Cascading firework

A fireworks, single technology, applied in the field of tandem fireworks, can solve the problems of high power, inconvenient operation, injury accidents, etc., and achieve the effects of high work efficiency, simple structure and convenient connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

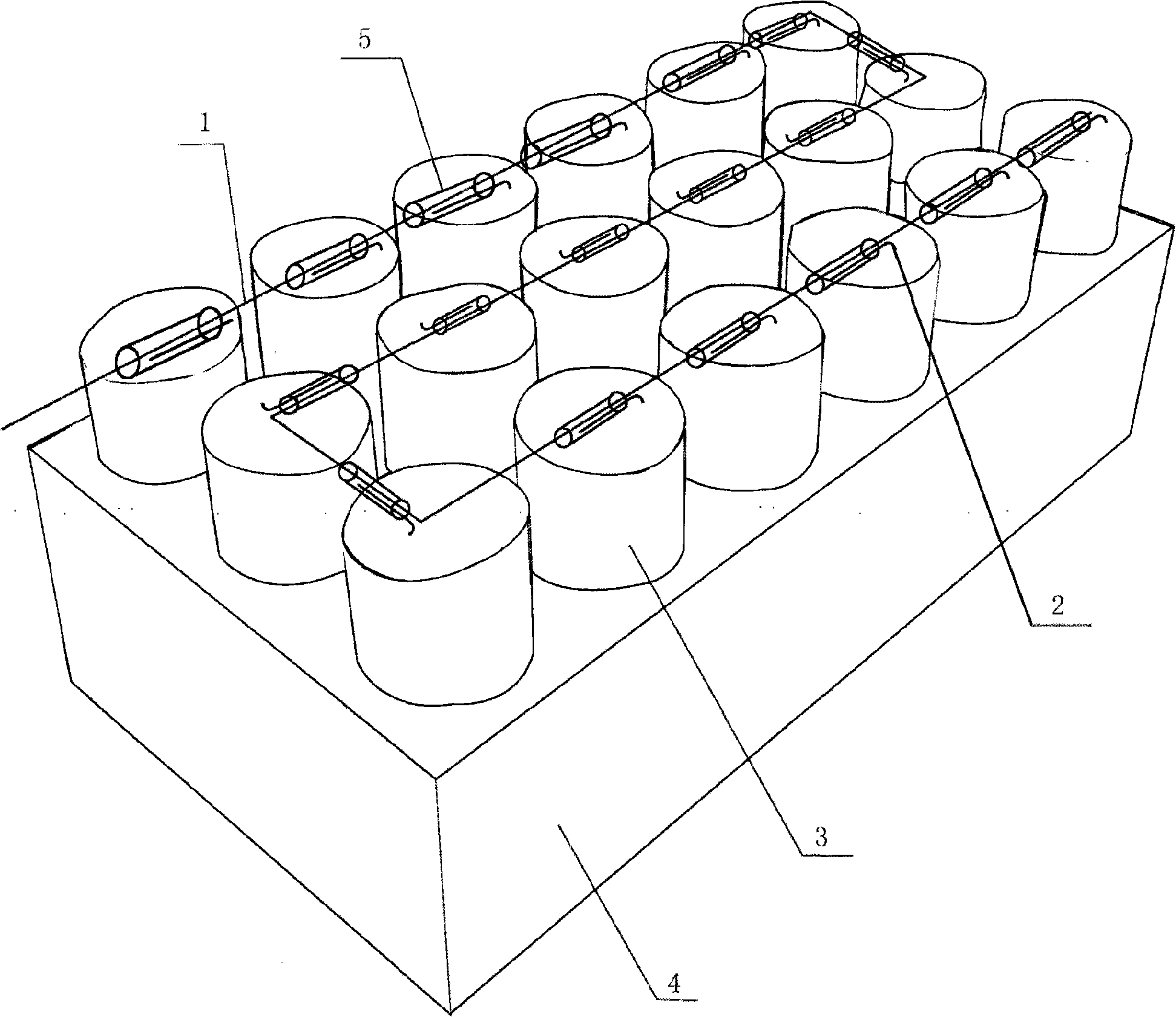

[0010] see figure 1 , a box-type series discharge of fireworks, including a main fuse 1, a single firework ignition lead 2, a single firework 3 and a box-type installation seat 4 for fireworks. The ignition device 5 and a main ignition wire 1, the ignition device 5 is respectively arranged on a single firework 3, the single firework ignition wire 2 is inserted into the respective ignition device 5, and the main ignition wire 1 passes through the single firework 3 respectively. The ignition device 5 is sequentially placed on a single firework in the box-type tandem discharge fireworks and approaches or intersects with the ignition lead 2 in the ignition device 5 . That is to say, the total fuse 1 passing through the ignition device 5 is in the same cavity as the single ignition fuse 2, so that the ignition fuse 2 of a single firework is ignited by the flame temperature generated during combustion by utilizing the total fuse. The fire contact device 5 of the present invention i...

Embodiment 2

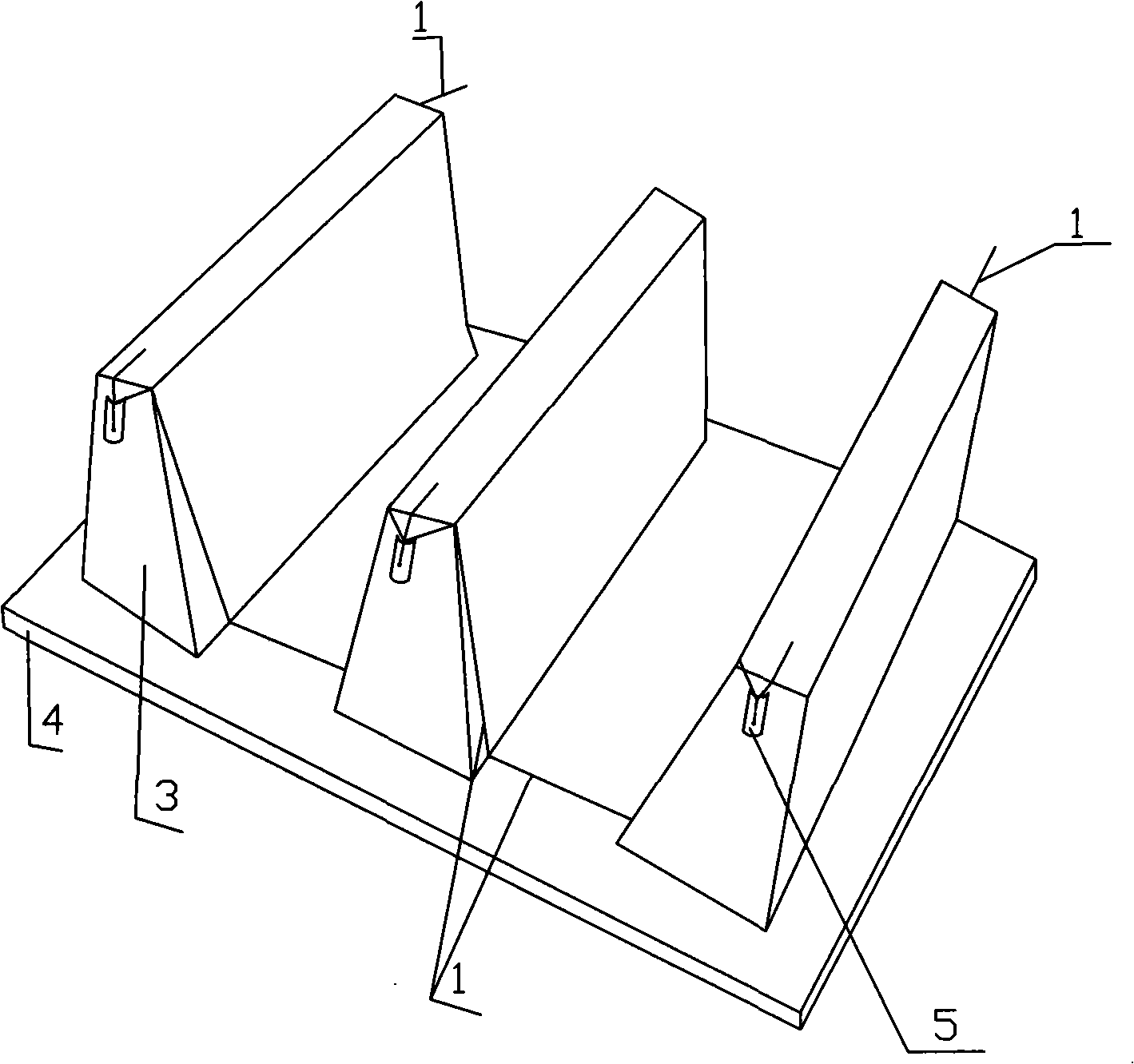

[0012] see figure 2 , a kind of flat-panel series discharge fireworks, comprising a series fuse 1, a single firework ignition lead 2, a single firework 3 and a flat-plate firework mounting seat 4, the single fireworks 3 are evenly arranged on the mounting base 4, and a set is arranged on the series discharge fireworks. There are ignition devices 5 equal to the number of individual fireworks 3 and one or more ignition wires 1 connected in series, the ignition devices 5 are respectively arranged on individual fireworks 3, and the single fireworks ignition leads 2 are inserted into respective ignition devices 5 Inside, the ignition wire 1 respectively passes through the ignition device 5 on a single firework 3 and approaches or intersects with the ignition wire 2 in the ignition device. The fire contact device 5 of the present invention is a prefabricated casing.

[0013] There are three individual fireworks 3 and three fire-connecting devices 5 in the embodiment of flat-panel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com