High trip rate drilling rig

A technology for drilling rigs and pipe fittings, applied in the field of land-based transportable drilling rigs, can solve the problems of difficult loading and unloading, speeding up the tripping rate, increasing risks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

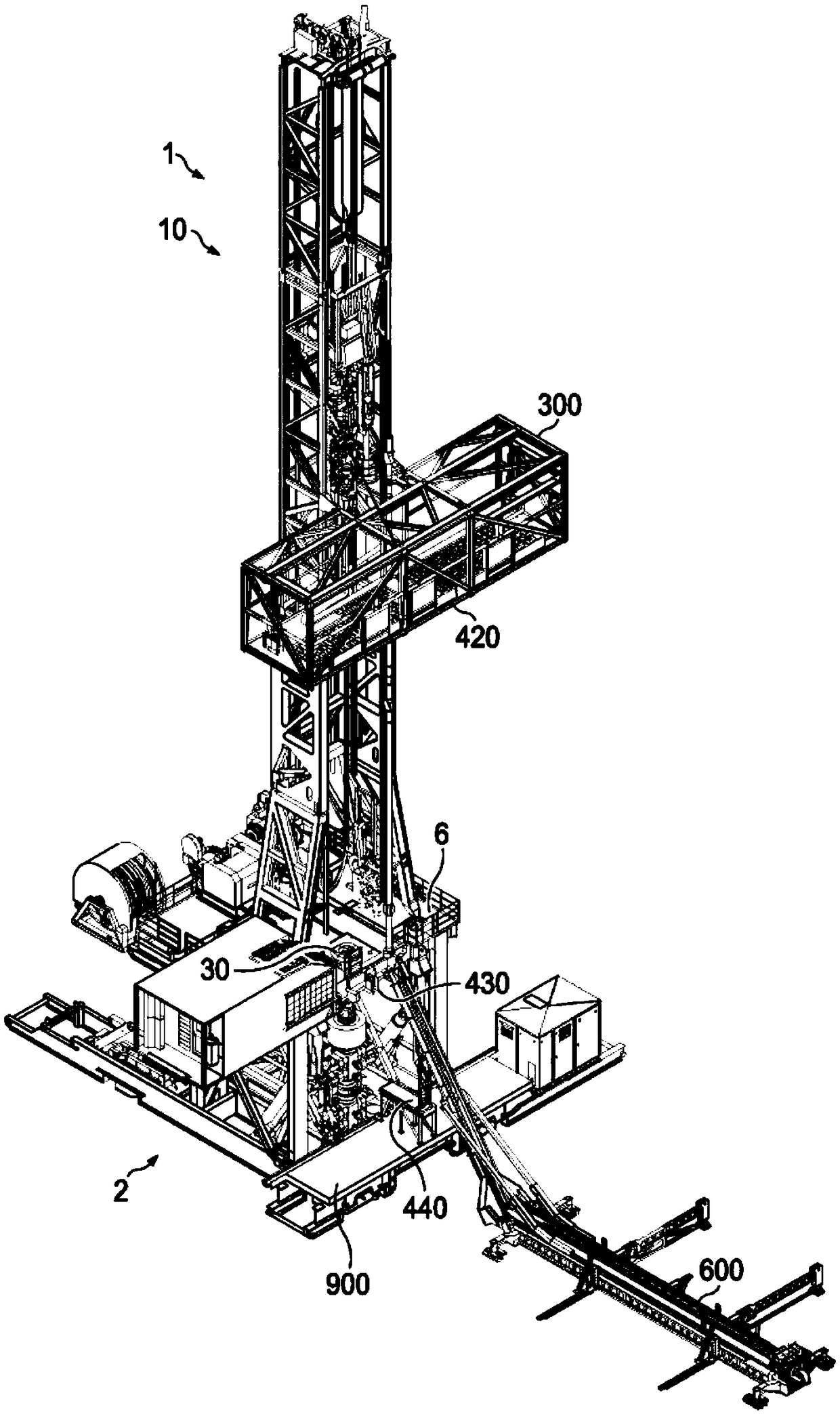

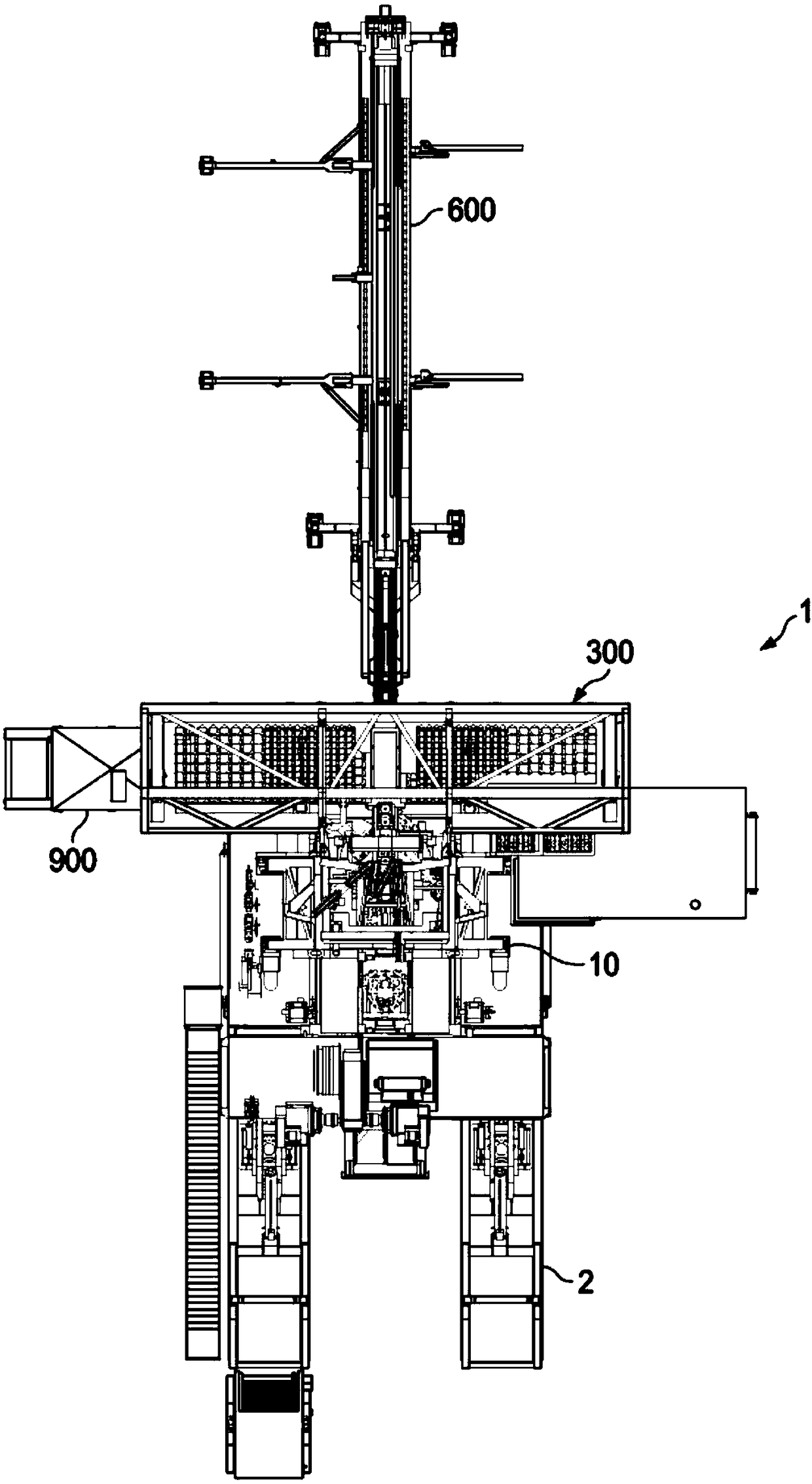

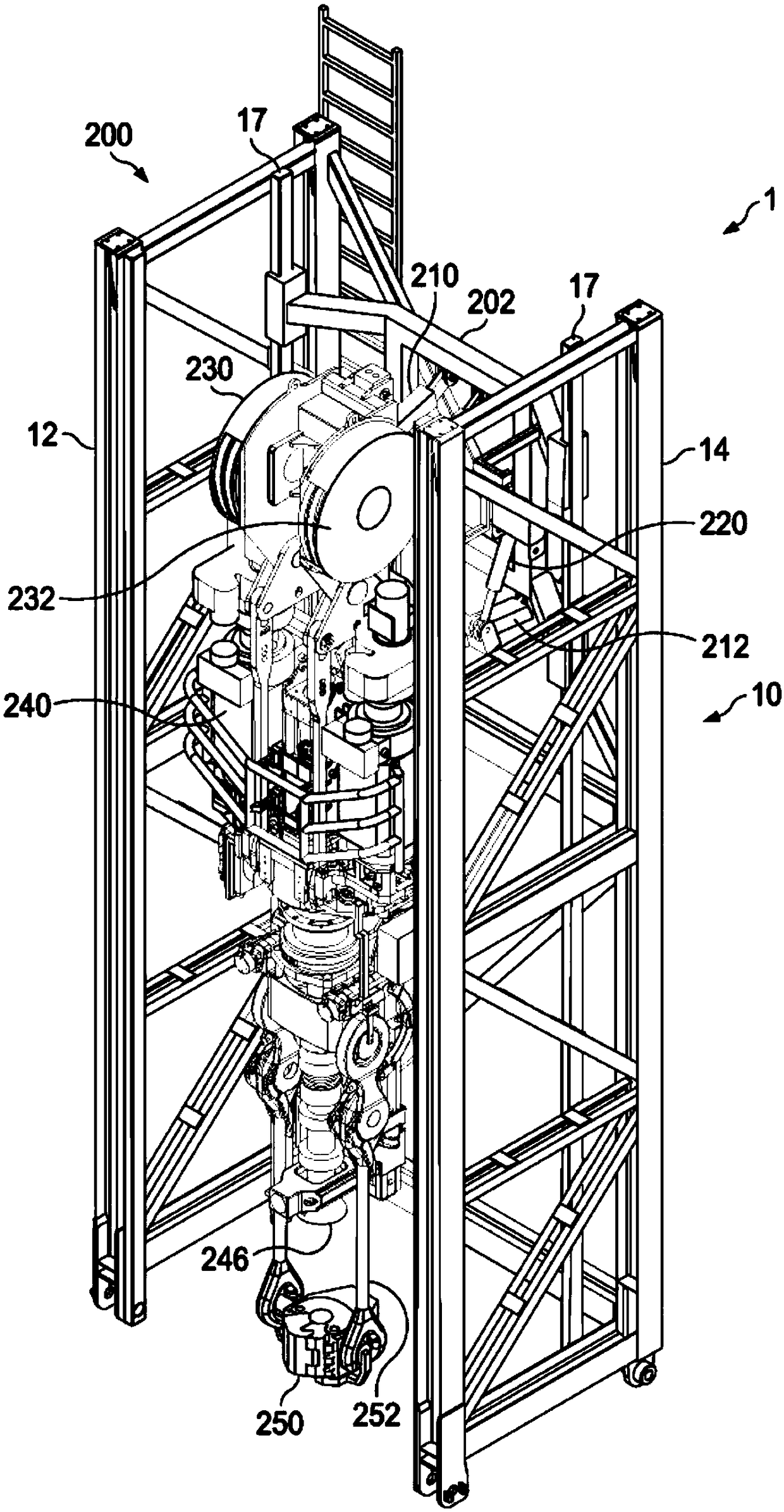

[0163] 1. A drilling rig [1] comprising:

[0164] a top drive assembly [200] that can translate vertically along the mast [10] of the drilling rig [1];

[0165] a tubular delivery arm [500] translatable vertically along said mast [10]; and

[0166] The tubular delivery arm [500] has a tubular clasp [550] movable between a wellhead center position [30] above wellhead center and a second position [50] forward of the wellhead center position .

[0167] 2. The drilling rig according to embodiment 1, further comprising:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com