Textile storage mobile vehicle

A mobile vehicle and textile technology, applied in the direction of rigid containers, anti-rot containers, containers, etc., can solve the problems of high labor intensity, coil collisions, uneven bottom surface, etc., to achieve optimized storage effect, ensure levelness, fixity Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

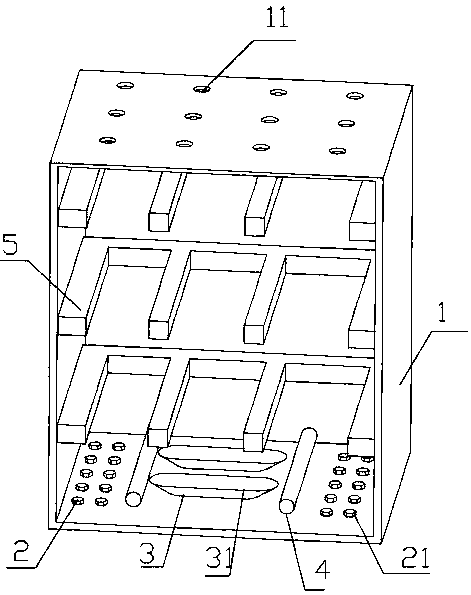

[0034] Example 1, such as figure 1 Shown: a kind of textile storage mobile car, comprising body 1, the outer frame of body 1 equipment. There are multiple storage layers 5 in the body 1, three layers are set in the figure, and the specific number of layers can be added or subtracted according to actual needs.

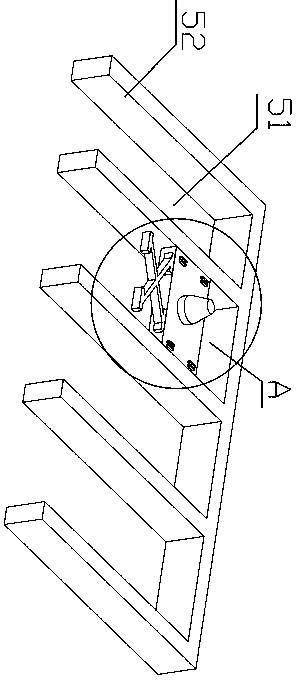

[0035] The storage method of each layer is as follows: figure 2 As shown, the storage layer 5 of each layer includes a plurality of storage rows 51 parallel to each other, and on each storage row 51, slide rails 52 are set on the left and right sides, and the slide block 53 can be mounted on the slide rails 52 slide. Slide block 53 is a plurality of, and each slide block 53 all serves as the basic storage unit of a team spinning yarn bobbin.

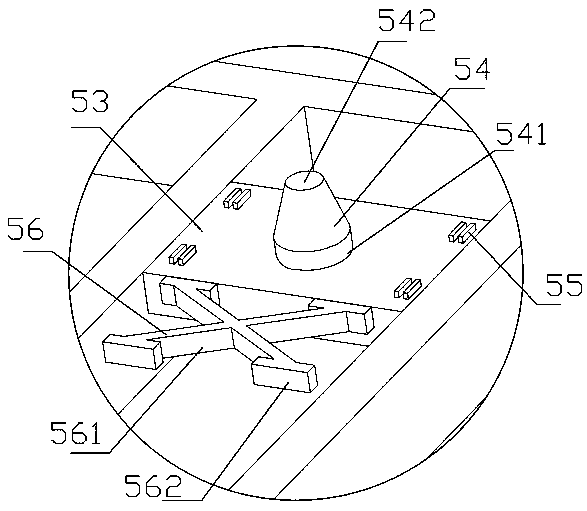

[0036] Such as image 3 As shown, on the slider 53, a fixed shaft 54 is provided. The fixed shaft 54 is in the shape of a truncated cone, and its diameter gradually gathers from bottom to top. Such a setting, one is to in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com