Concrete mixing plant

A mixing station and concrete technology, applied in mixing plants, cement mixing devices, clay preparation devices, etc., can solve the problems of concrete blocking the discharge pipe, dust overflow, no dust collection mechanism, etc., to improve the quality of concrete and improve the accuracy Sexuality and cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

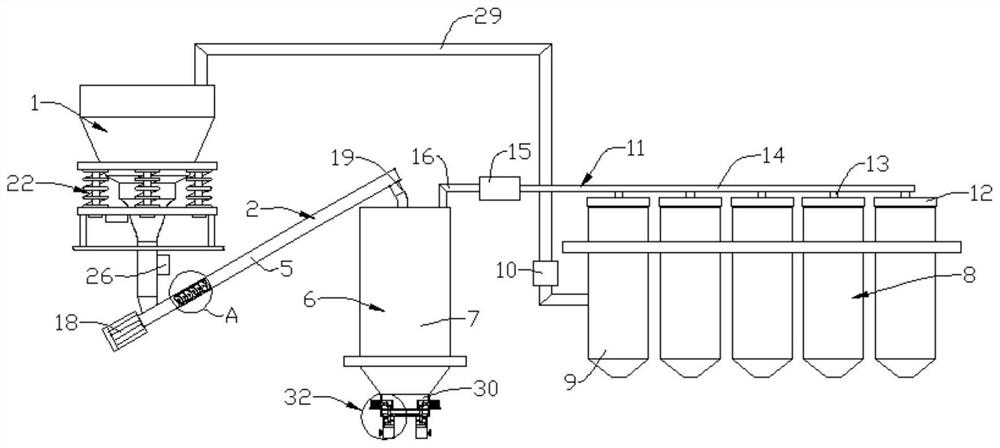

[0033] A concrete mixing plant, comprising:

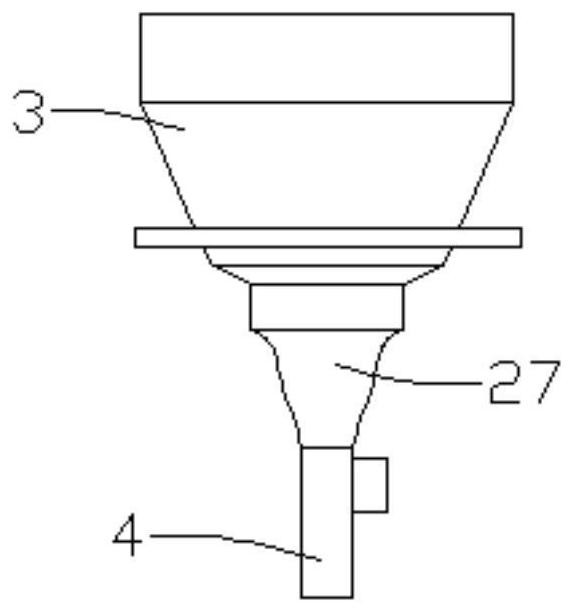

[0034] The batching mechanism 1 is used to accurately mix the concrete materials. The batching mechanism 1 includes a batching hopper 3, and a first connecting pipe 4 is arranged below the batching hopper 3;

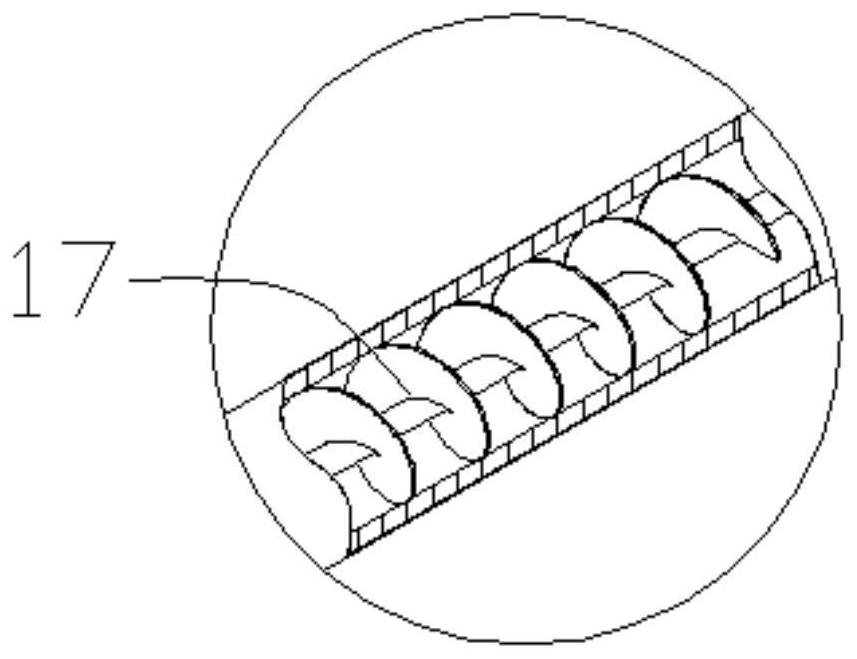

[0035] The conveying mechanism 2 is used for conveying materials. The conveying mechanism 2 includes a conveying pipe body 5, and the bottom of the first connecting pipe 4 communicates with and fixes the conveying pipe body 5;

[0036] The material mixing mechanism 6 is used to mix and stir various materials. The material mixing mechanism 6 includes the main tank 7 of the mixing station, and the discharge port of the delivery pipe body 5 is communicated with and fixed to the top of the main tank 7 of the mixing station;

[0037] The material storage mechanism 8 is used to store various materials. The material storage mechanism 8 includes a plurality of material storage tanks 9, and the material storage tanks 9 and the batchin...

Embodiment 2

[0051] A concrete mixing plant, comprising:

[0052] The batching mechanism 1 is used to accurately mix the concrete materials. The batching mechanism 1 includes a batching hopper 3, and a first connecting pipe 4 is arranged below the batching hopper 3;

[0053] The conveying mechanism 2 is used for conveying materials. The conveying mechanism 2 includes a conveying pipe body 5, and the bottom of the first connecting pipe 4 communicates with and fixes the conveying pipe body 5;

[0054] The material mixing mechanism 6 is used to mix and stir various materials. The material mixing mechanism 6 includes the main tank 7 of the mixing station, and the discharge port of the delivery pipe body 5 is communicated with and fixed to the top of the main tank 7 of the mixing station;

[0055] The material storage mechanism 8 is used to store various materials. The material storage mechanism 8 includes a plurality of material storage tanks 9, and the material storage tanks 9 and the batchin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com