Efficient flame-retardant plastic-wood composite board and preparation method thereof

A high-efficiency technology of plastic-wood composite materials, applied in the field of plastic-wood composite materials, can solve the problems of easy combustion, life-threatening of surrounding people, non-flammability, etc., and achieve the effects of low production cost, convenient production and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

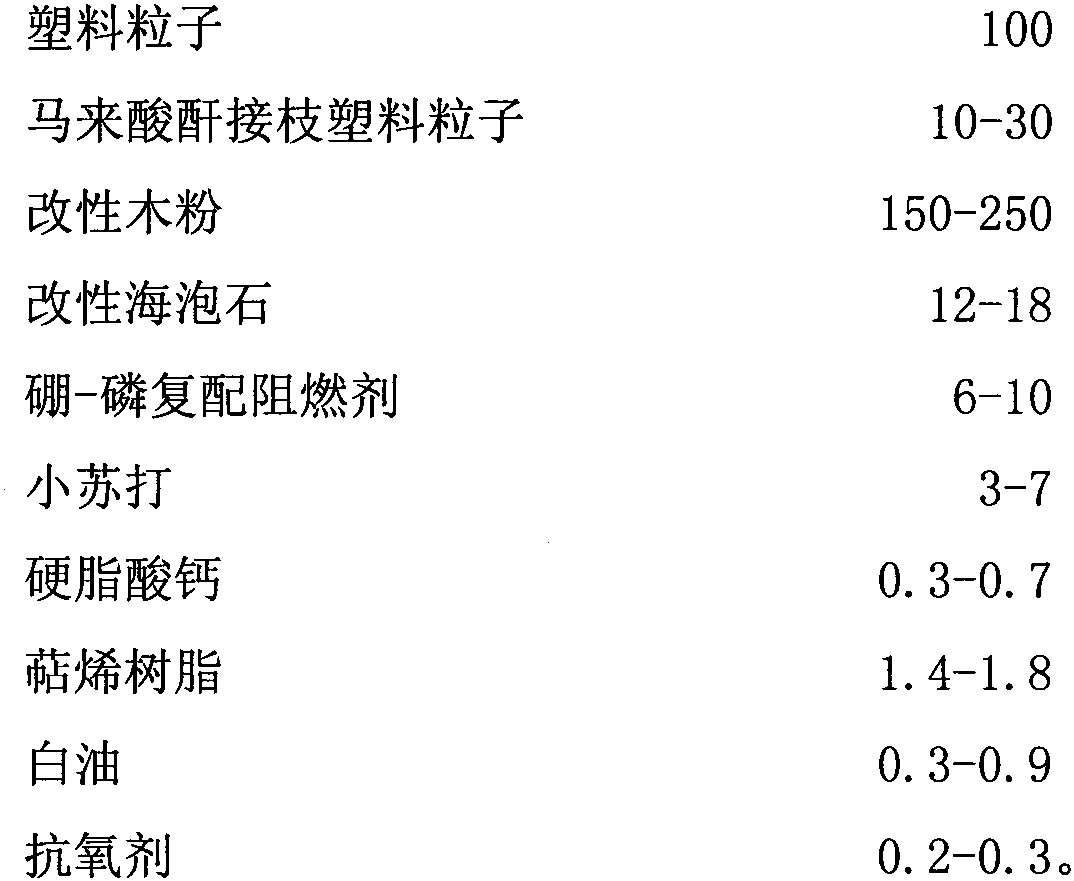

[0028] A high-efficiency flame-retardant plastic-wood composite material board is prepared from raw materials including the following parts by weight:

[0029]

[0030] A method for preparing a high-efficiency flame-retardant plastic-wood composite board, comprising the following steps:

[0031] (1) Weigh wood flour, distilled water, tetraethyl orthosilicate, sodium dodecylsulfonate and ammonia water respectively according to the mass ratio of 100:110:4:0.35:2.5, and distilled water, tetraethyl orthosilicate and ten Sodium dialkyl sulfonate was stirred and mixed for 1.5 hours, then wood powder was added to it, and the stirring was continued for 30 minutes; then ammonia water was added, reacted for 2.5 hours at room temperature, and then filtered to obtain the treated wood powder, and the treated wood powder was rinsed with distilled water powder until the filtrate is neutral, and finally the treated wood powder is dried and sieved to obtain modified wood powder;

[0032] (...

Embodiment 2

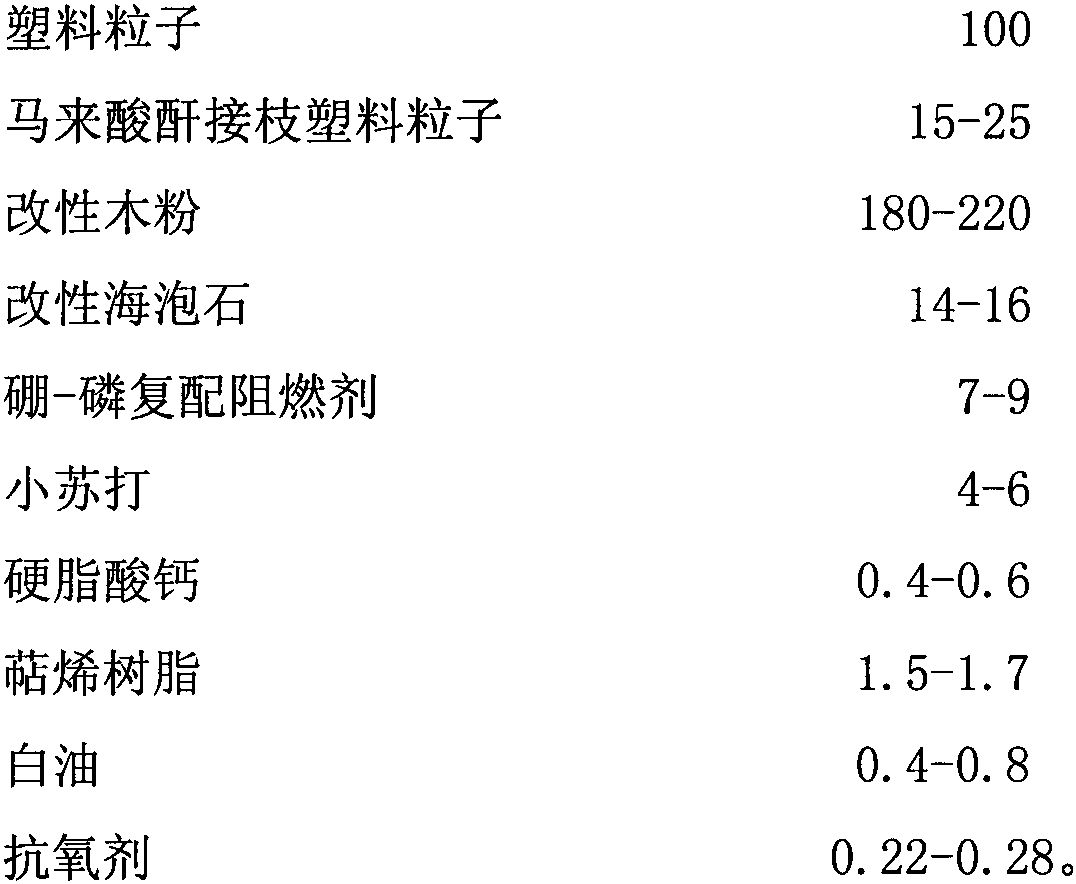

[0039] A high-efficiency flame-retardant plastic-wood composite material board is prepared from raw materials including the following parts by weight:

[0040]

[0041] A method for preparing a high-efficiency flame-retardant plastic-wood composite board, comprising the following steps:

[0042] (1) Weigh wood flour, distilled water, ethyl orthosilicate, sodium dodecylsulfonate and ammonia water respectively according to the mass ratio of 100:100:3:0.3:2, and distilled water, ethyl orthosilicate and ten Sodium dialkyl sulfonate was stirred and mixed for 1 hour, then wood powder was added therein, and the stirring was continued for 20 minutes; then ammonia water was added, reacted at room temperature for 2 hours, and then filtered to obtain the treated wood powder, which was rinsed with distilled water, until the filtrate is neutral, and finally the treated wood powder is dried and sieved to obtain the modified wood powder;

[0043](2), weigh bis-[γ-(triethoxysilyl) propyl]...

Embodiment 3

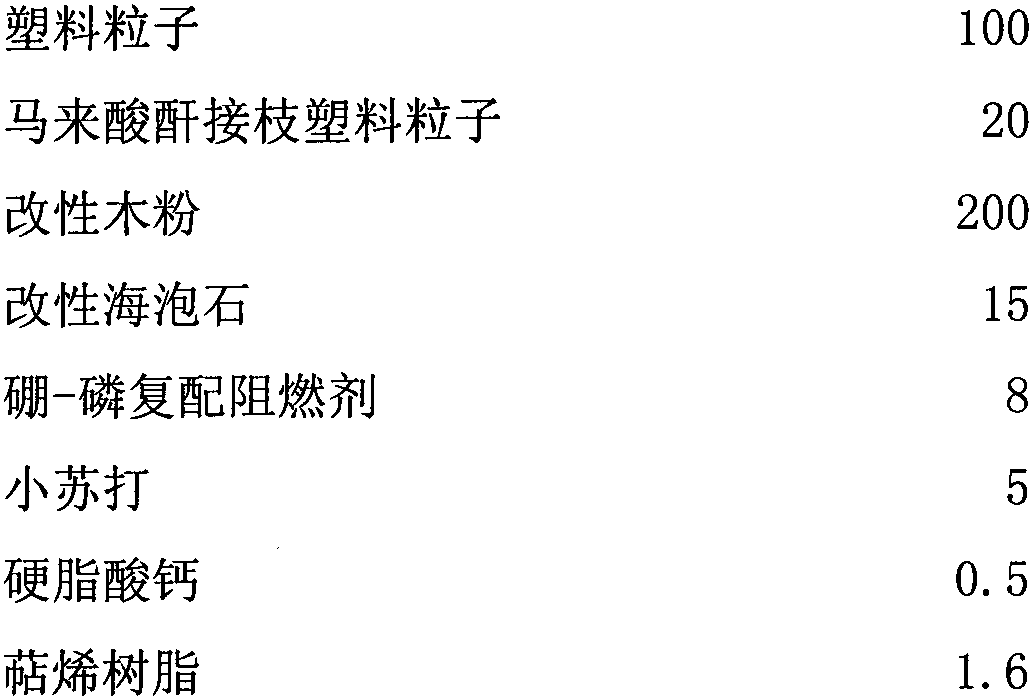

[0050] A high-efficiency flame-retardant plastic-wood composite material board is prepared from raw materials including the following parts by weight:

[0051]

[0052] A method for preparing a high-efficiency flame-retardant plastic-wood composite board, comprising the following steps:

[0053] (1), weigh wood powder, distilled water, ethyl orthosilicate, sodium dodecylsulfonate and ammonia water respectively according to mass ratio 100:120:5:0.4:3, and distilled water, ethyl orthosilicate and ten Sodium dialkyl sulfonate was stirred and mixed for 2 hours, then wood powder was added therein, and the stirring was continued for 40 minutes; then ammonia water was added, reacted at room temperature for 3 hours, and then filtered to obtain the treated wood powder, which was rinsed with distilled water, until the filtrate is neutral, and finally the treated wood powder is dried and sieved to obtain the modified wood powder;

[0054] (2), weigh bis-[γ-(triethoxysilyl) propyl]tet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Static bending strength | aaaaa | aaaaa |

| Static modulus | aaaaa | aaaaa |

| Heat release rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com