Patents

Literature

83results about How to "Discharge orderly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

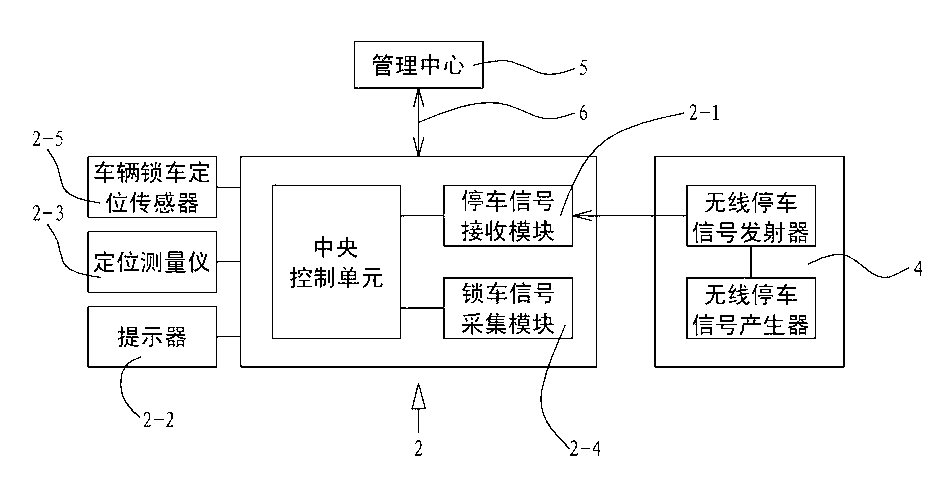

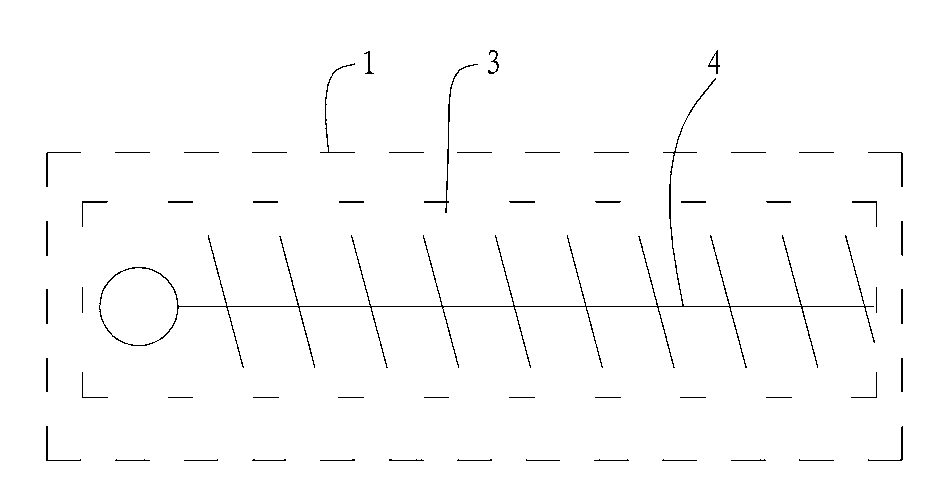

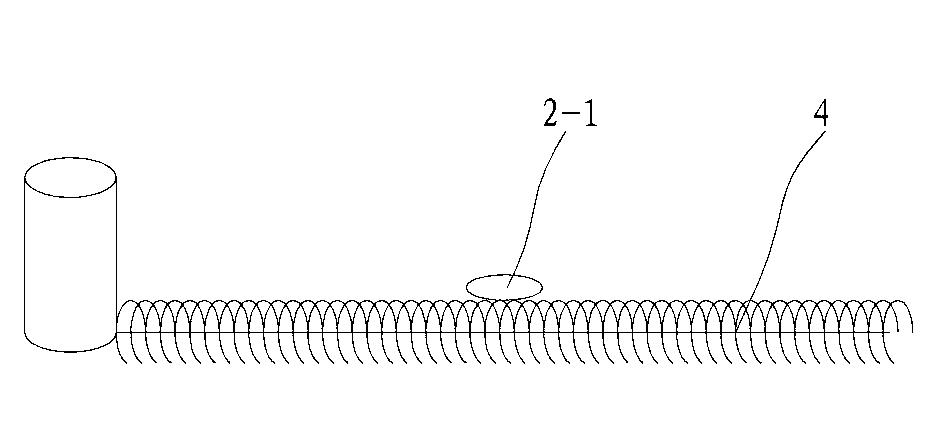

Public bicycle pile-free parking management system for parking in order

The invention relates to a public bicycle pile-free parking management system for parking in order, belonging to the technical field of public bicycle management. The system comprises a pile-free parking lot and bicycle information managers arranged on bicycles, wherein the parking lot is provided with marks and a regular parking zone formed by the marks; parking guide devices for transmitting wireless parking signals of set communication distance are arranged inside the parking zone; the bicycle information managers are provided with parking signal receiving modules for receiving wireless parking signals and prompters for generating prompting signals; when bicycles enter the parking zone completely, the spatial straight line distance between each bicycle information manager and each parking guide device is within a range of the set communication distance; the parking signal receiving modules receive the wireless parking signals and transmit feedback signals to the bicycle information managers; and the bicycle information managers control the prompters to generate first prompting signals after receiving the feedback signals. With the adoption of the system, the parking in order of multiple bicycles is realized without fixed parking piles.

Owner:JIANGSU HONGPU TECH LTD

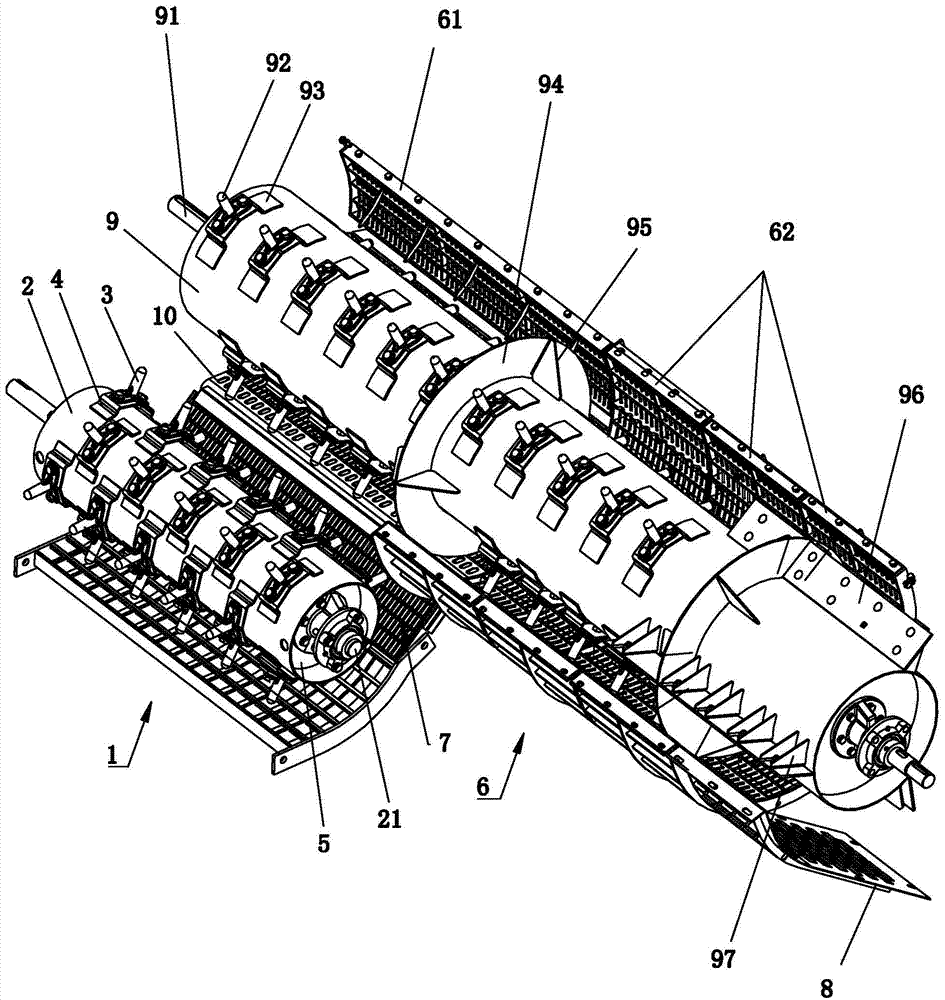

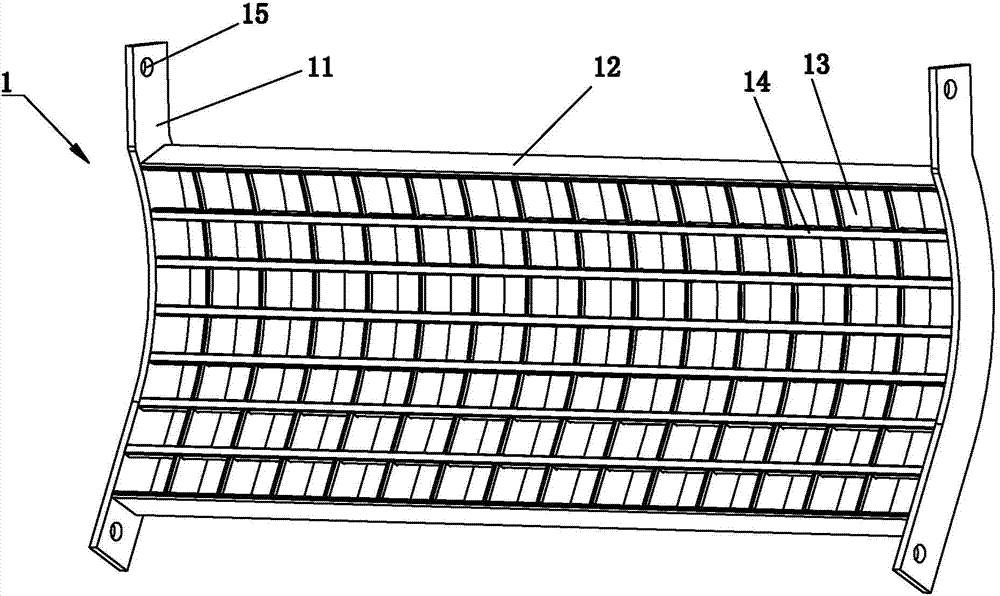

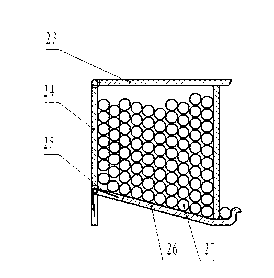

Corn kernel threshing and separating device

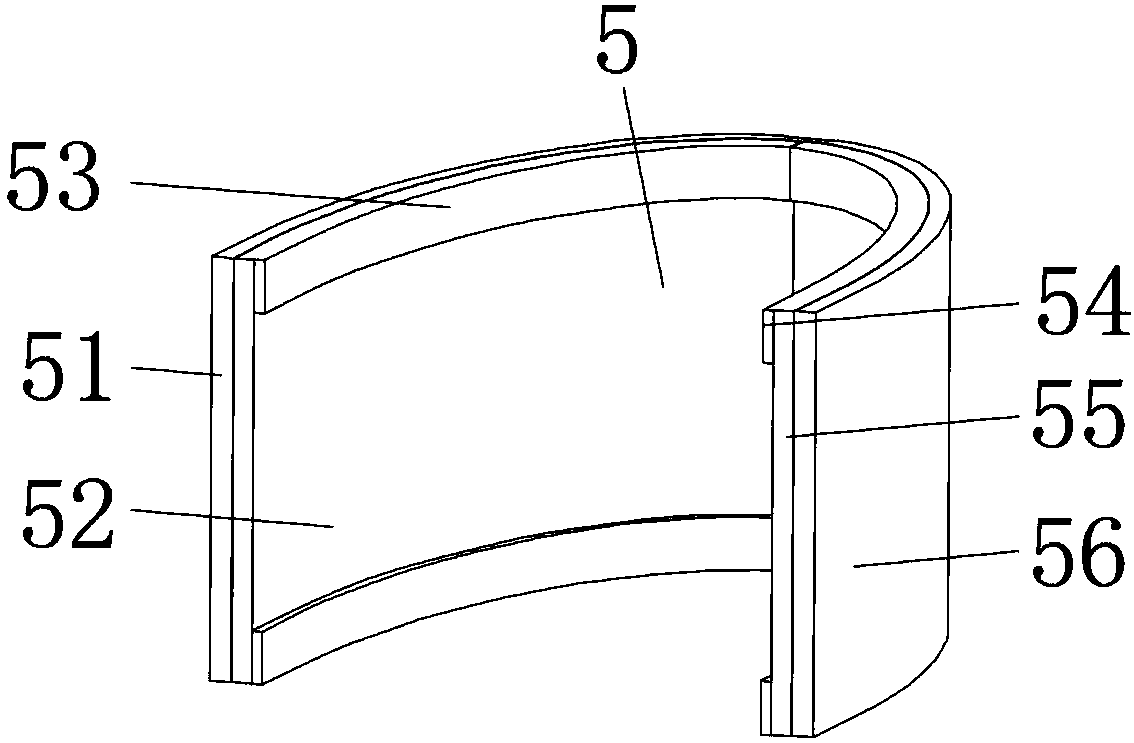

The invention discloses a corn kernel threshing and separating device which comprises a threshing roller with threshing teeth. Each threshing tooth comprises a tooth rod with a spherical top end, a threshing concave plate is arranged below the threshing roller and comprises a concave plate body, the concave plate body comprises two side plates, supporting plates are arranged between the two side plates, a longitudinal separation plate is arranged between the two supporting plates, separation bars are arranged on the longitudinal separation plate, and the separation bars and the longitudinal separation plate are flush with the side plates. A separation roller is arranged on one side of the flowing direction of crops, and separation teeth and separation plates are arranged on the separation roller in a staggered mode. A separation concave plate communicated with the threshing concave plate is arranged below the separation plate. Through rubbing between the threshing teeth and the threshing concave plate, threshing is achieved, power consumption is little, and cost is low. Through the threshing concave plate, while passing ability and screening efficiency are guaranteed, strength and use reliability are improved, and the crushing rate is lowered; meanwhile, through replacement of the corn kernel threshing and separating device, the effect of harvesting corn crops at the same time is achieved, and the use rate of a rice and wheat harvester is improved.

Owner:LOVOL HEAVY IND CO LTD

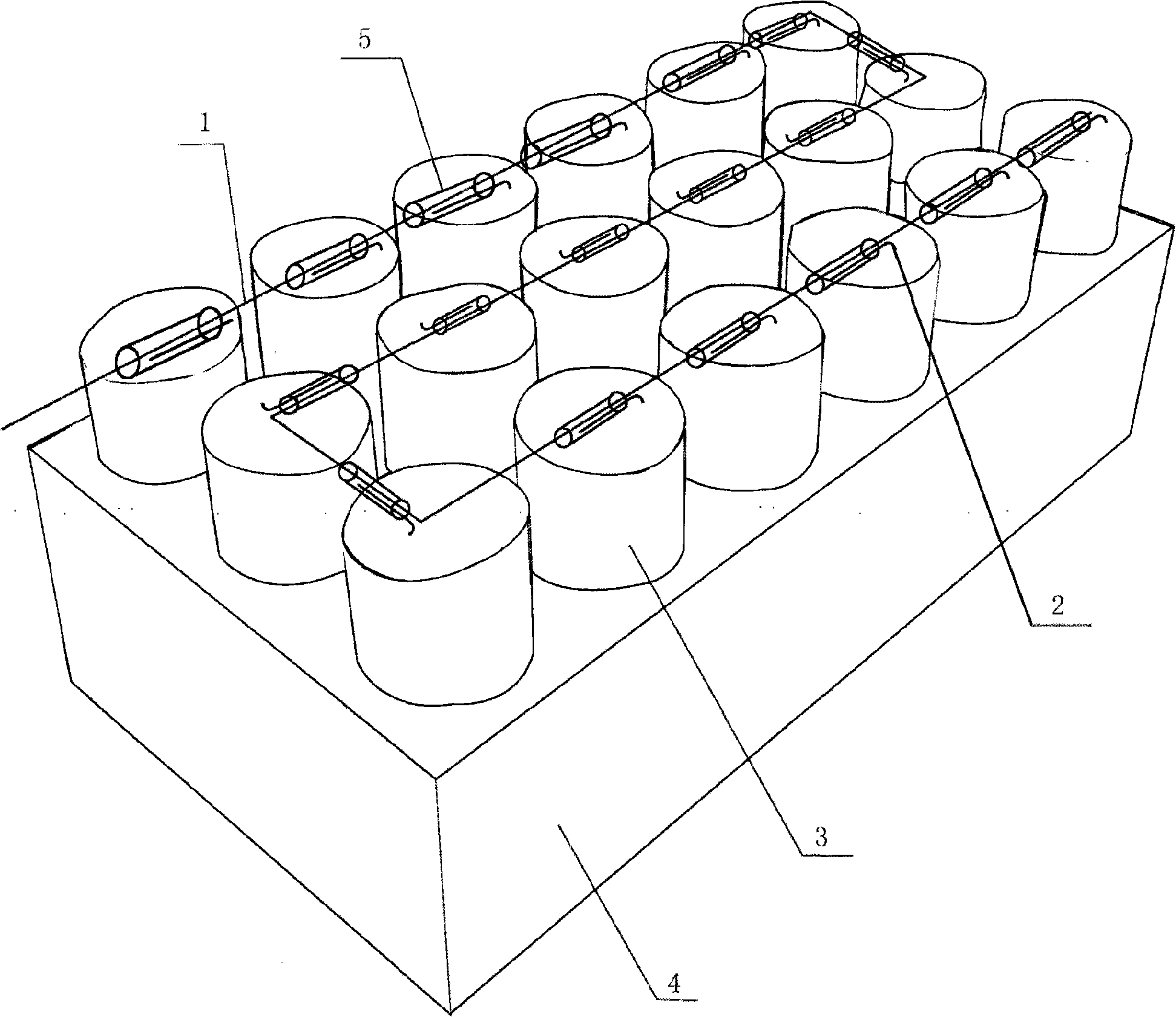

Cascading firework

InactiveCN101270966ASimple structureEasy connectionFireworksEngineeringElectrical and Electronics engineering

The invention relates to a series firing firework including a general firing cable or a series firing cable, a single firework igniter fuse, a single firework and a installing seat for firework, which is characterized in that the same number of ignition devices as the single fireworks are mounted on the series firing firework, the ignition device are installed on the single firework, the single firework igniter fuse is inserted into respective ignition device and the ignition device on the single firework is respectively passed through by the general firing cable and the general firing cable is close to or intersects with the general ignition wire in the ignition device. The ignition device is a prefabricated casing. The installing seat for firework is a box installing seat or a flat-plate installing seat. In the invention, the ignition device is mounted to pass through the general firing cable to be located in the same casing with the single firework igniter fuse and the end of single firework lead is unexposed, thereby achieving safe ignition and ordered firing. The firework has simple structure and good appearance, and just needs to ignite the general firing cable, and the single firework will be fired in turn in the casing to reach the effect of safe, ordered and continuous fireworks.

Owner:醴陵神马花炮有限公司

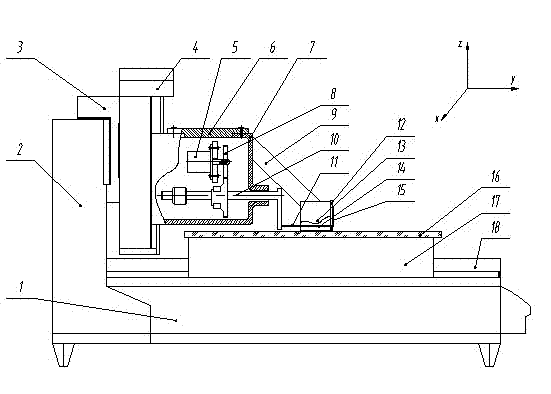

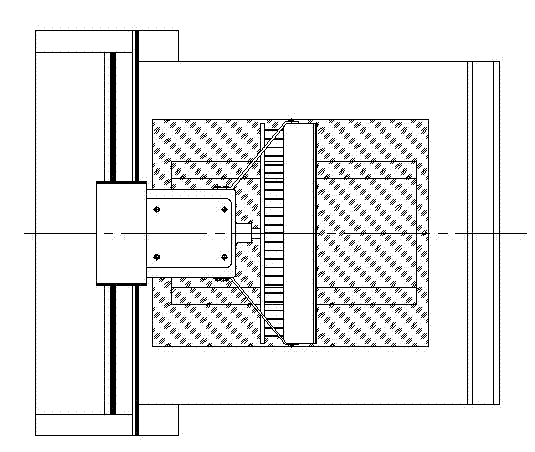

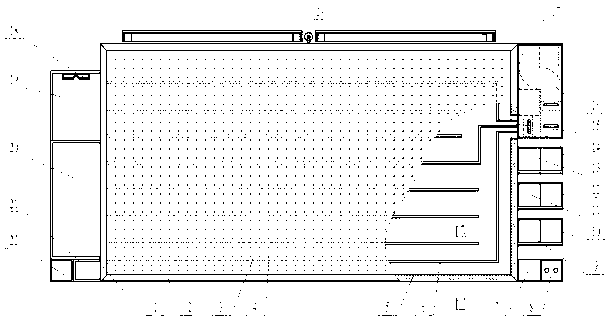

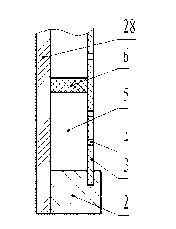

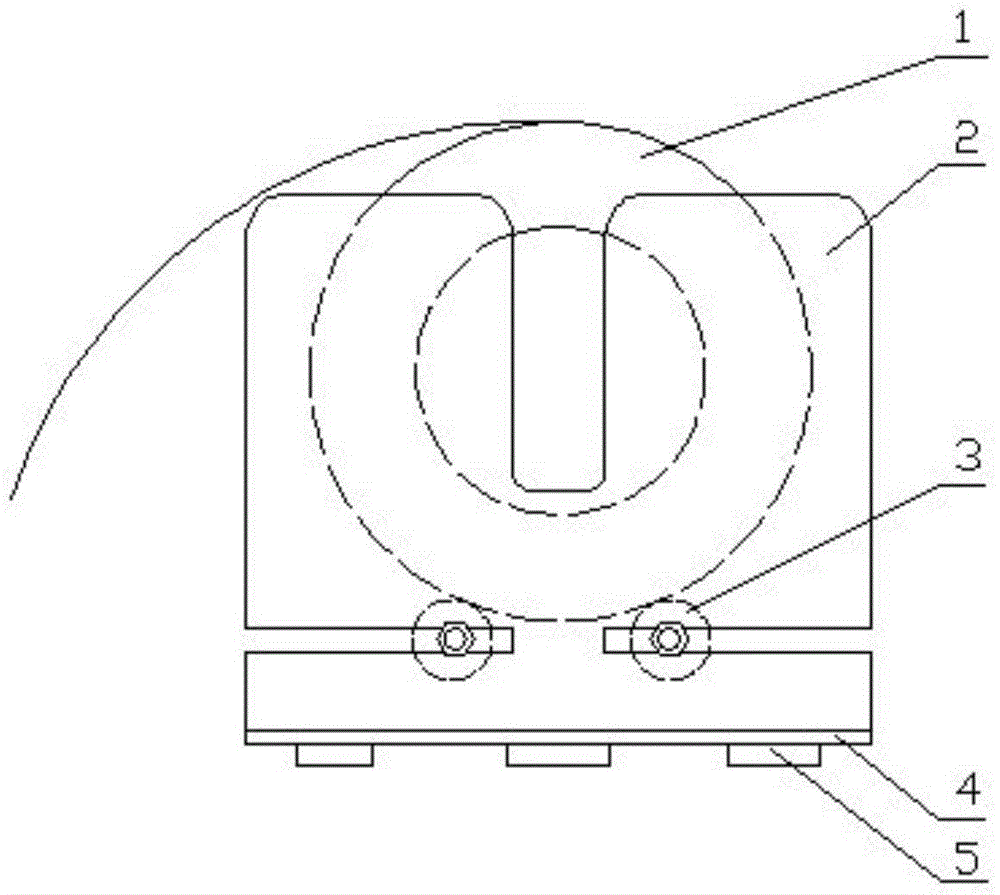

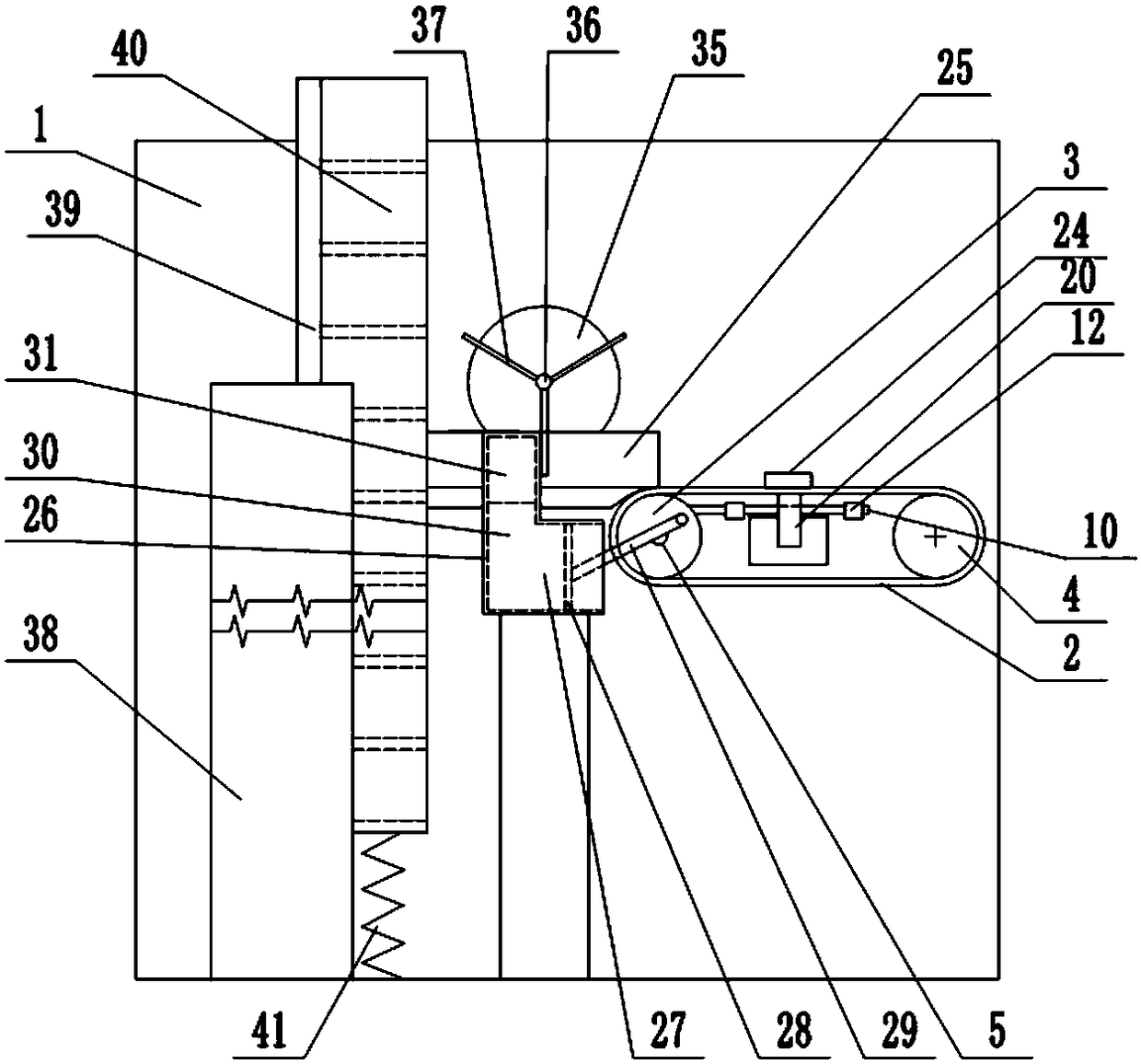

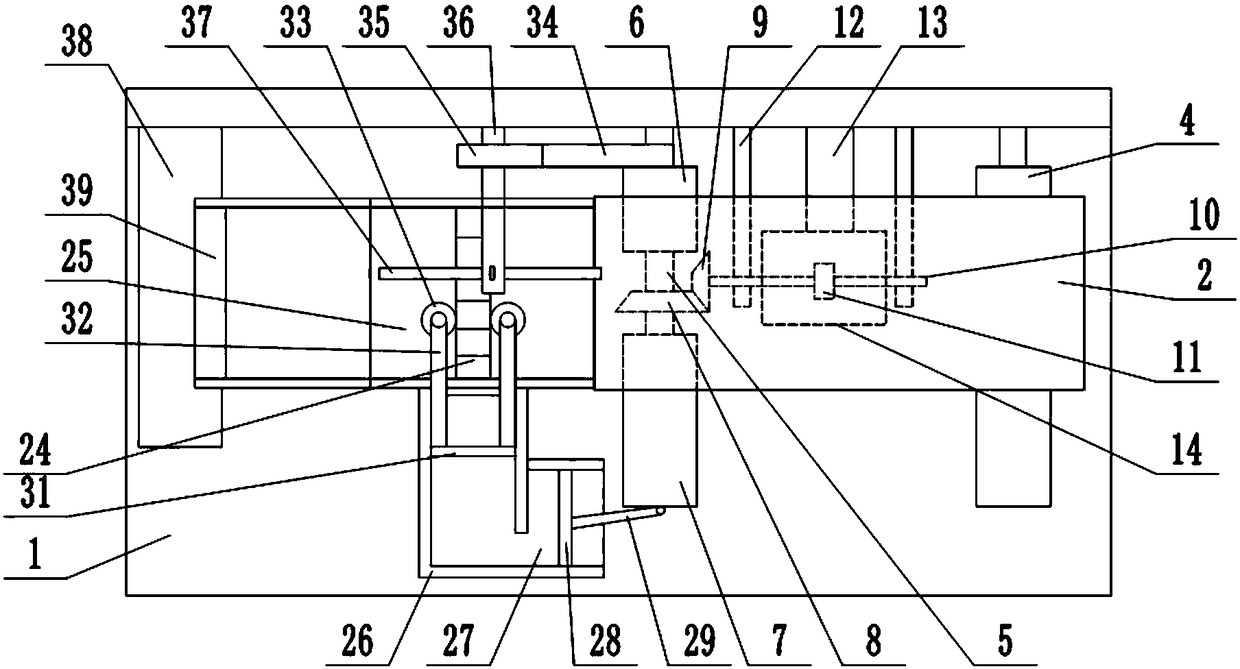

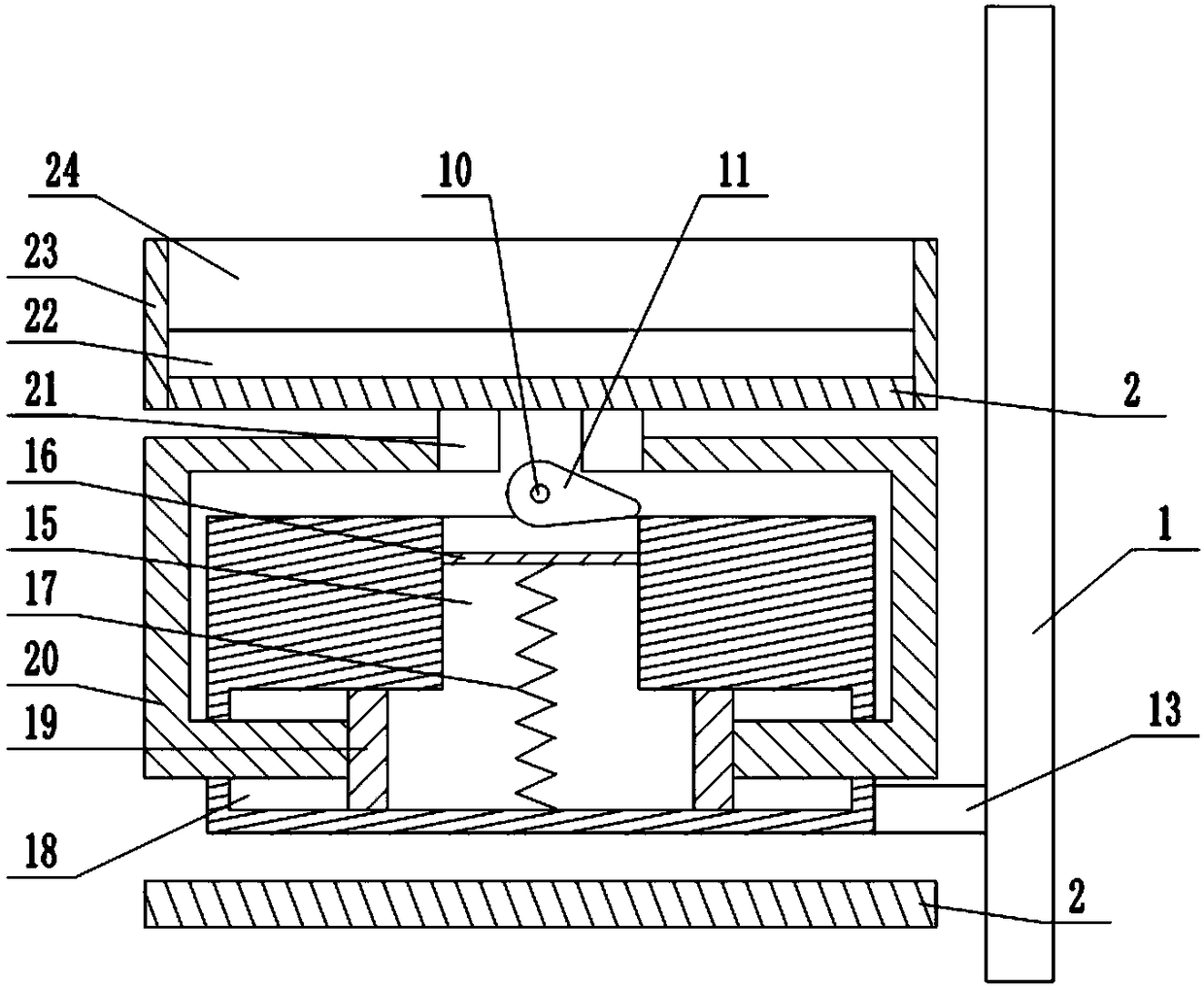

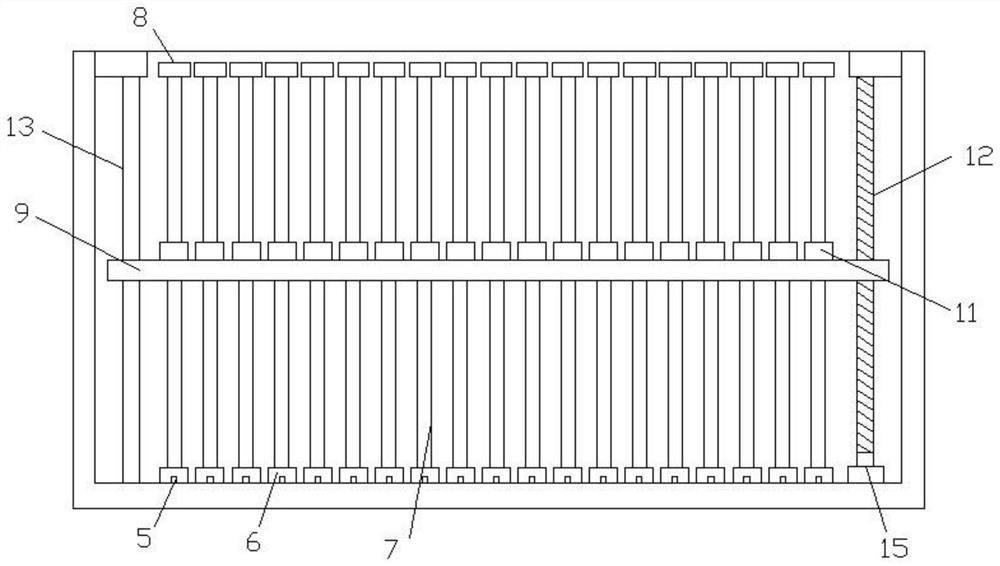

Vacuum glass support pillar layout device

The invention discloses a vacuum glass support pillar layout device which comprises a base and a stand column. The vacuum glass support pillar layout device is characterized by being provided with a y-axis guide rail, an x-axis guide rail, a z-axis guide rail, a workbench, a transmission mechanism and a shearing mechanism, wherein the y-axis guide rail is arranged on the base, the workbench is arranged on the y-axis guide rail, and the bottom of the workbench is provided with a guide structure matched with the y-axis guide rail; and the x-axis guide rail and the z-axis guide rail are respectively connected with the stand column, the transmission mechanism is connected with the stand column by the x-axis guide rail and the z-axis guide rail respectively, and the shearing mechanism is connected with and fixed on the transmission mechanism by a lateral suspension frame plate and is positioned above the workbench. The vacuum glass support pillar layout device is reasonable and compact in structure, has a good using effect, can meet the standard requirement on the layout positions of support pillars, and can be widely used in various layout occasions. A stepping motor can be used for realizing pause at a fixed point and fixed time and can avoid lagging. The vacuum glass support pillar layout device can be used for laying the support pillars while shearing copper wires to form the support pillars, so that the working efficiency is greatly improved, and the processing progress of vacuum glass is promoted.

Owner:扬州智创企业运营管理服务有限公司

Method for extracting vanadium by calcining vanadium-containing stone coal powder in calciner and pickling

InactiveCN102212709AAvoid energy consumptionShort production processProcess efficiency improvementCinderDecarburization

The invention discloses a method for extracting vanadium by calcining vanadium-containing stone coal powder in a calciner and pickling, which comprises the following steps: 1) crushing stone coal, of which the calorific capacity is 800 kilocalories, into 60-mesh undersize which accounts for 85% or above; 2) uniformly feeding the stone coal obtained in the step 1) into a calciner, calcining at 800-1000 DEG C under a bottom wind pressure of 3000-6000pa, and mixing collected fine dust and cinder at an overflow port; 3) leaching the product collected in the step 2) with 20-25% (mass concentration) sulphuric acid, wherein the liquid-to-solid ratio is (1-1.5):1, the leaching temperature is 80-95 degrees, and the leaching time is 2-6 hours; and 4) after the leaching process is finished, carrying out solid-liquid separation to extract vanadium from the leach solution. According to the invention, the carbon content of stone coal can be effectively utilized; the secondary calcination process required for stone coal having high carbon content, including decarburization and oxidative calcination steps, is avoided; and the energy consumption in the secondary oxidative calcination process is avoided, thereby realizing the effective utilization of energy in stone coal.

Owner:北京华夏建龙矿业科技有限公司

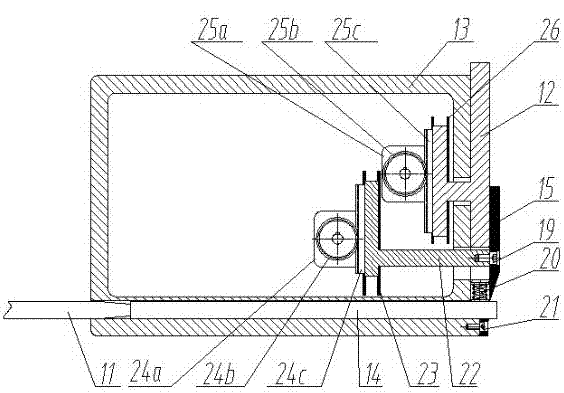

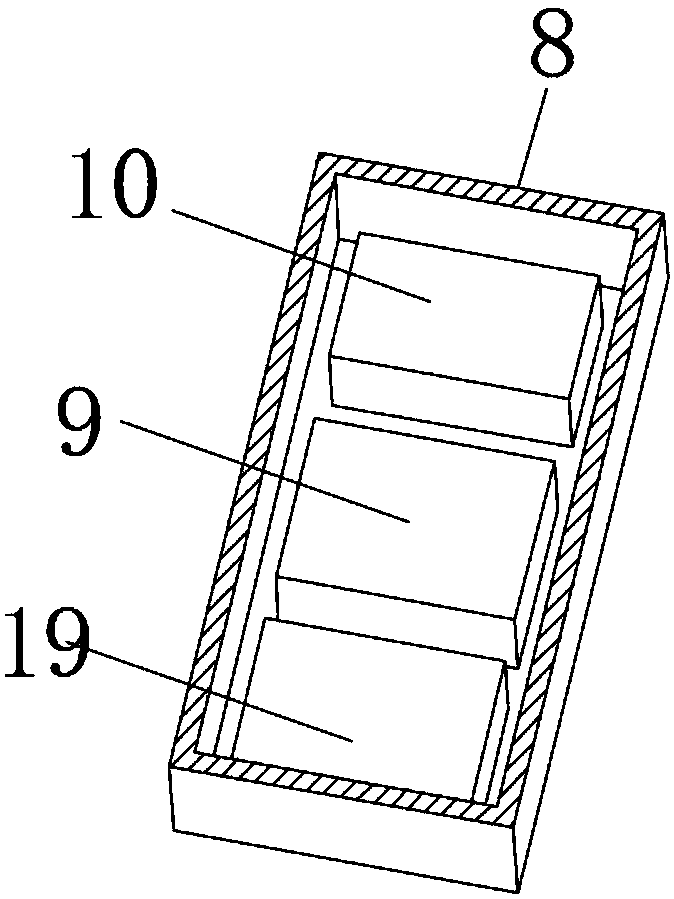

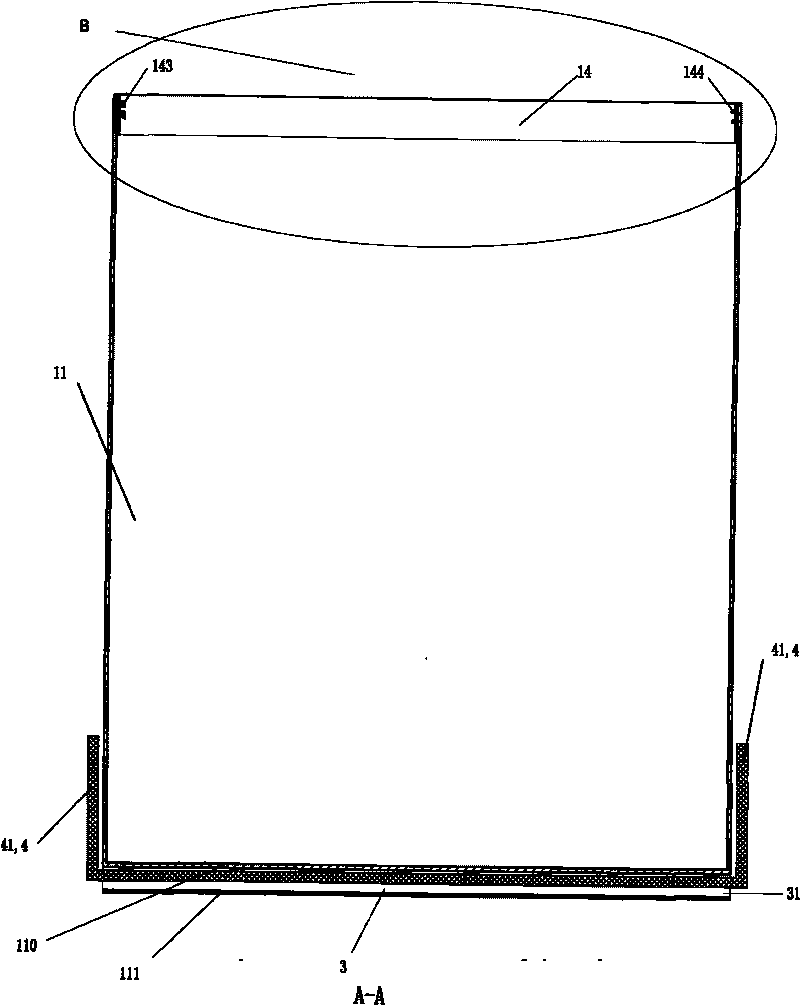

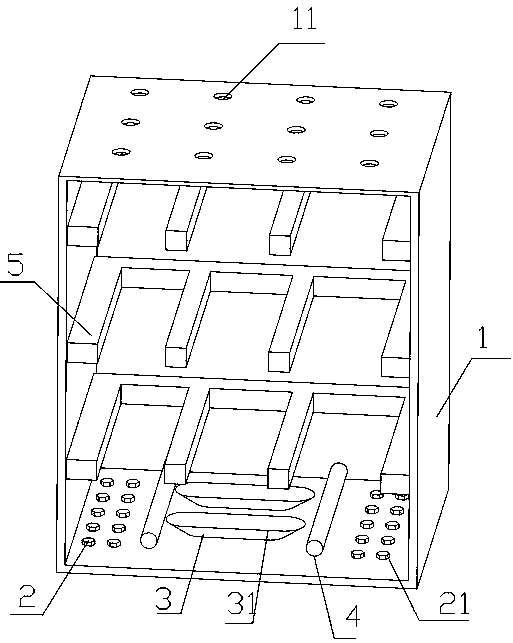

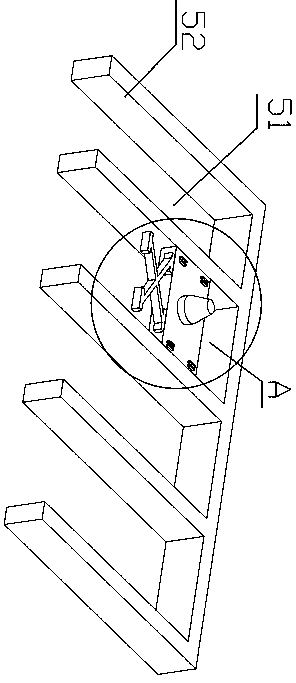

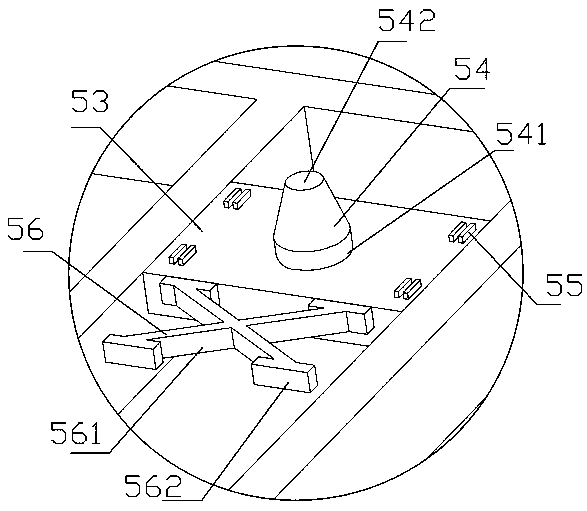

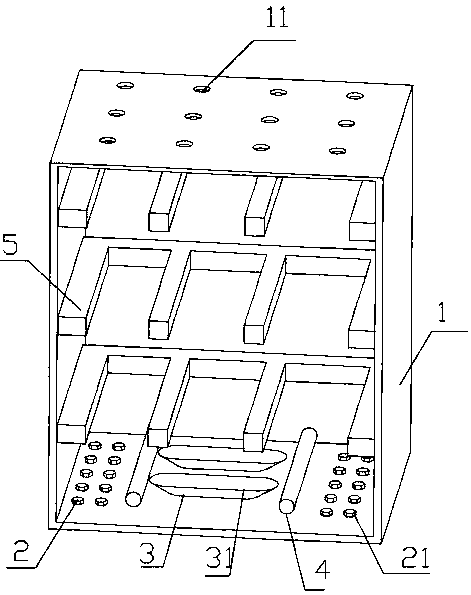

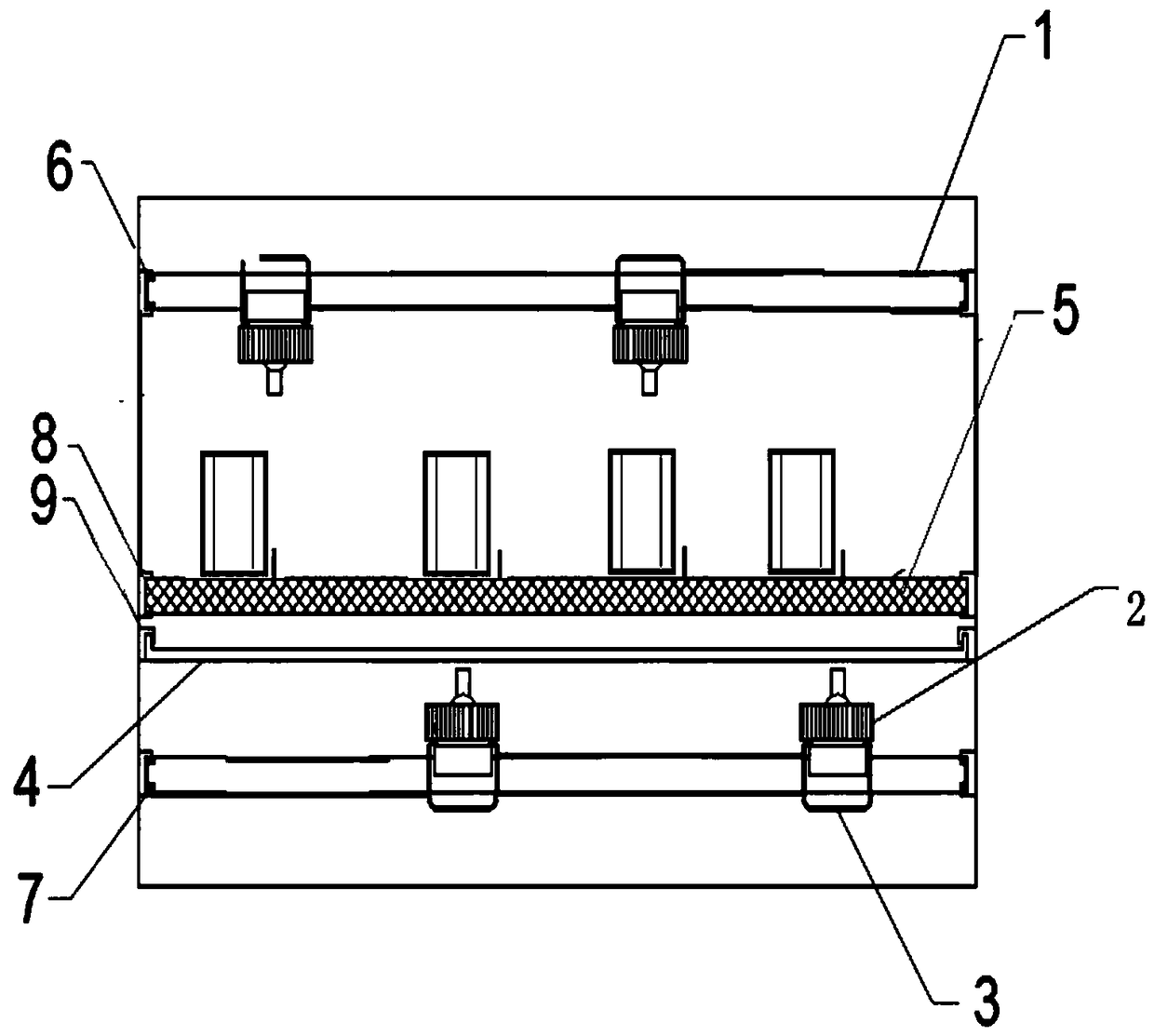

Electric discharging device of press-filter machine

InactiveCN102847356ARealization intervalDischarge orderlyFiltration separationElectric dischargeFilter press

The invention belongs to the technical field of the discharging of a press-filter machine, and particularly relates to an electric discharging device of a press-filter machine, and the electric discharging device comprises a press-filter machine discharging bucket and an electric control box, wherein the press-filter machine discharging bucket is provided with a split-type electric baffle plate, the split-type electric baffle plate is connected with the electric control box, the press-filter machine discharging bucket consists of a rectangular bucket body, double drainage channels and an unloading port, the double drainage channels are connected with the bottom of an inner cavity of the rectangular bucket body, a soleplate of the rectangular bucket body is a pair of inclined plates, the bottom ends of the pair of the inclined plates are connected with the unloading port, the split-type electric baffle plate consists of a central fixed hinge seat, two retractable rods, two rotary arms, two symmetric swinging cover plates and two drive devices, and the bottom ends of the two symmetric swinging cover plates are respectively provided with a rotating shaft. Due to the adoption of the electric discharging device, filtered products, filtered water and washing water are spaced to be respectively discharged in different channels, so that the environmental protection is realized, stability and reliability in running can be realized, the maintenance work is small, the automation degree is high, and the successful production can be guaranteed.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

Novel negative pressure environmentally-friendly multi-functional blackboard

InactiveCN103231603AVersatileSimple structureBoard cleaning devicesWriting boardsEngineeringSmall hole

The invention discloses a novel negative pressure environmentally-friendly multi-functional blackboard which comprises a blackboard body, a dust removal device, a practical color separation chalk box, a waste small chalk recovery box, a switch panel, a head lamp, a schedule clip, a teaching aid collection case, an absorption nail collection box and an eraser collection box. The blackboard body is provided with a negative pressure cavity composed of a frame, a blackboard surface with small holes arranged in lattice, a blackboard backing board and a division bar in the cavity together. By means of adsorption force of a fan of the dust removal device, dust is absorbed, dust-free environment of chalk writing and erasing is achieved, and health of teachers and students is protected. The small holes arranged on the blackboard surface in a lattice mode are convenient for the teachers to write on the blackboard neat and orderly, are convenient for ruler and compass construction and wall chart adsorption, and can also reduce reflection light of the blackboard surface. The blackboard achieves that chalk of various colors is placed in the practical chalk box and is convenient to take. Cracked and used waste small chalk is put in the chalk recovery box and is convenient to recycle, and environmental protection is reduced. The blackboard achieves classification placement and convenient pick-and-place of a schedule, teaching aids, adsorption nails, an eraser and the like.

Owner:XIAN AERONAUTICAL UNIV

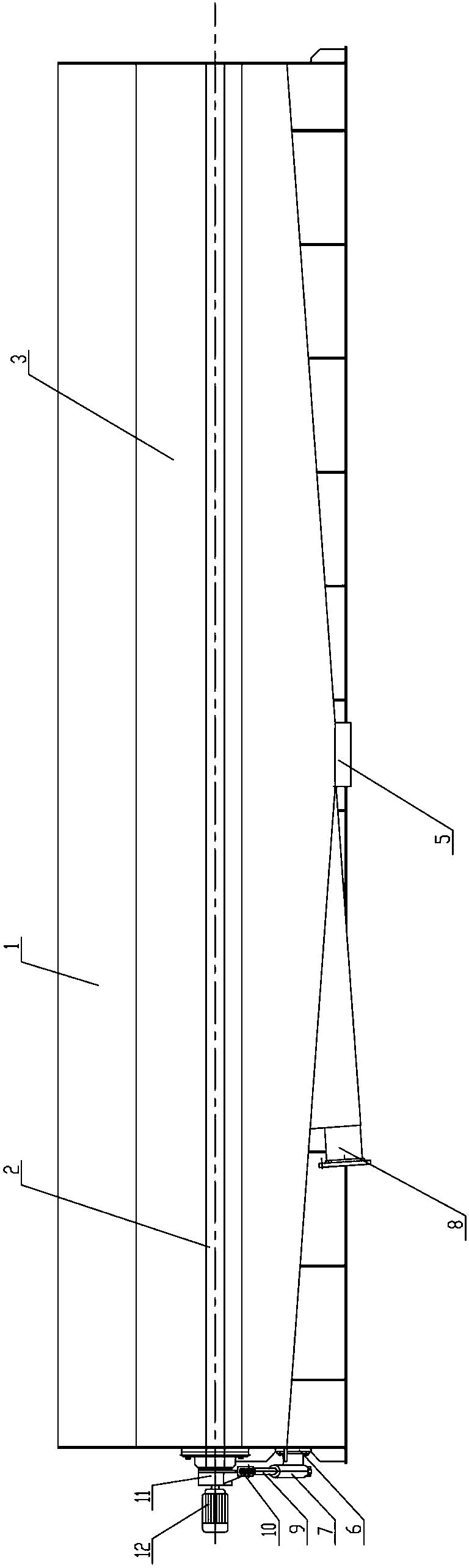

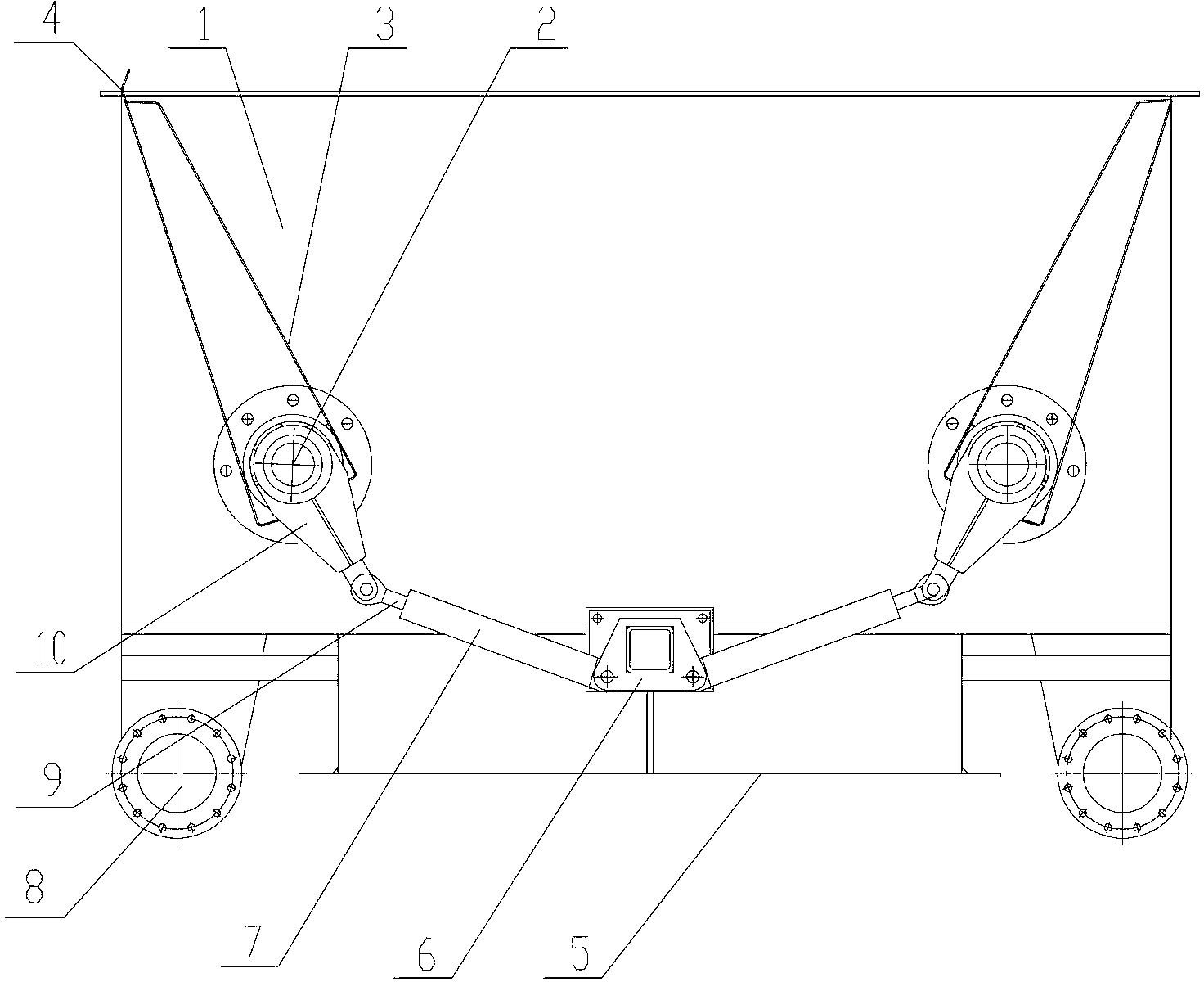

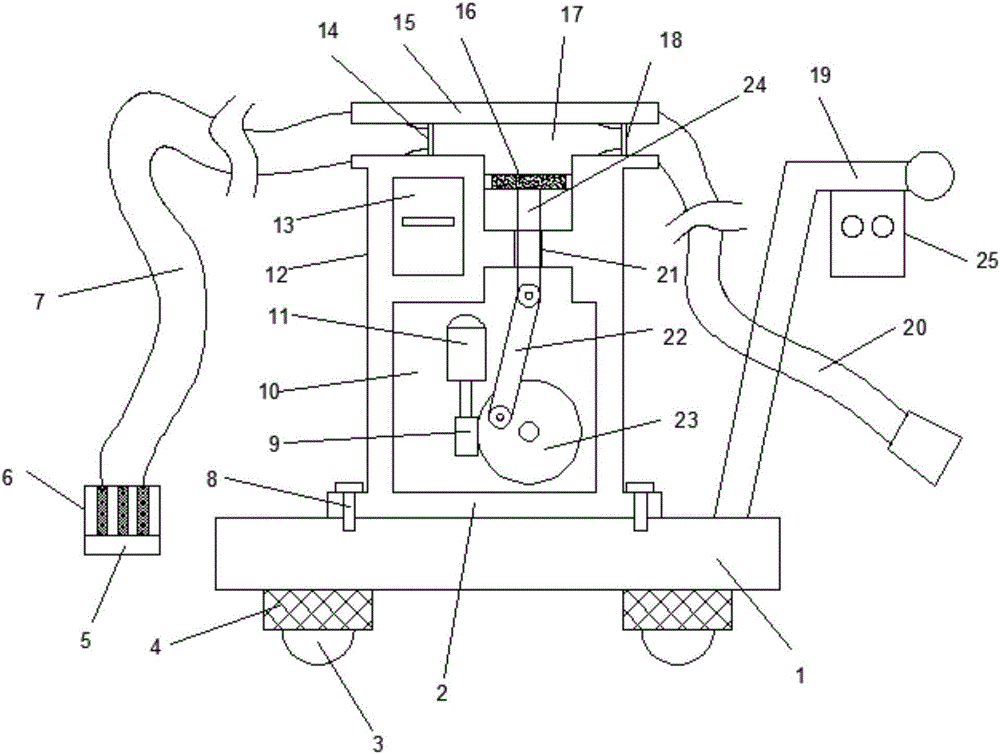

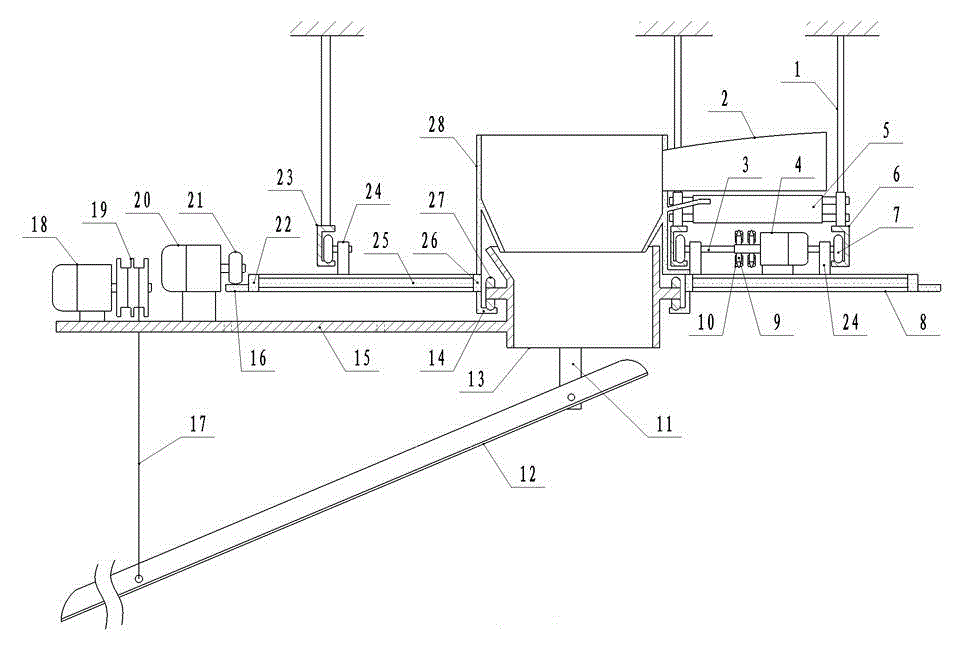

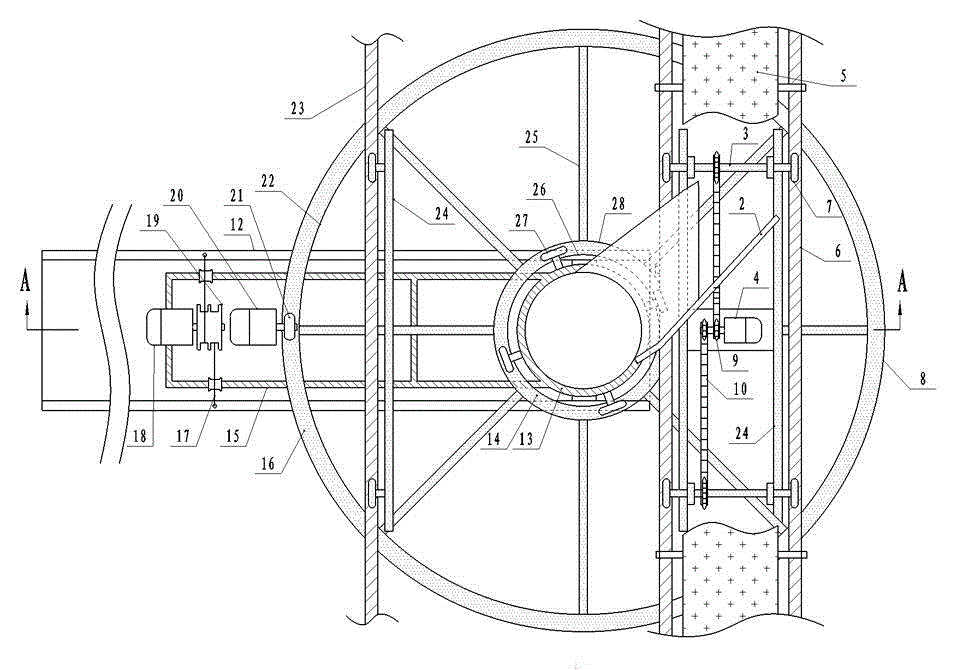

Pure mechanical trash removing machine for hydrological engineering

InactiveCN106759605AReasonable structureInnovative designMechanical machines/dredgersElectric machineryPiston

The invention discloses a pure mechanical trash removing machine for hydrological engineering. The pure mechanical trash removing machine comprises a base and a machine body, wherein buffer cushions are connected with two sides of the lower end of the base; traveling wheels are connected with the lower ends of the buffer cushions; a fixing plate is connected with the lower end of the machine body; fixing bolts are connected with two ends of the fixing plate; a driving box is arranged at the inner lower end of the machine body; a driving motor is arranged inside the driving box; a worm is connected with the lower end of the driving motor; a worm gear is connected with the right end of the worm; a crank is connected with the middle of the worm gear; a guiding rod is connected with the upper end of the crank; a piston is connected with the upper end of the guiding rod; a piston cavity is formed in the upper end of the piston; a trash inlet one-way valve is connected with the left end of the piston cavity; a trash inlet pipe is connected with the left end of the trash inlet one-way valve; a trash outlet one-way valve is connected with the right end of the piston cavity; a trash outlet pipe is connected with the right end of the trash outlet one-way valve; and a storage battery pack is arranged at the left end of the middle of the machine body. By adoption of the pure mechanical trash removing machine disclosed by the invention, sludge in water can be extracted and discharged, and sludge inside the piston cavity can be extracted and discharged orderly, thereby improving the trash removing efficiency and achieving high practicability.

Owner:HEFEI ZHIHUI LONGTUTENG INTPROP CO LTD

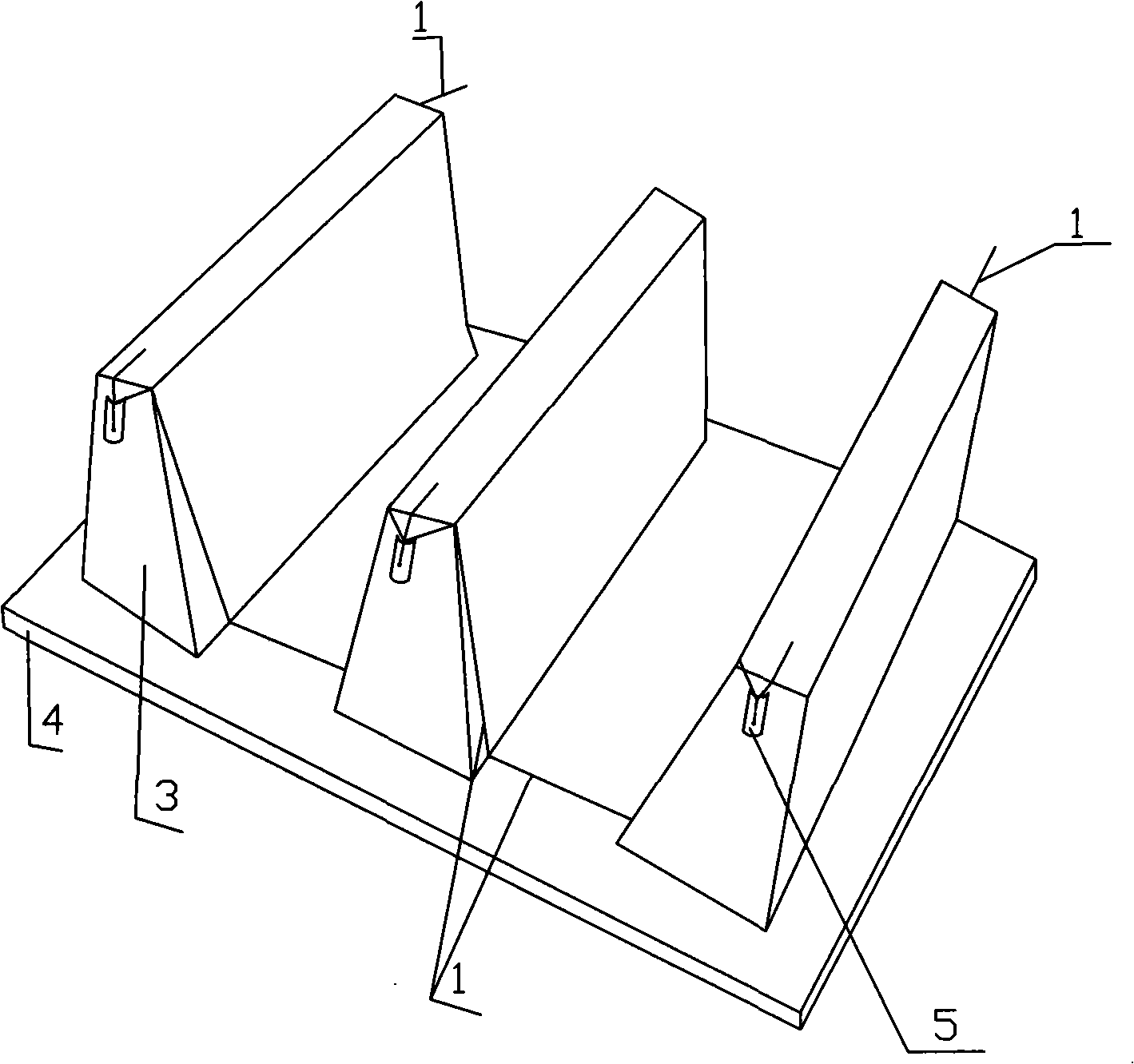

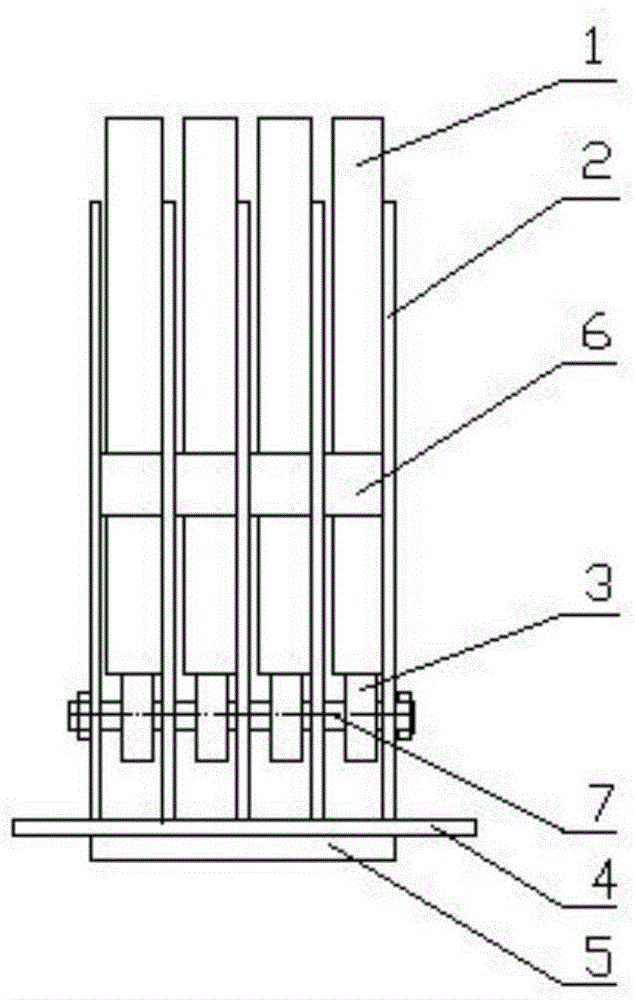

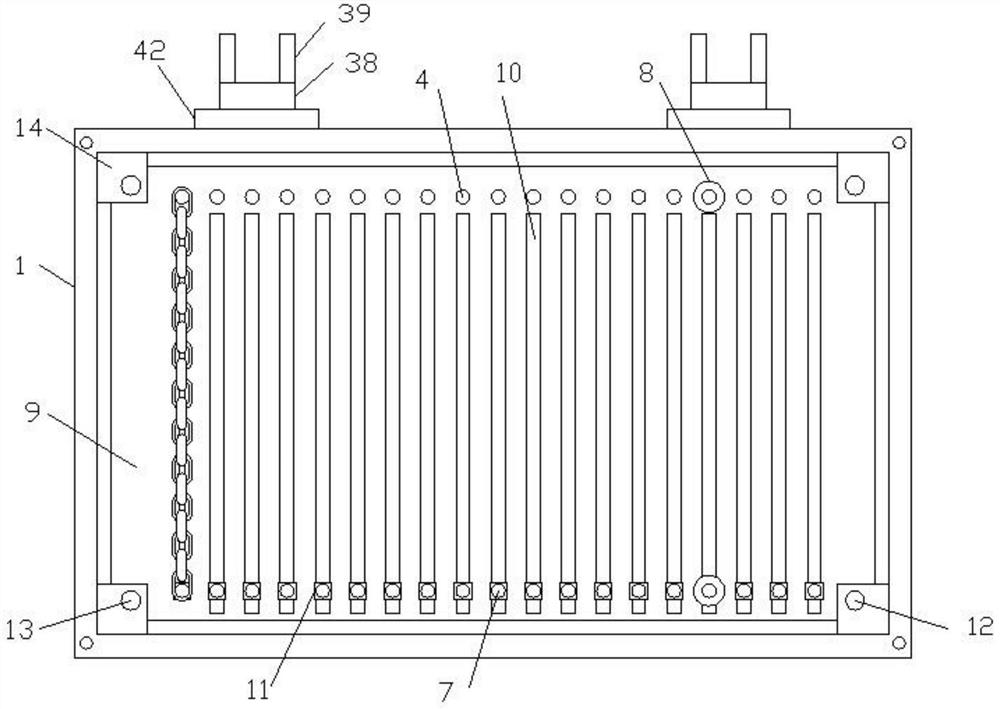

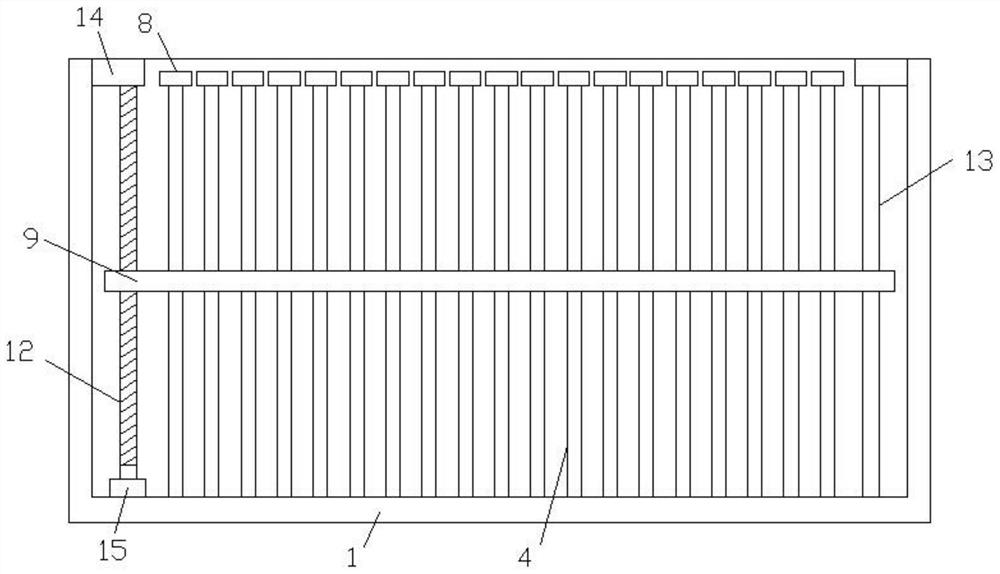

A binding steel belt storage rack

The invention relates to a binding steel belt storage rack. A square bottom plate is fixedly mounted to a base; separation plates are fixedly, vertically and uniformly mounted on the bottom plate at intervals; the two sides of the separation plates are connected via baffles; the bottom portions of the two side edges of each separation plate are provided with grooves in mirror symmetry; rolling shafts in mirror symmetry are connected with the separation plates after penetrating the grooves; rollers are arranged between the separation plates and on the rolling shafts; the two ends of each rolling shaft are fastened via nuts; binding steel belts are arranged between every two adjacent separation plates, located on the rollers and supported by the rollers. The binding steel belt storage rack is compact in design, enables a plurality of bundles of binding steel belts to be stored and used at the same time, can store binding belts of different models, facilitates use of operators and reduces the binding belt replacing efficiency.

Owner:TIANJIN SHENGLIDA MECHANICAL EQUIP CO LTD

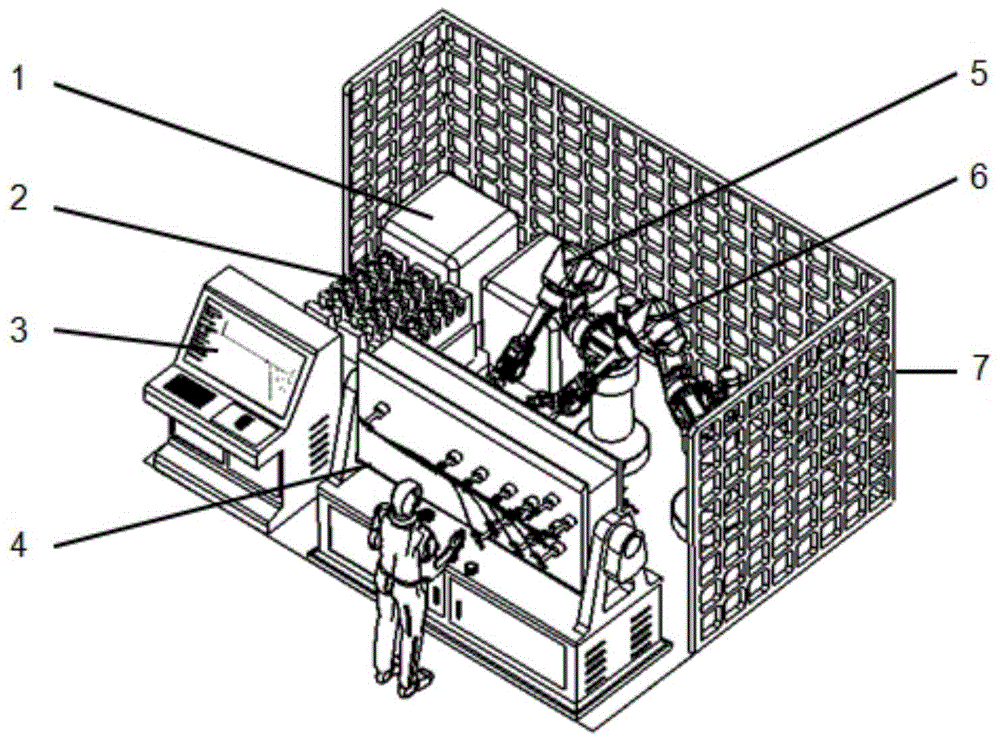

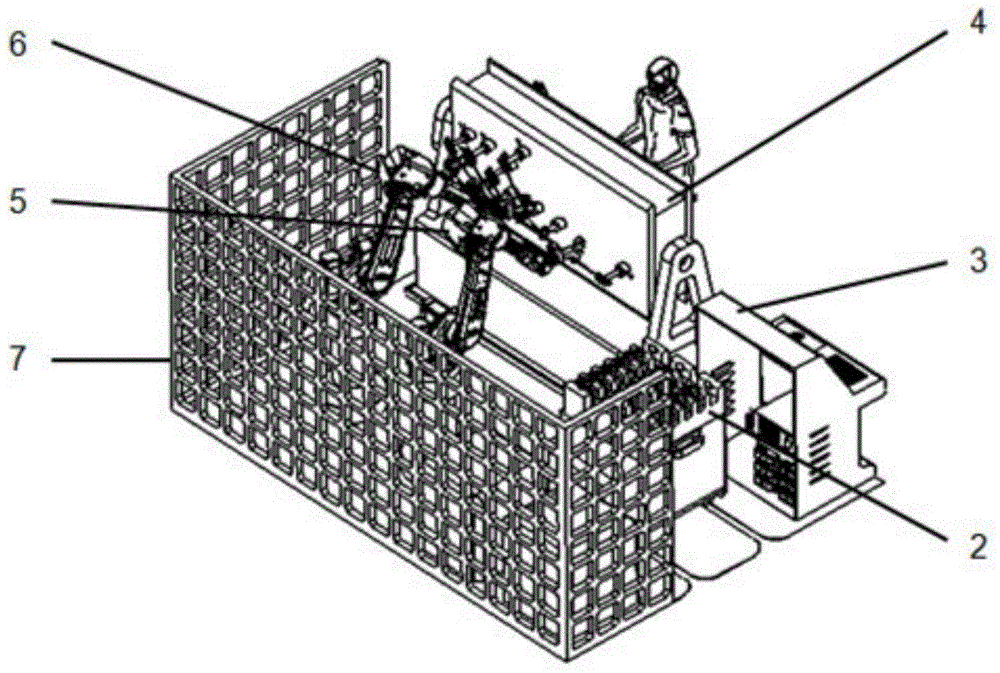

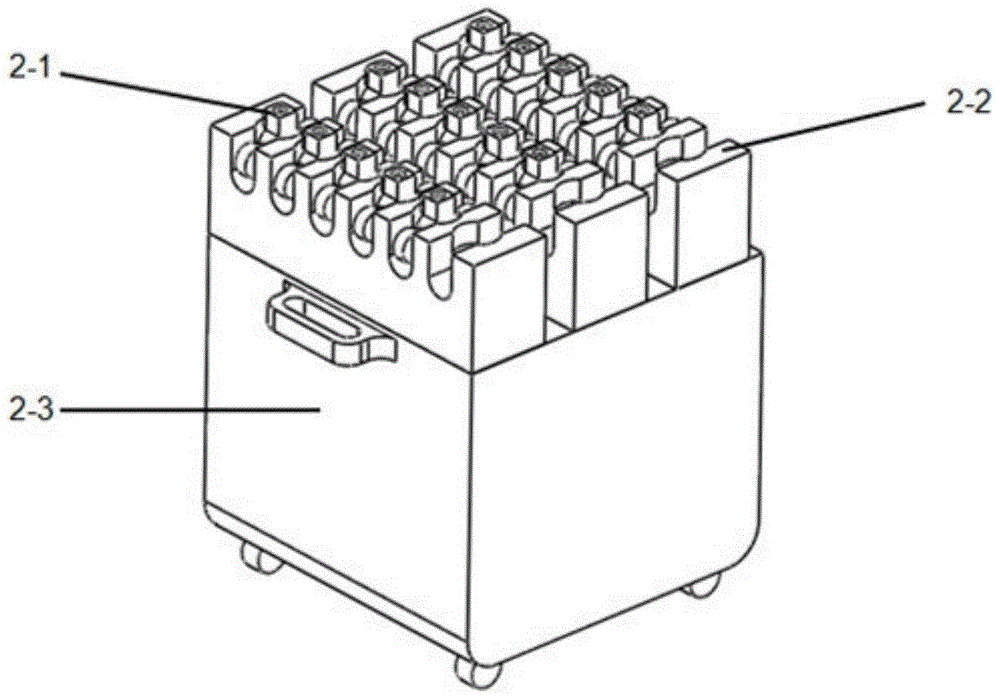

Full-automatic pre-locking, rubber coating and electrical detection platform equipment and usage method

ActiveCN104950790ASmall footprintImprove efficiencyProgramme control in sequence/logic controllersElectricityRobot control

The invention discloses full-automatic pre-locking, rubber coating and electrical detection platform equipment and a usage method. The equipment comprises robot control cabinets, a rubber coating machine tool magazine, a master control console, an intelligent working platform, a rubber coating robot, an auxiliary robot and a protective fence, wherein the intelligent working platform and the master control console are arranged in a same horizontal line; the protective fence is arranged behind the intelligent working platform and the master control console; the two robot control cabinets, one rubber coating robot, one auxiliary robot and the rubber coating machine tool magazine are arranged in space defined by the intelligent working platform, the master control console and the protective fence. According to the full-automatic pre-locking, rubber coating and electrical detection platform equipment and the usage method, scattered and different stations are organically integrated, so that operation of multiple procedures can be realized at one station. Hands of workers can be liberated to the maximum extent, and the efficiency of a harness factory is greatly improved. Meanwhile, the pre-locking, rubber coating and electrical detection quality difference caused by human factors such as sex, proficiency and the like of the workers can be effectively avoided, and the harness quality is improved.

Owner:ZHUJI CANU AUTOMATION EQUIP CO LTD

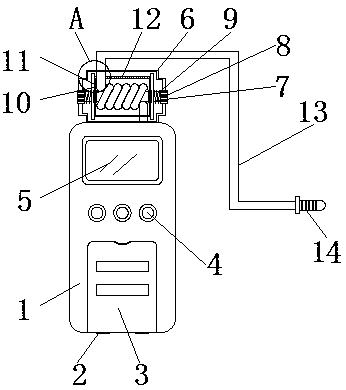

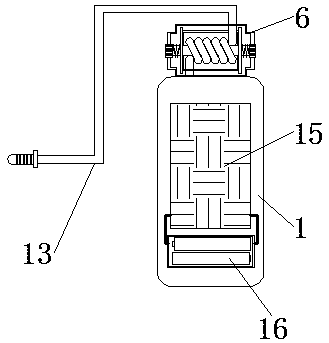

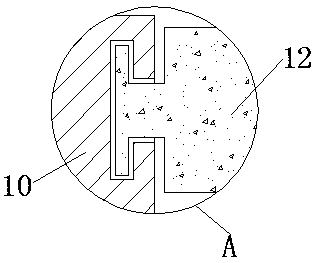

Hand-held water hardness measuring instrument

InactiveCN107727817AEasy to rewindAvoid entanglementTesting water hardnessMeasuring instrumentHand held

The invention discloses a hand-held detector for measuring water hardness, which comprises an instrument main body, a casing and a data line. The lower end of the instrument main body is connected with a dustproof cover through a pin shaft, and an indicator light is arranged outside the middle part of the instrument main body. A display screen is installed above the indicator light, and the display screen is located outside the main body of the instrument, the housing is arranged above the main body of the instrument, and a main shaft runs through the housing, and both ends of the main shaft are connected to the housing through bearings, and Both ends of the outer side of the main shaft are provided with a return spring, and a side baffle is installed inside the back spring, and the inside of the side baffle runs through the main shaft, and a tension mechanism is installed on the inner side of the side baffle, and a pressure plate is connected to the outside of the tension mechanism , and the pressure plate is located inside the side fence. The hand-held detector for measuring water hardness is equipped with a winding mechanism, which can facilitate the orderly winding of the outer lines, avoiding the winding of the lines, thereby avoiding the problem of reduced sensitivity of the device caused by long-term winding.

Owner:FOSHAN ZHIBEIHUI TECH CO LTD

Novel intensive-care nursing machine device

InactiveCN108210221AImprove comfortEasy to replaceDiagnosticsInfusion devicesMedical intensive care unitIntensive care

The invention discloses a novel intensive-care nursing machine device. The novel intensive-care nursing machine device comprises a bottom plate, wherein fixing columns are fixed at four vertex anglesof the upper surface of the bottom plate, the upper ends of the four fixing columns are fixedly connected with the lower surface of an upper plate, a T-shaped sliding rail is fixed on the left end ofthe upper surface of the upper plate along the front-back direction, the T-shaped sliding rail is in sliding connection with a T-shaped sliding chute in the lower surface of a slider, a fastening boltis mounted at the front side of the upper surface of the slider, the rear side of the upper surface of the slider is fixedly connected with the lower end of a telescopic rod, a sub-face velcro tape and a primary-face velcro tape are spliced, so that an infusion tube is fixed between a first electric heating plate and a second electric heating plate, the first electric heating plate and the secondelectric heating plate heat liquid medicine in the infusion tube, and thus the comfort of a patient is improved; an elastic arc-shaped plate is convenient to replace, a catheter of a medical facilityis clamped to the elastic arc-shaped plate, so that the catheter of the medical facility in an intensive care room is placed in order, and the rescue work of medical workers is conducted in good order.

Owner:亓志玲

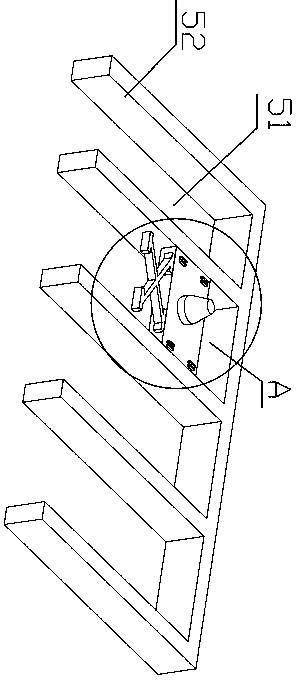

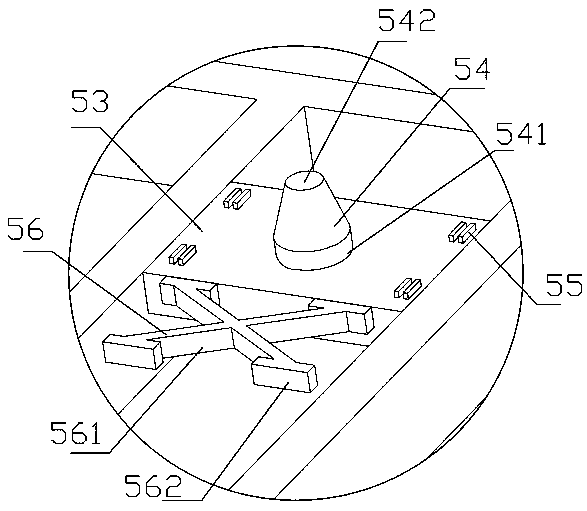

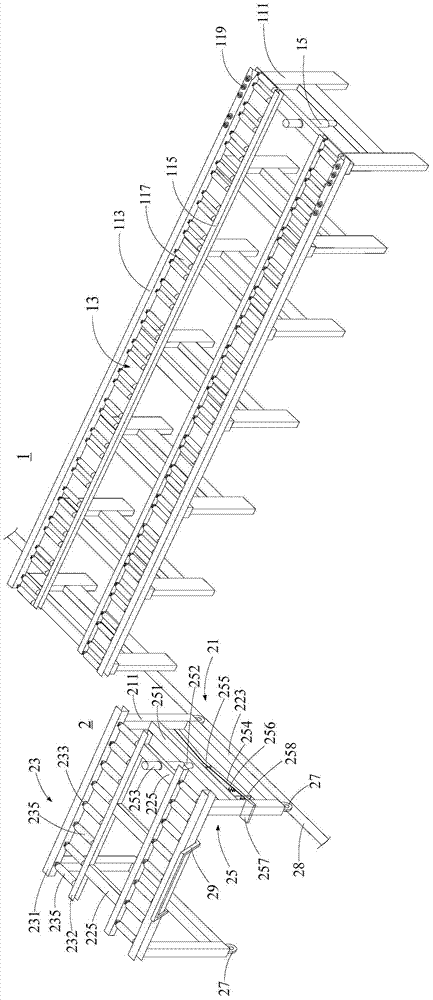

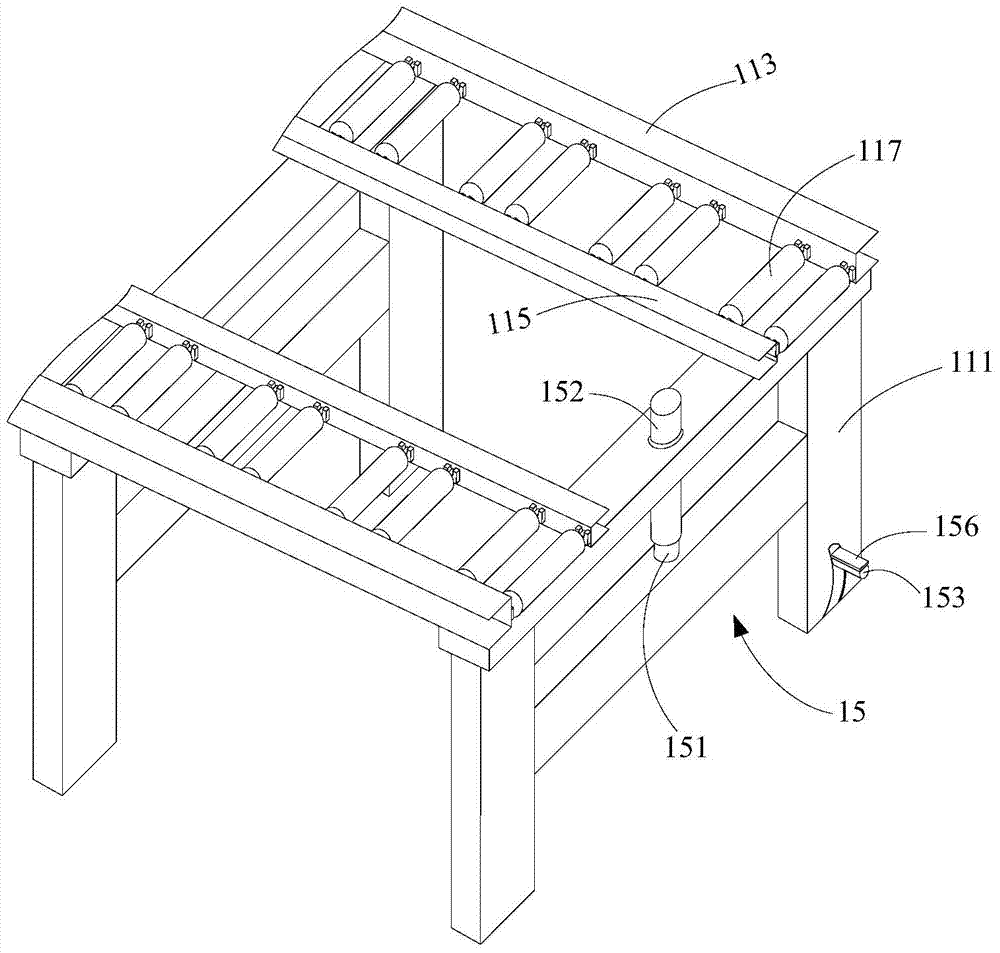

Suspension type universal conveying rack

ActiveCN104555491AFull range of mobilityAdjust the discharge heightLoading/unloadingSlide plateEngineering

The invention relates to a suspension type universal conveying rack. A translation conveying track and a balance track are mounted above a conveying site, and a cargo conveying belt is mounted above the inner side of the conveying track. A disc-shaped translation frame is mounted below the conveying track, a rolling wheel and a translation motor are mounted on the translation frame, a feeding cylinder is mounted above the inner guide rail of the translation frame, a rotating barrel is mounted below the inner guide rail, a driving frame is mounted below the outer wall of the rotating barrel, and a rotating motor and a lifting motor are mounted on the driving frame. A discharging slide plate is mounted below the rotating barrel. By the arrangement, the suspension type universal conveying rack has the advantages that a discharging port can be moved in an omnibearing manner to adjust discharging positions, and the conveying distance of a cargo transfer vehicle can be shortened; alignment of the discharging port and a lower transfer vehicle can be quickly achieved by rotating the slide plate, and cargo falling can be reduced and avoided; by the suspension type universal conveying rack, the cargo conveying and transfer efficiency can be improved, and the labor intensity of workers can be reduced greatly.

Owner:YUNNAN YANGGUANG HONGDA FOOD

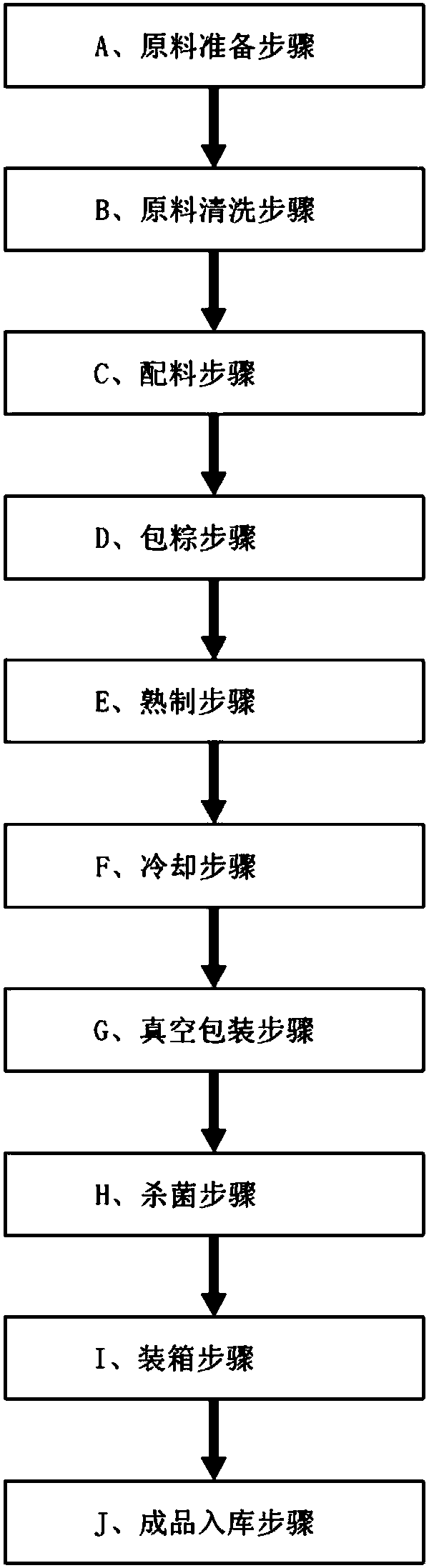

Rice dumpling preparation process

The invention relates to the technical field of snack food containing thin slices or other shapes originated from cereals. The rice dumpling preparation process specially comprises the following ricedumpling preparation steps: A, a step of preparing raw materials; B, a step of cleaning the raw materials; C, a step of proportioning the raw materials; D, a step of making rice dumplings; E, a step of cooking the rice dumplings: steaming and cooling the rice dumplings obtained in the step D in a pressurized manner, controlling pressure during serving of the rice dumplings to 2.0 to 2.4MPa and controlling temperature to 105 and 115 DEG C; F, a step of cooling: cooling the steamed and cooked rice dumplings obtained in the step E on a cooling line provided with a conveyor belt which has at leastthree levels and of which the conveying speed is sequentially increased; G, a step of packaging in vacuum; H, a step of sterilizing: sterilizing the packaged rice dumplings in the step G by utilizingsteam at a sterilization temperature of 115 to 125 DEG C for 40 to 60 minutes; I, a step of boxing; J, a step of enabling finished products to enter into a warehouse. According to the rice dumpling preparation process disclosed by the invention, the problem of lower production efficiency of the rice dumplings caused by long cooling time of the rice dumplings in the prior art is solved.

Owner:重庆凯年食品有限公司

Automatic cutting plotter for end face of screw rod

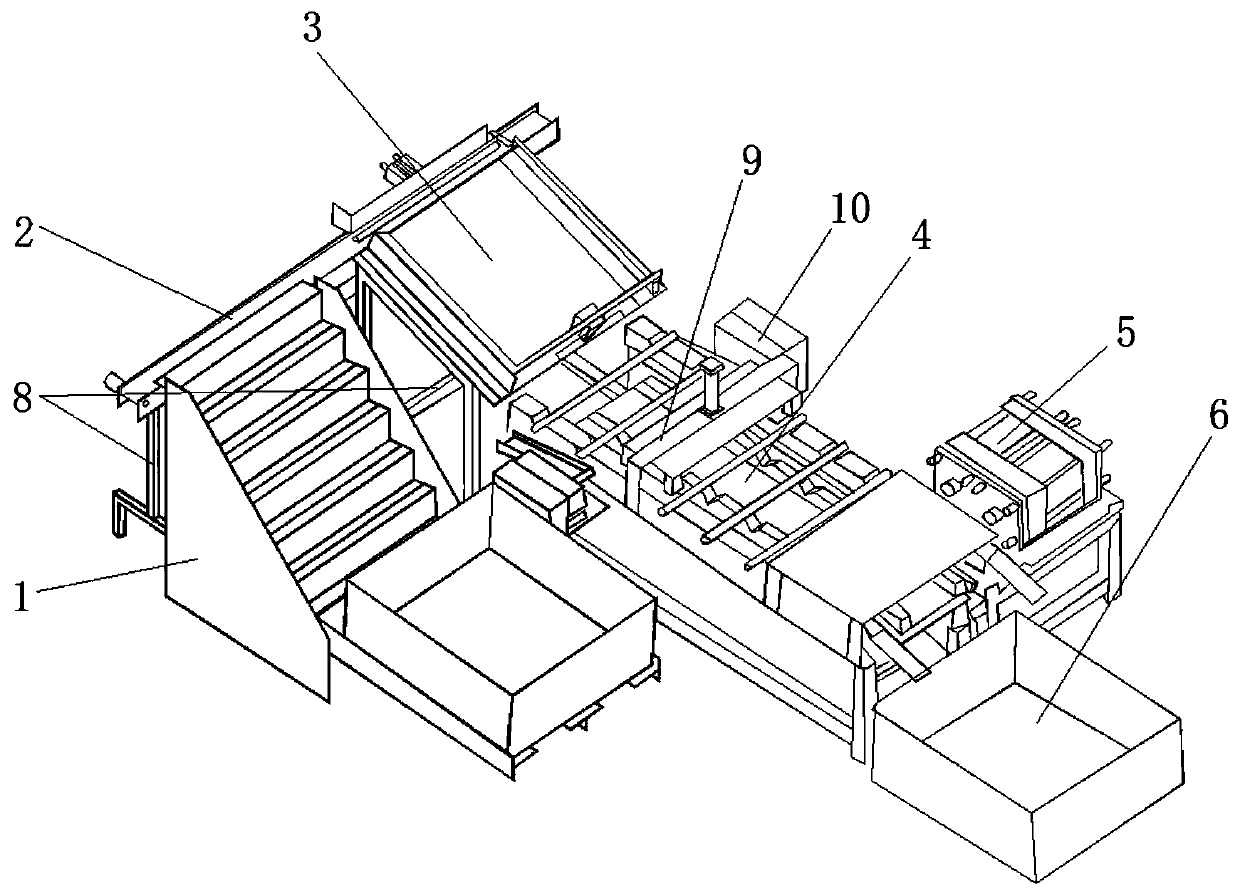

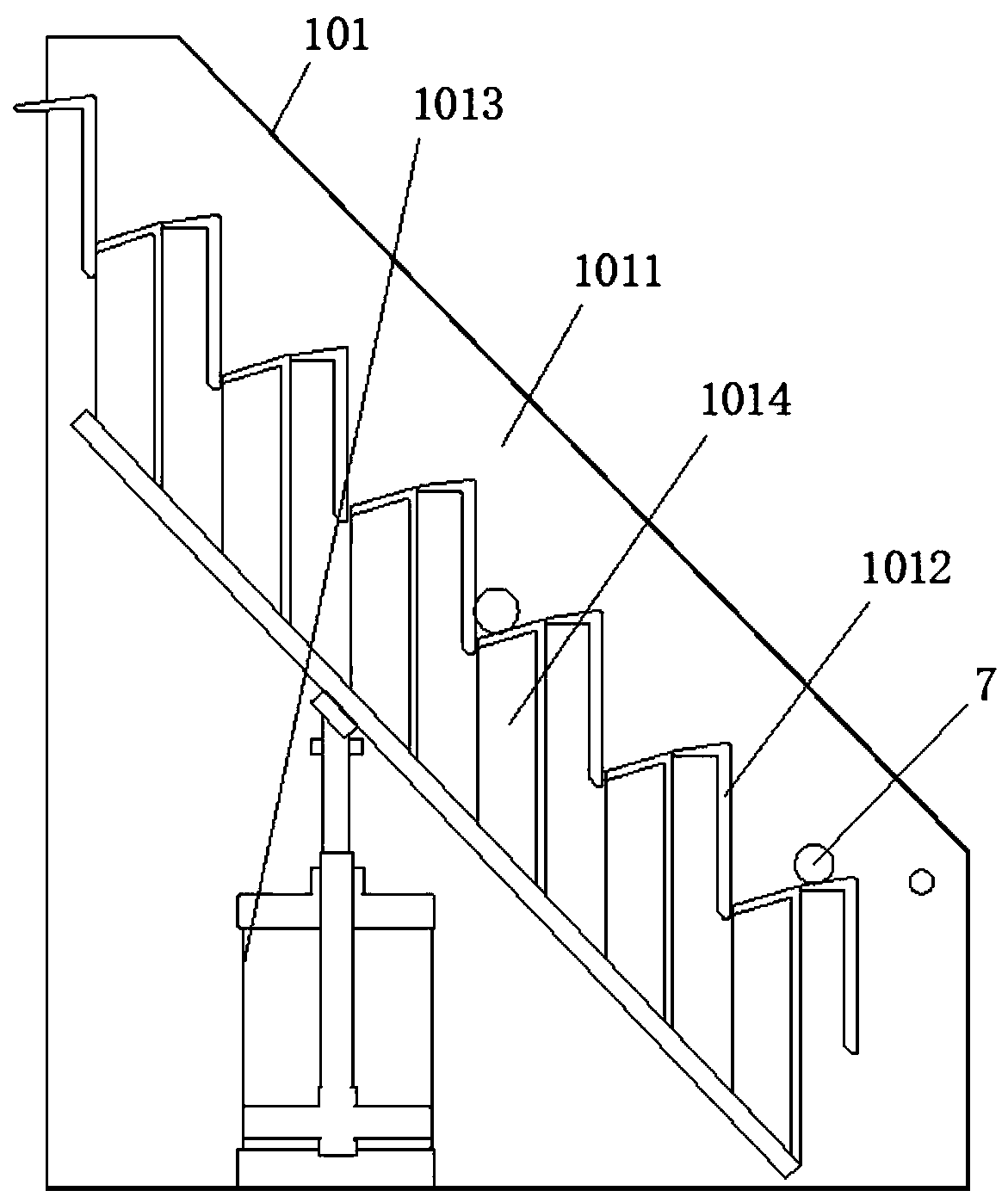

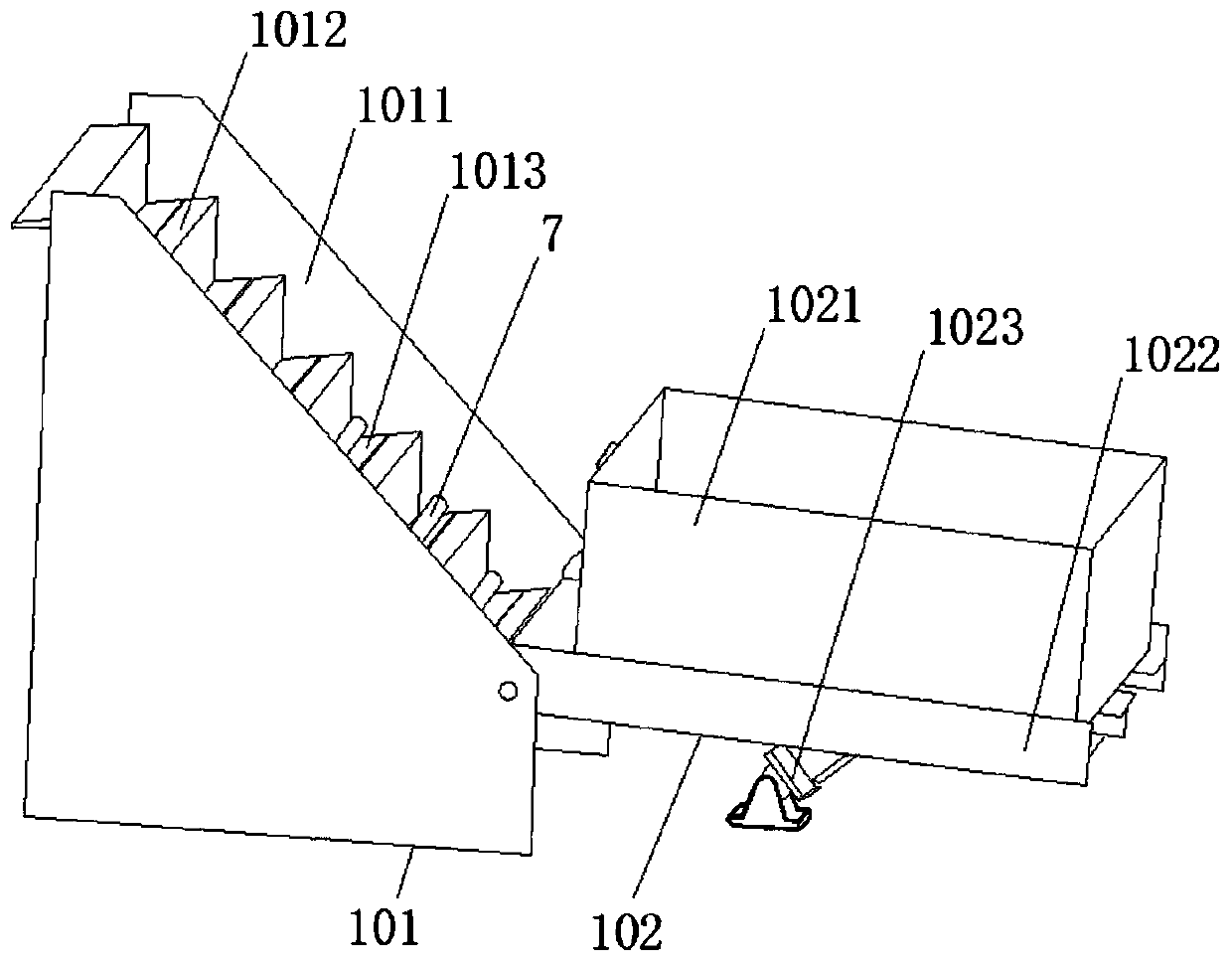

PendingCN111392359AGuaranteed separation effectGuaranteed continuityBottle emptyingLoading/unloadingEngineeringPower apparatus

The invention discloses an automatic cutting plotter for an end face of a screw rod. The automatic cutting plotter comprises an automatic feeding device, a fixed-distance conveying device, workpieces,a supporting frame system and a center hole station, the top end of the automatic feeding device is connected with a transmission line and comprises a stepped feeding mechanism and an automatic hopper tipping mechanism, the automatic hopper tipping mechanism comprises a hopper, a turning plate and an overturning power device, the hopper is fixedly mounted on the top face of the turning plate, a finished product box is arranged below the tail end of the fixed-distance conveying device, a compressing mechanism is mounted above the top end of the fixed-distance conveying device, the workpieces are placed in the hopper, and the compressing mechanism is composed of a fourth base plate, a third air cylinder and a pressure head. According to the automatic cutting plotter for the end face of thescrew rod, orderly and stable feeding can be ensured, separation of workpiece individuals can be ensured, the operation continuity is ensured conveniently, the stability of workpiece machining can beensured, and thus safe operation is facilitated.

Owner:绵阳富林岚科技有限责任公司

Automatic whole rowing device for sub-packaging boxes

ActiveCN108545437ARealize automatic alignmentOrderly storageConveyorsConveyor partsEngineeringFood processing

The invention relates to the field of food processing, and discloses an automatic whole rowing device for sub-packaging boxes. The automatic whole rowing device for the sub-packaging boxes comprises arack, a straight putting unit, a clearing unit, a placing unit and a pushing unit; the straight putting unit comprises a conveying belt, a straight putting box, two first magnets and one second magnet; the straight putting box comprises a perpendicular cavity and two transverse cavities; transverse plates are connected in the transverse cavities in a sliding manner, and bent rods are fixed to thetransverse plates; one end of each bent rod is fixedly connected with the corresponding first magnet; the second magnet is fixed to the bottom of each sub-packaging box; the clearing unit comprises aguiding plate, a clearing box and clearing wheels, and the clearing box comprises an extruding cavity and a pushing cavity; a pushing plate is connected in the pushing cavity in a sliding manner; twopushing rods are fixed to the pushing plate; the end, away from the pushing plate, of each pushing rod is rotationally connected with the corresponding clearing wheel; and each clearing wheel is wrapped by clearing cloth. The scheme can achieve automatic whole rowing of the sub-packaging boxes, the sub-packaging boxes are made stored in order, and the phenomenon that because of mutual collision between the sub-packaging boxes, materials topple and fall can be prevented.

Owner:重庆市长寿区可又可食品有限公司

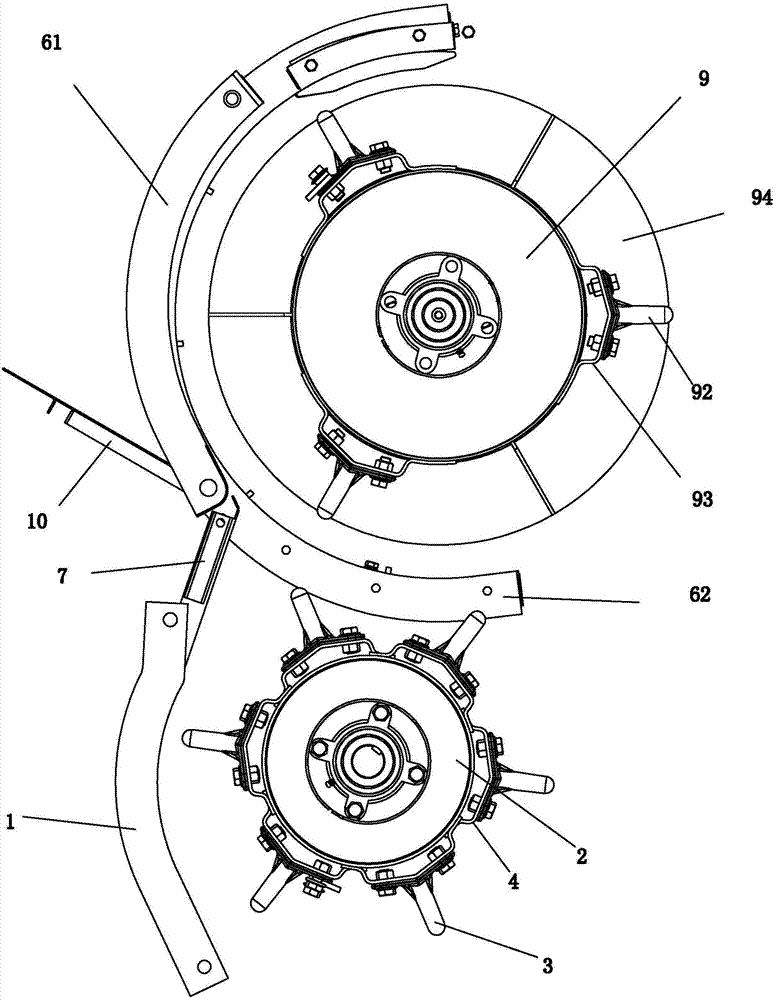

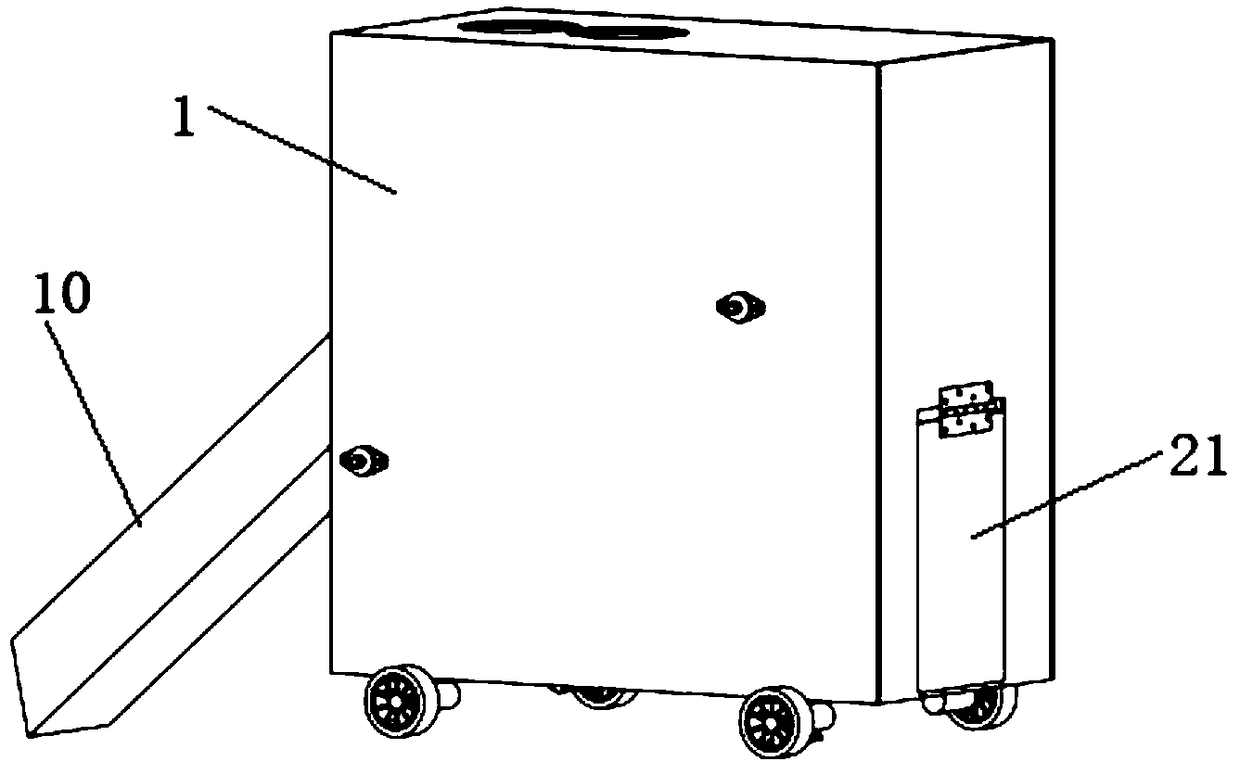

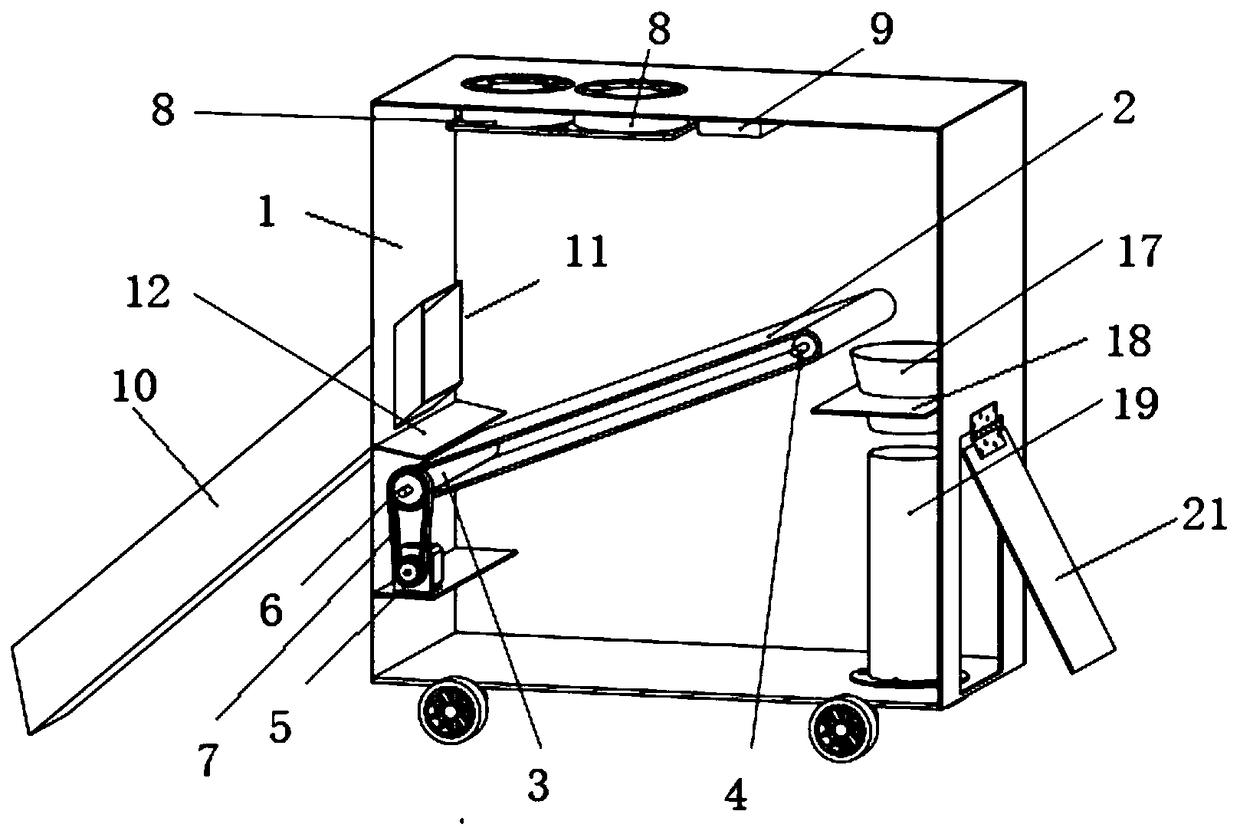

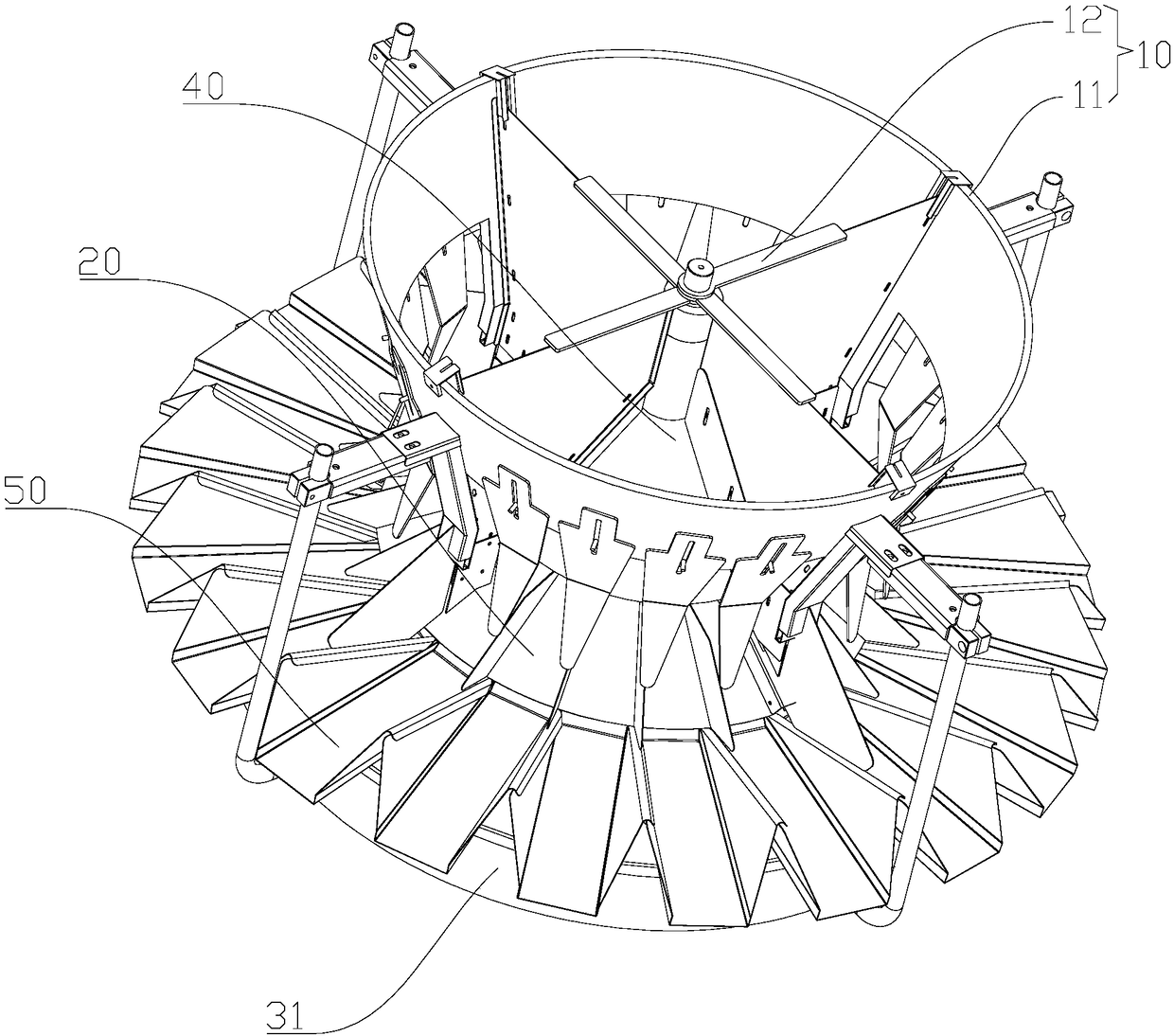

Badminton pick-up device and control method thereof

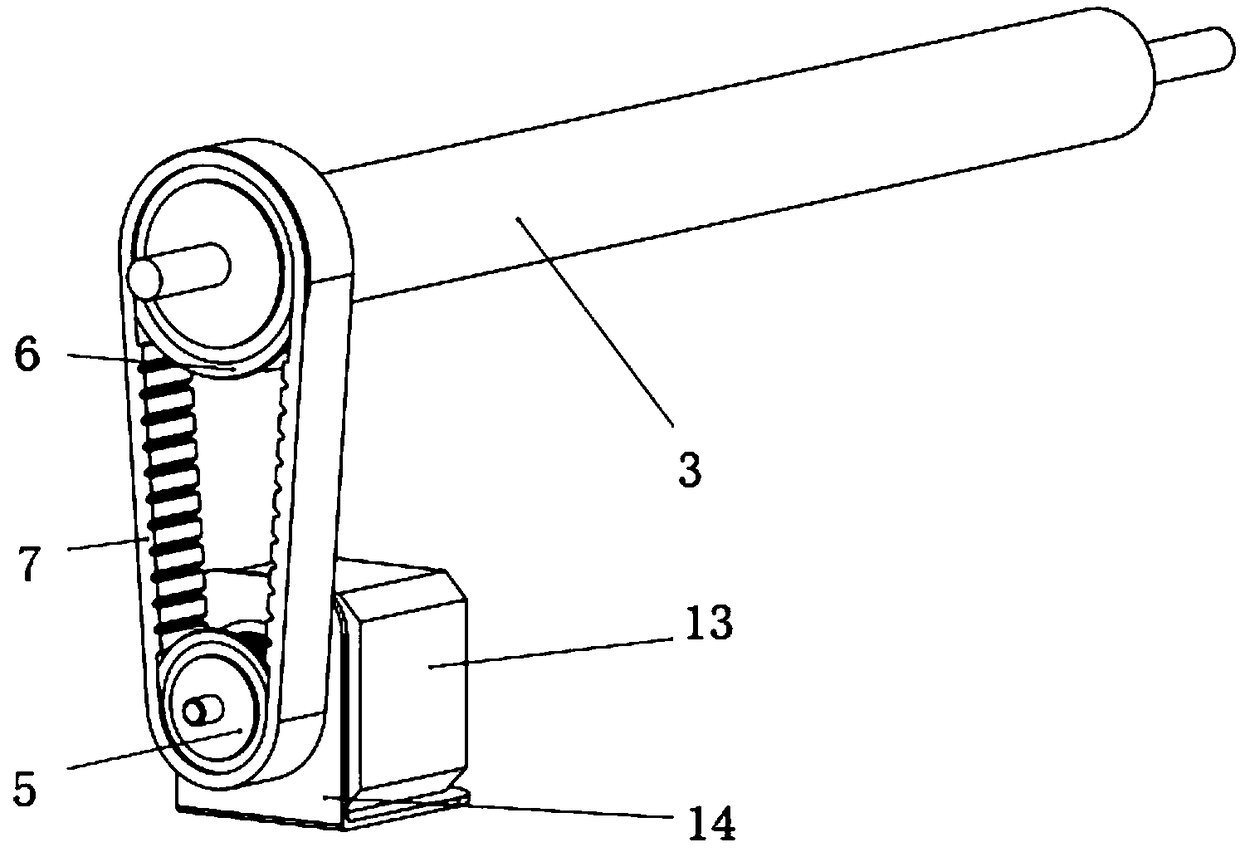

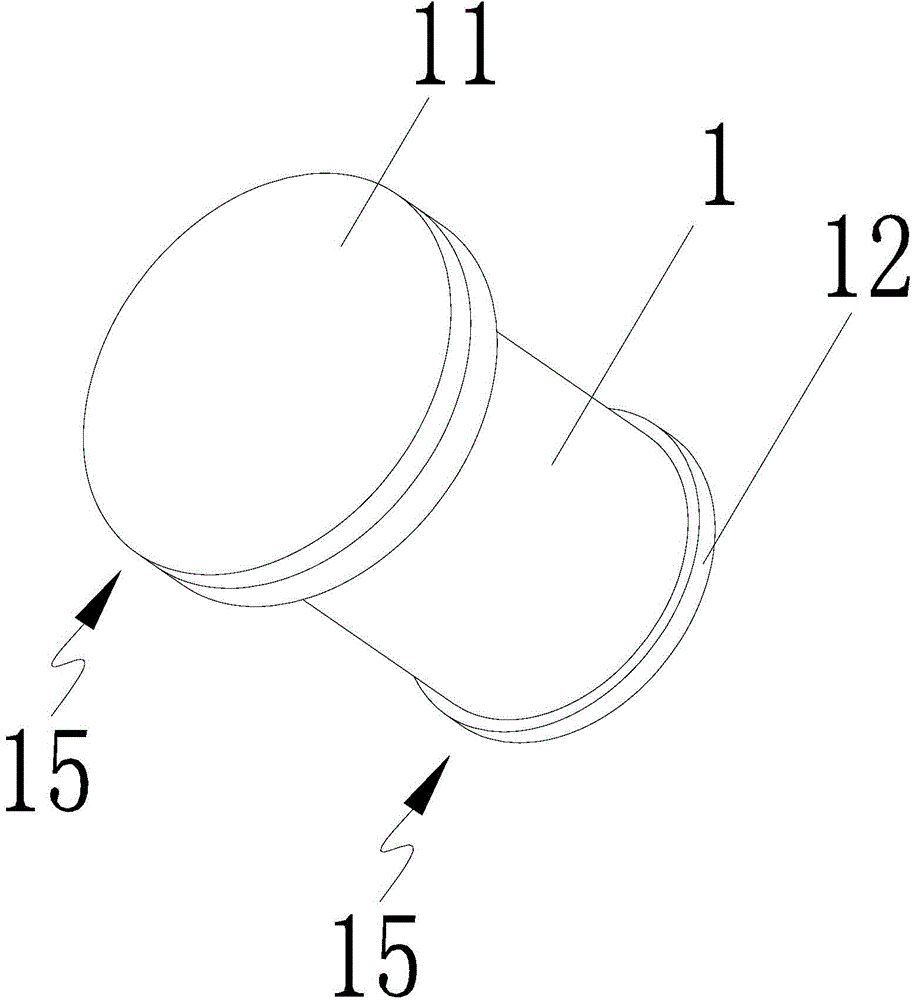

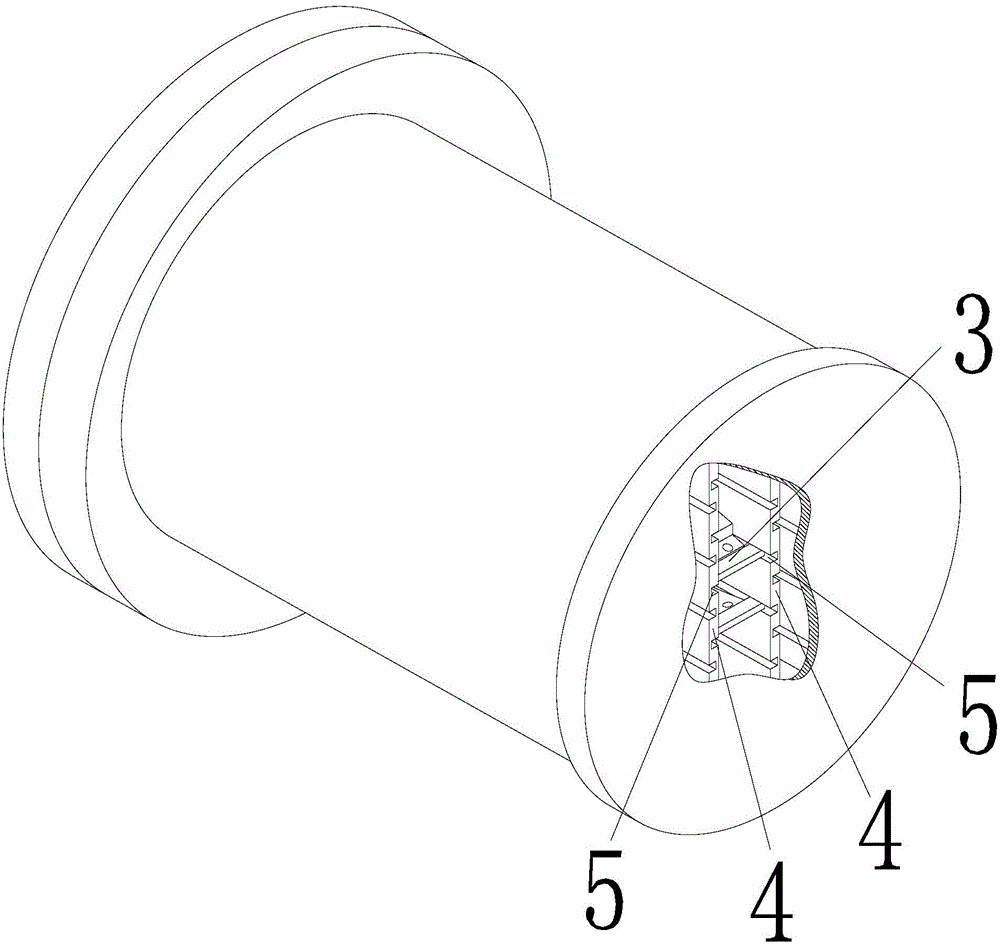

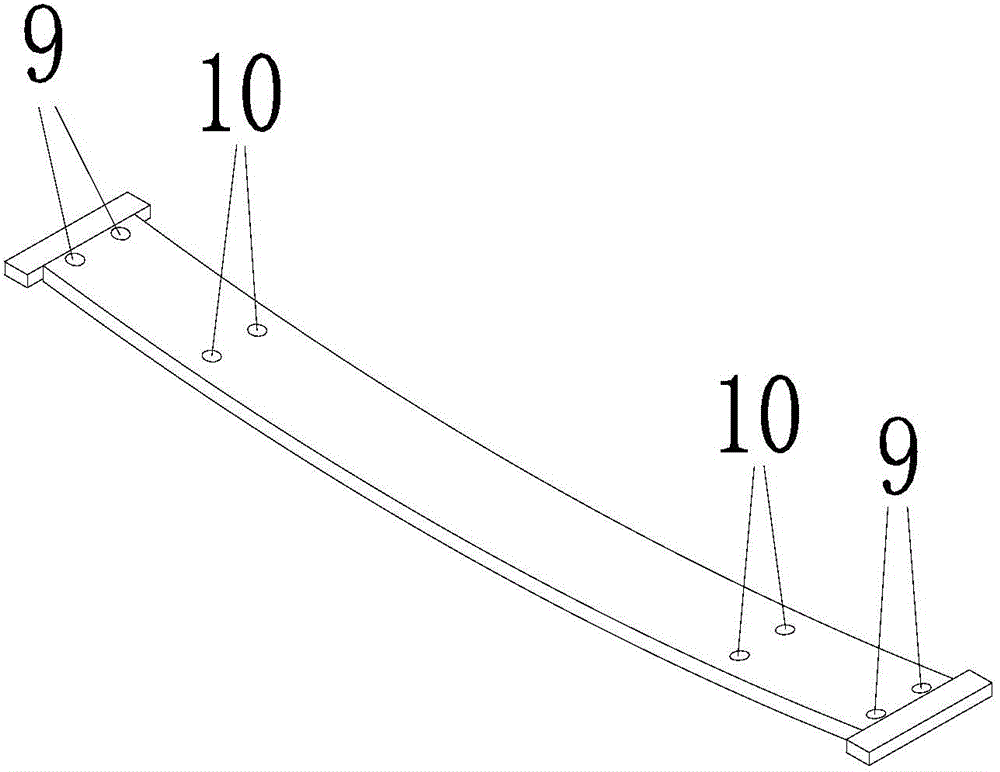

PendingCN108786043AReduce harmEasy to pick up the ballBall sportsRacket sportsDrive shaftTransmission belt

The invention provides a badminton pick-up device and a control method thereof. The badminton pick-up device comprises a tank body, a ball suction device, a conveying device, a ball collection deviceand a control device, wherein the conveying device comprises a conveying belt, a driving device, a driving transmission shaft, a driven rotating shaft, a driving belt wheel, a driven belt wheel and asynchronous belt; the conveying belt is mounted on the driving transmission shaft and the transmission belt, the driven belt wheel is connected with the driving transmission shaft, the driving belt wheel is mounted on the driving device, the synchronous belt is connected with the driving belt wheel and the driven belt wheel, the mounting position of the driven transmission shaft is higher than that of the driving transmission shaft, and the transmission belt is arranged to form a preset angle with the horizontal direction; and the control device is used for controlling the ball suction deviceto suck badmintons to the conveying belt, the badmintons on the conveying belts are rotated to the consistent direction under the effect of the gravity, and the control device is used for controllingthe driving device to work to convey the badmintons to the ball collection device through the conveying belt. According to the badminton pick-up device, the badmintons can be conveniently and rapidlypicked up.

Owner:GUANGZHOU UNIVERSITY

Equipment for testing resistance to environmental stress of plastic

InactiveCN105865912AWide range of curvatureEasy to compareWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesTest requirementsEngineering

The present invention discloses equipment for testing resistance to environmental stress of plastic. The equipment includes a test chamber, a rack bar for bending the test strip and a cover for sealing the test chamber; the test chamber is internally provided with a neck; and the rack bar is connected in the neck. The present invention has high degree of tightness, and can conduct an environmental stress cracking test on a volatile test reagent; the equipment is made of stainless steel with certain thickness, has the advantages of ideal compression effect, overall safety and reliability, flexible handling, easiness to clean and operate; the rack bar has wide range of bending rate, meets test requirements of different materials; the test results are easy for comparison; and the equipment is easy for processing and assembly, and has low manufacturing cost.

Owner:KINGFA SCI & TECH CO LTD +1

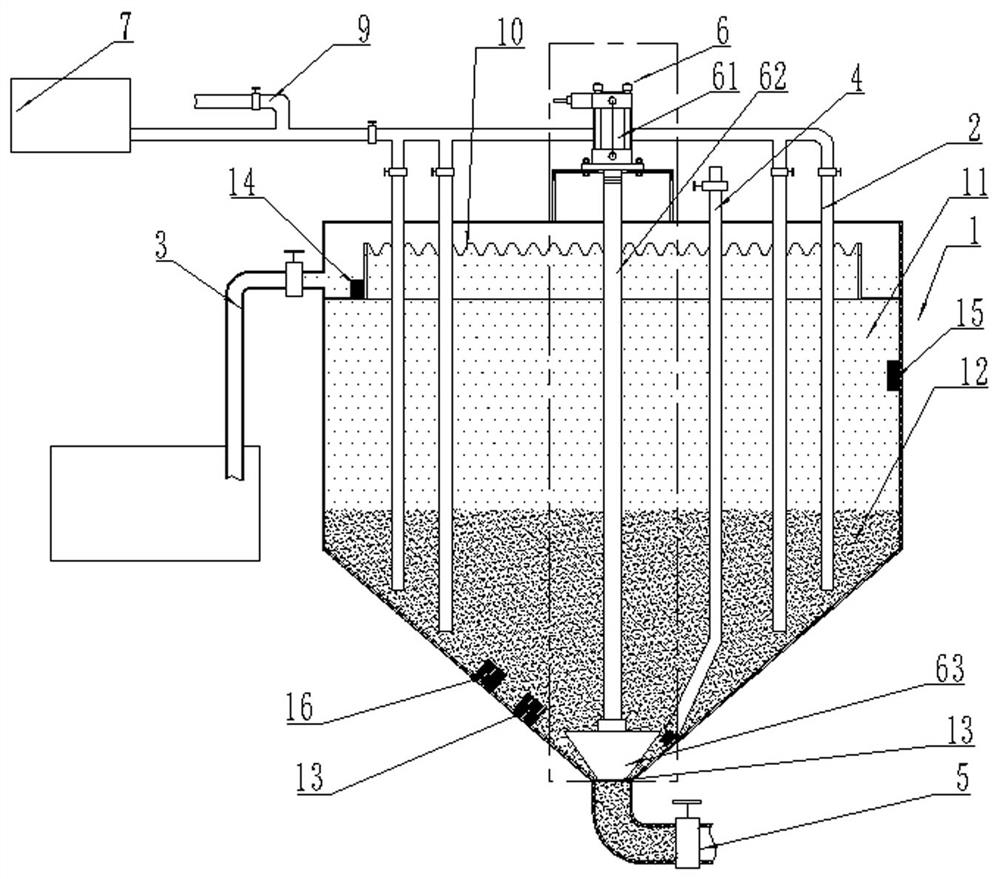

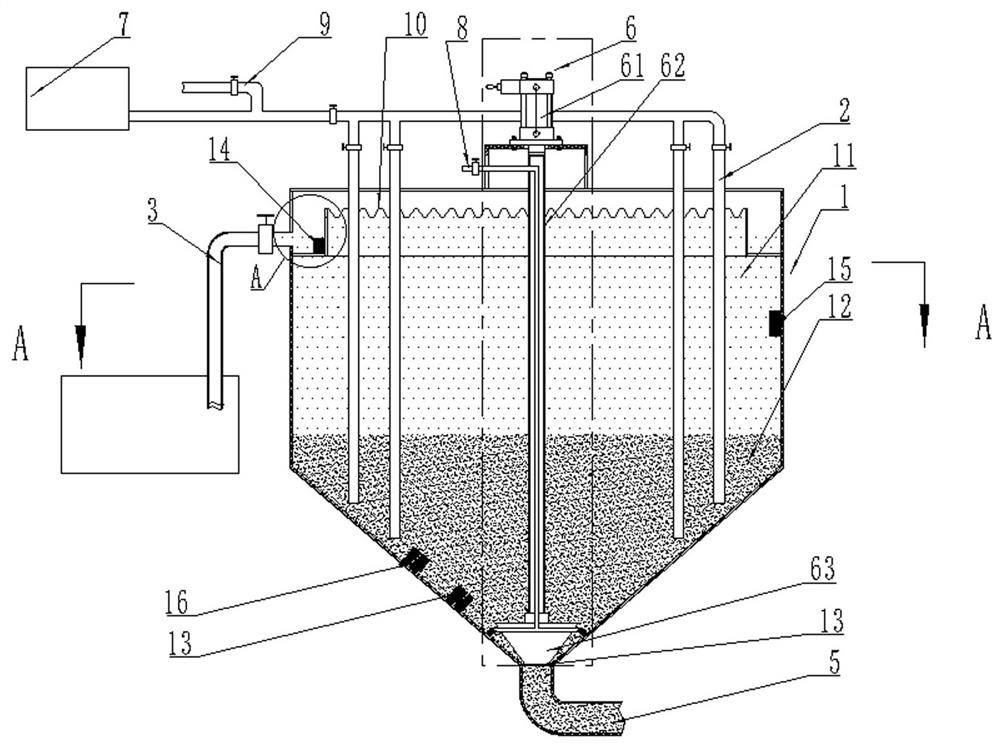

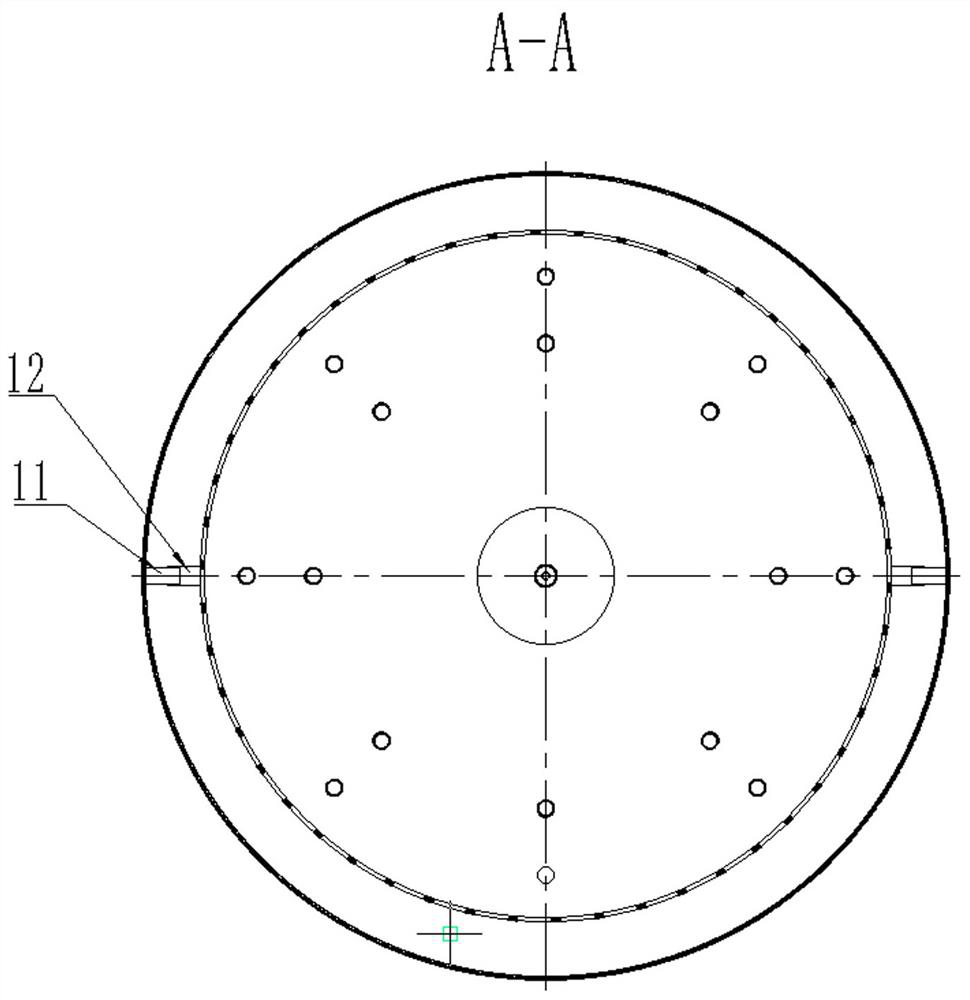

Sewage treatment method

PendingCN113479981AIncrease water intakeImprove efficiencyWater treatment parameter controlSpecific water treatment objectivesSewage outfallSewage treatment

The invention provides a sewage treatment method, and relates to the field of sewage treatment. The sewage treatment method involves a control system and a sewage treatment system. The sewage treatment system comprises a sewage buffer pool, a sewage sedimentation pool, a sewage inlet pipe, a clear water tank, a clear water pipe, a chemical feeding pipe, a liquid level meter, an anti-blocking device and a blow-off pipe. A water outlet of the sewage inlet pipe is far away from the center of the sewage sedimentation pool and is close to the lower pool body, one end of the anti-blocking device is arranged above a sewage outlet in the lower pool body, so that sedimentation waste is discharged in order, and the blow-off pipe is not easy to block. The chemical feeding pipe, the sewage inlet pipe and the clear water pipe are all provided with valves for controlling opening and closing. The system has multiple sewage treatment modes, can be suitable for sewage with different attributes, and has the advantages of simple structure, high efficiency, convenience and wide applicability.

Owner:HENAN DAZHANG FILTER EQUIP CO LTD

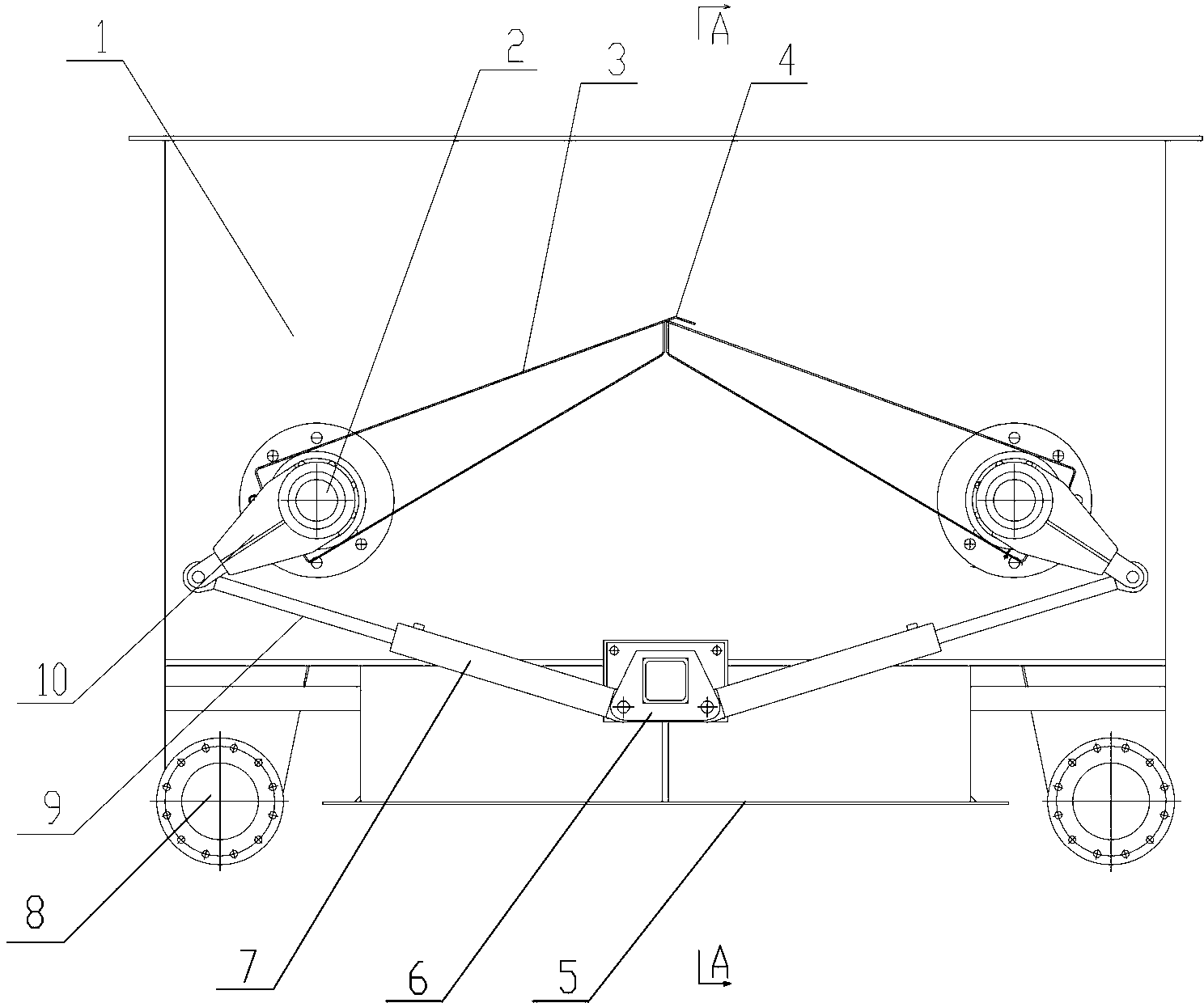

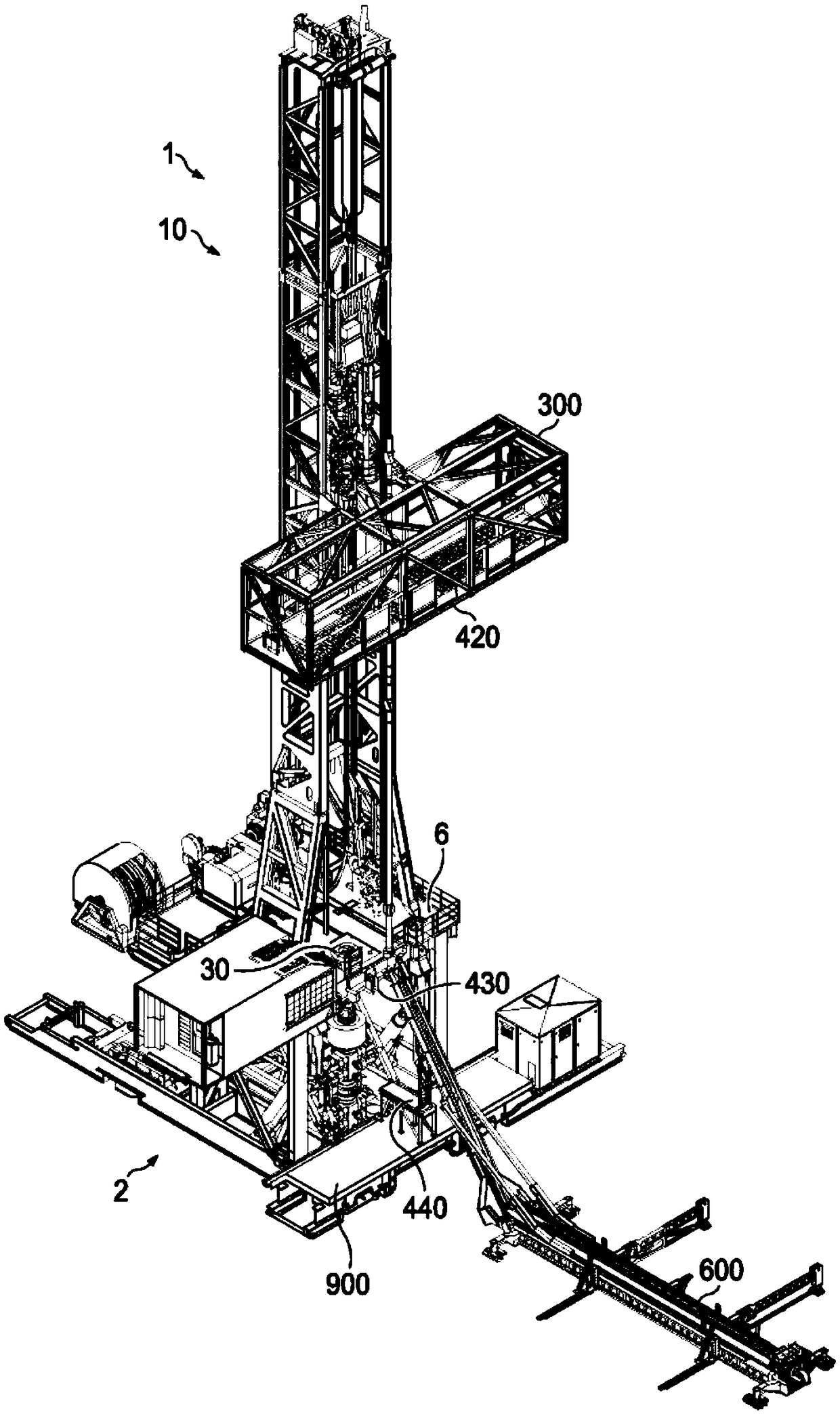

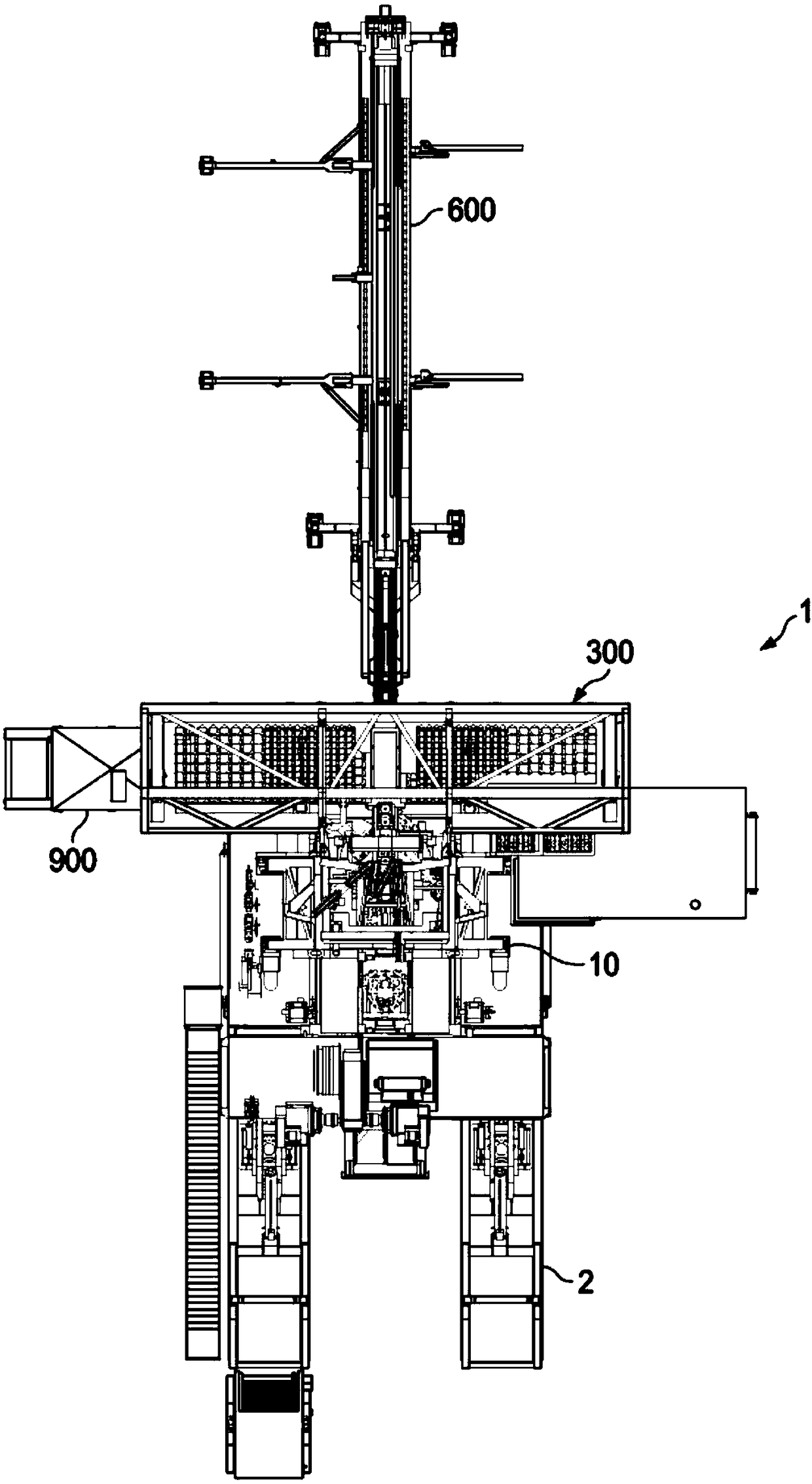

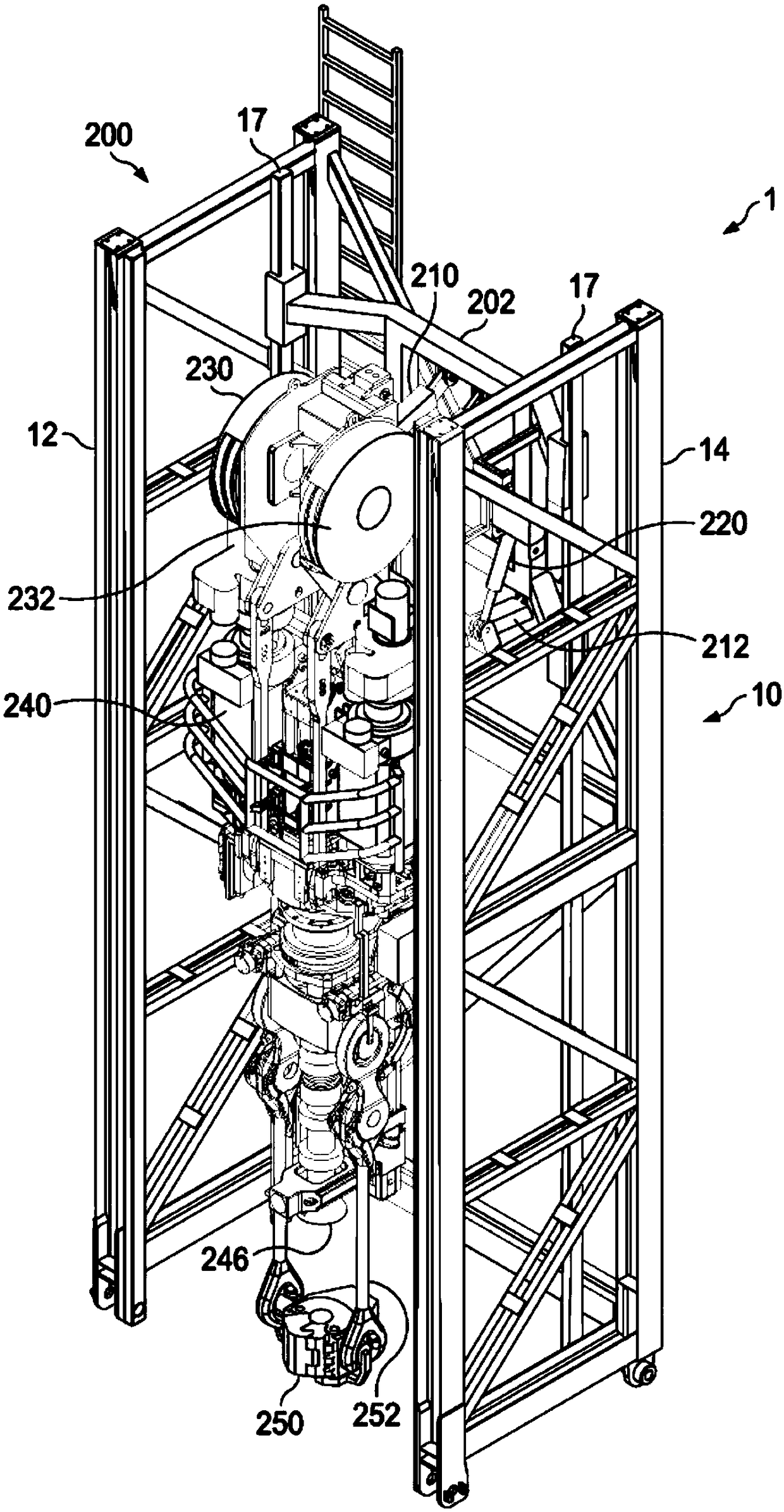

High trip rate drilling rig

InactiveCN109312606AShorten the timeDischarge orderlyDrilling rodsConstructionsTop driveClassical mechanics

A high trip rate drilling rig has first handling equipment to transport stands in / out of setback, second handling equipment to deliver stands to / from well center, and a hand-off position to set down stands for exchange between first / second equipment. Second equipment can include a top drive and a delivery arm translatable along the mast past each other, and a clasp on the arm slidable on the standfor constraint below the upper end, which can allow the top drive to engage / disengage the constrained stand above the arm. A high trip rate method transports stands in / out of setback, delivers standsto / from well center, and sets down and hands off stands at hand-off position between the setback transportation and well center delivery. The delivery can include engaging / dis engaging the top driveand a stand constrained by the clasp.

Owner:SCHLUMBERGER TECH LTD BV

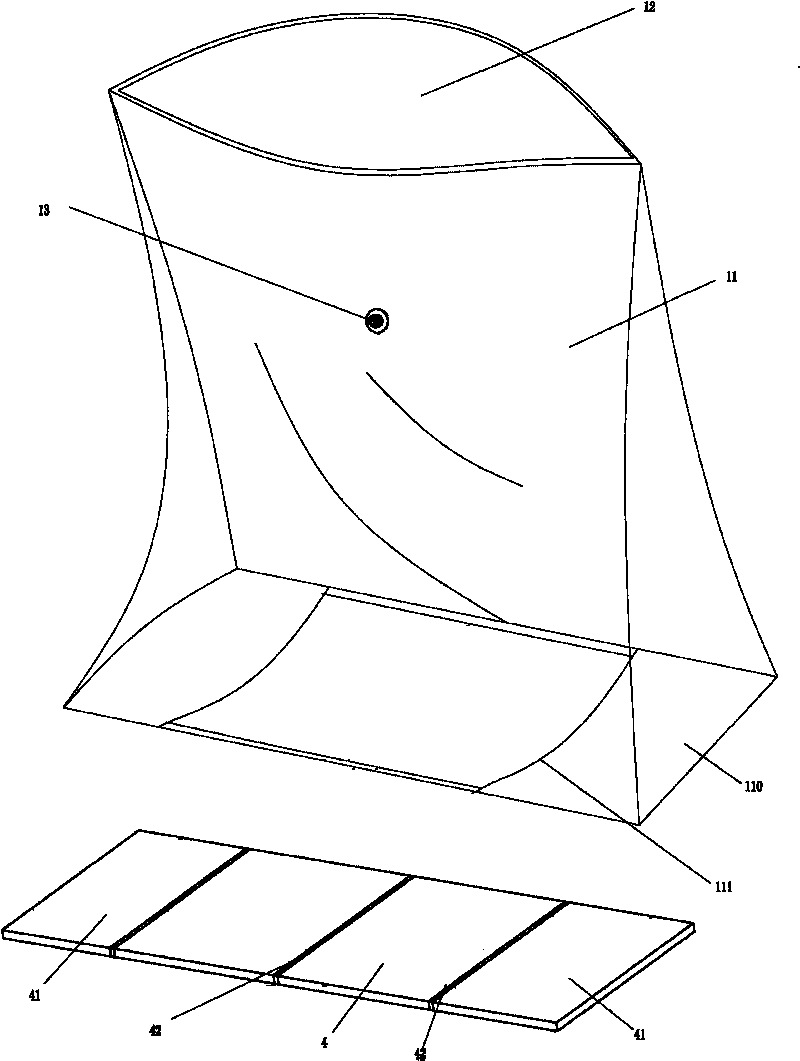

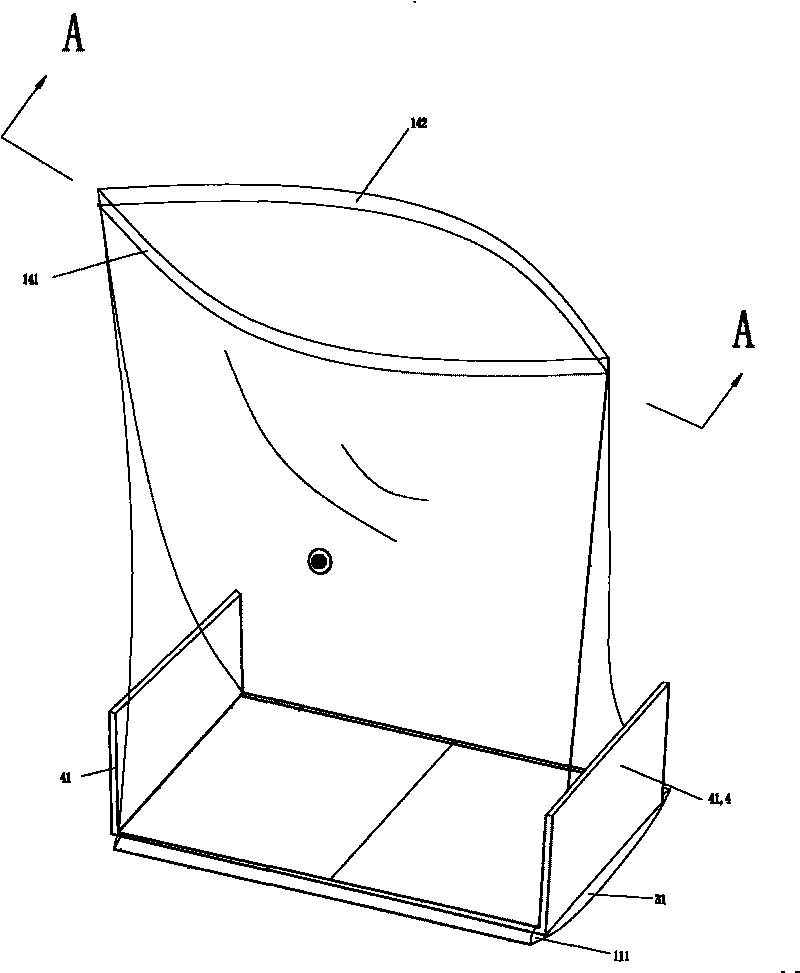

Vacuum bag and combination device of vacuum bag and stuff bag

The invention relates to a vacuum bag, which comprises a bag body and a bag mouth, wherein the bag body is provided with an air sucking faucet and a sealing device on the bag mouth. The vacuum bag is characterized in that an interlayer is arranged on the lower side of the bag bottom of the bag body; the bag bottom and the interlayer form an accommodation space with an opening; and a supporting board which can be separated from the bag body is inserted into the accommodation space and extends out of the opening of the accommodation space, and the extending segment can be folded. The invention relates to a combination device of the vacuum bag and a stuff bag; the stuff bag is arranged outside the bag body; and the size of the stuff bag is matched with the size of the bag bottom. The invention aims to overcome the defect that the existing vacuum bag has difficulty in combining with the supporting board at the bottom, and provides the vacuum bag with simple structure, easy combination of the vacuum bag and bottom supporting board and convenient transportation and storage, and the combination device of the vacuum bag and the stuff bag.

Owner:HUBEI TAILI HOUSEHOLD ARTICLE MFG

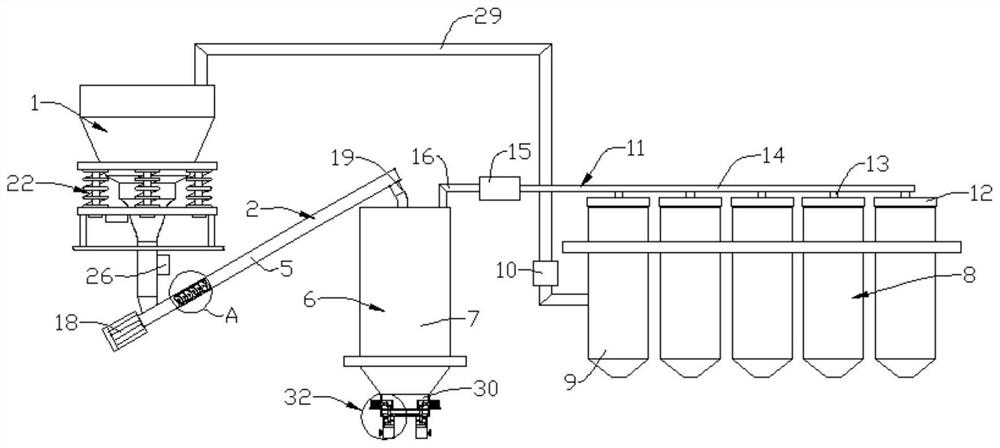

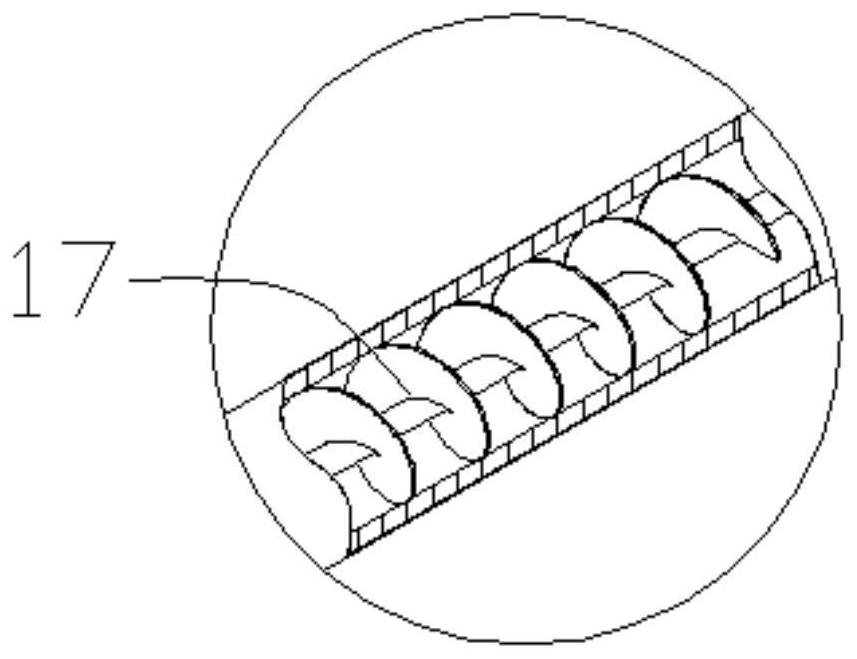

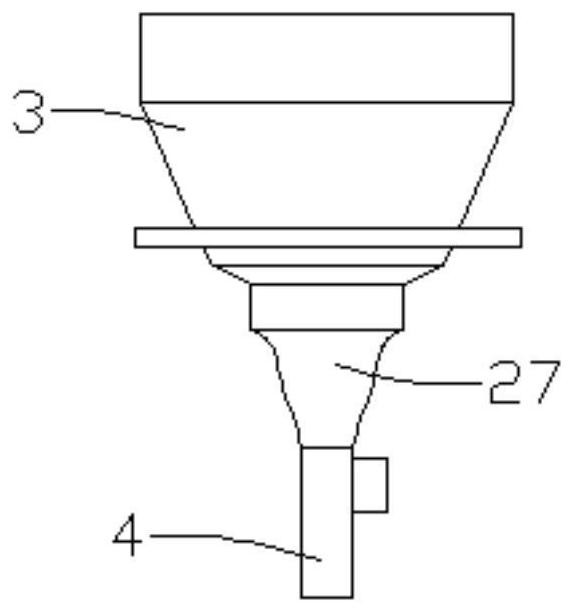

Concrete mixing plant

InactiveCN112936604AImprove qualityAccurately measure massDischarging apparatusMixing operation control apparatusArchitectural engineeringPipe

The invention discloses a concrete mixing plant. According to the technical scheme, the concrete mixing plant is characterized by comprising a batching mechanism used for accurately proportioning concrete materials, a conveying mechanism, a material mixing mechanism, a material storage mechanism and a dust collection mechanism, wherein the batching mechanism comprises a batching hopper, and a first connecting pipe is arranged below the batching hopper; the conveying mechanism is used for conveying materials, the conveying mechanism comprises a conveying pipe body, and the bottom of the first connecting pipe fixedly communicates with the conveying pipe body; the material mixing mechanism is used for mixing and stirring various materials, the material mixing mechanism comprises a mixing plant main tank, and a discharge port of the conveying pipe body fixedly communicates with the top end of the mixing plant main tank; and the material storage mechanism is used for storing various materials, the material storage mechanism comprises a plurality of material storage tanks, and the material storage tanks are connected with the batch hopper through material pumps. A dust collection mechanism; According to the concrete mixing plant, the discharge of the materials can be accurately controlled, and the effects of improving the proportioning accuracy of the concrete and improving the quality of the concrete are achieved.

Owner:张友双

Spinning spool storage equipment with sterilization adjusting device

The invention relates to the field of spinning equipment, in particular to spinning spool storage equipment with a sterilization adjusting device. The invention aims to provide the spinning spool storage equipment with the sterilization adjusting device. The equipment comprises a main machine. The equipment is characterized by further comprising a storage column which comprises a slide rail, wherein a slide block is slidably connected to the slide rail, and a fixed shaft for fixing a spinning spool is arranged on the slide block; the body is hinged to a rotary door, and a sterilizing device isarranged on the rotary door. The invention aims to provide the spinning spool storage equipment with the sterilization adjusting device. Coils are placed and stored in a classified manner conveniently, are conveniently stored and are hard to collide. The equipment has the sterilizing design and is stored favorably.

Owner:湖州棉甜服饰有限公司

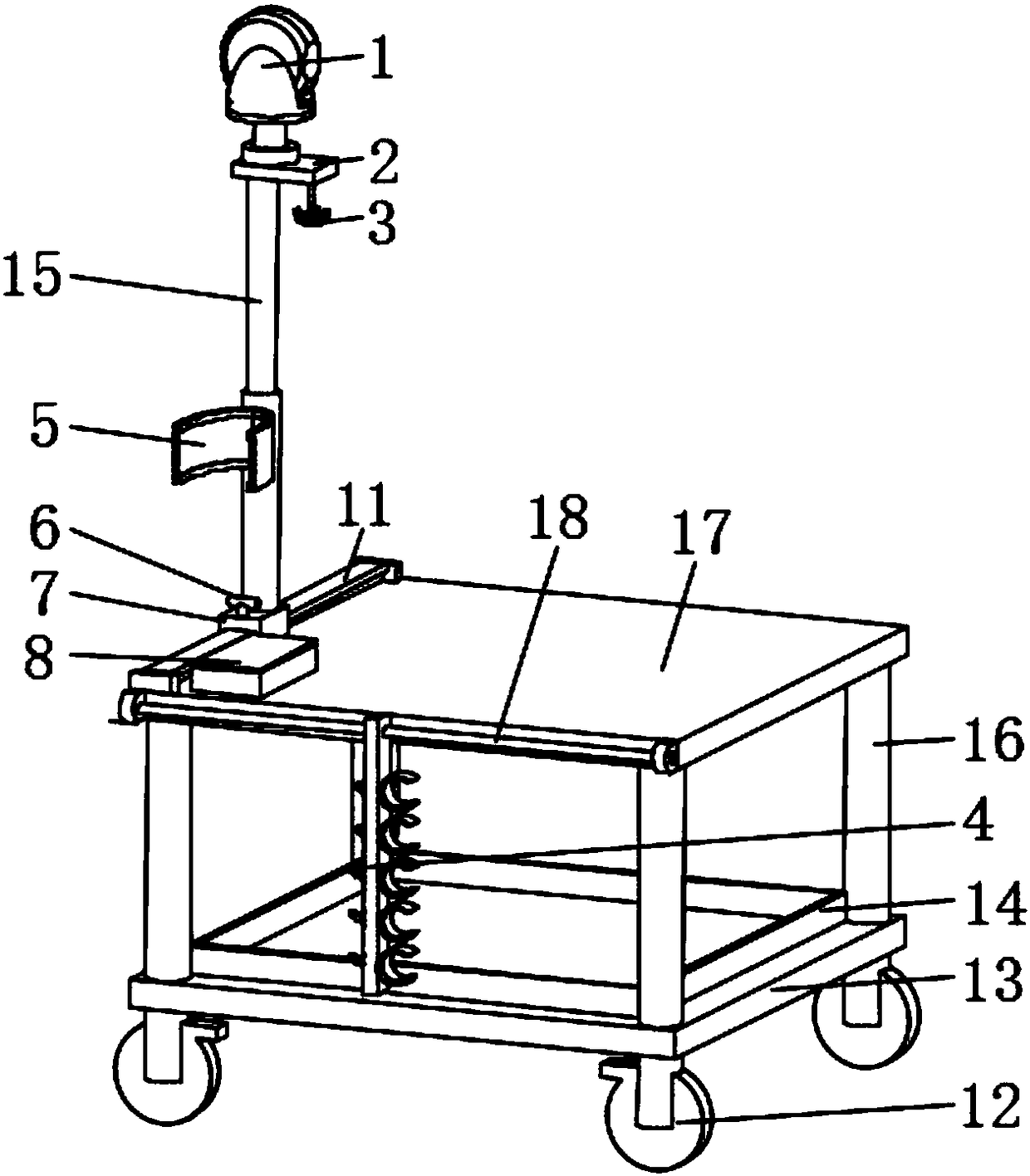

Textile storage mobile vehicle

PendingCN109205104AEfficient accessEasy to fixContainers for annular articlesContainers preventing decayMobile vehicleTerrain

The invention relates to the field of textile equipment, in particular to a textile storage mobile vehicle. The technical aim of the invention is realized by the following technical scheme that the textile storage mobile vehicle includes a main machine and is characterized by further comprising a storage column, wherein the storage column comprises a sliding rail, a sliding block is connected to the sliding rail in a sliding mode, and a fixing shaft used for fixing the spinning yarn barrel is arranged on the sliding block; a walking wheel set is arranged below the main machine, and the walkingwheel set comprises three walking wheels, wherein the walking wheel set is a main supporting wheel and two auxiliary wheels. The textile storage mobile vehicle is convenient for classified placementand storage of coils, is convenient to access, is not easy to collide, is convenient to transport and is suitable for unbalanced terrains.

Owner:湖州棉甜服饰有限公司

Transfer device for lifting chains

ActiveCN112278555AEasy accessReduce labor intensityRigid containersExternal fittingsEngineeringChain link

Owner:绩溪山合机械有限公司

Cleaning device for cylinder sleeves of engines

InactiveCN108114949APlay the role of positioningAvoid offsetHollow article cleaningCleaning using liquidsEngineeringMechanical field

The invention belongs to the field of machines, and relates to a cleaning device, particularly relates to a cleaning device for cylinder sleeves of engines. According to the cleaning device, the modethat spraying pipelines are arranged up and down correspondingly is adopted, the spraying pipelines are arranged in a staggered mode, and the spraying directions of nozzles arranged on the spraying pipelines point to a conveying belt so that two sides and insides of the cylinder sleeves on the conveying belt can be cleaned; and a baffle plate arranged between the upper spraying pipeline and the conveying belt can play a role in shielding the cylinder sleeves blown by the nozzles, so that the relative positions of the cylinder sleeves are prevented from shifting. The cleaning device comprises aspraying device and an automatic conveying device, wherein the spraying device comprises the spraying pipeline, the nozzles and pipe clamps, wherein the nozzles are distributed on the spraying pipelines, and the pipe clamps are used for fixing the nozzles; and the automatic conveying device comprises the conveying belt, the spraying pipelines are arranged on the upper side and the lower side of the conveying belt respectively, the spraying directions of the spraying nozzles point to the conveying belt, the baffle plate is arranged between the upper spraying pipeline and the conveying belt, and the conveying belt and the baffle plate are of a net structure.

Owner:沈阳元生鑫达科技有限公司

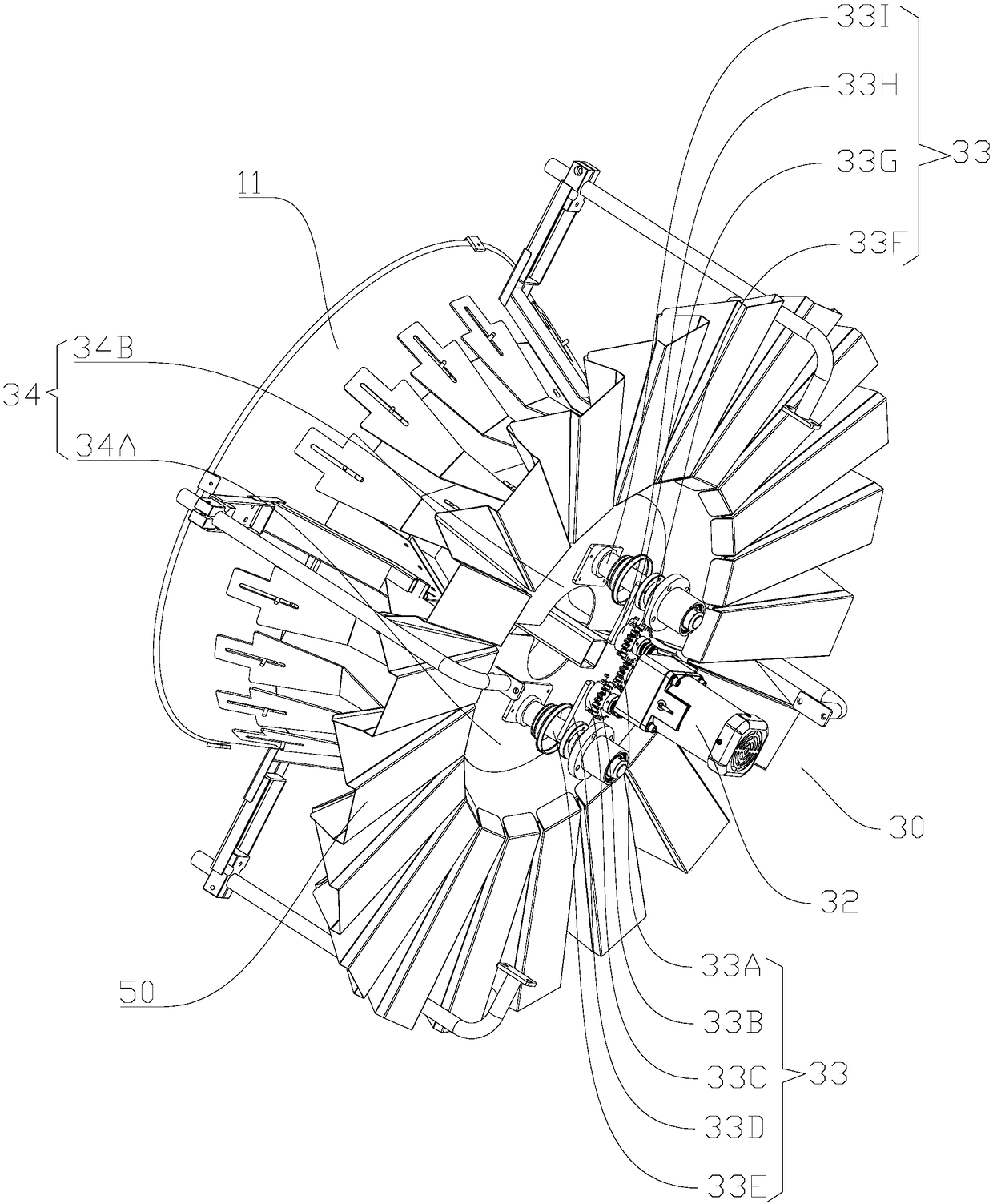

Polarization combined scale

PendingCN108454906ADischarge orderlyEfficient dischargeSolid materialWeighing auxillary devicesEngineeringMechanical engineering

The invention discloses a polarization combined scale and relates to the technical field of combined scales. The polarization combined scale comprises a material bin, a plurality of material guide channels and a polarization component, wherein the material bin is vertically through; a discharging slope extending into the material bin and tilting down is arranged under the material bin; a recedinggap for conveniently discharging materials is formed between the discharging slope and the material bin; the multiple material guide channels are uniformly distributed at the peripheral edge of the discharging slope; the output end of the polarization component is connected with the material guide channels; and through swinging, the materials on the material guide channels are stirred and dispersed. Through the technical scheme, the polarization component is used for swinging so as to stir and disperse the materials on the material guide channels so as to prevent the materials from being staggered with each other for adhesion and causing the phenomenon of blockage; and the materials are efficiently discharged in order.

Owner:ZHONGSHAN TO U INTELLIGENT EQUIP TECH CO LTD

Backflow water storage type waterproof structure

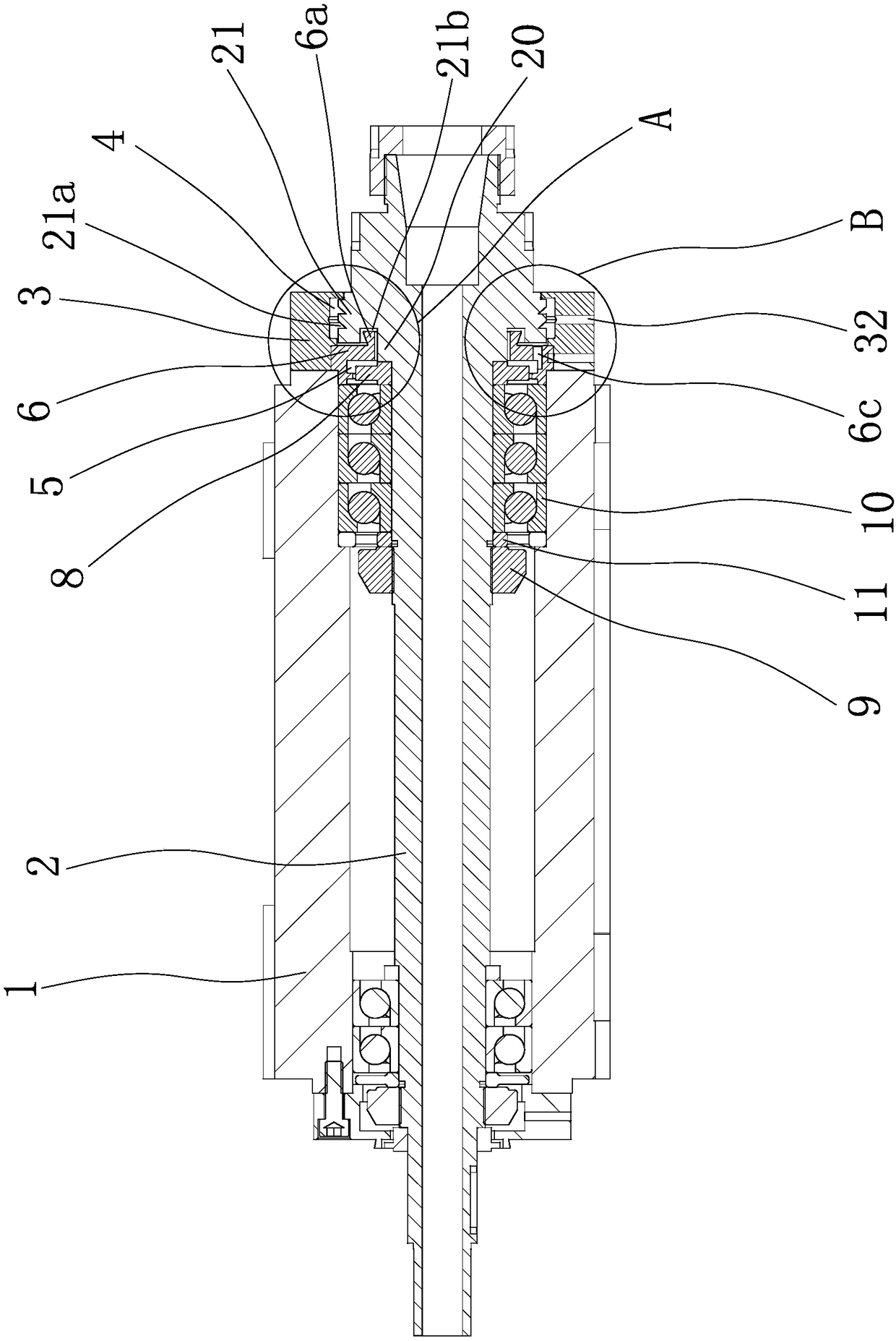

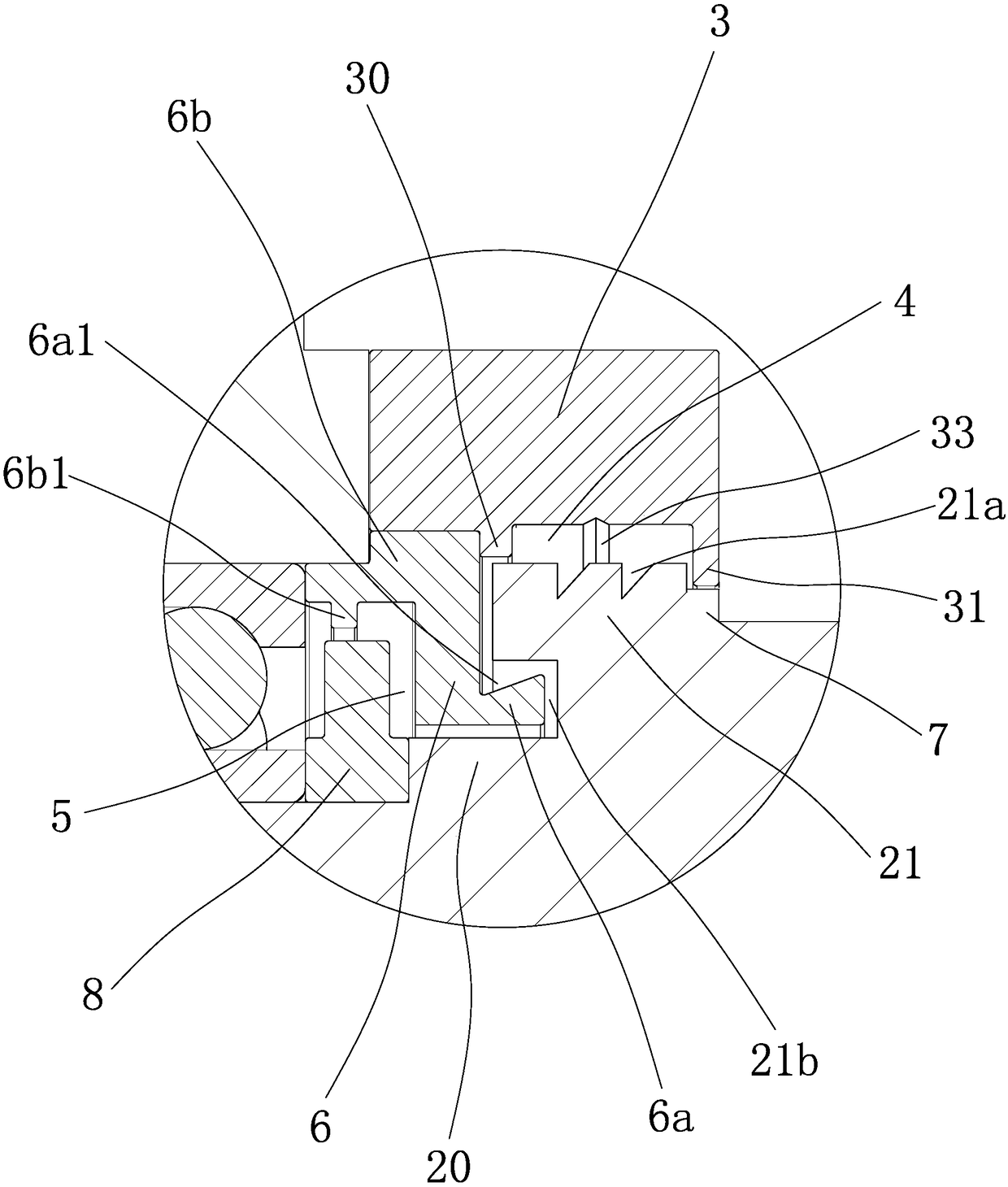

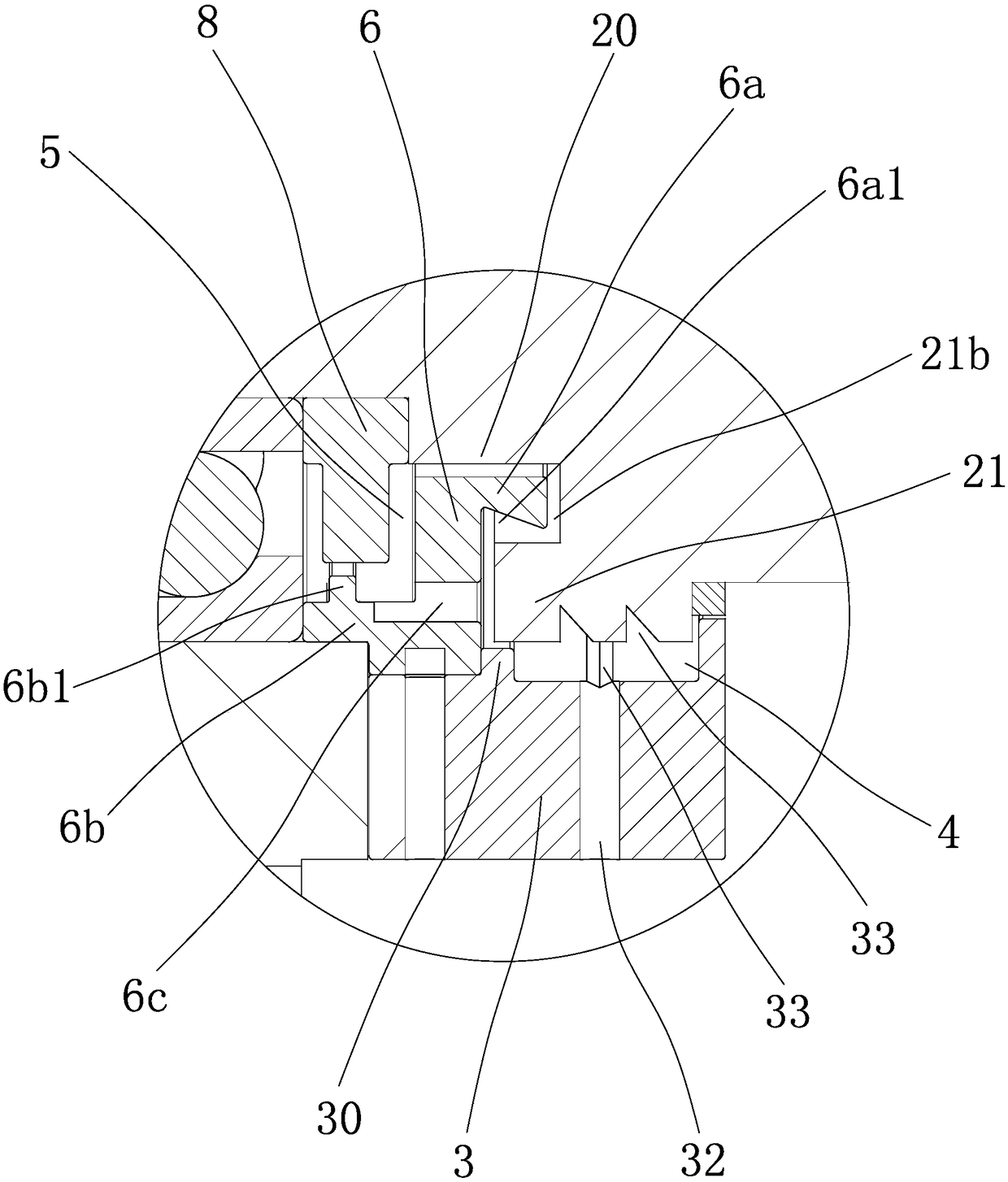

PendingCN108286608ADischarge orderlyImprove waterproof performanceEngine sealsShaftsAgricultural engineeringBackflow

The invention provides a backflow water storage type waterproof structure and belongs to the technical field of machines. The backflow water storage type waterproof structure solves the problem of thepoor waterproof effect of an existing main shaft waterproof structure. The backflow water storage type waterproof structure comprises a shell, a main shaft arranged in the shell and an end cover arranged at one end of the shell. The outer peripheral surface of one end of the main shaft is provided with an inner boss and an outer boss which are both annular. A centrifugal groove is formed in the outer peripheral surface of the outer boss. An annular avoiding groove is formed in the inner end face of the outer boss. A sealing ring fixed on the end cover is arranged in an inner chamber. An annular extending portion extending into the avoiding groove is arranged on the sealing ring. A backflow groove is formed in the outer peripheral surface of the extending portion. One side face of a sealing sleeve abuts against the inner end surface of the inner boss. A drainage structure for communicating an outer chamber with the inner chamber is arranged on the end cover and the sealing ring. Four waterproof structures sequentially block liquid from entering the interior of the main shaft from outside to inside, and both the outer chamber and the inner chamber drain the liquid through the drainage structure, and the waterproof effect of the main shaft is improved.

Owner:尹明

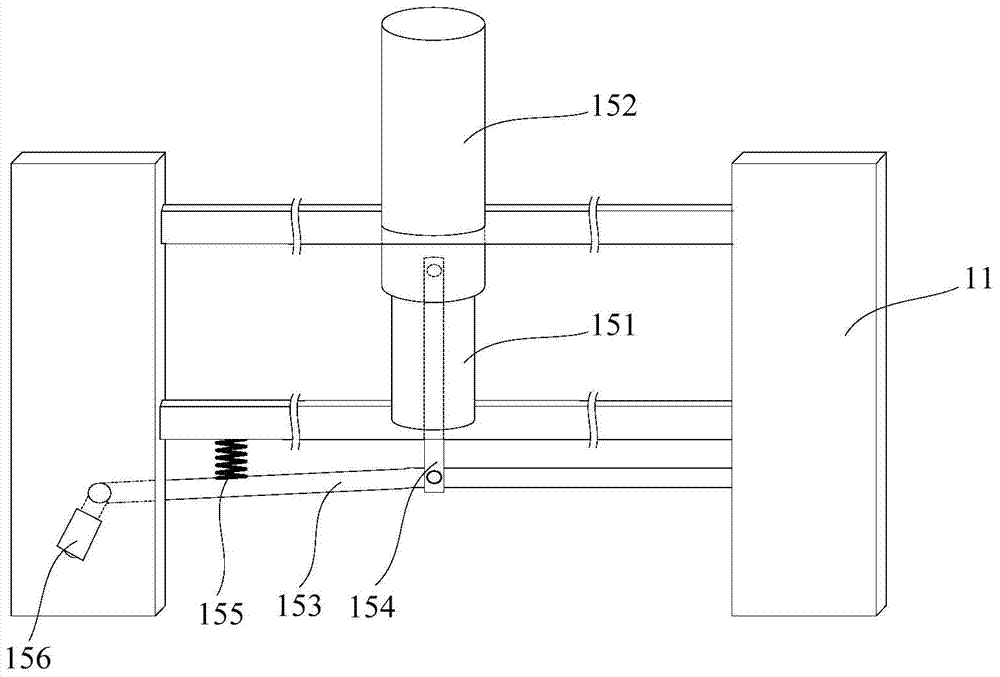

Flow system of automobile brake disc

ActiveCN104846323AOrderly storageEasy accessSolid state diffusion coatingFurnace typesTurnover timeVehicle frame

The invention provides a flow system of an automobile brake disc, comprising a flow frame and a flow transfer trolley, wherein the flow frame comprises a base framework, a first bearing roller platform and a first stopping mechanism and the flow transfer trolley comprises a trolley frame, a second bearing roller platform and a second stopping mechanism. By the flow frame, automobile brake disc treatment toolings can be orderly put on the bearing roller platforms; by the flow transfer trolley, the automobile brake disc treatment toolings can be arranged on the bearing roller platforms and can be transferred to a heat treatment device for heat treatment from the flow frame or can be transferred to the flow frame for storage after being subjected to heat treatment; the flow frame and the flow transfer trolley are matched mutually to realize transfer and storage of the automobile brake disc treatment toolings, thereby improving the space utilization of plant areas, saving labor force for carrying the automobile brake disc treatment toolings, increasing work efficiency and reducing the time for transferring automobile brake disc treatment toolings.

Owner:TONGFU HEAT TREATMENT KUNSHAN

Method for producing recycled polyester by replacing waste cloth or bubble materials with friction materials

InactiveCN107696332AIncrease awarenessEliminate personal safety hazardsPlastic recyclingMechanical material recoveryPre treatmentPolyester

The invention relates to a method for producing recycled polyester by replacing waste cloth or bubble materials with friction materials. The method comprises the following steps: (1) pretreating wastecloth; (2) grinding the pretreated waste cloth by a friction material machine so as to obtain a friction material; (3) conveying the friction material into a reactor by a pipeline for carrying out analcoholysis reaction, adding EG, the friction material and a catalyst into an alcoholysis kettle, carrying out an alcoholysis reaction at a temperature of 220-230 DEG C so as to produce BHET (Bs(2-Hydroxyethyl)Terephthalate), doffing and filtering to separate cotton impurities in the BHET liquid, concentrating to separate excessive EG from the BHET liquid, feeding the concentrated BHET liquid into an ester exchange kettle to carry out an ester exchange reaction with methanol, reacting to produce DMT (Dimethyl Terephthalate), performing centrifugal separation and distillation on the DMT liquidso as to obtain a pure DMT liquid serving as a raw material for producing the recycled polyester, carrying out an ester exchange reaction with the EG to produce the BHET, feeding the BHET into a polymerizing pot to carry out a polymerization reaction so as to produce PET (Polyethylene Terephthalate), thereby obtaining the final product. The method disclosed by the invention is simple in process and has wide application prospects.

Owner:浙江佳人新材料有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com