Rice dumpling preparation process

A technology for making rice dumplings, which is applied in food heat treatment, food science, etc., can solve the problems of long cooling time of rice dumplings and low production efficiency of rice dumplings, and achieve the effects of accelerating cooling efficiency, keeping the appearance intact, and being easy to lose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

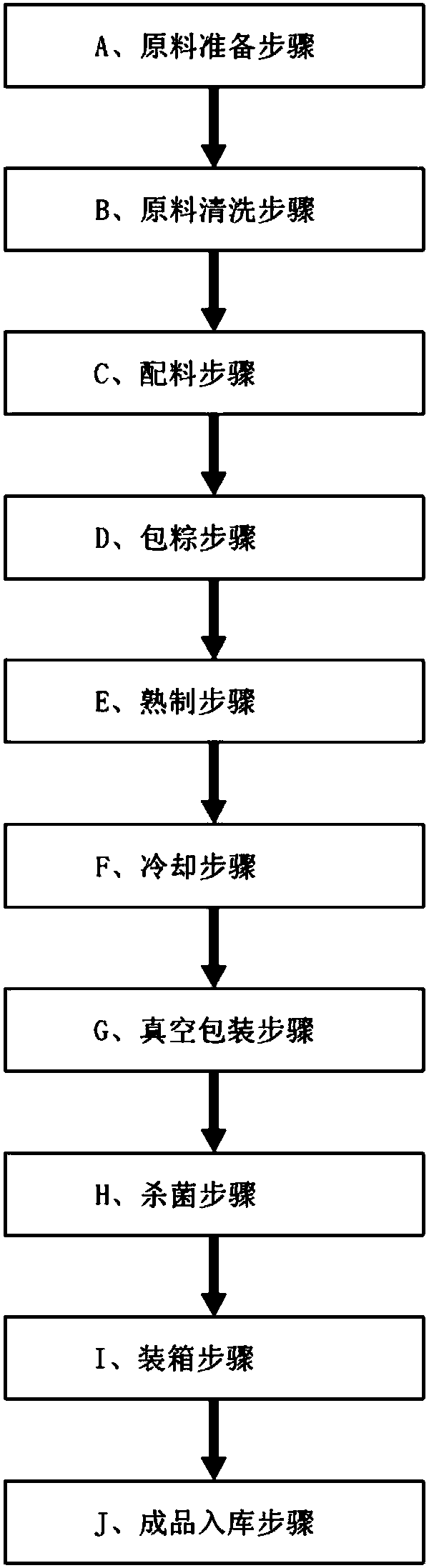

[0022] as attached figure 1 Shown: Zongzi making process, including the following steps:

[0023] A, raw material preparation steps: weigh glutinous rice, stuffing, seasoning and zong leaves with a platform scale;

[0024] B, raw material cleaning step: use the zong leaf cleaning machine to clean the zong leaves weighed in step A, then drain the zong leaves for subsequent use; use the rice washing machine to wash the glutinous rice weighed in step A, and then wash the glutinous rice Drain;

[0025] C, batching step: use a blender to stir and mix the glutinous rice in step B with the filling and seasoning in step A evenly, and the stirring time is 2 minutes;

[0026] D, step of making rice dumplings: fold the rice dumpling leaves obtained in step B into a funnel shape, then weigh the glutinous rice mixed with fillings in step C required for each rice dumpling, then fill the glutinous rice into the rice dumpling leaves, use the rice dumpling leaves Wrap the glutinous rice tig...

Embodiment 2

[0034] The only difference with Example 1 is: E, in the cooking step, when the pressure reaches 2.0 MPa, and the temperature reaches 105 ° C, the pot is started; H, in the sterilization step, the sterilization temperature is 115 ° C, and the time is 60 minutes.

Embodiment 3

[0036] The difference from Example 1 is only: in E, the cooking step, when the pressure reaches 2.4MPa, and the temperature reaches 115°C, the pot is started; in H, in the sterilization step, the sterilization temperature is 125°C, and the time is 40 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com