Equipment for testing resistance to environmental stress of plastic

A technology that is resistant to environmental stress and testing equipment. It is applied in the direction of applying stable tension/pressure to test material strength, measuring devices, and analyzing materials. problem, to achieve ideal compression effect, easy processing and assembly, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

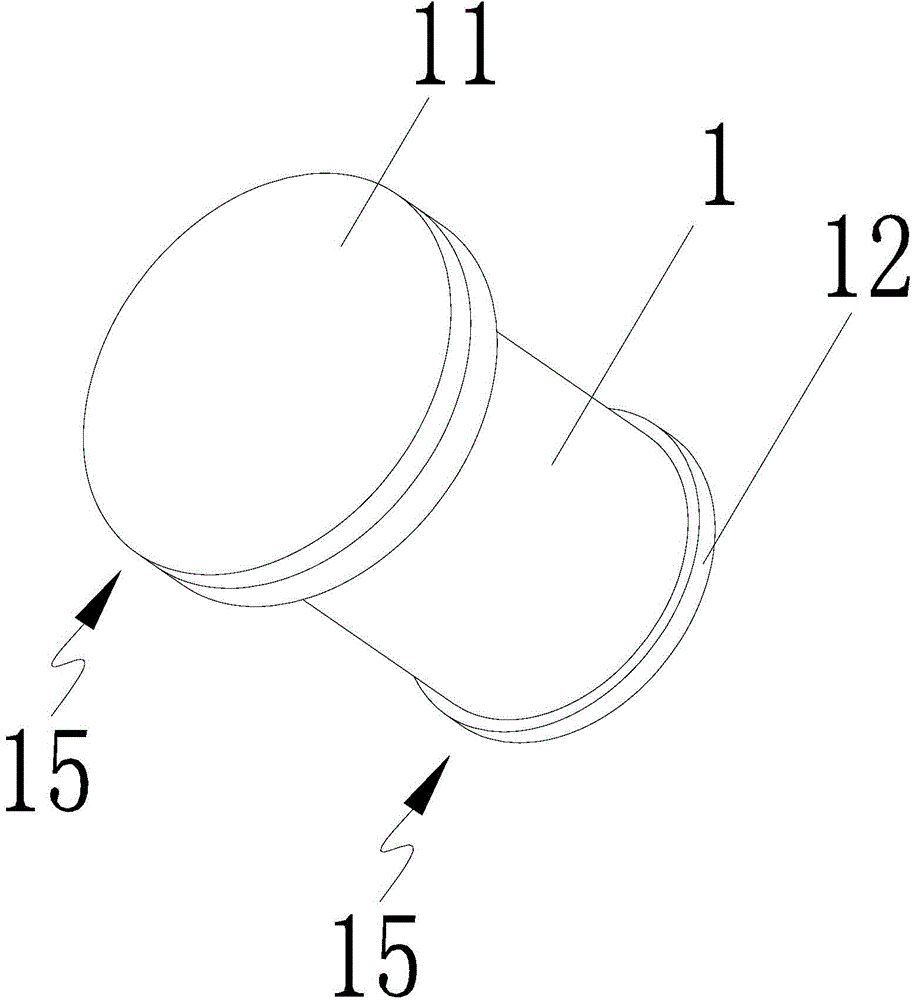

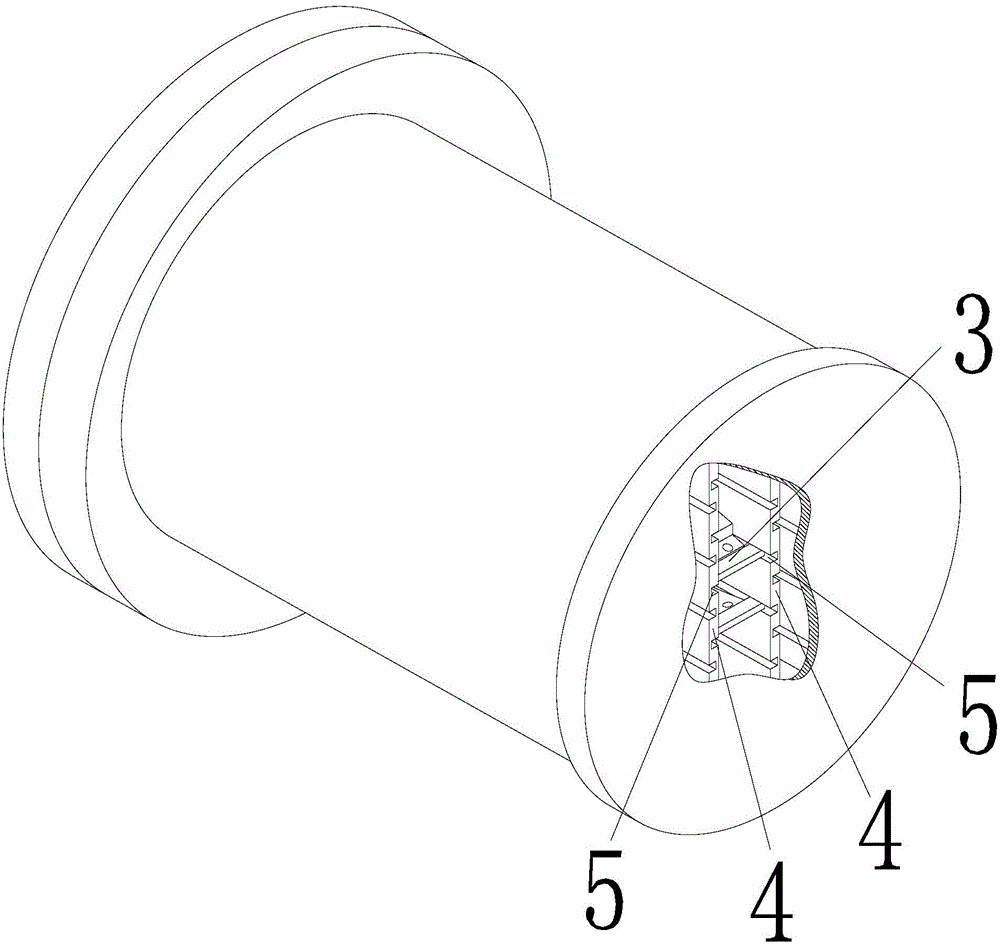

[0030] A plastic environmental stress testing device, comprising a test chamber 1, a frame bar 3 that bends a test sample 2, and a cover 15 that seals the test chamber 1, and the frame bar 3 is arranged in the test chamber 1 , preferably, a slot is provided in the test cavity 1, and the frame bar 3 is connected in the slot. The test cavity 1 is provided with at least two slot plates 4 , and the opposite sides of the two slot plates 4 are correspondingly provided with slots 5 , and the clamping slot is formed between the two slots 5 . Guide blocks 6 protrude from both ends of the frame bar 3 to both sides. The guide block 6 is connected in the draw-in groove, and can slide in the draw-in groove. By virtue of the cooperation of the guide block 6 and the draw-in groove, the frame bar 3 can be easily loaded and drawn out, which is convenient for testing.

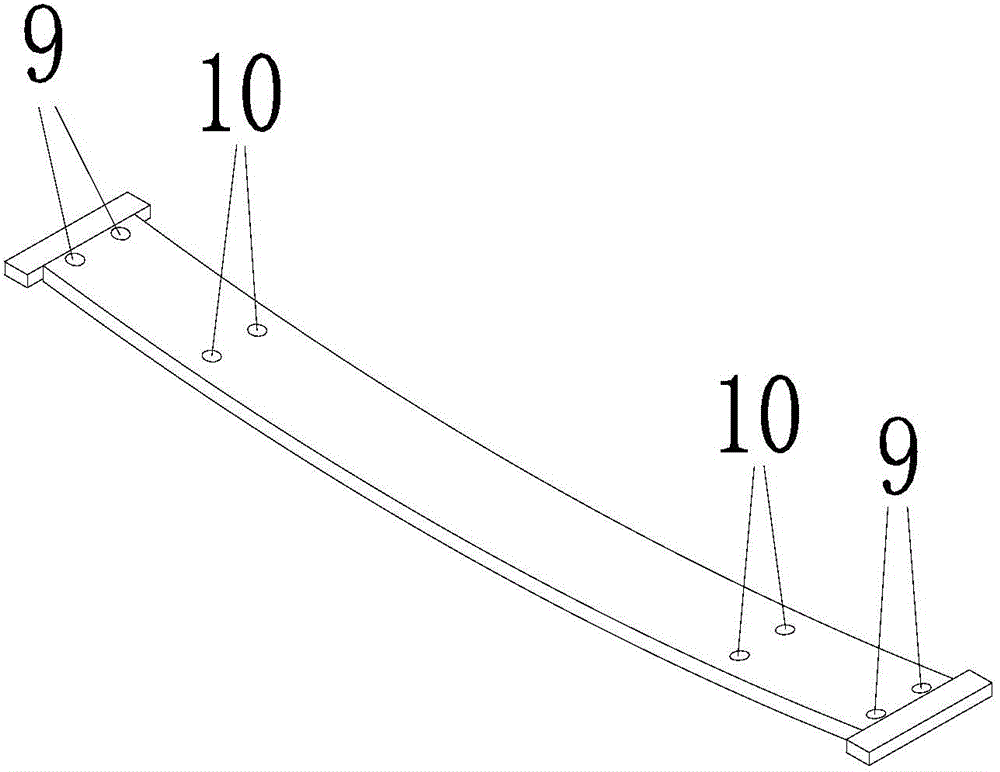

[0031] Preferably, the curvature ε of the frame bar 3 is ε=d / (2r+d)×100%, wherein, r is the radius of the frame bar 3, and d ...

Embodiment 2

[0038] The difference between this embodiment and the first embodiment lies in that: the frame bar 3 is straight, and the frame bar 3 is shorter than the test sample bar 2 . In this way, after the two ends of the test sample 2 and the frame bar 3 are respectively fixed, the test sample 2 is bent due to the length difference between the frame bar 3 and the test sample 2, thereby meeting the requirements of the test. The curvature of the spline 2 is controlled by the length difference between the frame bar 3 and the test sample 2. The greater the length difference between the two, the greater the bending of the test sample 2, that is, the smaller the radius of the test sample 2, the greater the test sample 2. The greater the bending stress, on the contrary, the smaller the length difference between the two, the smaller the bending of the test sample 2, that is, the larger the radius of the test sample 2, the smaller the bending stress of the test sample 2, so it can meet differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com