Cleaning device for cylinder sleeves of engines

A technology for cleaning device and engine cylinder, applied in the field of machinery, can solve problems such as difficulty in cylinder liner, inability to meet cleaning requirements, etc., and achieve the effect of convenient collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

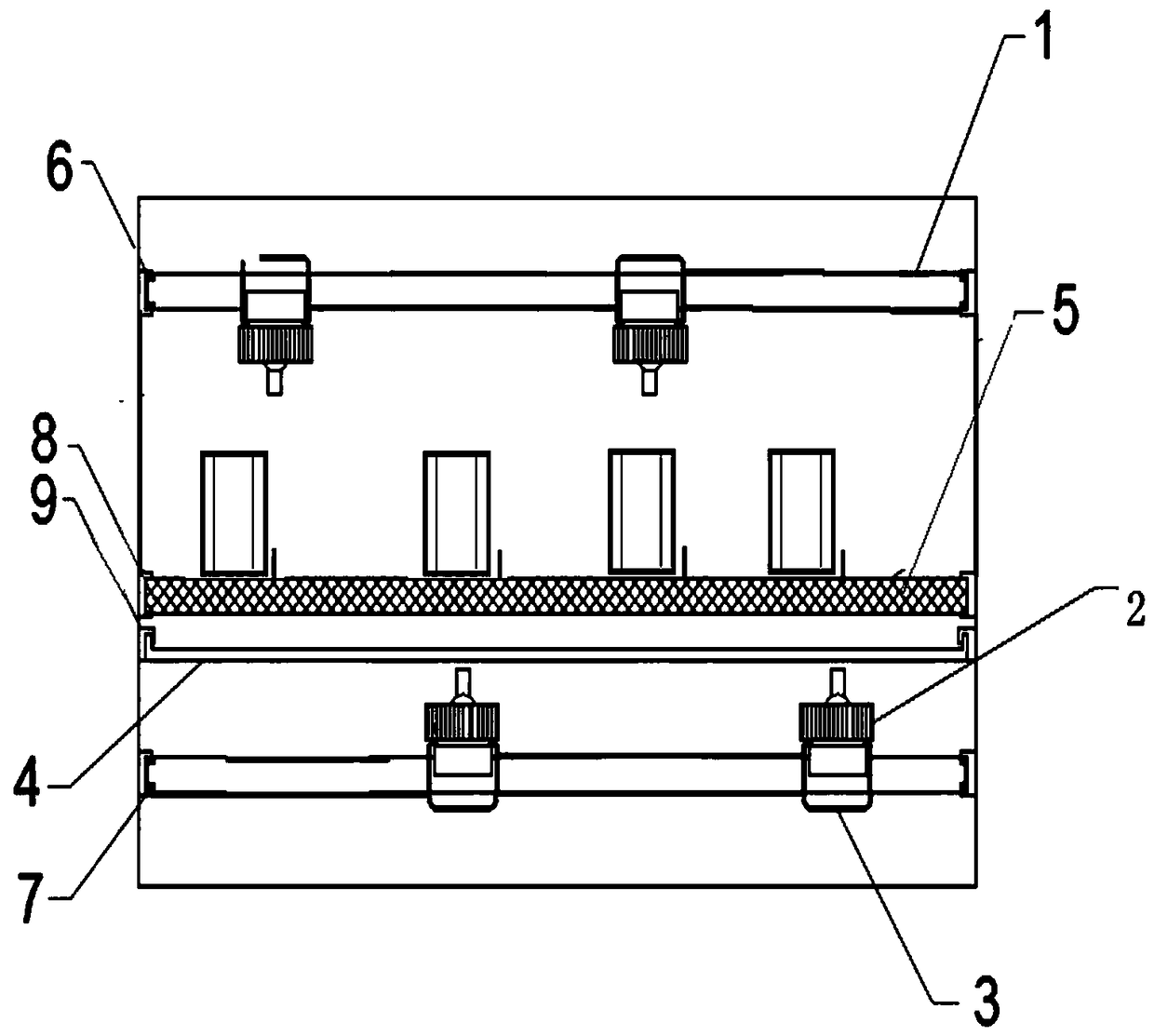

[0020] An automatic cylinder liner cleaning device, such as figure 1 As shown, it includes a spraying device and an automatic transmission device, and the described spraying device includes a spraying pipe 1, nozzles 2 distributed on the spraying pipe 1 and pipe clamps 3 for fixing the nozzles 2; the automatic The transmission device includes a conveyor belt 4, and the spray pipes 1 are arranged on the upper and lower sides of the conveyor belt 4 respectively. There is also a baffle 5 between them, and the conveyor belt 4 and the baffle 5 are all mesh structures.

[0021] The nozzle upper mounting frame 6 is located inside the cleaning device, and the upper spraying pipe 1 is slidable in the nozzle mounting frame 6; the nozzle lower mounting frame 7 is located inside the cleaning device, and the lower spraying pipe 1 It can slide in the installation frame 7 under the nozzle; the limiting groove A8 is located inside the cleaning device, and the baffle plate 5 is slidable in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com