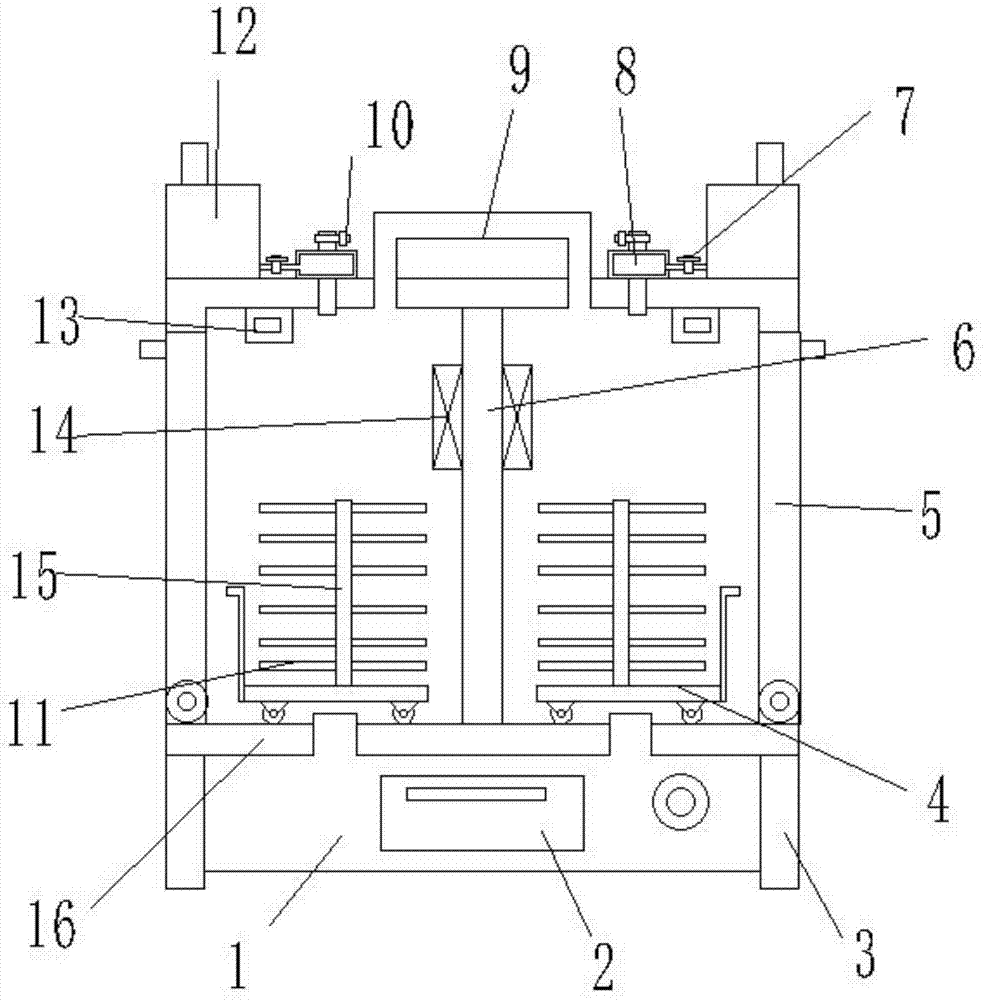

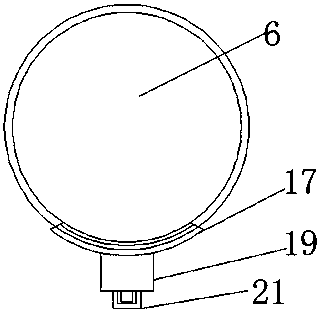

Blanching and sulfur smouldering device for preserved fruit processing

InactiveCN108850382AEvenly blanchedUniform sulfur fumigationConfectionerySweetmeatsSulfurEngineering

The invention discloses a blanching and sulfur smouldering device for preserved fruit processing. The blanching and sulfur smouldering device for preserved fruit processing comprises moving wheels, abracket, a push rod, a first motor, a tank cover, a mesh cage, a second motor, a fan body, a protective cover, an air guide pipe, nozzles, an air pump, a three-way pipe, a first guide pipe, a fixed plate, a second guide pipe, a first guide rail, a boiler, a supporting plate, a processing tank, a second guide rail, a sulfur combustion tank, a fixed block and a connection rod. For the blanching andsulphur smouldering device for preserved fruit processing, by utilizing the air pump, the three-way pipe and an electromagnetic valve, sulfur dioxide gas and hot steam are controlled to enter the processing tank to perform sulfur smouldering and blanching on fruits; by utilizing the first motor to drive a rotary rod to rotate, the mesh cage is driven to rotate, so that fruits are uniform in blanching and sulfur smouldering, the blanching and sulfur smouldering time of the fruits are shortened, and the working efficiency is improved. The device is convenient to load and unload the fruits, can perform blanching and sulfur smouldering on the fruits, is uniform in blanching and sulfur smouldering, improves the quality of preserved fruits and shortens the preparation time of the preserved fruitand reduces the cost.

Owner:湖州美果汇食品有限公司

Straw gasification furnace capable of continuously producing gas

The invention discloses a straw gasification furnace capable of continuously producing gas. Straws which are cut up are fed into a material storage tank, the straws placed in the material storage tank are conveyed into a rolling tube type furnace rake by a spiral feeding machine, after the rolling tube type furnace rake is fully filled with the straws, a driving motor rotates to drive the rolling tube type furnace rake to rotate, and a plastic bottle is extruded so that diesel oil can be uniformly sprayed onto the straws in the rolling tube type furnace rake. The straws sprayed with the diesel oil are ignited by the flame of a pistol type long pipe gas ignition gun, wind blown out from a blast blower supports the smouldering of the straws in the rolling tube type furnace rake, the straws can generate a large amount of carbon monoxide during the smouldering, fireproof ceramic balls or metal balls in the rolling tube type furnace rake stir the straws so that the uniform smouldering of the straws can be realized, coal tar generated by the smouldering is heated and decomposed into low-molecule combustible gas when passing through two layers of double-layer honeycomb-shaped metal nets of the back section of the red burnt rolling tube type furnace rake, hot smoke gas heats the wind blown out from a boiler and the blast blower, the generated vapor and hot wind enter an air outlet pipe, and humid and hot air supports the smouldering of the straws, the combustible gas content in the smoke gas can be increased, and the smoke gas is cooled.

Owner:张英华

Method for extinguishing a smouldering fire in a silo

The invention relates to a method for extinguishing a smouldering fire in a silo by introducing inert gas into the silo. The inert gas is introduced through a venturi-type nozzle above the stored content in the silo with a slow streaming velocity in such a way that mass ratio of the entrained surrounding gas to the incoming liquid inert gas is between 0.5 and 20. Thus a closed inert gas layer is formed above the smouldering fire.

Owner:HEISEL MICHAEL +1

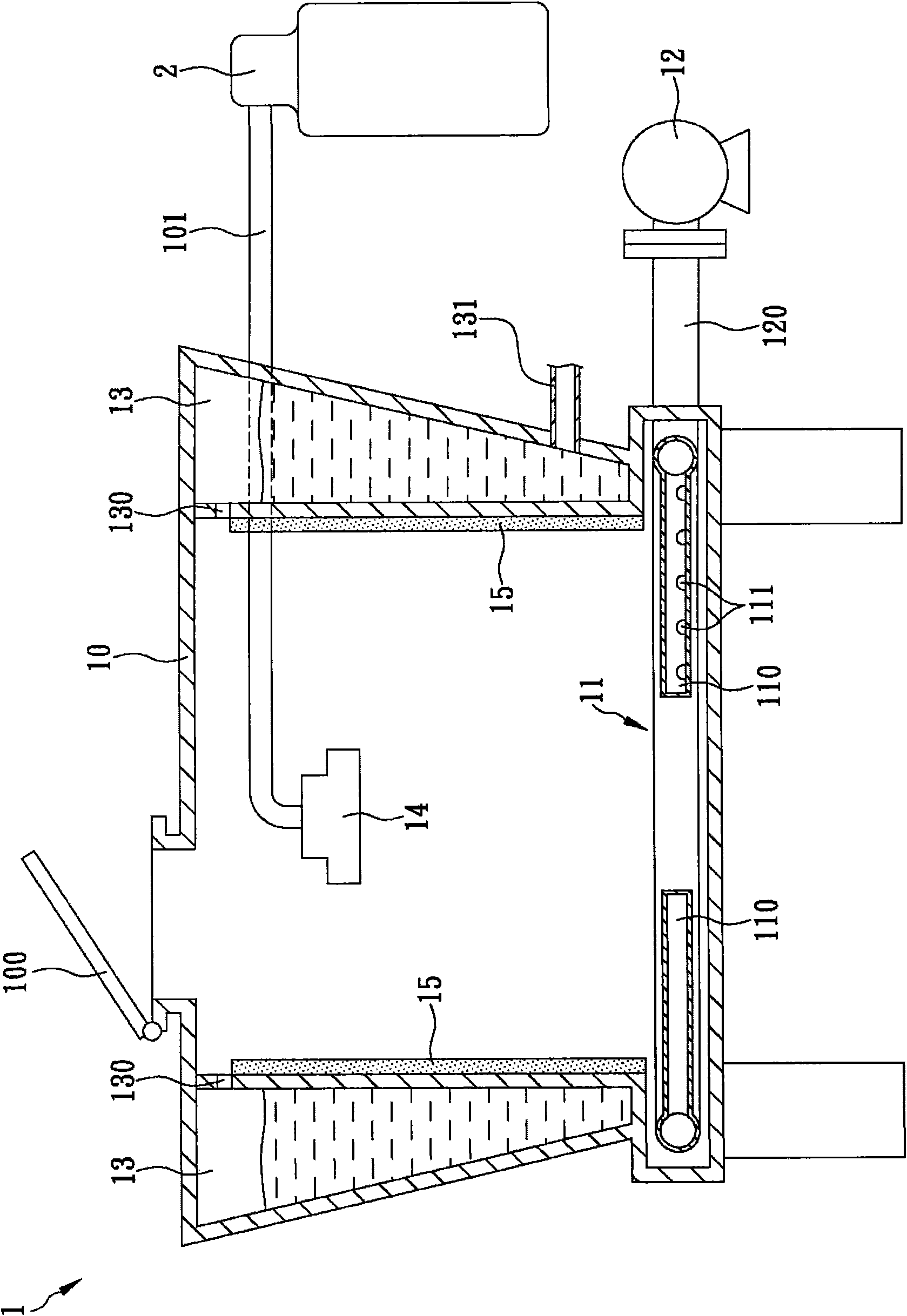

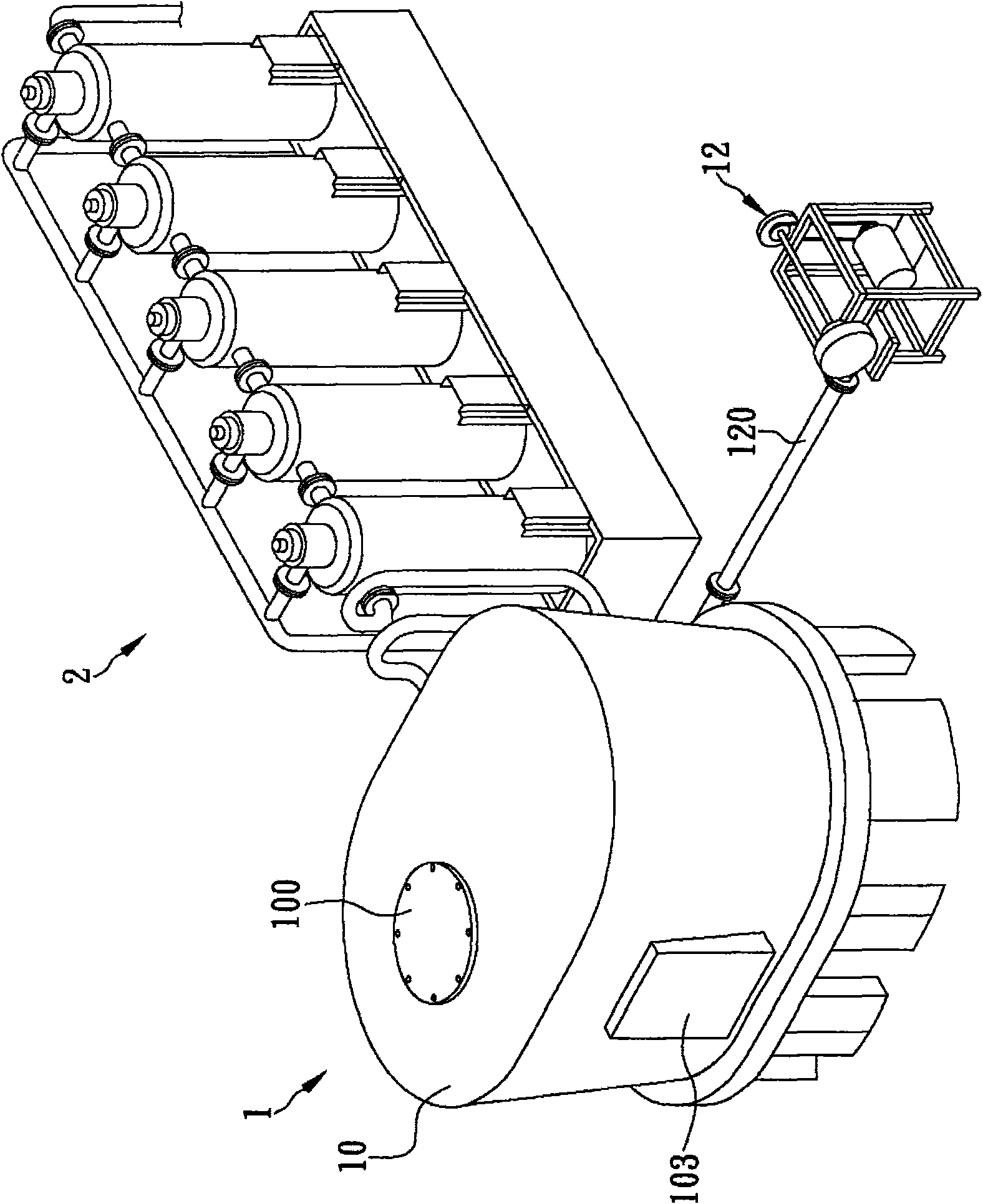

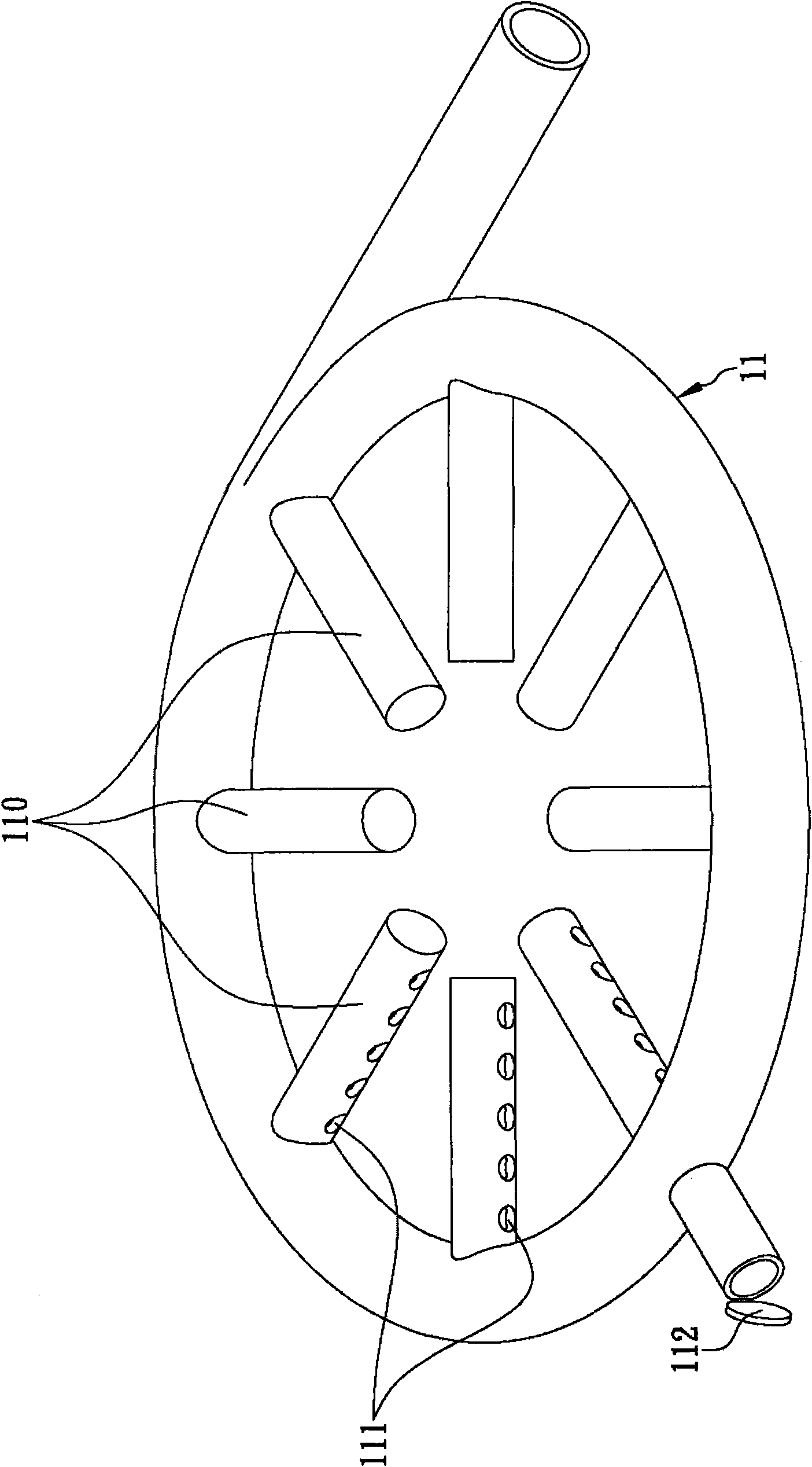

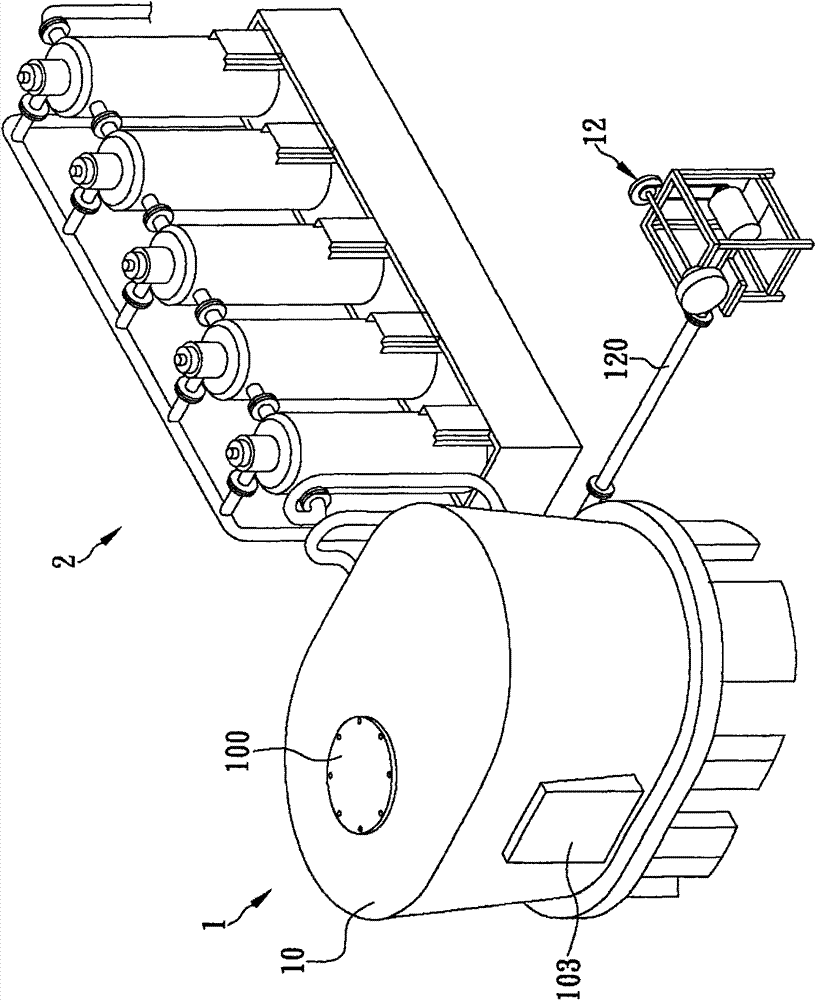

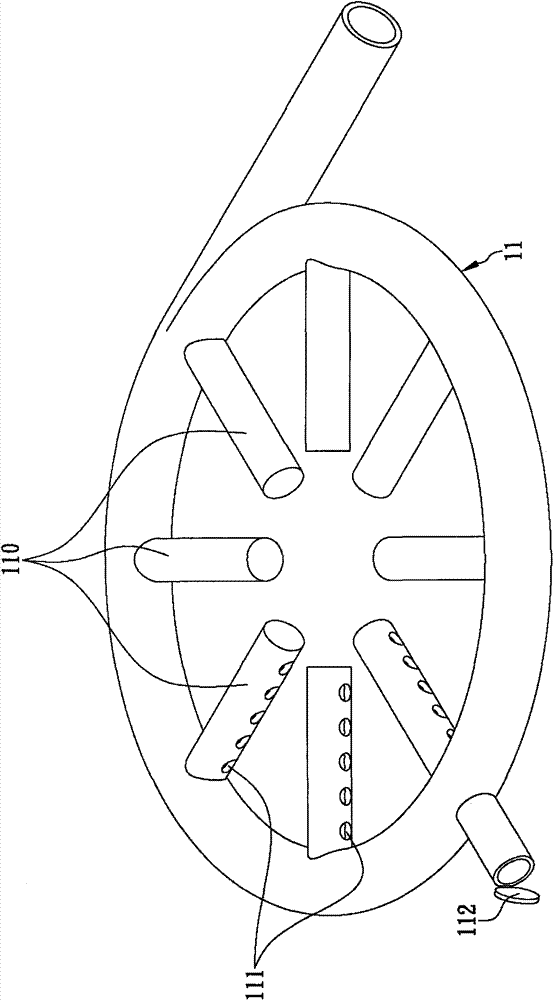

Combustible energy regeneration system and method thereof

InactiveCN102032579AImprove incineration efficiencySmoldering fullyIncinerator apparatusCombustible gas productionEnergy regenerationProduct gas

The invention relates to a combustible energy regeneration system and a method thereof. The regeneration system comprises a sealed furnace body, an intake module and a blower, wherein combustible waste materials can be filled in the furnace body; the intake module is arranged in the furnace body and contains a plurality of intake pipes; one intake pipe is used as an ignition pipe; and an air outlet pipe of the blower is communicated with the intake module and can smoulder uniformly from bottom to top, thus dense smoke and gas rich in combustible energy can be led out to a gas recovery mechanism or a combustion mechanism for recovery or reuse. Therefore, by adopting the regeneration system in the invention, the external air can be led in the furnace body uniformly to realize the uniform smoulder of the waste materials in the furnace body; the gas with combustible energy, generated by smouldering can be recovered or reused, thus the problem that smoke dust and impurities floating to theoutside to cause air pollution, can be effectively avoided; and the aim of regenerating and recycling energy can be realized and the green and environmental protection requirements on energy conservation and carbon emission reduction can be achieved.

Owner:HUNG CHIH CORP

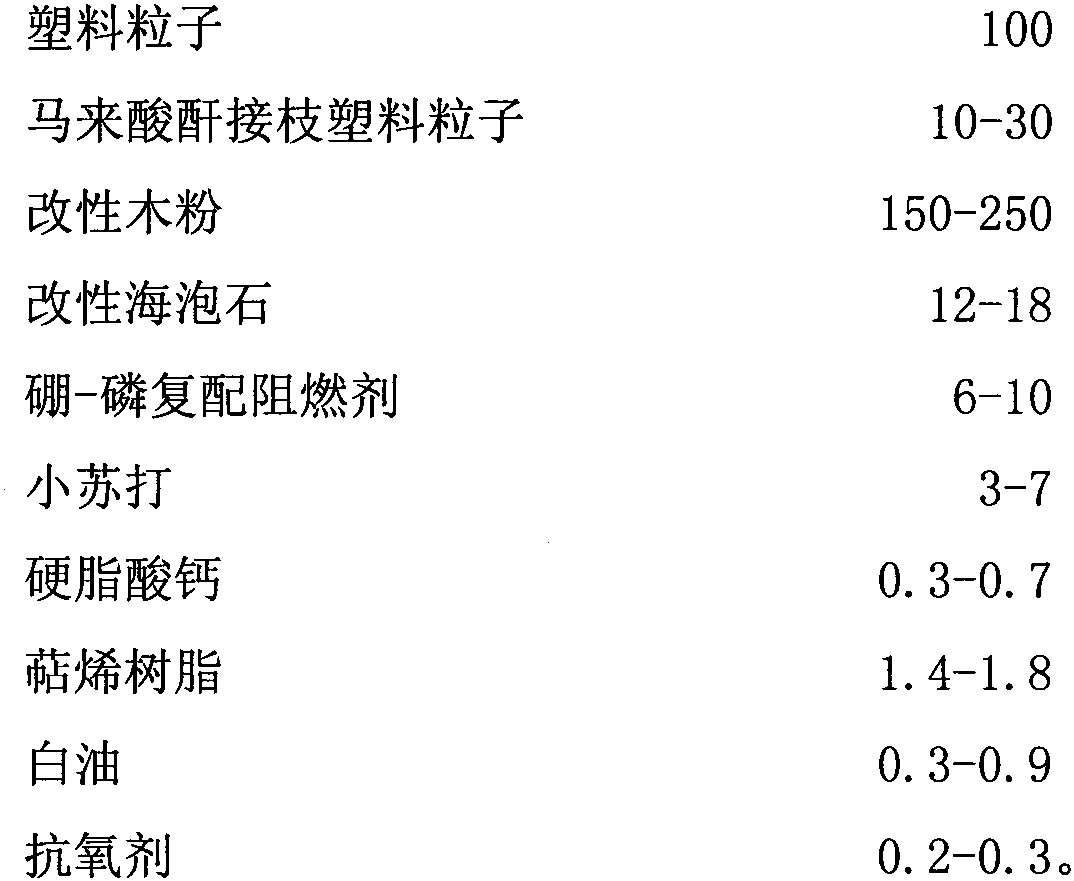

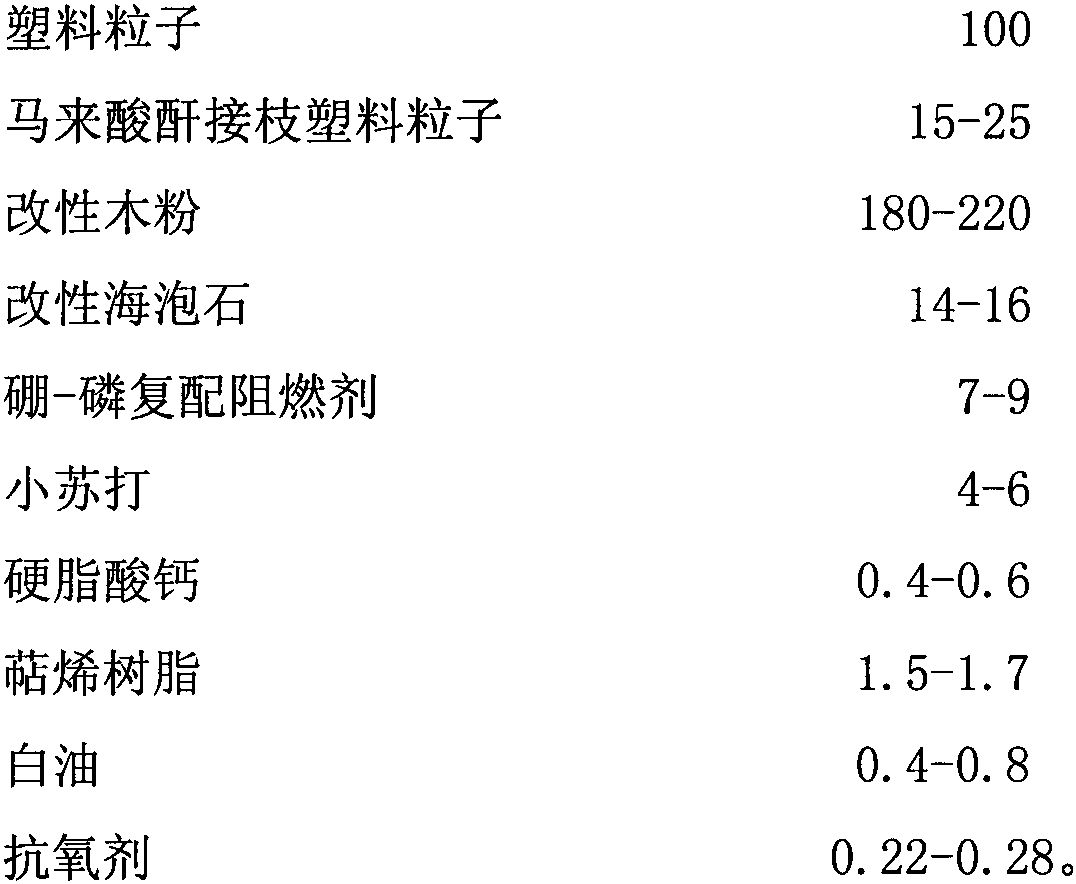

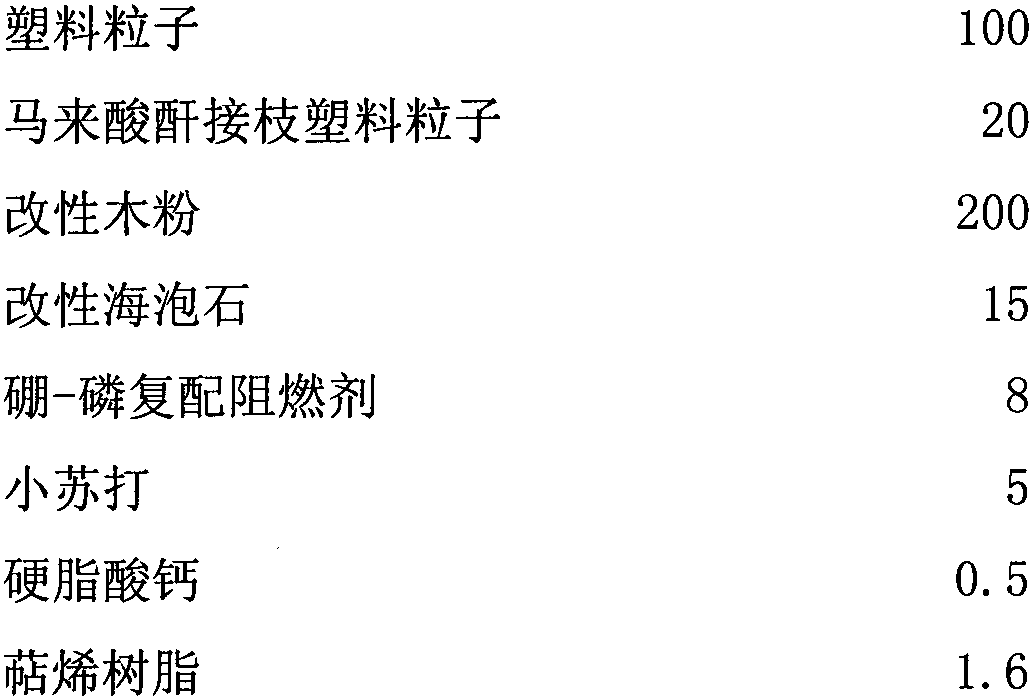

Efficient flame-retardant plastic-wood composite board and preparation method thereof

Owner:江苏明天材料科技有限公司

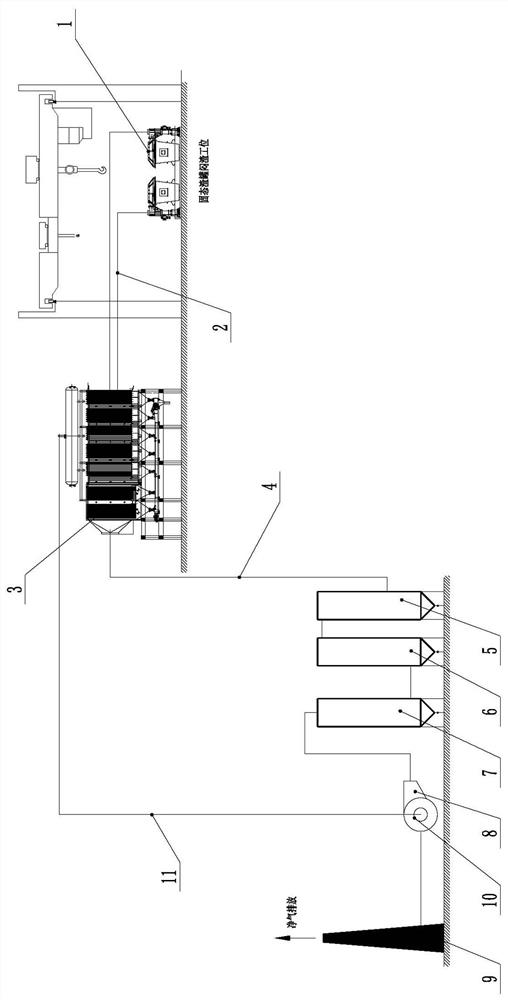

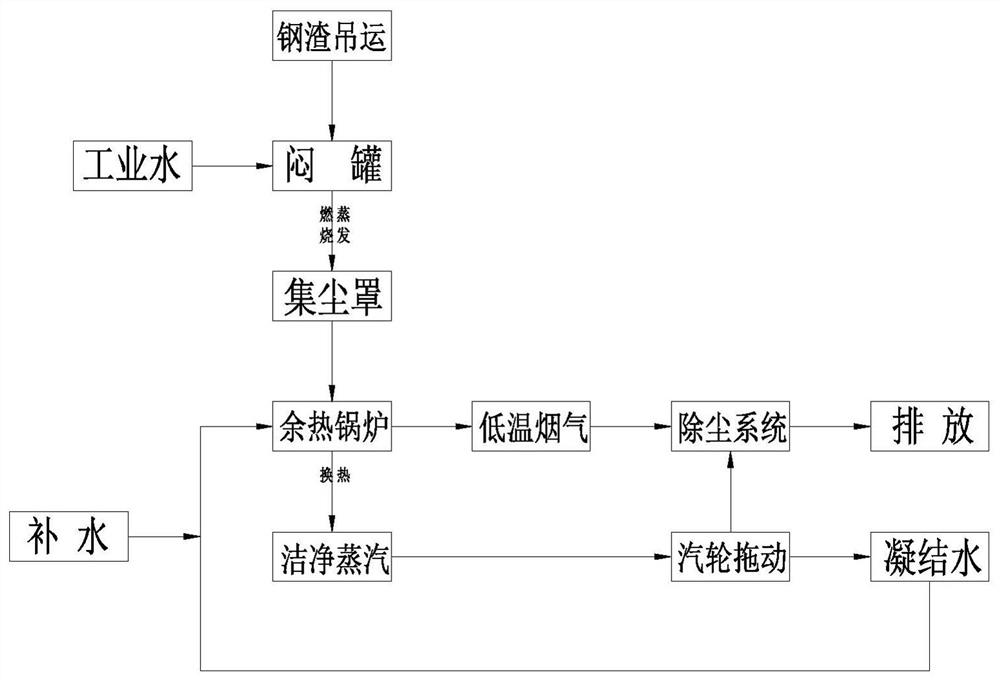

Reverse immersion method normal pressure hot-smouldering steel slag and waste heat recovery system and method

ActiveCN113736931ADischarge orderlyRealize airtight operationProcess efficiency improvementSteam generation using hot heat carriersSlagDust control

The invention relates to a reverse immersion method normal pressure hot-smouldering steel slag and waste heat recovery system. The system comprises a slag smouldering device and a waste heat recovery device connected with the slag smouldering device. The slag smouldering device comprises a solid slag tank, a water supply and drainage device communicated with the bottom of the solid slag tank and a water-cooling dust collecting cover arranged above the solid slag tank; the waste heat recovery device comprises a waste heat boiler connected with the water-cooling dust collecting cover through a water-cooling flue; a low-temperature flue gas pipeline of the waste heat boiler is communicated with a spray tower, a dehydrator, a wet type electronic dust removal tower, a dust removal fan and a purified gas discharge tower which are connected in sequence; the dust removal fan is dragged by a steam turbine; and a saturated steam pipeline of the waste heat boiler is connected with the steam turbine. The invention further relates to a method for slag smouldering and waste heat recovery through the system. According to the system and method, the temperature of the steel slag entering the tank can be increased, waste heat of the hot steel slag is fully utilized, meanwhile, combustible gas generated in the slag smouldering process is effectively treated and recycled, and the safety and energy conservation are achieved.

Owner:河北安泰工程技术有限公司

Smouldering washing solution for treating hemorrhoid and preparing method thereof

InactiveCN101584768BNo side effectsNo painPharmaceutical delivery mechanismAlkali/alkaline-earth metal chloride active ingredientsCure rateMedicine

The present invention relates to a smouldering washing solution for treating hemorrhoid and a preparing method thereof. The smouldering washing solution is prepared by safflower, Divaricate Saposhnikovia root, folium artemisiae argyi, green prickleyash and refined salt according to a fixed proportion. The treating to hemorrhoid with the medicine of the invention has the advantages of no toxic sideeffect, no pain, easy process, saved cost, high cure rate and no recurrence.

Owner:邵金芝

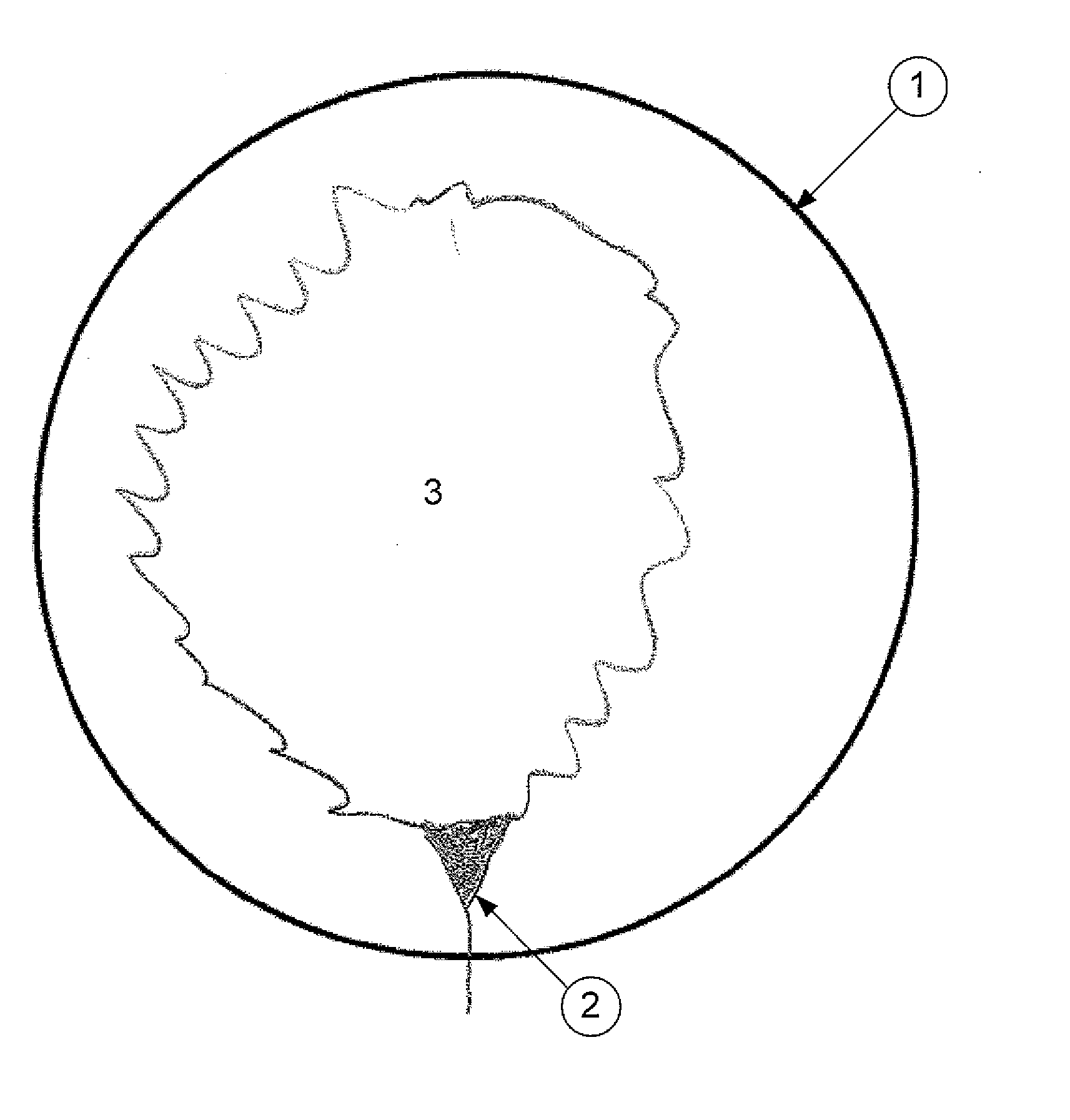

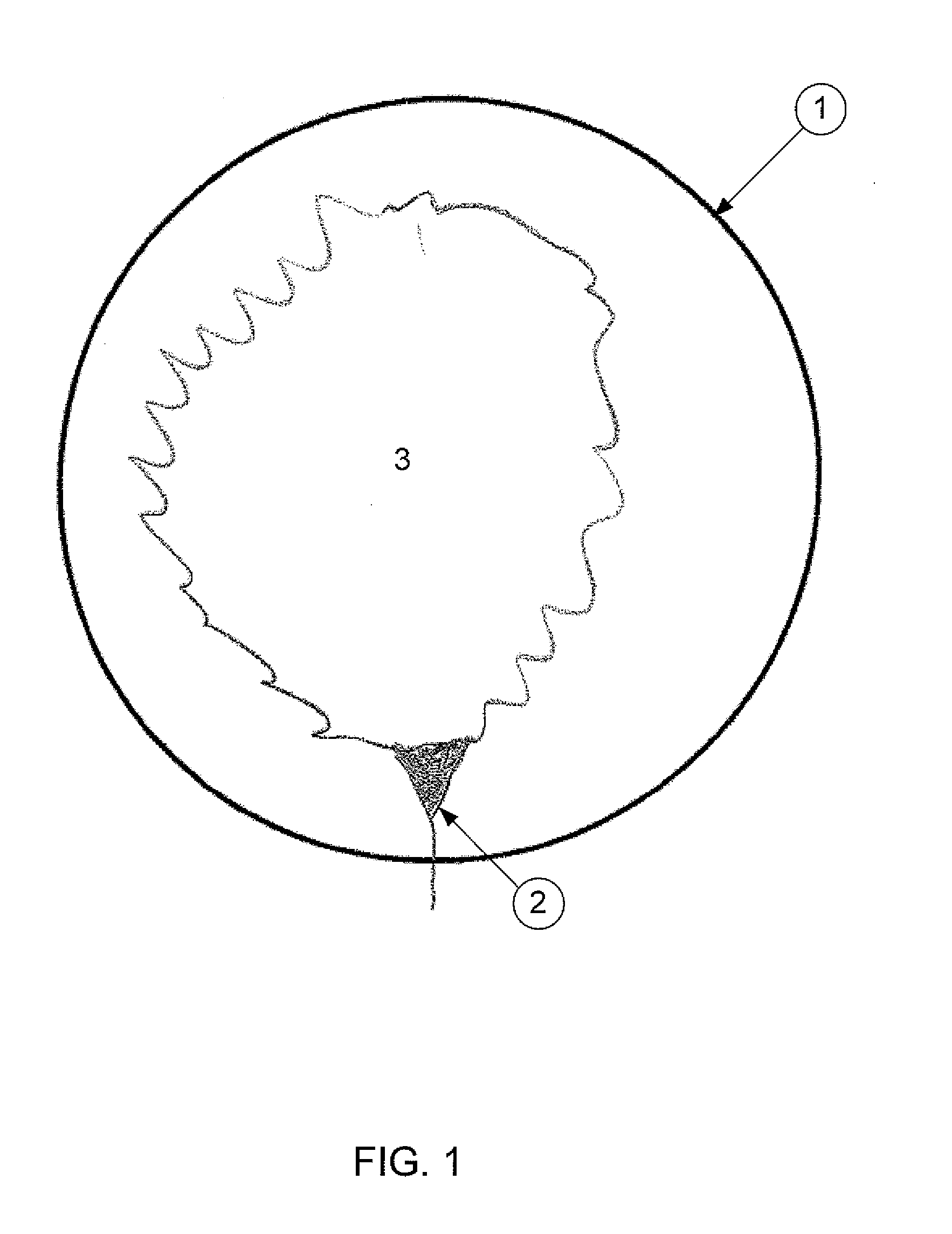

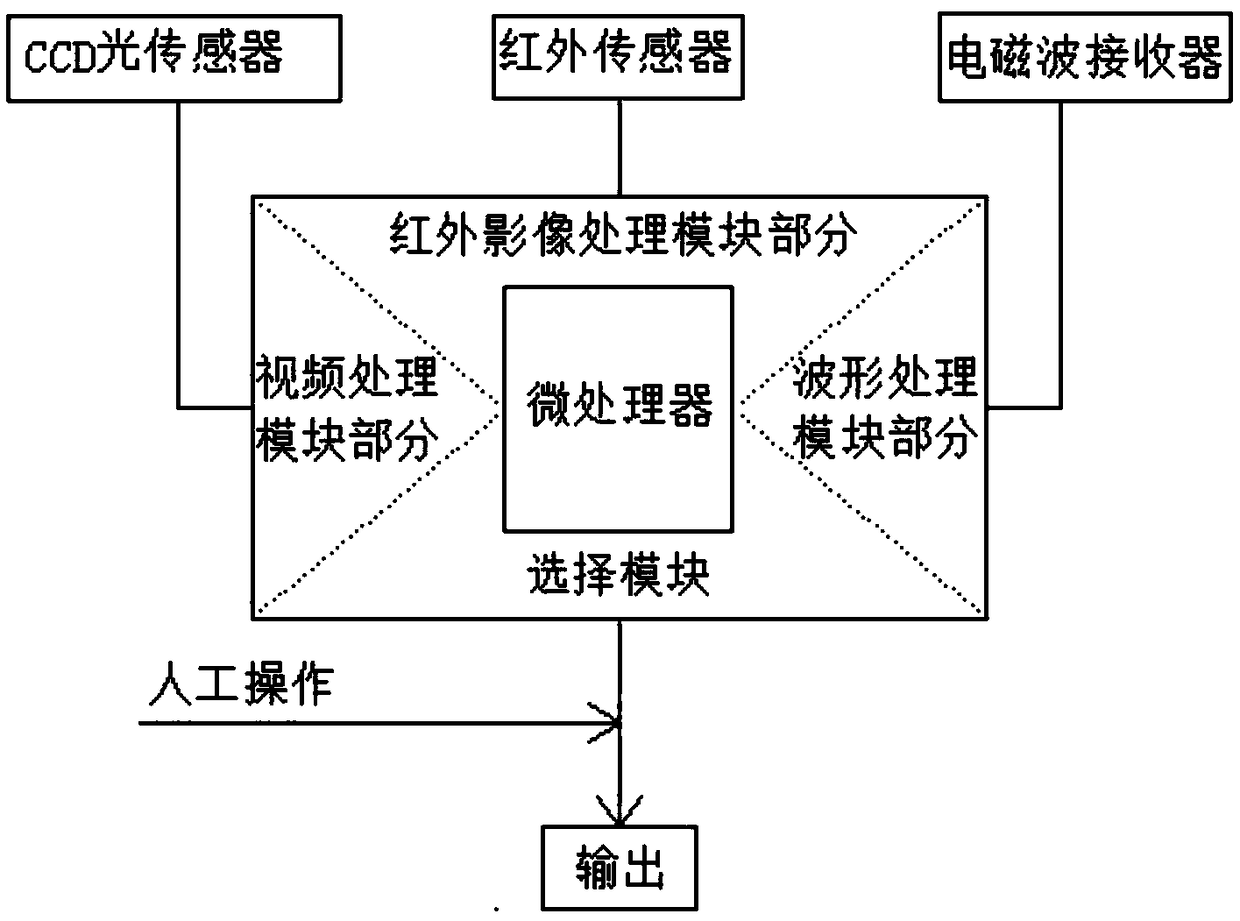

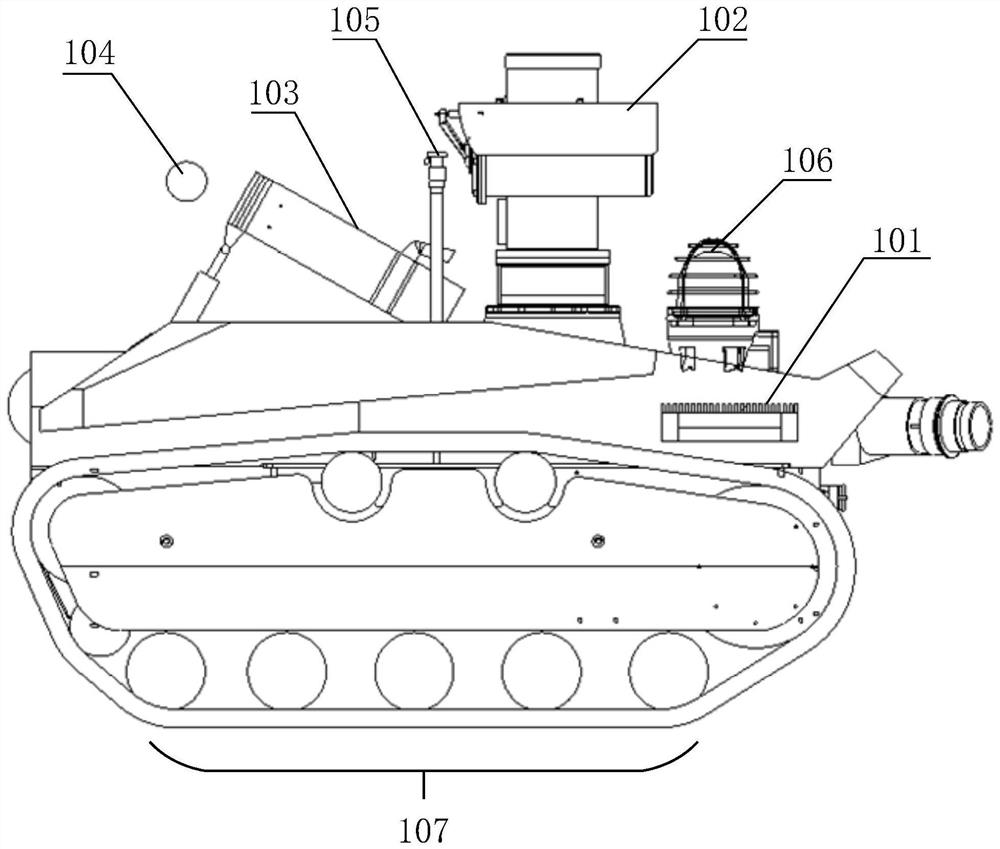

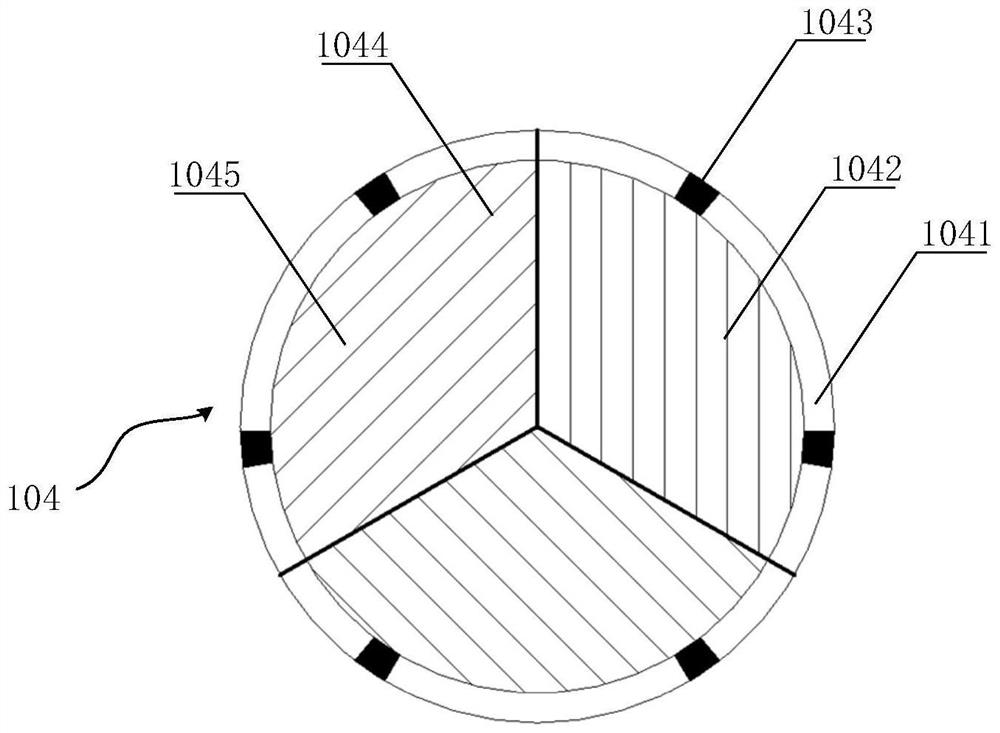

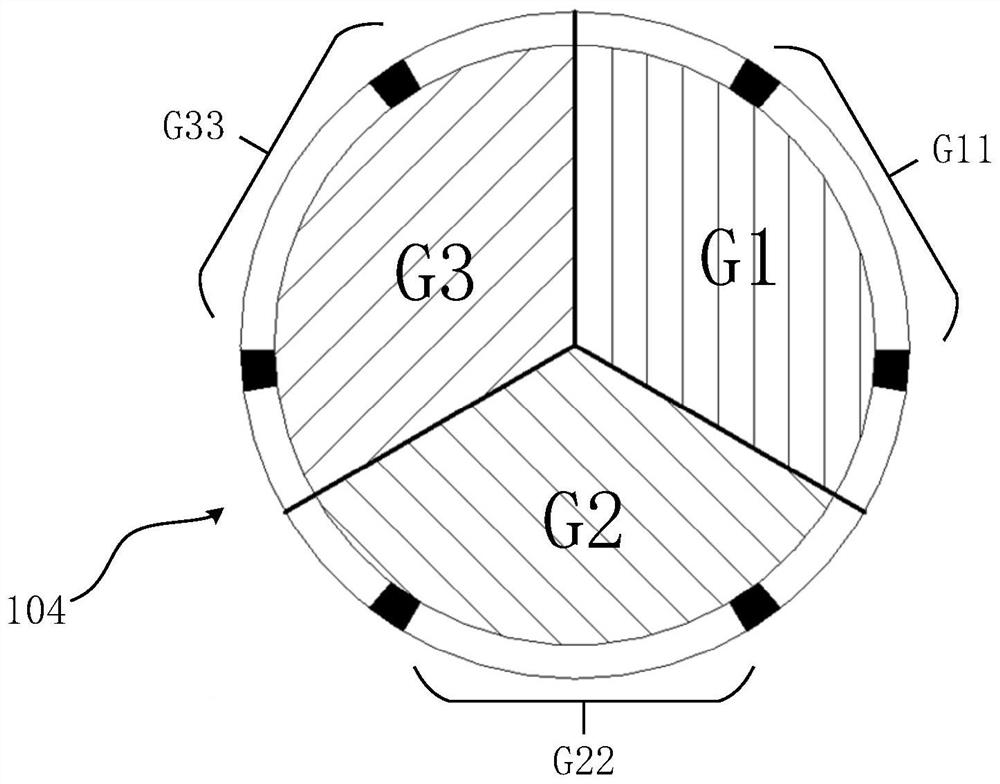

Method for cleaning forest embers by crawler robot

The invention discloses a method for cleaning forest embers by a crawler robot. The crawler robot is equipped with an ember detector, an infrared detecting system, an infrared positioning system and an ember cleaning device. The infrared detecting system comprises an infrared camera and an imaging spectrometer; the method is as follows: step (1) finding and judging an ember; step (2), based on thestep (1), accurately positioning the position of the found and judged ember by the infrared positioning system arranged on the crawler robot; step (3), using the ember detector to detect wild (forest) smokeless flame-free ground surface and ash-covered embers and under-weed smouldering fire which are not difficult to find by naked eyes; step (4), setting a fire-avoiding region; and step (5), cleaning up the embers. The method realizes the effective detection, judgment and positioning of the forest embers, has a real-time effective cleaning function, and can meet actual needs.

Owner:NANJING FOREST POLICE COLLEGE

System, method and storage medium for residual fire detection

The present application relates to an residual fire detection system, method and storage medium, wherein the residual fire detection system includes: a control device, a binocular camera, a launching device and a detection bomb, and the control device is electrically connected to the binocular camera and the launching device respectively; The binocular camera is used to obtain the image of the target area; the control device is used to control the launching device to launch the detection bomb into the target area, and to perform residual fire detection on the target area according to the image of the target area; wherein, the detection bomb can The ambient temperature releases the smoke corresponding to the ambient temperature. Through the present application, the problem of being unable to detect covered and smoldering embers in the related art is solved, and the effect of being able to detect covered and smoldering embers is realized.

Owner:浙江华消科技有限公司

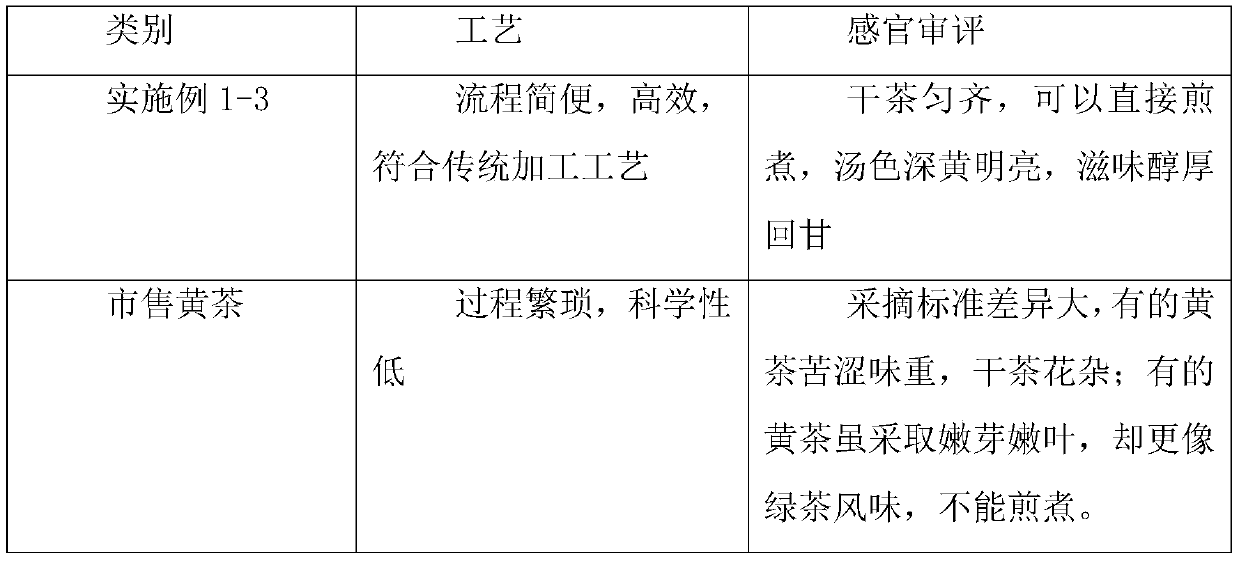

Yellow tea smouldered by electrolysis, and preparation method and application of yellow tea

The invention relates to yellow tea smouldered by electrolysis, and a preparation method and application of yellow tea. The preparation method includes the following steps that first, yellow tea is spreaded and aired in a ventilated place; gradient killing out is conducted on the yellow tea after being spreaded and aired through a roller; the yellow tea after being killed out is kneaded until teajuice is kneaded; the yellow tea after being kneaded is unpacked and loaded into a container for compressing, then 5-9 copper wires are inserted, the other end of one copper wire is grounded, and theother every two copper wires are electrified, and the yellow tea is kept at the room temperature for 2-3 days; and the yellow tea is obtained after being unpacked and then dried. According to the method for generating the yellow tea smouldered with flavone by electrolysis, yellow tea smouldering is conducted after killing out and kneading, at the same time, the yellow tea smouldering process is promoted by adopting innovatively an electric conduction method, biological, chemical and physical changes in the yellow tea production process are respected, and scientificity is high. Through the electric conduction smouldering technology, a traditional processing process is respected, the prior art is applied to the traditional process, the product quality is improved, and commercial prospects are good.

Owner:上海复晨生物科技有限公司

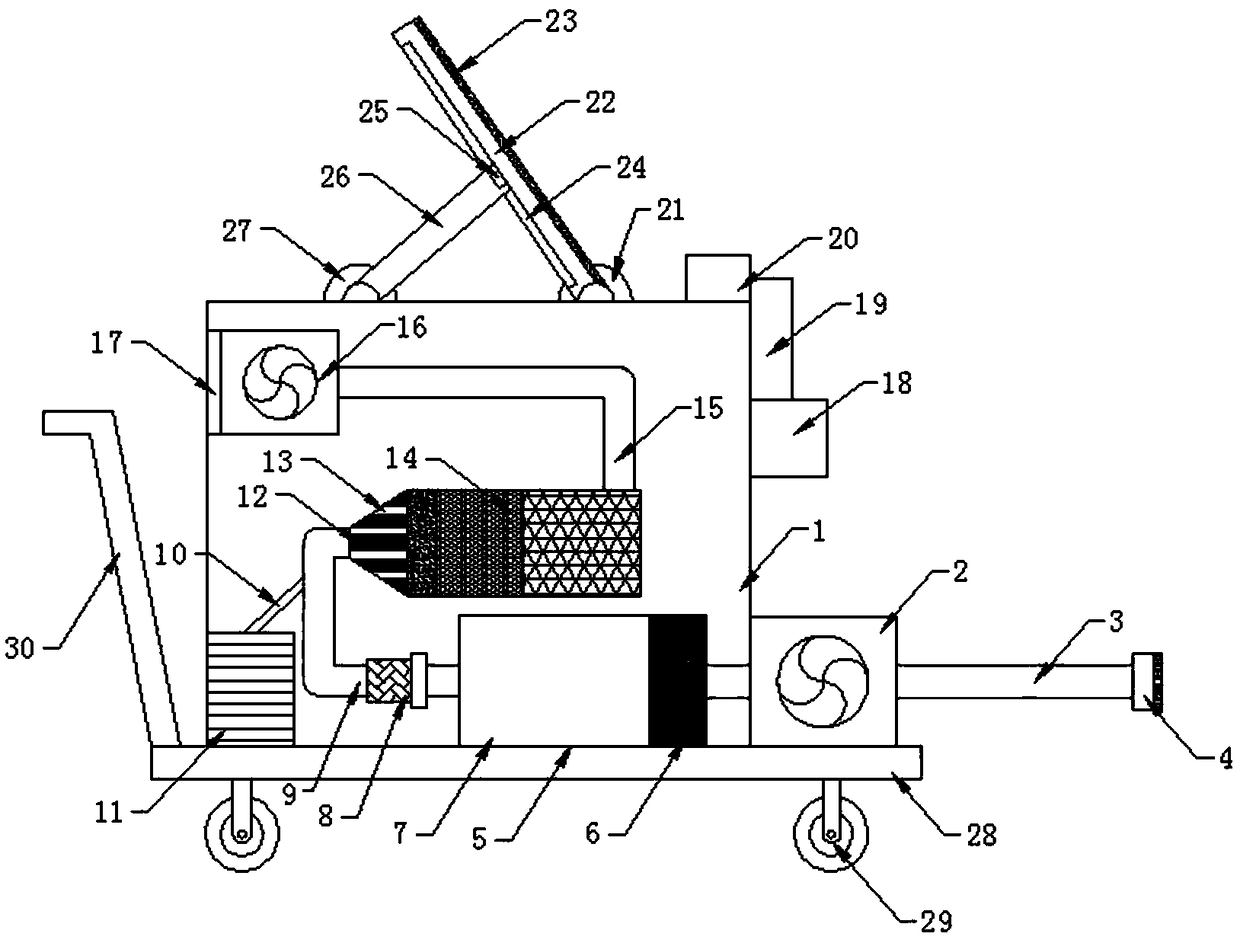

Environment-protection agricultural moving equipment based on solar continuous smouldering internal combustion

ActiveCN108980872APrevent spontaneous combustionEffective filteringPhotovoltaic supportsBatteries circuit arrangementsFlame arresterSpontaneous combustion

The invention discloses environment protection agricultural moving equipment based on solar continuous smouldering internal combustion. The environment protection agricultural moving equipment comprises a machine case. A first exhaust fan is fixedly mounted at one end outside the machine case. One end of the first exhaust fan is connected with a suction pipe. One end of the suction pipe is connected with a suction head. A flame arresting device fixedly mounted inside the machine case. A flame arrester is arranged at one side inside the flame arresting device. A sliding block is arranged insidea sliding groove. A second support is mounted at one end of the sliding block. A second connecting roller is mounted at one end of the second support. According to the environment-friendly agricultural moving equipment, the flame arrester is mounted inside the machine case; sparks in flue gas are extinguished through the flame arrester in the flame arresting device; the problem that spontaneous combustion is caused by the excessively-high temperature of the flue gas is prevented through a vacuum box in the flame arresting device, and thus, the good flame arresting effect is achieved; by meansof a filter device, the flue gas is filtered, and particles in the flue gas are effectively filtered out, and the flue gas is converted into pure air to be exhausted out of the machine case; and theenvironment protection effect is achieved.

Owner:JIAXING YUQIAN ENVIRONMENTAL PROTECTION TECH CO LTD

Harmless treatment method for seedling bed of small plant seeds

The invention relates to a harmless treatment method for a seedling bed of small plant seeds. Soil of the seedling bed is harmlessly treated by high temperature of smouldering. Weed seeds, bacteria, nematodes, viruses and eggs are killed, diseases and insects are prevented by tea seed cakes, the problem of plant diseases and insect pests in production of the seedling bed is solved comprehensively, the problem of weeds of the seedling bed is also solved, the seedling culture cost can be reduced, the structure of soil is improved, soil fertility is improved, and pesticide is prevented from polluting the environment. The method comprises the following steps: (1) selection of the site of a nursery garden, (2) harmless treatment of base soil of the seedling bed, (3) preparation of nutrient soil, (4) preparation of soil covering the seedling bed, (5) treatment of a furowed field, (6) preparation of the seedling bed, (7) application of the base soil of the seedling bed, (8) seed sowing and soil covering, (9) shielding with protecting nets, and (10) seedling management.

Owner:大冶市远红种养殖专业合作社

Combustible energy regeneration system and method thereof

InactiveCN102032579BImprove incineration efficiencySmoldering fullyIncinerator apparatusCombustible gas productionEnergy regenerationProduct gas

The invention relates to a combustible energy regeneration system and a method thereof. The regeneration system comprises a sealed furnace body, an intake module and a blower, wherein combustible waste materials can be filled in the furnace body; the intake module is arranged in the furnace body and contains a plurality of intake pipes; one intake pipe is used as an ignition pipe; and an air outlet pipe of the blower is communicated with the intake module and can smoulder uniformly from bottom to top, thus dense smoke and gas rich in combustible energy can be led out to a gas recovery mechanism or a combustion mechanism for recovery or reuse. Therefore, by adopting the regeneration system in the invention, the external air can be led in the furnace body uniformly to realize the uniform smoulder of the waste materials in the furnace body; the gas with combustible energy, generated by smouldering can be recovered or reused, thus the problem that smoke dust and impurities floating to the outside to cause air pollution, can be effectively avoided; and the aim of regenerating and recycling energy can be realized and the green and environmental protection requirements on energy conservation and carbon emission reduction can be achieved.

Owner:HUNG CHIH CORP

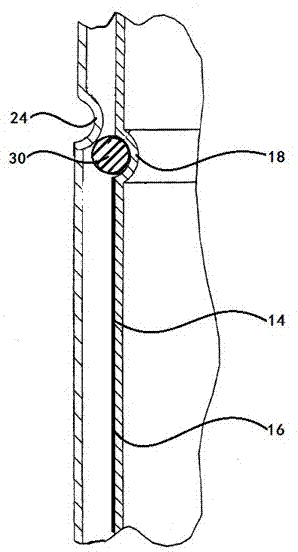

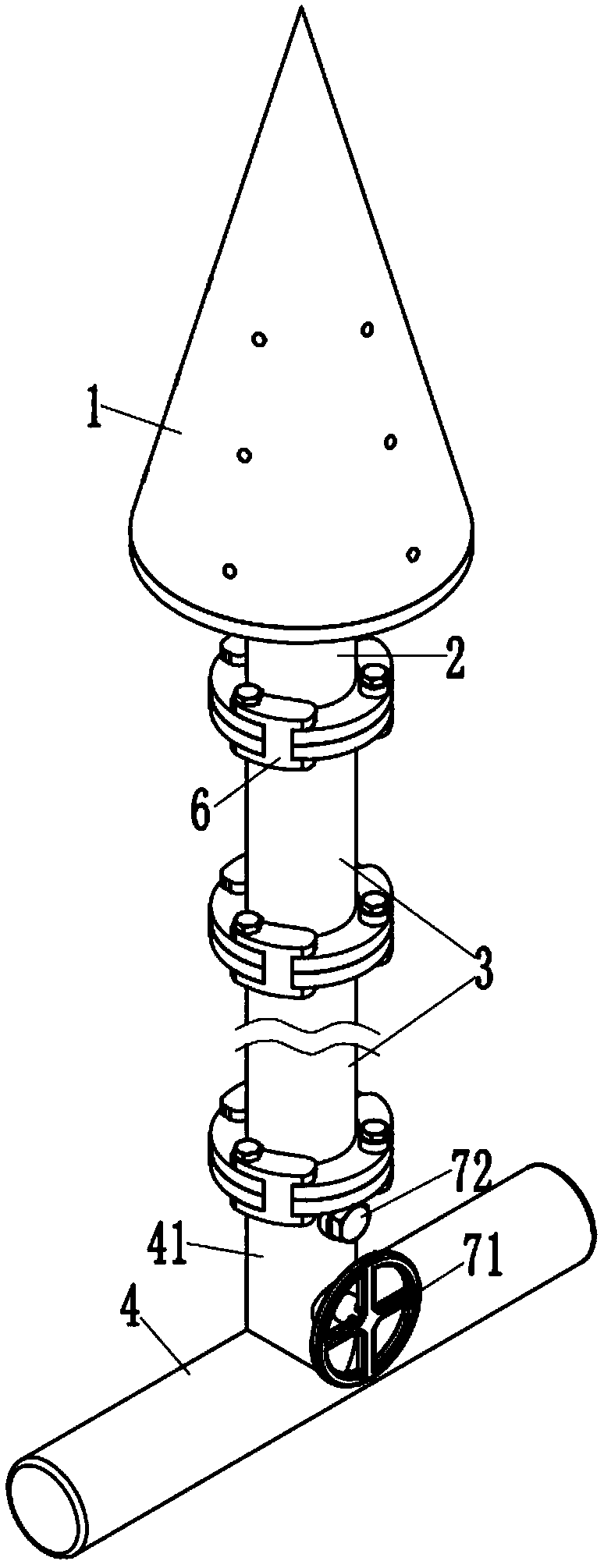

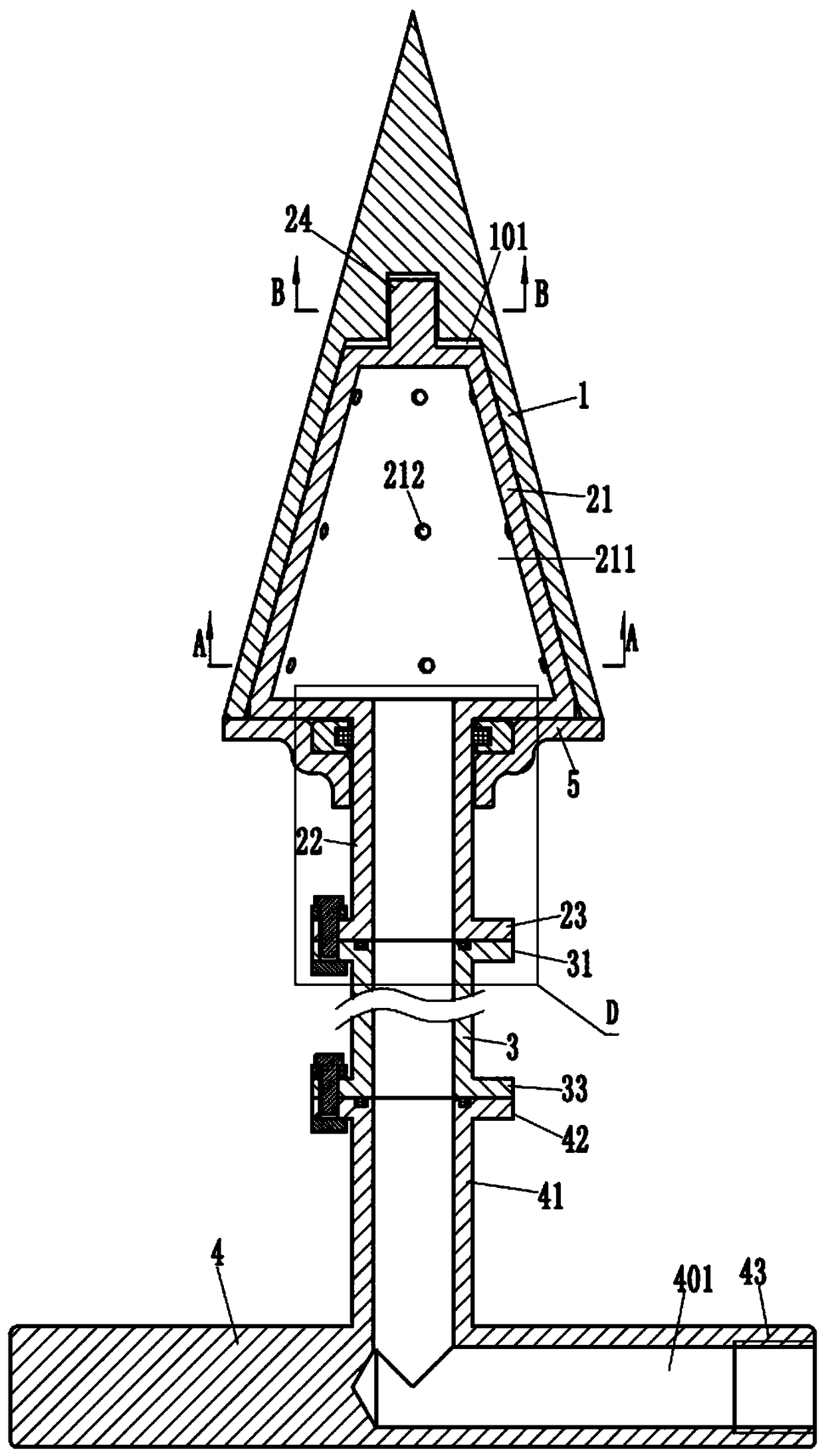

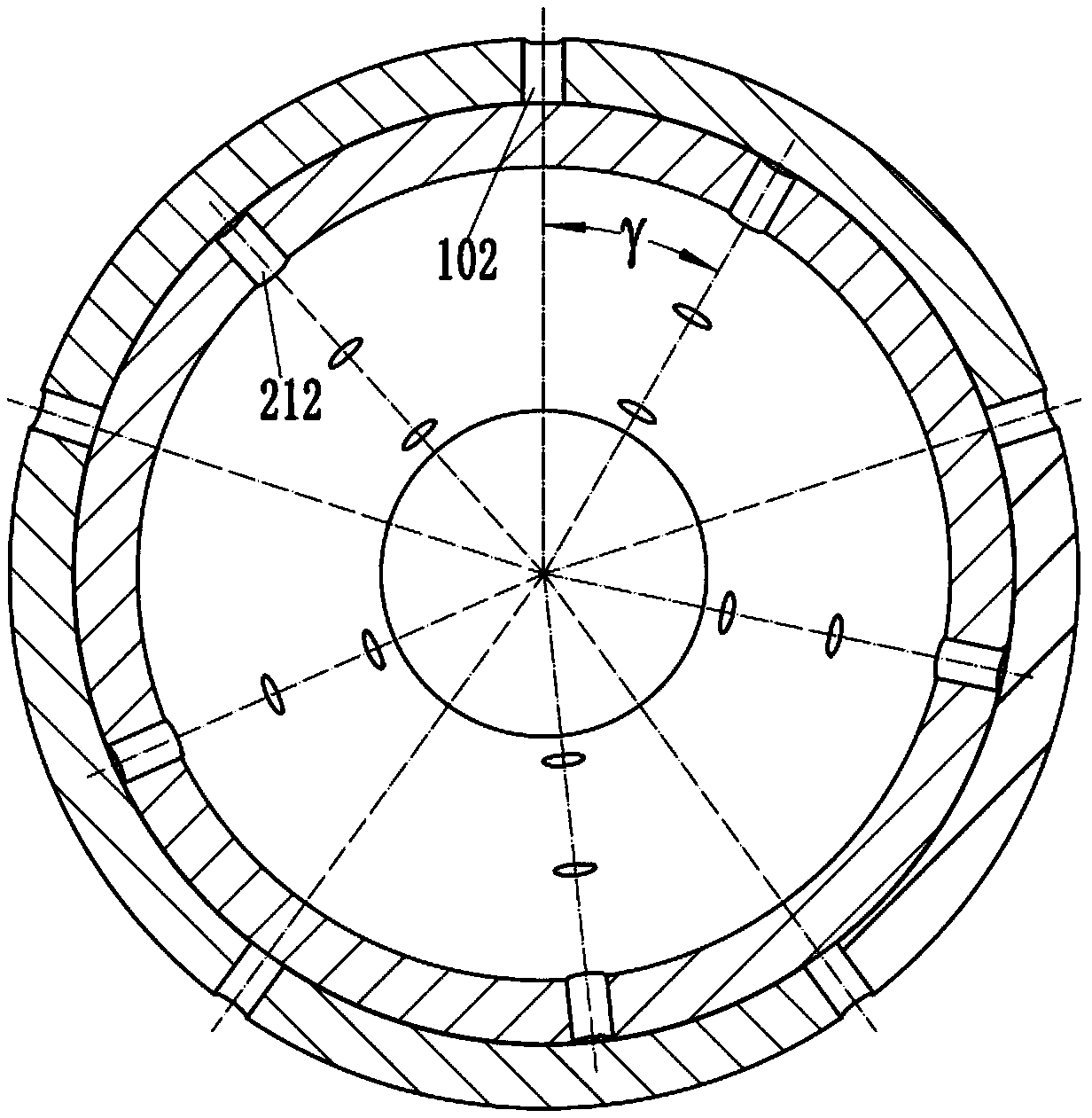

Adjustable length spray gun for eliminating smouldering

InactiveCN109331383AEffective fire extinguishingEasy to insertFire rescueMechanical engineeringWater pipe

The invention discloses an adjustable length spray gun for eliminating smouldering. The adjustable length spray gun includes a tapered gun head, a water storage part, a plurality of connecting rods, ahandle and a sealing seat, a taper and a plurality of first water outlet holes are formed on the tapered gun head, the water storage part includes a tapered table inserted into a tapered hole in a sleeved mode and a water inlet pipe fixedly connected with the tapered table, a cavity communicating with the water inlet pipe and a plurality of second water outlet holes are formed on the tapered table, and each row of the second water outlet holes and the corresponding row of the first water outlet hoes are arranged at equal height; and the sealing seat is inserted into the water inlet pipe in asleeving mdoe and fixedly connected with the tapered gun head in a sealing mode, and the water inlet pipe is connected with a water inlet hole of the handle through the connecting rods. According to the adjustable length spray gun for eliminating smouldering, the tapered gun head is used for easily inserting into a combustion material; and meanwhile by increasing or decreasing the number of the connecting rods, the length of the whole structure can be changed to convenient to adapt to different working conditions, and smouldering fire inside the combustion material can be effectively extinguished.

Owner:沈正祥

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com